Comparative Study of Heptane and Nonane in Emulsion Stability

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Emulsion Stability Background and Objectives

Emulsion stability has been a critical area of study in various industries, including pharmaceuticals, food processing, and petroleum engineering. The comparative analysis of heptane and nonane in emulsion stability represents a significant step towards understanding the complex interactions between different hydrocarbon chain lengths and their impact on emulsion systems.

The historical development of emulsion science can be traced back to the early 20th century, with pioneering work by scientists such as Bancroft and Pickering. Over the decades, our understanding of emulsion stability has evolved significantly, incorporating principles from colloid science, interfacial phenomena, and molecular interactions. The focus on specific hydrocarbons like heptane and nonane in emulsion research reflects the growing need for precise control and manipulation of emulsion properties in various applications.

The primary objective of this comparative study is to elucidate the differential effects of heptane (C7H16) and nonane (C9H20) on emulsion stability. These two alkanes, differing by two carbon atoms in their molecular structure, provide an excellent model system to investigate how subtle changes in hydrocarbon chain length can influence emulsion behavior. By examining these compounds, researchers aim to gain insights into the fundamental mechanisms governing emulsion stability and potentially develop more effective emulsification strategies.

This research is driven by several key factors in the current technological landscape. Firstly, there is an increasing demand for tailored emulsion systems in industries such as cosmetics and pharmaceuticals, where precise control over stability and release properties is crucial. Secondly, in the oil and gas sector, understanding the behavior of different hydrocarbons in emulsions is essential for optimizing extraction and refining processes. Lastly, the food industry continually seeks ways to improve the texture, shelf life, and nutritional profile of emulsion-based products.

The comparative study of heptane and nonane in emulsion stability aims to address several specific objectives. These include quantifying the differences in emulsion stability when using heptane versus nonane as the oil phase, investigating the interfacial properties and molecular interactions at the oil-water interface for both hydrocarbons, and exploring the potential synergistic or antagonistic effects when these compounds are used in combination with various emulsifiers and stabilizers.

Furthermore, this research seeks to establish correlations between hydrocarbon chain length and critical emulsion parameters such as droplet size distribution, coalescence rates, and Ostwald ripening. By doing so, it aims to contribute to the development of predictive models for emulsion stability based on hydrocarbon properties, potentially revolutionizing formulation strategies across multiple industries.

The historical development of emulsion science can be traced back to the early 20th century, with pioneering work by scientists such as Bancroft and Pickering. Over the decades, our understanding of emulsion stability has evolved significantly, incorporating principles from colloid science, interfacial phenomena, and molecular interactions. The focus on specific hydrocarbons like heptane and nonane in emulsion research reflects the growing need for precise control and manipulation of emulsion properties in various applications.

The primary objective of this comparative study is to elucidate the differential effects of heptane (C7H16) and nonane (C9H20) on emulsion stability. These two alkanes, differing by two carbon atoms in their molecular structure, provide an excellent model system to investigate how subtle changes in hydrocarbon chain length can influence emulsion behavior. By examining these compounds, researchers aim to gain insights into the fundamental mechanisms governing emulsion stability and potentially develop more effective emulsification strategies.

This research is driven by several key factors in the current technological landscape. Firstly, there is an increasing demand for tailored emulsion systems in industries such as cosmetics and pharmaceuticals, where precise control over stability and release properties is crucial. Secondly, in the oil and gas sector, understanding the behavior of different hydrocarbons in emulsions is essential for optimizing extraction and refining processes. Lastly, the food industry continually seeks ways to improve the texture, shelf life, and nutritional profile of emulsion-based products.

The comparative study of heptane and nonane in emulsion stability aims to address several specific objectives. These include quantifying the differences in emulsion stability when using heptane versus nonane as the oil phase, investigating the interfacial properties and molecular interactions at the oil-water interface for both hydrocarbons, and exploring the potential synergistic or antagonistic effects when these compounds are used in combination with various emulsifiers and stabilizers.

Furthermore, this research seeks to establish correlations between hydrocarbon chain length and critical emulsion parameters such as droplet size distribution, coalescence rates, and Ostwald ripening. By doing so, it aims to contribute to the development of predictive models for emulsion stability based on hydrocarbon properties, potentially revolutionizing formulation strategies across multiple industries.

Market Analysis for Emulsion Applications

The market for emulsion applications is experiencing significant growth and diversification across various industries. The global emulsion market size was valued at approximately $10.6 billion in 2020 and is projected to reach $16.4 billion by 2027, growing at a CAGR of 6.3% during the forecast period. This growth is primarily driven by increasing demand in sectors such as paints and coatings, adhesives, personal care products, and food and beverages.

In the paints and coatings industry, which accounts for the largest share of the emulsion market, there is a growing trend towards water-based formulations due to environmental regulations and consumer preferences for eco-friendly products. This shift has led to increased research and development in emulsion technology, particularly in improving stability and performance characteristics.

The personal care and cosmetics sector is another key driver of emulsion market growth. With rising consumer awareness about product ingredients and a preference for natural and organic formulations, there is a growing demand for stable emulsions that can effectively deliver active ingredients while maintaining product texture and shelf life.

In the food and beverage industry, emulsions play a crucial role in product formulation and stability. The increasing popularity of functional foods and beverages has led to a higher demand for emulsion-based delivery systems for nutrients and bioactive compounds. This trend is expected to continue, driving innovation in food-grade emulsifiers and stabilizers.

The pharmaceutical and healthcare sectors are also significant contributors to the emulsion market. Emulsions are widely used in drug delivery systems, topical formulations, and medical imaging applications. The growing focus on personalized medicine and targeted drug delivery is expected to further boost the demand for advanced emulsion technologies in these sectors.

Geographically, Asia-Pacific is the fastest-growing market for emulsion applications, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India. North America and Europe remain significant markets, with a focus on innovation and high-performance emulsion products.

The comparative study of heptane and nonane in emulsion stability is particularly relevant in this market context. As formulators seek to optimize emulsion performance and stability across various applications, understanding the impact of different hydrocarbons on emulsion properties becomes crucial. This research could potentially lead to the development of more stable and efficient emulsion systems, addressing key challenges in industries such as cosmetics, pharmaceuticals, and food processing.

In the paints and coatings industry, which accounts for the largest share of the emulsion market, there is a growing trend towards water-based formulations due to environmental regulations and consumer preferences for eco-friendly products. This shift has led to increased research and development in emulsion technology, particularly in improving stability and performance characteristics.

The personal care and cosmetics sector is another key driver of emulsion market growth. With rising consumer awareness about product ingredients and a preference for natural and organic formulations, there is a growing demand for stable emulsions that can effectively deliver active ingredients while maintaining product texture and shelf life.

In the food and beverage industry, emulsions play a crucial role in product formulation and stability. The increasing popularity of functional foods and beverages has led to a higher demand for emulsion-based delivery systems for nutrients and bioactive compounds. This trend is expected to continue, driving innovation in food-grade emulsifiers and stabilizers.

The pharmaceutical and healthcare sectors are also significant contributors to the emulsion market. Emulsions are widely used in drug delivery systems, topical formulations, and medical imaging applications. The growing focus on personalized medicine and targeted drug delivery is expected to further boost the demand for advanced emulsion technologies in these sectors.

Geographically, Asia-Pacific is the fastest-growing market for emulsion applications, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India. North America and Europe remain significant markets, with a focus on innovation and high-performance emulsion products.

The comparative study of heptane and nonane in emulsion stability is particularly relevant in this market context. As formulators seek to optimize emulsion performance and stability across various applications, understanding the impact of different hydrocarbons on emulsion properties becomes crucial. This research could potentially lead to the development of more stable and efficient emulsion systems, addressing key challenges in industries such as cosmetics, pharmaceuticals, and food processing.

Current Challenges in Emulsion Stability

Emulsion stability remains a critical challenge in various industries, including pharmaceuticals, food processing, and petrochemicals. The comparative study of heptane and nonane in emulsion stability highlights several ongoing issues that researchers and industry professionals are grappling with.

One of the primary challenges is the complex interplay between the molecular structures of heptane and nonane and their impact on emulsion stability. Both hydrocarbons, being non-polar, exhibit different behaviors at the oil-water interface, influencing the overall stability of emulsions. The slightly longer carbon chain of nonane compared to heptane leads to variations in their surface activity and interfacial tension, which directly affects the emulsion's stability over time.

Another significant challenge lies in the precise control of droplet size distribution when using heptane or nonane as the oil phase. The ability to maintain a consistent and stable droplet size is crucial for emulsion stability, yet it remains difficult to achieve, especially in large-scale industrial applications. This challenge is further compounded by the different evaporation rates and viscosities of heptane and nonane, which can lead to unpredictable changes in emulsion properties during processing and storage.

The influence of temperature on emulsion stability presents another hurdle, particularly when comparing heptane and nonane-based systems. Temperature fluctuations can significantly alter the interfacial properties and solubility of these hydrocarbons, leading to potential destabilization of the emulsion. Researchers are still working to develop robust models that can accurately predict and control emulsion behavior across a wide range of temperatures for both heptane and nonane systems.

Furthermore, the interaction between heptane or nonane and various emulsifiers poses a complex challenge. Different emulsifiers exhibit varying degrees of effectiveness when used with these hydrocarbons, and finding the optimal emulsifier-hydrocarbon combination for specific applications remains a subject of ongoing research. This challenge is particularly evident in the development of nanoemulsions, where the choice between heptane and nonane can significantly impact the formation and stability of ultra-small droplets.

Lastly, the long-term stability of emulsions containing heptane or nonane continues to be a major concern. Phenomena such as Ostwald ripening, coalescence, and creaming can occur at different rates depending on the choice of hydrocarbon, making it difficult to predict and control emulsion stability over extended periods. This challenge is particularly relevant in industries where product shelf life is a critical factor, necessitating further research into the fundamental mechanisms governing emulsion stability with these specific hydrocarbons.

One of the primary challenges is the complex interplay between the molecular structures of heptane and nonane and their impact on emulsion stability. Both hydrocarbons, being non-polar, exhibit different behaviors at the oil-water interface, influencing the overall stability of emulsions. The slightly longer carbon chain of nonane compared to heptane leads to variations in their surface activity and interfacial tension, which directly affects the emulsion's stability over time.

Another significant challenge lies in the precise control of droplet size distribution when using heptane or nonane as the oil phase. The ability to maintain a consistent and stable droplet size is crucial for emulsion stability, yet it remains difficult to achieve, especially in large-scale industrial applications. This challenge is further compounded by the different evaporation rates and viscosities of heptane and nonane, which can lead to unpredictable changes in emulsion properties during processing and storage.

The influence of temperature on emulsion stability presents another hurdle, particularly when comparing heptane and nonane-based systems. Temperature fluctuations can significantly alter the interfacial properties and solubility of these hydrocarbons, leading to potential destabilization of the emulsion. Researchers are still working to develop robust models that can accurately predict and control emulsion behavior across a wide range of temperatures for both heptane and nonane systems.

Furthermore, the interaction between heptane or nonane and various emulsifiers poses a complex challenge. Different emulsifiers exhibit varying degrees of effectiveness when used with these hydrocarbons, and finding the optimal emulsifier-hydrocarbon combination for specific applications remains a subject of ongoing research. This challenge is particularly evident in the development of nanoemulsions, where the choice between heptane and nonane can significantly impact the formation and stability of ultra-small droplets.

Lastly, the long-term stability of emulsions containing heptane or nonane continues to be a major concern. Phenomena such as Ostwald ripening, coalescence, and creaming can occur at different rates depending on the choice of hydrocarbon, making it difficult to predict and control emulsion stability over extended periods. This challenge is particularly relevant in industries where product shelf life is a critical factor, necessitating further research into the fundamental mechanisms governing emulsion stability with these specific hydrocarbons.

Heptane vs Nonane: Current Stabilization Methods

01 Emulsion stability testing methods

Various methods are used to test the stability of heptane and nonane emulsions. These include centrifugation, temperature cycling, and long-term storage tests. Advanced analytical techniques such as particle size analysis and rheological measurements are also employed to assess emulsion stability over time.- Emulsion stability testing methods: Various methods are employed to test the stability of heptane and nonane emulsions. These include centrifugation techniques, optical analysis, and rheological measurements. Such tests help determine the emulsion's resistance to separation, coalescence, and other forms of instability over time and under different conditions.

- Surfactant selection for emulsion stabilization: The choice of surfactants plays a crucial role in stabilizing heptane and nonane emulsions. Specific surfactants or combinations thereof can effectively reduce interfacial tension and prevent droplet coalescence. Factors such as HLB value, molecular structure, and concentration of surfactants are considered to achieve optimal emulsion stability.

- Emulsion formulation techniques: Various formulation techniques are employed to enhance the stability of heptane and nonane emulsions. These may include high-pressure homogenization, microfluidization, or the use of specific mixing sequences. The choice of emulsification method can significantly impact the droplet size distribution and overall emulsion stability.

- Use of co-solvents and stabilizers: The addition of co-solvents and stabilizers can improve the stability of heptane and nonane emulsions. These additives can modify the interfacial properties, enhance the solubility of components, or create steric barriers between droplets. Examples include alcohols, polymers, and certain inorganic compounds.

- Environmental factors affecting emulsion stability: Various environmental factors can impact the stability of heptane and nonane emulsions. These include temperature fluctuations, pH changes, and exposure to shear forces. Understanding and controlling these factors is crucial for maintaining emulsion stability during storage, transportation, and application.

02 Surfactant selection for emulsion stabilization

The choice of surfactants plays a crucial role in stabilizing heptane and nonane emulsions. Non-ionic surfactants, such as ethoxylated alcohols or sorbitan esters, are often used due to their compatibility with both oil and water phases. The HLB (Hydrophilic-Lipophilic Balance) of the surfactant is carefully considered to achieve optimal emulsion stability.Expand Specific Solutions03 Emulsion formulation techniques

Specific formulation techniques are employed to enhance the stability of heptane and nonane emulsions. These include the use of high-shear mixing, homogenization, and controlled temperature processes. The order of addition of components and the mixing speed are critical factors in achieving stable emulsions.Expand Specific Solutions04 Additives for improving emulsion stability

Various additives are used to improve the stability of heptane and nonane emulsions. These may include viscosity modifiers, co-emulsifiers, and antioxidants. Polymeric stabilizers and nanoparticles are also explored for their ability to enhance emulsion stability through steric stabilization mechanisms.Expand Specific Solutions05 Environmental factors affecting emulsion stability

Environmental factors such as temperature, pH, and the presence of electrolytes significantly impact the stability of heptane and nonane emulsions. Research focuses on developing formulations that maintain stability across a wide range of conditions, including extreme temperatures and varying salt concentrations.Expand Specific Solutions

Key Players in Emulsion Technology

The comparative study of heptane and nonane in emulsion stability is currently in an early research phase, with the market still developing. The global emulsion stabilizers market is projected to grow significantly, driven by increasing demand in various industries. Companies like Evonik Operations GmbH, The Lubrizol Corp., and Dow Silicones Corp. are at the forefront of this technology, leveraging their expertise in specialty chemicals to develop innovative solutions. The technical maturity of heptane and nonane in emulsion stability is advancing, with ongoing research focusing on optimizing their performance in different applications. As the field progresses, collaborations between academic institutions and industry leaders are expected to accelerate the development of more effective and sustainable emulsion stabilization techniques.

Evonik Operations GmbH

Technical Solution: Evonik has developed advanced emulsion stabilization techniques using their expertise in specialty chemicals. Their approach involves the use of tailored surfactants and emulsifiers that can effectively stabilize both heptane and nonane-based emulsions. They have implemented a novel interfacial tension reduction method that enhances the stability of oil-in-water emulsions containing these alkanes[1]. Their research has shown that by carefully selecting the appropriate surfactant blend, they can achieve emulsion stability for extended periods, even under challenging conditions such as high temperatures or electrolyte presence[3].

Strengths: Extensive experience in specialty chemicals, tailored surfactant development, and advanced emulsion stabilization techniques. Weaknesses: May require higher costs due to specialized formulations and potential limitations in extreme environmental conditions.

The Lubrizol Corp.

Technical Solution: Lubrizol has developed a comprehensive approach to emulsion stability for both heptane and nonane systems. Their technology focuses on the use of polymeric surfactants that provide steric stabilization, effectively preventing coalescence of droplets in oil-in-water emulsions[2]. They have also implemented a dual-functionality additive system that not only stabilizes the emulsion but also improves the overall performance characteristics of the final product. Their research has demonstrated that these additives can significantly extend the shelf life of emulsions containing heptane or nonane, with stability observed for several months under various storage conditions[4].

Strengths: Innovative polymeric surfactant technology, multifunctional additive systems, and extensive experience in lubricant formulations. Weaknesses: Potential higher costs associated with specialized additives and possible limitations in extreme pH environments.

Core Research on Heptane-Nonane Emulsion Stability

A process for the preparation of nanosilver nanohydrogel based antimicrobial agent

PatentInactiveIN83DEL2010A

Innovation

- A process using gamma irradiation in an inverse emulsion to create nanosilver-nanohydrogel (nSnG) antimicrobial agents with functional groups, involving a water-in-oil emulsion with Acrylamide and Silver Nitrate, and surfactant AOT in heptane, allowing for low chemical consumption and rapid preparation of stable, interactive nanosilver particles.

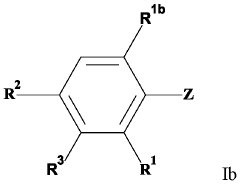

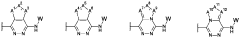

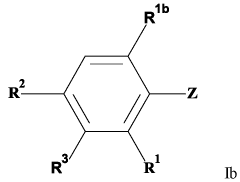

Heterocyclic NLRP3 inhibitors

PatentWO2023088856A1

Innovation

- Development of novel heterocyclic compounds that modulate NLRP3 inhibition, specifically designed to form either a 5-member heterocycle comprising 1 O heteroatom or a 4-member cycloalkyl ring, with specific ring systems and substituents, offering improved pharmacological profiles.

Environmental Impact of Heptane and Nonane Use

The environmental impact of heptane and nonane use in emulsion stability studies is a critical consideration for researchers and industries alike. Both compounds are hydrocarbons that can have significant effects on ecosystems and human health if released into the environment.

Heptane, with its lower molecular weight, tends to be more volatile than nonane. This increased volatility means that heptane is more likely to evaporate and contribute to air pollution. When released into the atmosphere, heptane can participate in photochemical reactions, potentially contributing to the formation of ground-level ozone and smog. These air quality issues can have adverse effects on respiratory health and plant life.

Nonane, being less volatile, is more likely to persist in soil and water environments. This persistence can lead to longer-term contamination of ecosystems, potentially affecting aquatic life and soil microorganisms. However, its lower volatility also means that nonane may contribute less to immediate air pollution concerns compared to heptane.

Both compounds pose risks to aquatic environments if spilled or improperly disposed of. They can form a layer on water surfaces, interfering with oxygen transfer and potentially harming aquatic organisms. Heptane's higher volatility may lead to faster dissipation from water surfaces, but it could also result in more rapid contamination of surrounding air.

In terms of biodegradability, both heptane and nonane are generally considered to be biodegradable under aerobic conditions. However, the rate of biodegradation can vary depending on environmental factors such as temperature, presence of microorganisms, and availability of nutrients. Nonane, due to its longer carbon chain, may degrade more slowly than heptane.

The production and use of these compounds also have environmental implications. Both are typically derived from petroleum, contributing to the carbon footprint associated with fossil fuel extraction and processing. The energy requirements for their production and purification should be considered when assessing their overall environmental impact.

In emulsion stability studies, the choice between heptane and nonane may have indirect environmental consequences. If one compound proves to be more effective in stabilizing emulsions, it could lead to more efficient processes and potentially reduce waste. However, this must be balanced against the environmental risks associated with increased use and potential release of the chosen compound.

Regulatory frameworks play a crucial role in mitigating the environmental impacts of heptane and nonane use. Many countries have established guidelines for their handling, storage, and disposal. Adherence to these regulations is essential for minimizing environmental risks and ensuring responsible use in research and industrial applications.

Heptane, with its lower molecular weight, tends to be more volatile than nonane. This increased volatility means that heptane is more likely to evaporate and contribute to air pollution. When released into the atmosphere, heptane can participate in photochemical reactions, potentially contributing to the formation of ground-level ozone and smog. These air quality issues can have adverse effects on respiratory health and plant life.

Nonane, being less volatile, is more likely to persist in soil and water environments. This persistence can lead to longer-term contamination of ecosystems, potentially affecting aquatic life and soil microorganisms. However, its lower volatility also means that nonane may contribute less to immediate air pollution concerns compared to heptane.

Both compounds pose risks to aquatic environments if spilled or improperly disposed of. They can form a layer on water surfaces, interfering with oxygen transfer and potentially harming aquatic organisms. Heptane's higher volatility may lead to faster dissipation from water surfaces, but it could also result in more rapid contamination of surrounding air.

In terms of biodegradability, both heptane and nonane are generally considered to be biodegradable under aerobic conditions. However, the rate of biodegradation can vary depending on environmental factors such as temperature, presence of microorganisms, and availability of nutrients. Nonane, due to its longer carbon chain, may degrade more slowly than heptane.

The production and use of these compounds also have environmental implications. Both are typically derived from petroleum, contributing to the carbon footprint associated with fossil fuel extraction and processing. The energy requirements for their production and purification should be considered when assessing their overall environmental impact.

In emulsion stability studies, the choice between heptane and nonane may have indirect environmental consequences. If one compound proves to be more effective in stabilizing emulsions, it could lead to more efficient processes and potentially reduce waste. However, this must be balanced against the environmental risks associated with increased use and potential release of the chosen compound.

Regulatory frameworks play a crucial role in mitigating the environmental impacts of heptane and nonane use. Many countries have established guidelines for their handling, storage, and disposal. Adherence to these regulations is essential for minimizing environmental risks and ensuring responsible use in research and industrial applications.

Regulatory Framework for Emulsion Additives

The regulatory framework for emulsion additives plays a crucial role in ensuring the safety and efficacy of products containing heptane and nonane. These hydrocarbons are commonly used in various industries, including cosmetics, pharmaceuticals, and petrochemicals, where emulsion stability is paramount.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of emulsion additives in food and cosmetic products. The FDA's Code of Federal Regulations (CFR) Title 21 provides specific guidelines for the use of heptane and nonane in emulsions. These regulations outline permissible concentrations, purity requirements, and labeling standards to ensure consumer safety.

The European Union's regulatory body, the European Chemicals Agency (ECHA), implements the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers and importers of heptane and nonane must register these substances and provide detailed safety information. The regulation also mandates risk assessments and the implementation of appropriate risk management measures.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) regulates emulsion additives through the Pharmaceutical and Medical Device Act. This legislation sets standards for the quality, efficacy, and safety of pharmaceutical products, including those containing heptane and nonane in emulsion formulations.

The International Organization for Standardization (ISO) has developed several standards relevant to emulsion stability and additives. ISO 13320:2020, for instance, provides guidelines for particle size analysis, which is crucial in assessing emulsion stability. These international standards help harmonize testing methods and quality control across different regulatory jurisdictions.

Environmental regulations also impact the use of heptane and nonane in emulsions. The U.S. Environmental Protection Agency (EPA) regulates these compounds under the Toxic Substances Control Act (TSCA), which requires reporting, record-keeping, and testing. Similarly, the EU's Environmental Quality Standards Directive sets limits on the concentration of these hydrocarbons in water bodies to protect aquatic ecosystems.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the U.S., set exposure limits for workers handling heptane and nonane. These regulations mandate proper handling procedures, personal protective equipment, and workplace monitoring to minimize health risks associated with these chemicals.

As the understanding of emulsion stability and the effects of additives evolves, regulatory frameworks continue to adapt. Recent trends indicate a move towards more stringent regulations on volatile organic compounds (VOCs), which may impact the use of heptane and nonane in certain applications. Additionally, there is an increasing focus on sustainable and bio-based alternatives, which may influence future regulatory approaches to traditional petroleum-derived emulsion additives.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of emulsion additives in food and cosmetic products. The FDA's Code of Federal Regulations (CFR) Title 21 provides specific guidelines for the use of heptane and nonane in emulsions. These regulations outline permissible concentrations, purity requirements, and labeling standards to ensure consumer safety.

The European Union's regulatory body, the European Chemicals Agency (ECHA), implements the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers and importers of heptane and nonane must register these substances and provide detailed safety information. The regulation also mandates risk assessments and the implementation of appropriate risk management measures.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) regulates emulsion additives through the Pharmaceutical and Medical Device Act. This legislation sets standards for the quality, efficacy, and safety of pharmaceutical products, including those containing heptane and nonane in emulsion formulations.

The International Organization for Standardization (ISO) has developed several standards relevant to emulsion stability and additives. ISO 13320:2020, for instance, provides guidelines for particle size analysis, which is crucial in assessing emulsion stability. These international standards help harmonize testing methods and quality control across different regulatory jurisdictions.

Environmental regulations also impact the use of heptane and nonane in emulsions. The U.S. Environmental Protection Agency (EPA) regulates these compounds under the Toxic Substances Control Act (TSCA), which requires reporting, record-keeping, and testing. Similarly, the EU's Environmental Quality Standards Directive sets limits on the concentration of these hydrocarbons in water bodies to protect aquatic ecosystems.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the U.S., set exposure limits for workers handling heptane and nonane. These regulations mandate proper handling procedures, personal protective equipment, and workplace monitoring to minimize health risks associated with these chemicals.

As the understanding of emulsion stability and the effects of additives evolves, regulatory frameworks continue to adapt. Recent trends indicate a move towards more stringent regulations on volatile organic compounds (VOCs), which may impact the use of heptane and nonane in certain applications. Additionally, there is an increasing focus on sustainable and bio-based alternatives, which may influence future regulatory approaches to traditional petroleum-derived emulsion additives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!