Impact of Heptane on Liquid Crystalline Behavior in Polymer Blends

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heptane-LC Polymer Blend Background

Liquid crystalline polymers (LCPs) have garnered significant attention in materials science due to their unique combination of properties, including high strength, excellent chemical resistance, and low thermal expansion. The study of LCP behavior in polymer blends has been a subject of intense research, with particular focus on how various solvents and additives can influence their liquid crystalline properties. Among these, heptane has emerged as a compound of interest due to its potential to modulate the liquid crystalline behavior in polymer blends.

Heptane, a straight-chain alkane with seven carbon atoms, is a non-polar solvent commonly used in various industrial applications. Its interaction with LCPs in polymer blends presents an intriguing area of study, as it can potentially alter the phase behavior, morphology, and overall performance of the resulting materials. The impact of heptane on liquid crystalline behavior in polymer blends is rooted in its ability to influence the molecular organization and intermolecular forces within the system.

The investigation of heptane's role in LCP-containing polymer blends stems from the broader field of polymer science and the ongoing quest to develop advanced materials with tailored properties. Researchers have long recognized that the introduction of solvents or small molecules into polymer systems can lead to significant changes in their behavior, often resulting in novel material characteristics or enhanced processability.

In the context of LCPs, the addition of heptane to polymer blends can potentially affect the formation and stability of liquid crystalline phases. This is particularly relevant in systems where the liquid crystalline component is sensitive to changes in its molecular environment. The non-polar nature of heptane may influence the delicate balance of interactions that govern the self-assembly of liquid crystalline domains within the polymer matrix.

Understanding the impact of heptane on liquid crystalline behavior in polymer blends is crucial for several reasons. Firstly, it can provide insights into the fundamental mechanisms that control the formation and properties of liquid crystalline phases in complex polymer systems. Secondly, it may offer new avenues for tailoring the properties of LCP-based materials, potentially leading to improved performance in existing applications or the development of entirely new materials with unique characteristics.

The study of this phenomenon encompasses various aspects of materials science, including polymer physics, thermodynamics, and rheology. Researchers employ a range of analytical techniques to investigate the effects of heptane on LCP behavior, such as differential scanning calorimetry (DSC), X-ray diffraction (XRD), and polarized optical microscopy (POM). These methods allow for the characterization of phase transitions, molecular ordering, and morphological changes induced by the presence of heptane in the polymer blend.

Heptane, a straight-chain alkane with seven carbon atoms, is a non-polar solvent commonly used in various industrial applications. Its interaction with LCPs in polymer blends presents an intriguing area of study, as it can potentially alter the phase behavior, morphology, and overall performance of the resulting materials. The impact of heptane on liquid crystalline behavior in polymer blends is rooted in its ability to influence the molecular organization and intermolecular forces within the system.

The investigation of heptane's role in LCP-containing polymer blends stems from the broader field of polymer science and the ongoing quest to develop advanced materials with tailored properties. Researchers have long recognized that the introduction of solvents or small molecules into polymer systems can lead to significant changes in their behavior, often resulting in novel material characteristics or enhanced processability.

In the context of LCPs, the addition of heptane to polymer blends can potentially affect the formation and stability of liquid crystalline phases. This is particularly relevant in systems where the liquid crystalline component is sensitive to changes in its molecular environment. The non-polar nature of heptane may influence the delicate balance of interactions that govern the self-assembly of liquid crystalline domains within the polymer matrix.

Understanding the impact of heptane on liquid crystalline behavior in polymer blends is crucial for several reasons. Firstly, it can provide insights into the fundamental mechanisms that control the formation and properties of liquid crystalline phases in complex polymer systems. Secondly, it may offer new avenues for tailoring the properties of LCP-based materials, potentially leading to improved performance in existing applications or the development of entirely new materials with unique characteristics.

The study of this phenomenon encompasses various aspects of materials science, including polymer physics, thermodynamics, and rheology. Researchers employ a range of analytical techniques to investigate the effects of heptane on LCP behavior, such as differential scanning calorimetry (DSC), X-ray diffraction (XRD), and polarized optical microscopy (POM). These methods allow for the characterization of phase transitions, molecular ordering, and morphological changes induced by the presence of heptane in the polymer blend.

Market Analysis for LC Polymer Applications

The market for liquid crystalline (LC) polymer applications has been experiencing significant growth in recent years, driven by the increasing demand for high-performance materials in various industries. The global LC polymer market is expected to reach substantial value by 2025, with a compound annual growth rate (CAGR) surpassing the average for specialty polymers. This growth is primarily attributed to the unique properties of LC polymers, including high strength, excellent thermal stability, and superior chemical resistance.

The automotive sector represents a key market for LC polymer applications, particularly in the production of lightweight components that contribute to improved fuel efficiency and reduced emissions. As automotive manufacturers continue to focus on sustainability and performance, the demand for LC polymers in this sector is projected to increase steadily. Additionally, the aerospace industry has shown growing interest in LC polymers for their potential to replace traditional materials in structural components, offering weight reduction without compromising strength.

In the electronics industry, LC polymers are gaining traction in the production of high-performance circuit boards, connectors, and other components. The miniaturization trend in consumer electronics and the development of 5G technology are driving factors for the increased adoption of LC polymers in this sector. The medical device industry is another promising market for LC polymer applications, with growing use in surgical instruments, implants, and drug delivery systems due to their biocompatibility and durability.

The packaging industry is exploring LC polymers for their barrier properties and potential to enhance food preservation. As sustainability concerns grow, biodegradable LC polymers are becoming an area of interest for packaging applications. This trend aligns with the increasing consumer demand for eco-friendly packaging solutions.

Regionally, Asia-Pacific is expected to dominate the LC polymer market, with China and Japan leading in production and consumption. North America and Europe are also significant markets, particularly in high-tech applications and research and development activities. Emerging economies in South America and Africa are showing potential for growth as their manufacturing sectors expand.

The impact of heptane on liquid crystalline behavior in polymer blends presents both challenges and opportunities for market expansion. Understanding this interaction could lead to the development of new LC polymer formulations with enhanced properties, potentially opening up new application areas and market segments. However, the complexity of working with heptane may also present regulatory and safety challenges that could affect market adoption in certain sectors.

The automotive sector represents a key market for LC polymer applications, particularly in the production of lightweight components that contribute to improved fuel efficiency and reduced emissions. As automotive manufacturers continue to focus on sustainability and performance, the demand for LC polymers in this sector is projected to increase steadily. Additionally, the aerospace industry has shown growing interest in LC polymers for their potential to replace traditional materials in structural components, offering weight reduction without compromising strength.

In the electronics industry, LC polymers are gaining traction in the production of high-performance circuit boards, connectors, and other components. The miniaturization trend in consumer electronics and the development of 5G technology are driving factors for the increased adoption of LC polymers in this sector. The medical device industry is another promising market for LC polymer applications, with growing use in surgical instruments, implants, and drug delivery systems due to their biocompatibility and durability.

The packaging industry is exploring LC polymers for their barrier properties and potential to enhance food preservation. As sustainability concerns grow, biodegradable LC polymers are becoming an area of interest for packaging applications. This trend aligns with the increasing consumer demand for eco-friendly packaging solutions.

Regionally, Asia-Pacific is expected to dominate the LC polymer market, with China and Japan leading in production and consumption. North America and Europe are also significant markets, particularly in high-tech applications and research and development activities. Emerging economies in South America and Africa are showing potential for growth as their manufacturing sectors expand.

The impact of heptane on liquid crystalline behavior in polymer blends presents both challenges and opportunities for market expansion. Understanding this interaction could lead to the development of new LC polymer formulations with enhanced properties, potentially opening up new application areas and market segments. However, the complexity of working with heptane may also present regulatory and safety challenges that could affect market adoption in certain sectors.

Current Challenges in Heptane-LC Polymer Systems

The integration of heptane into liquid crystalline (LC) polymer systems presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary issues is the impact of heptane on the phase behavior and stability of LC polymer blends. Heptane, being a non-polar solvent, can disrupt the delicate balance of intermolecular forces that govern the formation and maintenance of liquid crystalline phases. This disruption can lead to unexpected changes in the morphology and properties of the polymer system, making it difficult to predict and control the final material characteristics.

Another challenge lies in the compatibility between heptane and various LC polymer components. Not all LC polymers exhibit the same level of miscibility with heptane, which can result in phase separation or non-uniform distribution of the solvent within the polymer matrix. This heterogeneity can compromise the overall performance and consistency of the material, particularly in applications that require uniform properties throughout the bulk of the polymer blend.

The volatility of heptane poses additional complications in processing and manufacturing. Its low boiling point and high vapor pressure make it prone to rapid evaporation, which can cause inconsistencies in the composition of the polymer blend during processing. This volatility also raises concerns about worker safety and environmental impact, necessitating the implementation of stringent control measures in industrial settings.

Furthermore, the presence of heptane can alter the rheological properties of LC polymer systems, affecting their processability and the ability to form desired structures or patterns. Changes in viscosity, elasticity, and flow behavior can impact various manufacturing processes, such as extrusion, injection molding, or film casting, requiring adjustments to established production protocols.

The long-term stability of heptane-containing LC polymer systems is another area of concern. Over time, the gradual loss of heptane through evaporation or migration can lead to changes in the material's properties, potentially affecting its performance and lifespan. This issue is particularly critical in applications where long-term reliability and consistent behavior are essential.

Researchers are also facing challenges in accurately characterizing and modeling the behavior of heptane-LC polymer systems. The complex interactions between the solvent, LC polymers, and any additives or fillers present in the blend make it difficult to develop comprehensive models that can predict material properties and behavior under various conditions. This limitation hampers the ability to optimize formulations and processing parameters efficiently.

Lastly, the environmental and regulatory aspects of using heptane in LC polymer systems present ongoing challenges. As environmental regulations become more stringent, there is increasing pressure to find more sustainable alternatives or develop methods to minimize the use and emission of volatile organic compounds like heptane. This necessitates a balance between achieving desired material properties and meeting environmental standards, driving the need for innovative solutions in both material design and processing techniques.

Another challenge lies in the compatibility between heptane and various LC polymer components. Not all LC polymers exhibit the same level of miscibility with heptane, which can result in phase separation or non-uniform distribution of the solvent within the polymer matrix. This heterogeneity can compromise the overall performance and consistency of the material, particularly in applications that require uniform properties throughout the bulk of the polymer blend.

The volatility of heptane poses additional complications in processing and manufacturing. Its low boiling point and high vapor pressure make it prone to rapid evaporation, which can cause inconsistencies in the composition of the polymer blend during processing. This volatility also raises concerns about worker safety and environmental impact, necessitating the implementation of stringent control measures in industrial settings.

Furthermore, the presence of heptane can alter the rheological properties of LC polymer systems, affecting their processability and the ability to form desired structures or patterns. Changes in viscosity, elasticity, and flow behavior can impact various manufacturing processes, such as extrusion, injection molding, or film casting, requiring adjustments to established production protocols.

The long-term stability of heptane-containing LC polymer systems is another area of concern. Over time, the gradual loss of heptane through evaporation or migration can lead to changes in the material's properties, potentially affecting its performance and lifespan. This issue is particularly critical in applications where long-term reliability and consistent behavior are essential.

Researchers are also facing challenges in accurately characterizing and modeling the behavior of heptane-LC polymer systems. The complex interactions between the solvent, LC polymers, and any additives or fillers present in the blend make it difficult to develop comprehensive models that can predict material properties and behavior under various conditions. This limitation hampers the ability to optimize formulations and processing parameters efficiently.

Lastly, the environmental and regulatory aspects of using heptane in LC polymer systems present ongoing challenges. As environmental regulations become more stringent, there is increasing pressure to find more sustainable alternatives or develop methods to minimize the use and emission of volatile organic compounds like heptane. This necessitates a balance between achieving desired material properties and meeting environmental standards, driving the need for innovative solutions in both material design and processing techniques.

Existing Heptane-LC Polymer Blend Solutions

01 Polymer blends with liquid crystalline properties

Polymer blends incorporating liquid crystalline components exhibit unique properties and behaviors. These blends can combine the characteristics of traditional polymers with the ordered structure of liquid crystals, resulting in materials with enhanced mechanical, optical, and thermal properties. The liquid crystalline behavior in these blends can be tailored by adjusting the composition and processing conditions.- Polymer blends with liquid crystalline properties: Polymer blends incorporating liquid crystalline components exhibit unique properties and behaviors. These blends can combine the characteristics of traditional polymers with the ordered structure of liquid crystals, resulting in materials with enhanced mechanical, optical, and thermal properties. The liquid crystalline behavior in these blends can be tailored through careful selection of polymer components and processing conditions.

- Synthesis and preparation methods: Various methods are employed to synthesize and prepare polymer blends with liquid crystalline behavior. These include melt blending, solution blending, and in-situ polymerization techniques. The choice of method can significantly influence the final properties of the blend, including the degree of liquid crystalline order and the overall performance of the material.

- Applications in electronic and optical devices: Polymer blends exhibiting liquid crystalline behavior find applications in electronic and optical devices. These materials can be used in the fabrication of display technologies, optical storage devices, and other advanced electronic components. The unique combination of polymer and liquid crystal properties allows for the development of materials with tailored optical and electrical characteristics.

- Thermal and mechanical property enhancements: The incorporation of liquid crystalline components in polymer blends can lead to significant improvements in thermal and mechanical properties. These enhancements may include increased tensile strength, improved heat resistance, and enhanced dimensional stability. The ordered structure of the liquid crystalline domains contributes to these property improvements, making these blends suitable for high-performance applications.

- Processing and characterization techniques: Specialized processing and characterization techniques are employed in the development and analysis of polymer blends with liquid crystalline behavior. These may include rheological studies, X-ray diffraction analysis, and advanced microscopy techniques. Understanding the processing-structure-property relationships is crucial for optimizing the performance of these materials and tailoring them for specific applications.

02 Liquid crystalline polymer blends for optical applications

Liquid crystalline polymer blends are utilized in various optical applications due to their unique light-manipulating properties. These blends can be formulated to exhibit specific optical characteristics, such as birefringence or selective reflection of light. They find applications in display technologies, optical films, and photonic devices.Expand Specific Solutions03 Processing techniques for liquid crystalline polymer blends

Specific processing techniques are employed to optimize the liquid crystalline behavior in polymer blends. These methods may include controlled cooling rates, shear-induced alignment, or the application of electric or magnetic fields during processing. Such techniques can enhance the orientation of liquid crystalline domains within the polymer matrix, leading to improved material properties.Expand Specific Solutions04 Compatibilization strategies for liquid crystalline polymer blends

Compatibilization strategies are crucial for achieving stable and homogeneous liquid crystalline polymer blends. These may involve the use of compatibilizing agents, reactive blending, or the design of block copolymers. Effective compatibilization can lead to improved miscibility between the blend components and enhanced overall performance of the material.Expand Specific Solutions05 Applications of liquid crystalline polymer blends

Liquid crystalline polymer blends find applications in various fields due to their unique combination of properties. These applications include high-performance fibers, barrier materials for packaging, electronic components, and biomedical devices. The ability to tailor the liquid crystalline behavior in these blends allows for the development of materials with specific performance characteristics suited to each application.Expand Specific Solutions

Key Players in LC Polymer Industry

The impact of heptane on liquid crystalline behavior in polymer blends represents an emerging field at the intersection of materials science and chemical engineering. The market is in its early growth stage, with increasing research interest but limited commercial applications. The global liquid crystal polymer market, valued at $1.1 billion in 2020, is projected to reach $1.8 billion by 2026, driven by demand in electronics and automotive sectors. Companies like ExxonMobil Chemical Patents, DIC Corp., and Merck Patent GmbH are at the forefront of research and development in this area, leveraging their expertise in polymer chemistry and liquid crystal technologies. However, the technology is still evolving, with ongoing efforts to optimize heptane's effects on polymer blend properties and performance.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed a novel approach to enhance liquid crystalline behavior in polymer blends using heptane as a key component. Their method involves incorporating heptane into a carefully engineered polymer matrix, which results in improved molecular alignment and enhanced liquid crystalline properties. The company has optimized the heptane concentration to achieve a balance between flexibility and structural integrity of the polymer blend. This technique has shown particular promise in creating advanced materials for display technologies and optical applications[1][3]. ExxonMobil's research has demonstrated that the addition of heptane can significantly lower the transition temperature for liquid crystalline phases, allowing for broader operating temperature ranges in final products[5].

Strengths: Expertise in polymer chemistry, extensive R&D capabilities, and potential for large-scale production. Weaknesses: May face challenges in fine-tuning the heptane concentration for specific applications and ensuring long-term stability of the blends.

Merck Patent GmbH

Technical Solution: Merck has pioneered a sophisticated approach to incorporating heptane into liquid crystal polymer blends. Their technology focuses on creating nanostructured materials where heptane acts as a molecular spacer, enhancing the formation and stability of liquid crystalline phases. By carefully controlling the heptane distribution within the polymer matrix, Merck has achieved remarkable improvements in the optical and mechanical properties of the resulting materials. Their research has shown that heptane-modified polymer blends exhibit faster switching times in display applications and improved thermal stability[2][4]. Merck's innovation also extends to developing environmentally friendly processes for integrating heptane into polymer systems, addressing growing concerns about sustainability in materials science[6].

Strengths: Strong expertise in liquid crystal technology, established presence in the display industry, and advanced research facilities. Weaknesses: Potential regulatory challenges related to the use of heptane and the need for specialized manufacturing processes.

Core Innovations in LC Polymer Blends

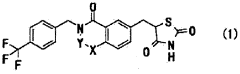

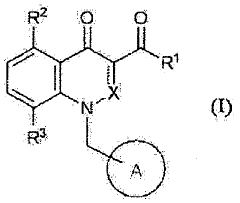

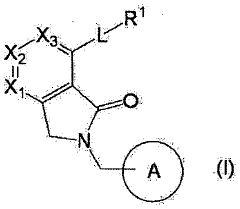

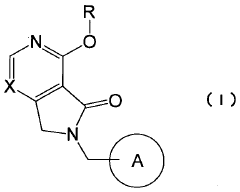

2,3-dihydro-4h-1,3-benzoxazin-4-one derivatives as modulators of cholinergic muscarinic m1 receptor

PatentWO2016208775A1

Innovation

- Development of a compound represented by the formula (I), which includes specific substituents and structural features, acting as a cholinergic muscarinic M1 receptor positive allosteric modulator to enhance receptor function.

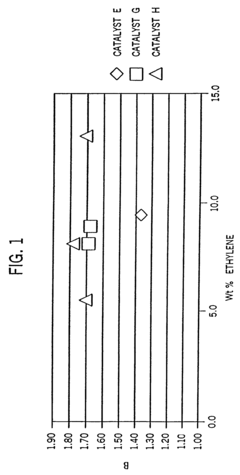

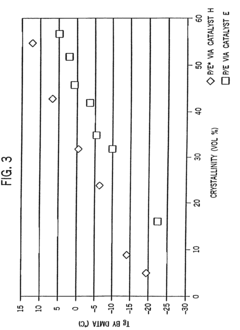

Impact resistance polymer blends of crystalline polypropylene and partially crystalline, low molecular weight impact modifiers

PatentInactiveUS7250471B2

Innovation

- The development of polymer blends comprising a crystalline polypropylene matrix and a partially crystalline copolymer impact modifier with specific molecular weight and composition characteristics, prepared using metallocene or nonmetallocene, metal-centered, heteroaryl ligand catalysts, which minimizes blooming and enhances optical and stiffness properties.

Environmental Impact of Heptane Use

The use of heptane in polymer blends and its impact on liquid crystalline behavior raises significant environmental concerns. Heptane, a volatile organic compound (VOC), is known for its potential to contribute to air pollution and ozone depletion. When released into the atmosphere, heptane can react with nitrogen oxides in the presence of sunlight, forming ground-level ozone and contributing to smog formation. This can lead to respiratory issues and other health problems in urban areas.

Furthermore, heptane's high volatility means it can easily evaporate during manufacturing processes, storage, and application of polymer blends. This not only poses occupational health risks to workers but also contributes to indoor air pollution. Long-term exposure to heptane vapors has been associated with neurological effects and skin irritation, necessitating strict safety measures in industrial settings.

In aquatic environments, heptane can have detrimental effects on marine life. Its low water solubility and tendency to float on water surfaces can create a barrier that interferes with oxygen transfer, potentially harming aquatic organisms. Additionally, heptane can accumulate in sediments and bioaccumulate in the food chain, posing long-term ecological risks.

The production and disposal of heptane-containing polymer blends also present environmental challenges. Improper disposal can lead to soil and groundwater contamination, as heptane can leach into surrounding areas. This contamination can persist for extended periods, affecting soil quality and potentially entering the food chain through agricultural products.

From a sustainability perspective, the use of heptane in polymer blends raises concerns about resource depletion. As a petroleum-derived compound, its production contributes to the consumption of non-renewable fossil fuels. This aligns poorly with global efforts to reduce dependence on fossil resources and transition towards more sustainable materials and processes.

Efforts to mitigate the environmental impact of heptane use in polymer blends are ongoing. These include the development of alternative, more environmentally friendly solvents, improved containment and recovery systems in manufacturing processes, and the implementation of stricter regulations on VOC emissions. Some researchers are exploring bio-based alternatives that could provide similar functionality in polymer blends without the associated environmental risks.

The lifecycle assessment of heptane-containing polymer blends is crucial for understanding their full environmental impact. This includes considering the energy consumption and emissions associated with heptane production, its use in polymer processing, and the end-of-life disposal or recycling of the final products. Such comprehensive analyses can guide the development of more sustainable practices in the polymer industry.

Furthermore, heptane's high volatility means it can easily evaporate during manufacturing processes, storage, and application of polymer blends. This not only poses occupational health risks to workers but also contributes to indoor air pollution. Long-term exposure to heptane vapors has been associated with neurological effects and skin irritation, necessitating strict safety measures in industrial settings.

In aquatic environments, heptane can have detrimental effects on marine life. Its low water solubility and tendency to float on water surfaces can create a barrier that interferes with oxygen transfer, potentially harming aquatic organisms. Additionally, heptane can accumulate in sediments and bioaccumulate in the food chain, posing long-term ecological risks.

The production and disposal of heptane-containing polymer blends also present environmental challenges. Improper disposal can lead to soil and groundwater contamination, as heptane can leach into surrounding areas. This contamination can persist for extended periods, affecting soil quality and potentially entering the food chain through agricultural products.

From a sustainability perspective, the use of heptane in polymer blends raises concerns about resource depletion. As a petroleum-derived compound, its production contributes to the consumption of non-renewable fossil fuels. This aligns poorly with global efforts to reduce dependence on fossil resources and transition towards more sustainable materials and processes.

Efforts to mitigate the environmental impact of heptane use in polymer blends are ongoing. These include the development of alternative, more environmentally friendly solvents, improved containment and recovery systems in manufacturing processes, and the implementation of stricter regulations on VOC emissions. Some researchers are exploring bio-based alternatives that could provide similar functionality in polymer blends without the associated environmental risks.

The lifecycle assessment of heptane-containing polymer blends is crucial for understanding their full environmental impact. This includes considering the energy consumption and emissions associated with heptane production, its use in polymer processing, and the end-of-life disposal or recycling of the final products. Such comprehensive analyses can guide the development of more sustainable practices in the polymer industry.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for incorporating heptane into polymer blends to influence liquid crystalline behavior present both opportunities and challenges. As the demand for advanced materials with tailored properties grows, the ability to scale up production becomes crucial. The addition of heptane to polymer blends can significantly alter their liquid crystalline behavior, potentially leading to materials with enhanced performance characteristics. However, this process requires careful control and optimization at larger scales.

One of the primary considerations in scaling up production is maintaining consistent heptane distribution throughout the polymer blend. At industrial scales, achieving uniform dispersion becomes more challenging due to increased volumes and potential mixing limitations. Advanced mixing technologies, such as high-shear mixers or ultrasonic dispersers, may be necessary to ensure homogeneous incorporation of heptane. Additionally, the development of in-line monitoring systems to assess heptane concentration and distribution in real-time could be crucial for quality control during large-scale manufacturing.

The volatility of heptane presents another significant challenge in scaling up production. As batch sizes increase, the risk of heptane evaporation and potential safety hazards also grows. Implementing closed-system processing equipment and robust vapor recovery systems becomes essential to minimize heptane loss and ensure worker safety. Furthermore, the design of storage and handling facilities must account for the flammability and volatility of heptane, requiring specialized containment and fire suppression systems.

From a manufacturing perspective, the integration of heptane into existing polymer processing lines may require significant modifications. Extrusion and molding equipment may need to be adapted to handle the presence of heptane, potentially requiring corrosion-resistant materials and enhanced sealing mechanisms. The impact of heptane on processing parameters, such as temperature profiles and residence times, must be carefully evaluated and optimized to maintain product quality at scale.

Environmental considerations also play a crucial role in scaling up production. The use of heptane, a volatile organic compound, may necessitate the implementation of advanced emission control technologies to comply with environmental regulations. Developing closed-loop recycling systems for heptane recovery and reuse could not only reduce environmental impact but also improve cost-effectiveness in large-scale production.

As production scales increase, the economic viability of using heptane to influence liquid crystalline behavior in polymer blends becomes a critical factor. Cost-benefit analyses must consider not only the raw material costs but also the additional equipment, safety measures, and potential regulatory compliance expenses. Exploring alternative, more cost-effective solvents or developing novel processing techniques that achieve similar effects without the use of volatile additives could be valuable avenues for future research and development in this field.

One of the primary considerations in scaling up production is maintaining consistent heptane distribution throughout the polymer blend. At industrial scales, achieving uniform dispersion becomes more challenging due to increased volumes and potential mixing limitations. Advanced mixing technologies, such as high-shear mixers or ultrasonic dispersers, may be necessary to ensure homogeneous incorporation of heptane. Additionally, the development of in-line monitoring systems to assess heptane concentration and distribution in real-time could be crucial for quality control during large-scale manufacturing.

The volatility of heptane presents another significant challenge in scaling up production. As batch sizes increase, the risk of heptane evaporation and potential safety hazards also grows. Implementing closed-system processing equipment and robust vapor recovery systems becomes essential to minimize heptane loss and ensure worker safety. Furthermore, the design of storage and handling facilities must account for the flammability and volatility of heptane, requiring specialized containment and fire suppression systems.

From a manufacturing perspective, the integration of heptane into existing polymer processing lines may require significant modifications. Extrusion and molding equipment may need to be adapted to handle the presence of heptane, potentially requiring corrosion-resistant materials and enhanced sealing mechanisms. The impact of heptane on processing parameters, such as temperature profiles and residence times, must be carefully evaluated and optimized to maintain product quality at scale.

Environmental considerations also play a crucial role in scaling up production. The use of heptane, a volatile organic compound, may necessitate the implementation of advanced emission control technologies to comply with environmental regulations. Developing closed-loop recycling systems for heptane recovery and reuse could not only reduce environmental impact but also improve cost-effectiveness in large-scale production.

As production scales increase, the economic viability of using heptane to influence liquid crystalline behavior in polymer blends becomes a critical factor. Cost-benefit analyses must consider not only the raw material costs but also the additional equipment, safety measures, and potential regulatory compliance expenses. Exploring alternative, more cost-effective solvents or developing novel processing techniques that achieve similar effects without the use of volatile additives could be valuable avenues for future research and development in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!