Heptane Solvent Effects on Polymer Film Formation and Properties

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heptane Solvent Background and Objectives

Heptane, a saturated hydrocarbon with the chemical formula C7H16, has been widely used as a solvent in various industrial applications, particularly in polymer processing and film formation. The history of heptane as a solvent dates back to the early 20th century when it was first isolated from petroleum. Its low boiling point, low polarity, and excellent solvency for non-polar substances have made it an attractive choice for many industrial processes.

In the context of polymer film formation, heptane has gained significant attention due to its unique properties that can influence the final characteristics of the polymer films. The use of heptane as a solvent in polymer processing has evolved over the years, with researchers and industry professionals continuously exploring its effects on various polymer systems. The primary objective of studying heptane solvent effects on polymer film formation and properties is to optimize the film-forming process and enhance the final product's performance.

One of the key areas of interest is the impact of heptane on the morphology and microstructure of polymer films. Researchers aim to understand how the solvent-polymer interactions during the film formation process affect the arrangement of polymer chains and the resulting film properties. This knowledge is crucial for developing high-performance polymer films with tailored characteristics for specific applications.

Another important aspect of heptane solvent research is its influence on the kinetics of film formation. The evaporation rate of heptane, its miscibility with different polymer systems, and its effect on polymer chain mobility all play critical roles in determining the final film structure and properties. Understanding these factors can lead to better control over the film formation process and improved product quality.

The environmental and safety considerations associated with heptane use have also become increasingly important in recent years. As regulations on volatile organic compounds (VOCs) become more stringent, there is a growing need to optimize heptane-based processes to minimize environmental impact while maintaining or improving product performance. This has led to research into alternative solvents and solvent systems that can provide similar benefits to heptane while addressing environmental concerns.

In the broader context of materials science and engineering, the study of heptane solvent effects on polymer film formation contributes to the development of advanced materials with enhanced properties. This research has implications for various industries, including coatings, adhesives, electronics, and biomedical applications. By understanding and controlling the solvent effects, researchers and manufacturers can design polymer films with improved mechanical strength, barrier properties, optical characteristics, and other functional attributes.

In the context of polymer film formation, heptane has gained significant attention due to its unique properties that can influence the final characteristics of the polymer films. The use of heptane as a solvent in polymer processing has evolved over the years, with researchers and industry professionals continuously exploring its effects on various polymer systems. The primary objective of studying heptane solvent effects on polymer film formation and properties is to optimize the film-forming process and enhance the final product's performance.

One of the key areas of interest is the impact of heptane on the morphology and microstructure of polymer films. Researchers aim to understand how the solvent-polymer interactions during the film formation process affect the arrangement of polymer chains and the resulting film properties. This knowledge is crucial for developing high-performance polymer films with tailored characteristics for specific applications.

Another important aspect of heptane solvent research is its influence on the kinetics of film formation. The evaporation rate of heptane, its miscibility with different polymer systems, and its effect on polymer chain mobility all play critical roles in determining the final film structure and properties. Understanding these factors can lead to better control over the film formation process and improved product quality.

The environmental and safety considerations associated with heptane use have also become increasingly important in recent years. As regulations on volatile organic compounds (VOCs) become more stringent, there is a growing need to optimize heptane-based processes to minimize environmental impact while maintaining or improving product performance. This has led to research into alternative solvents and solvent systems that can provide similar benefits to heptane while addressing environmental concerns.

In the broader context of materials science and engineering, the study of heptane solvent effects on polymer film formation contributes to the development of advanced materials with enhanced properties. This research has implications for various industries, including coatings, adhesives, electronics, and biomedical applications. By understanding and controlling the solvent effects, researchers and manufacturers can design polymer films with improved mechanical strength, barrier properties, optical characteristics, and other functional attributes.

Market Analysis for Heptane-Based Polymer Films

The market for heptane-based polymer films has been experiencing significant growth in recent years, driven by the increasing demand for high-performance materials in various industries. Heptane, as a solvent, plays a crucial role in the formation and properties of polymer films, making it an essential component in the production process.

The global market for heptane-based polymer films is primarily segmented into packaging, electronics, automotive, and construction industries. In the packaging sector, these films are widely used for food packaging, pharmaceutical packaging, and industrial packaging due to their excellent barrier properties and chemical resistance. The electronics industry utilizes heptane-based polymer films in the production of flexible displays, printed circuit boards, and other electronic components, benefiting from their high dielectric strength and thermal stability.

The automotive sector has also shown a growing interest in heptane-based polymer films for applications such as interior trim, exterior coatings, and lightweight components. The films' ability to enhance fuel efficiency and reduce vehicle weight aligns with the industry's focus on sustainability and environmental regulations. In the construction industry, these films find applications in insulation, weatherproofing, and decorative laminates, owing to their durability and weather resistance.

Market trends indicate a shift towards eco-friendly and sustainable polymer films, driving research and development efforts to optimize heptane-based formulations. Manufacturers are focusing on improving the biodegradability and recyclability of these films to meet the growing consumer demand for environmentally responsible products.

The Asia-Pacific region dominates the market for heptane-based polymer films, with China and India leading in production and consumption. This can be attributed to the rapid industrialization, growing population, and increasing disposable income in these countries. North America and Europe follow closely, with a strong presence in high-tech applications and stringent quality standards.

Key market drivers include the growing demand for flexible packaging, advancements in electronic devices, and the increasing adoption of lightweight materials in the automotive industry. However, challenges such as volatile raw material prices and stringent environmental regulations may impact market growth.

The competitive landscape of the heptane-based polymer film market is characterized by the presence of both large multinational corporations and smaller specialized manufacturers. Leading companies are investing heavily in research and development to improve film properties, reduce production costs, and develop innovative applications.

The global market for heptane-based polymer films is primarily segmented into packaging, electronics, automotive, and construction industries. In the packaging sector, these films are widely used for food packaging, pharmaceutical packaging, and industrial packaging due to their excellent barrier properties and chemical resistance. The electronics industry utilizes heptane-based polymer films in the production of flexible displays, printed circuit boards, and other electronic components, benefiting from their high dielectric strength and thermal stability.

The automotive sector has also shown a growing interest in heptane-based polymer films for applications such as interior trim, exterior coatings, and lightweight components. The films' ability to enhance fuel efficiency and reduce vehicle weight aligns with the industry's focus on sustainability and environmental regulations. In the construction industry, these films find applications in insulation, weatherproofing, and decorative laminates, owing to their durability and weather resistance.

Market trends indicate a shift towards eco-friendly and sustainable polymer films, driving research and development efforts to optimize heptane-based formulations. Manufacturers are focusing on improving the biodegradability and recyclability of these films to meet the growing consumer demand for environmentally responsible products.

The Asia-Pacific region dominates the market for heptane-based polymer films, with China and India leading in production and consumption. This can be attributed to the rapid industrialization, growing population, and increasing disposable income in these countries. North America and Europe follow closely, with a strong presence in high-tech applications and stringent quality standards.

Key market drivers include the growing demand for flexible packaging, advancements in electronic devices, and the increasing adoption of lightweight materials in the automotive industry. However, challenges such as volatile raw material prices and stringent environmental regulations may impact market growth.

The competitive landscape of the heptane-based polymer film market is characterized by the presence of both large multinational corporations and smaller specialized manufacturers. Leading companies are investing heavily in research and development to improve film properties, reduce production costs, and develop innovative applications.

Current Challenges in Heptane-Polymer Interactions

The interaction between heptane and polymers presents several significant challenges in the field of polymer film formation and properties. One of the primary issues is the solvent's impact on polymer chain conformation and entanglement. Heptane, being a non-polar solvent, can significantly affect the solubility and conformational behavior of polymers, particularly those with polar groups. This interaction can lead to unexpected changes in film morphology and mechanical properties.

Another challenge lies in controlling the evaporation rate of heptane during film formation. The relatively low boiling point of heptane (98.4°C) can result in rapid evaporation, which may cause defects in the polymer film such as pinholes, uneven thickness, or trapped solvent bubbles. Balancing the evaporation rate with polymer chain relaxation and reorganization is crucial for achieving desired film properties.

The influence of heptane on polymer crystallization kinetics poses additional complexities. For semi-crystalline polymers, heptane can act as a plasticizer, altering the crystallization behavior and resulting in changes to the film's thermal and mechanical properties. This effect can be particularly pronounced in thin films, where surface effects dominate.

Residual solvent retention is another significant challenge. Even after apparent drying, trace amounts of heptane can remain trapped within the polymer matrix. This residual solvent can act as a plasticizer, affecting the glass transition temperature, mechanical strength, and long-term stability of the film. Removing these last traces of solvent without damaging the polymer structure requires careful process control.

The environmental and safety concerns associated with heptane usage present additional challenges. As a volatile organic compound (VOC), heptane contributes to air pollution and poses health risks to workers. Developing alternative solvents or solvent-free processes while maintaining desired film properties is an ongoing area of research.

Lastly, the interaction between heptane and additives commonly used in polymer formulations, such as plasticizers, stabilizers, or nanofillers, adds another layer of complexity. These interactions can lead to unexpected phase separations, aggregations, or changes in additive effectiveness, impacting the overall performance of the polymer film.

Addressing these challenges requires a multidisciplinary approach, combining polymer science, surface chemistry, and process engineering. Advances in in-situ characterization techniques and molecular dynamics simulations are providing new insights into heptane-polymer interactions, paving the way for more precise control over film formation and properties.

Another challenge lies in controlling the evaporation rate of heptane during film formation. The relatively low boiling point of heptane (98.4°C) can result in rapid evaporation, which may cause defects in the polymer film such as pinholes, uneven thickness, or trapped solvent bubbles. Balancing the evaporation rate with polymer chain relaxation and reorganization is crucial for achieving desired film properties.

The influence of heptane on polymer crystallization kinetics poses additional complexities. For semi-crystalline polymers, heptane can act as a plasticizer, altering the crystallization behavior and resulting in changes to the film's thermal and mechanical properties. This effect can be particularly pronounced in thin films, where surface effects dominate.

Residual solvent retention is another significant challenge. Even after apparent drying, trace amounts of heptane can remain trapped within the polymer matrix. This residual solvent can act as a plasticizer, affecting the glass transition temperature, mechanical strength, and long-term stability of the film. Removing these last traces of solvent without damaging the polymer structure requires careful process control.

The environmental and safety concerns associated with heptane usage present additional challenges. As a volatile organic compound (VOC), heptane contributes to air pollution and poses health risks to workers. Developing alternative solvents or solvent-free processes while maintaining desired film properties is an ongoing area of research.

Lastly, the interaction between heptane and additives commonly used in polymer formulations, such as plasticizers, stabilizers, or nanofillers, adds another layer of complexity. These interactions can lead to unexpected phase separations, aggregations, or changes in additive effectiveness, impacting the overall performance of the polymer film.

Addressing these challenges requires a multidisciplinary approach, combining polymer science, surface chemistry, and process engineering. Advances in in-situ characterization techniques and molecular dynamics simulations are providing new insights into heptane-polymer interactions, paving the way for more precise control over film formation and properties.

Existing Heptane Solvent Solutions for Polymer Films

01 Polymer film formation techniques

Various methods are employed to form polymer films, including solution casting, melt extrusion, and vapor deposition. These techniques influence the film's structure, thickness, and uniformity. The choice of method depends on the polymer type, desired properties, and application requirements.- Polymer film formation techniques: Various methods are employed to form polymer films, including solution casting, melt extrusion, and vapor deposition. These techniques influence the film's structure, thickness, and uniformity. The choice of method depends on the polymer type, desired properties, and application requirements.

- Mechanical properties of polymer films: The mechanical properties of polymer films, such as tensile strength, elasticity, and tear resistance, are crucial for their performance. These properties can be tailored by adjusting the polymer composition, molecular weight, and processing conditions. Additives and reinforcing agents may also be incorporated to enhance specific mechanical characteristics.

- Barrier properties and permeability: Polymer films often serve as barriers against gases, moisture, and other substances. The permeability of these films is influenced by factors such as polymer chemistry, crystallinity, and film thickness. Multilayer structures and surface treatments can be employed to improve barrier properties for specific applications.

- Surface modification and functionalization: The surface properties of polymer films can be modified to enhance adhesion, wettability, or introduce specific functionalities. Techniques such as plasma treatment, chemical grafting, and nanoparticle incorporation are used to tailor the film surface for various applications, including packaging, electronics, and biomedical devices.

- Thermal and optical properties: The thermal stability, heat resistance, and optical properties of polymer films are important for many applications. These properties can be optimized through polymer selection, additives, and processing techniques. Factors such as crystallinity, orientation, and film thickness play crucial roles in determining thermal and optical characteristics.

02 Mechanical properties of polymer films

The mechanical properties of polymer films, such as tensile strength, elongation, and flexibility, are crucial for their performance in various applications. These properties can be tailored by adjusting the polymer composition, molecular weight, and processing conditions. Additives and reinforcements may also be incorporated to enhance specific mechanical characteristics.Expand Specific Solutions03 Barrier properties and permeability

Polymer films often serve as barriers against gases, moisture, and other substances. The permeability of these films is influenced by factors such as polymer chemistry, crystallinity, and film thickness. Multilayer structures and surface treatments can be employed to improve barrier properties for specific applications like packaging or protective coatings.Expand Specific Solutions04 Surface modification and functionalization

The surface properties of polymer films can be modified to enhance their performance or add functionality. Techniques such as plasma treatment, chemical grafting, and nanoparticle incorporation are used to alter surface energy, improve adhesion, or impart specific properties like antimicrobial activity or conductivity.Expand Specific Solutions05 Thermal and optical properties

The thermal stability, heat resistance, and optical properties of polymer films are important for many applications. These properties can be optimized through polymer selection, additives, and processing techniques. Factors such as crystallinity, orientation, and film thickness influence thermal behavior and optical characteristics like transparency and refractive index.Expand Specific Solutions

Key Players in Polymer Film Industry

The competitive landscape for "Heptane Solvent Effects on Polymer Film Formation and Properties" is characterized by a mature market with established players and ongoing research. The global polymer film market is substantial, with key companies like DuPont, LG Chem, and Mitsui Chemicals leading in innovation. These firms, along with others such as JSR Corp. and Solutia, Inc., are investing in R&D to enhance film properties and performance. The technology's maturity varies across applications, with advanced developments in electronics and packaging, while emerging opportunities exist in sustainable and bio-based polymers. Collaboration between industry and academic institutions like the University of Akron is driving further advancements in this field.

JSR Corp.

Technical Solution: JSR Corp. has developed advanced polymer film formation techniques using heptane as a solvent. Their approach involves controlling the evaporation rate of heptane to achieve optimal film morphology and properties. The company utilizes a proprietary blend of heptane with other solvents to fine-tune the polymer solution's rheological properties, resulting in improved film uniformity and reduced defects[1]. JSR's method also incorporates in-situ monitoring of solvent evaporation and polymer chain conformation during film formation, allowing for real-time adjustments to processing parameters[3].

Strengths: Precise control over film morphology, reduced defects, and adaptability to various polymer systems. Weaknesses: Potential environmental concerns due to heptane volatility and the need for specialized equipment for in-situ monitoring.

Akron Polymer Systems, Inc.

Technical Solution: Akron Polymer Systems has developed a novel approach to polymer film formation using heptane as a primary solvent. Their technique involves a two-stage solvent evaporation process, where heptane is first used to create a uniform polymer solution, followed by a controlled evaporation stage that utilizes temperature gradients to manipulate film properties[2]. The company has also implemented a proprietary additive package that enhances the compatibility between heptane and various polymer systems, expanding the range of materials that can be processed using this method[4]. Additionally, Akron Polymer Systems has developed a surface modification technique that improves the adhesion of heptane-cast films to various substrates[5].

Strengths: Versatility in processing different polymer systems, improved film adhesion, and enhanced control over film properties. Weaknesses: Potential increased production costs due to the two-stage process and specialized additives.

Core Innovations in Heptane-Polymer Film Formation

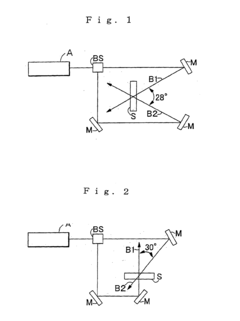

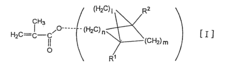

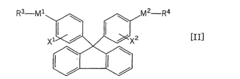

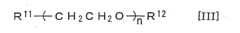

Composition for hologram-recording material, hologram-recording medium, and process for producing the same

PatentInactiveEP1376268A1

Innovation

- A hologram recording material composition comprising a thermoplastic resin, a radical polymerizable compound with a 9,9-diarylfluorene skeleton, a plasticizer, and a photopolymerization initiator, where the radical polymerizable compound is solid at ordinary temperature, and the weight percentage ratio of components is optimized to enhance refractive index modulation and diffraction efficiency.

Environmental Impact of Heptane in Polymer Processing

The use of heptane as a solvent in polymer processing has significant environmental implications that warrant careful consideration. Heptane, a volatile organic compound (VOC), is known for its high evaporation rate and low boiling point, which contribute to its effectiveness as a solvent but also raise concerns about its environmental impact. When released into the atmosphere, heptane can participate in photochemical reactions, potentially contributing to the formation of ground-level ozone and smog. These air quality issues can have detrimental effects on human health and ecosystems.

In polymer film formation processes, the release of heptane into the environment primarily occurs through evaporation during drying stages. This emission can be substantial, especially in large-scale industrial operations. The environmental fate of heptane in the atmosphere is relatively short-lived, with a half-life of approximately 1-2 days due to its reactivity with hydroxyl radicals. However, its rapid evaporation and widespread use in various industries contribute to its persistent presence in urban and industrial atmospheres.

Water contamination is another environmental concern associated with heptane use in polymer processing. Although heptane has low water solubility, accidental spills or improper disposal can lead to soil and groundwater contamination. In aquatic environments, heptane can form a surface film, potentially impacting oxygen transfer and affecting aquatic life. The bioaccumulation potential of heptane in aquatic organisms is generally considered low, but its presence can still disrupt ecosystems.

From a regulatory perspective, the use of heptane in polymer processing is subject to increasingly stringent environmental regulations. Many countries have implemented VOC emission limits and require the use of best available techniques to minimize environmental impact. This has led to the development of various emission control technologies, such as thermal oxidizers, carbon adsorption systems, and solvent recovery units, specifically designed to capture and treat heptane emissions from industrial processes.

The environmental impact of heptane extends beyond its direct effects on air and water quality. The production and transportation of heptane also contribute to its overall environmental footprint. As a petroleum-derived solvent, its lifecycle is associated with the environmental impacts of fossil fuel extraction and processing. Additionally, the energy-intensive nature of solvent recovery and emission control processes adds to the overall environmental burden of using heptane in polymer processing.

In response to these environmental concerns, there is a growing trend towards the development of more environmentally friendly alternatives to heptane in polymer processing. This includes the exploration of bio-based solvents, water-based systems, and solvent-free processing techniques. However, the transition to these alternatives often presents technical challenges in achieving comparable polymer film properties and processing efficiencies.

In polymer film formation processes, the release of heptane into the environment primarily occurs through evaporation during drying stages. This emission can be substantial, especially in large-scale industrial operations. The environmental fate of heptane in the atmosphere is relatively short-lived, with a half-life of approximately 1-2 days due to its reactivity with hydroxyl radicals. However, its rapid evaporation and widespread use in various industries contribute to its persistent presence in urban and industrial atmospheres.

Water contamination is another environmental concern associated with heptane use in polymer processing. Although heptane has low water solubility, accidental spills or improper disposal can lead to soil and groundwater contamination. In aquatic environments, heptane can form a surface film, potentially impacting oxygen transfer and affecting aquatic life. The bioaccumulation potential of heptane in aquatic organisms is generally considered low, but its presence can still disrupt ecosystems.

From a regulatory perspective, the use of heptane in polymer processing is subject to increasingly stringent environmental regulations. Many countries have implemented VOC emission limits and require the use of best available techniques to minimize environmental impact. This has led to the development of various emission control technologies, such as thermal oxidizers, carbon adsorption systems, and solvent recovery units, specifically designed to capture and treat heptane emissions from industrial processes.

The environmental impact of heptane extends beyond its direct effects on air and water quality. The production and transportation of heptane also contribute to its overall environmental footprint. As a petroleum-derived solvent, its lifecycle is associated with the environmental impacts of fossil fuel extraction and processing. Additionally, the energy-intensive nature of solvent recovery and emission control processes adds to the overall environmental burden of using heptane in polymer processing.

In response to these environmental concerns, there is a growing trend towards the development of more environmentally friendly alternatives to heptane in polymer processing. This includes the exploration of bio-based solvents, water-based systems, and solvent-free processing techniques. However, the transition to these alternatives often presents technical challenges in achieving comparable polymer film properties and processing efficiencies.

Regulatory Framework for Solvent Use in Polymer Industry

The regulatory framework for solvent use in the polymer industry is a complex and evolving landscape that significantly impacts the development, production, and application of polymer films. In recent years, there has been an increased focus on environmental protection and worker safety, leading to more stringent regulations governing the use of solvents, including heptane, in polymer manufacturing processes.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) have established guidelines for the safe use and disposal of solvents. These guidelines often serve as a basis for national and regional regulations. The European Union, through its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, has implemented a comprehensive system for controlling chemical substances, including solvents used in polymer production.

In the United States, the Environmental Protection Agency (EPA) regulates solvent use under various acts, including the Clean Air Act and the Toxic Substances Control Act. The Occupational Safety and Health Administration (OSHA) sets standards for workplace exposure limits to solvents, including heptane, to protect worker health and safety.

Many countries have adopted similar regulatory frameworks, often tailoring them to their specific environmental and industrial contexts. For instance, Japan's Chemical Substances Control Law and China's Measures for Environmental Management of New Chemical Substances provide regulatory oversight for solvent use in their respective polymer industries.

These regulations typically address several key areas: emissions control, workplace safety, product safety, and waste management. Manufacturers are required to implement pollution control technologies, conduct regular environmental impact assessments, and adhere to strict reporting requirements. Additionally, there are often restrictions on the volatile organic compound (VOC) content in products, which directly affects the use of solvents like heptane in polymer film formation.

The regulatory landscape also influences research and development in the polymer industry. There is a growing trend towards the development of water-based and bio-based solvents as alternatives to traditional petroleum-based solvents like heptane. This shift is driven by both regulatory pressures and market demand for more environmentally friendly products.

Compliance with these regulations presents both challenges and opportunities for the polymer industry. While adherence to strict standards can increase production costs and complexity, it also drives innovation in cleaner technologies and more sustainable practices. Companies that successfully navigate this regulatory environment often gain a competitive advantage in the global market.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) have established guidelines for the safe use and disposal of solvents. These guidelines often serve as a basis for national and regional regulations. The European Union, through its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, has implemented a comprehensive system for controlling chemical substances, including solvents used in polymer production.

In the United States, the Environmental Protection Agency (EPA) regulates solvent use under various acts, including the Clean Air Act and the Toxic Substances Control Act. The Occupational Safety and Health Administration (OSHA) sets standards for workplace exposure limits to solvents, including heptane, to protect worker health and safety.

Many countries have adopted similar regulatory frameworks, often tailoring them to their specific environmental and industrial contexts. For instance, Japan's Chemical Substances Control Law and China's Measures for Environmental Management of New Chemical Substances provide regulatory oversight for solvent use in their respective polymer industries.

These regulations typically address several key areas: emissions control, workplace safety, product safety, and waste management. Manufacturers are required to implement pollution control technologies, conduct regular environmental impact assessments, and adhere to strict reporting requirements. Additionally, there are often restrictions on the volatile organic compound (VOC) content in products, which directly affects the use of solvents like heptane in polymer film formation.

The regulatory landscape also influences research and development in the polymer industry. There is a growing trend towards the development of water-based and bio-based solvents as alternatives to traditional petroleum-based solvents like heptane. This shift is driven by both regulatory pressures and market demand for more environmentally friendly products.

Compliance with these regulations presents both challenges and opportunities for the polymer industry. While adherence to strict standards can increase production costs and complexity, it also drives innovation in cleaner technologies and more sustainable practices. Companies that successfully navigate this regulatory environment often gain a competitive advantage in the global market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!