Phase Partitioning of Heptane in Water/Oil Emulsions

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heptane Partitioning Background and Objectives

The phase partitioning of heptane in water/oil emulsions is a critical area of study in the field of petroleum engineering and chemical sciences. This phenomenon plays a significant role in various industrial processes, particularly in oil recovery and environmental remediation. The behavior of heptane, a straight-chain alkane with seven carbon atoms, in complex emulsion systems has been the subject of extensive research due to its relevance in understanding the dynamics of hydrocarbon-water interactions.

The historical development of this field can be traced back to the early 20th century when the importance of emulsions in petroleum production was first recognized. Since then, the study of phase partitioning has evolved significantly, incorporating advanced analytical techniques and theoretical models to better understand the distribution of hydrocarbons like heptane between water and oil phases.

In recent years, the focus has shifted towards developing more accurate predictive models for heptane partitioning, driven by the need for improved oil recovery techniques and environmental protection measures. The advent of nanotechnology and advanced imaging methods has opened up new avenues for investigating the behavior of heptane at the molecular level, providing unprecedented insights into the mechanisms governing its distribution in complex emulsion systems.

The primary objective of studying heptane partitioning in water/oil emulsions is to enhance our understanding of the factors influencing the distribution of hydrocarbons in multiphase systems. This knowledge is crucial for optimizing oil recovery processes, designing more effective emulsion breakers, and developing strategies for oil spill remediation. Additionally, it contributes to the broader field of interfacial science, with implications for diverse applications ranging from drug delivery systems to food technology.

Another key goal is to develop robust predictive models that can accurately describe the partitioning behavior of heptane under various conditions. These models are essential for simulating complex reservoir conditions, designing efficient separation processes, and predicting the environmental fate of hydrocarbons. The ultimate aim is to bridge the gap between theoretical understanding and practical applications, enabling more efficient and environmentally friendly oil production and processing methods.

Furthermore, researchers are increasingly focusing on the role of surfactants and other additives in modulating heptane partitioning. Understanding these interactions is crucial for developing novel emulsion stabilization or destabilization techniques, which have far-reaching implications for both the petroleum industry and environmental protection efforts. As global energy demands continue to rise, coupled with increasing environmental concerns, the study of heptane partitioning remains at the forefront of efforts to balance resource extraction with ecological sustainability.

The historical development of this field can be traced back to the early 20th century when the importance of emulsions in petroleum production was first recognized. Since then, the study of phase partitioning has evolved significantly, incorporating advanced analytical techniques and theoretical models to better understand the distribution of hydrocarbons like heptane between water and oil phases.

In recent years, the focus has shifted towards developing more accurate predictive models for heptane partitioning, driven by the need for improved oil recovery techniques and environmental protection measures. The advent of nanotechnology and advanced imaging methods has opened up new avenues for investigating the behavior of heptane at the molecular level, providing unprecedented insights into the mechanisms governing its distribution in complex emulsion systems.

The primary objective of studying heptane partitioning in water/oil emulsions is to enhance our understanding of the factors influencing the distribution of hydrocarbons in multiphase systems. This knowledge is crucial for optimizing oil recovery processes, designing more effective emulsion breakers, and developing strategies for oil spill remediation. Additionally, it contributes to the broader field of interfacial science, with implications for diverse applications ranging from drug delivery systems to food technology.

Another key goal is to develop robust predictive models that can accurately describe the partitioning behavior of heptane under various conditions. These models are essential for simulating complex reservoir conditions, designing efficient separation processes, and predicting the environmental fate of hydrocarbons. The ultimate aim is to bridge the gap between theoretical understanding and practical applications, enabling more efficient and environmentally friendly oil production and processing methods.

Furthermore, researchers are increasingly focusing on the role of surfactants and other additives in modulating heptane partitioning. Understanding these interactions is crucial for developing novel emulsion stabilization or destabilization techniques, which have far-reaching implications for both the petroleum industry and environmental protection efforts. As global energy demands continue to rise, coupled with increasing environmental concerns, the study of heptane partitioning remains at the forefront of efforts to balance resource extraction with ecological sustainability.

Market Analysis for Emulsion Applications

The market for emulsion applications, particularly those involving heptane in water/oil systems, has shown significant growth and diversification in recent years. This trend is driven by the increasing demand for advanced emulsion technologies across various industries, including pharmaceuticals, cosmetics, food and beverages, and petrochemicals.

In the pharmaceutical sector, emulsions play a crucial role in drug delivery systems, enhancing the bioavailability of poorly water-soluble drugs. The market for pharmaceutical emulsions is expected to expand due to the rising prevalence of chronic diseases and the need for more effective drug formulations. Heptane-based emulsions are being explored for their potential in creating stable, long-lasting drug delivery vehicles.

The cosmetics industry has also embraced emulsion technology, with a growing focus on natural and organic products. Water-in-oil emulsions containing heptane are utilized in various skincare and haircare products, offering improved texture and stability. The global natural cosmetics market, which heavily relies on emulsion technology, is projected to experience substantial growth in the coming years.

In the food and beverage sector, emulsions are widely used as stabilizers, texture modifiers, and flavor carriers. The demand for clean-label and natural ingredients has led to increased research into heptane-based emulsions as potential alternatives to synthetic emulsifiers. This trend is particularly evident in the functional food and nutraceutical segments, where emulsion stability and bioavailability are critical factors.

The petrochemical industry represents another significant market for heptane in water/oil emulsions. These emulsions are employed in enhanced oil recovery techniques, helping to improve the efficiency of oil extraction from mature fields. As global energy demand continues to rise, the market for advanced emulsion technologies in oil recovery is expected to expand.

Environmental concerns and regulatory pressures are driving innovation in emulsion technology, with a focus on developing more sustainable and biodegradable formulations. This trend is creating new opportunities for heptane-based emulsions that offer improved environmental profiles compared to traditional petroleum-derived emulsifiers.

The Asia-Pacific region is emerging as a key growth market for emulsion applications, driven by rapid industrialization, increasing disposable incomes, and growing consumer awareness of advanced personal care and pharmaceutical products. North America and Europe remain significant markets, with a strong focus on research and development of novel emulsion technologies.

Overall, the market for heptane in water/oil emulsions is characterized by ongoing technological advancements, expanding application areas, and a shift towards more sustainable solutions. As industries continue to recognize the versatility and potential of emulsion technology, the demand for innovative formulations and improved understanding of phase partitioning behavior is expected to drive further market growth and research investment in this field.

In the pharmaceutical sector, emulsions play a crucial role in drug delivery systems, enhancing the bioavailability of poorly water-soluble drugs. The market for pharmaceutical emulsions is expected to expand due to the rising prevalence of chronic diseases and the need for more effective drug formulations. Heptane-based emulsions are being explored for their potential in creating stable, long-lasting drug delivery vehicles.

The cosmetics industry has also embraced emulsion technology, with a growing focus on natural and organic products. Water-in-oil emulsions containing heptane are utilized in various skincare and haircare products, offering improved texture and stability. The global natural cosmetics market, which heavily relies on emulsion technology, is projected to experience substantial growth in the coming years.

In the food and beverage sector, emulsions are widely used as stabilizers, texture modifiers, and flavor carriers. The demand for clean-label and natural ingredients has led to increased research into heptane-based emulsions as potential alternatives to synthetic emulsifiers. This trend is particularly evident in the functional food and nutraceutical segments, where emulsion stability and bioavailability are critical factors.

The petrochemical industry represents another significant market for heptane in water/oil emulsions. These emulsions are employed in enhanced oil recovery techniques, helping to improve the efficiency of oil extraction from mature fields. As global energy demand continues to rise, the market for advanced emulsion technologies in oil recovery is expected to expand.

Environmental concerns and regulatory pressures are driving innovation in emulsion technology, with a focus on developing more sustainable and biodegradable formulations. This trend is creating new opportunities for heptane-based emulsions that offer improved environmental profiles compared to traditional petroleum-derived emulsifiers.

The Asia-Pacific region is emerging as a key growth market for emulsion applications, driven by rapid industrialization, increasing disposable incomes, and growing consumer awareness of advanced personal care and pharmaceutical products. North America and Europe remain significant markets, with a strong focus on research and development of novel emulsion technologies.

Overall, the market for heptane in water/oil emulsions is characterized by ongoing technological advancements, expanding application areas, and a shift towards more sustainable solutions. As industries continue to recognize the versatility and potential of emulsion technology, the demand for innovative formulations and improved understanding of phase partitioning behavior is expected to drive further market growth and research investment in this field.

Current Challenges in Heptane Phase Partitioning

The phase partitioning of heptane in water/oil emulsions presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary difficulties lies in accurately predicting and controlling the distribution of heptane between the water and oil phases. This is particularly complex due to the dynamic nature of emulsions and the various factors influencing phase behavior.

A major challenge is the impact of temperature fluctuations on heptane partitioning. As temperature changes, the solubility and interfacial properties of heptane can shift dramatically, leading to unpredictable phase behavior. This temperature sensitivity makes it difficult to maintain stable emulsions in industrial processes where temperature control may be limited or costly.

Another significant hurdle is the influence of emulsion composition on heptane partitioning. The presence of other hydrocarbons, surfactants, and impurities can significantly alter the phase behavior of heptane. These compositional variations can lead to unexpected changes in emulsion stability and heptane distribution, complicating process design and control.

The formation of complex interfacial structures poses an additional challenge. Heptane molecules can interact with surfactants and other components at the oil-water interface, creating intricate molecular arrangements that are difficult to characterize and predict. These interfacial phenomena can have a profound impact on emulsion stability and heptane partitioning behavior.

Scale-up issues present yet another obstacle in heptane phase partitioning. Laboratory-scale experiments often fail to accurately represent the behavior of large-scale industrial systems. Factors such as mixing dynamics, heat transfer, and interfacial area-to-volume ratios can differ significantly between scales, leading to discrepancies in heptane partitioning behavior.

Furthermore, the development of accurate modeling and simulation tools for heptane partitioning remains a challenge. Current models often struggle to account for the complex interplay of factors affecting phase behavior, limiting their predictive capabilities. This gap in modeling accuracy hampers the ability to optimize processes and design new emulsion systems effectively.

Lastly, the environmental and health concerns associated with heptane usage add another layer of complexity to its phase partitioning challenges. Stricter regulations on volatile organic compounds (VOCs) and the push for more sustainable practices are driving the need for better containment and recovery methods for heptane in emulsion systems.

A major challenge is the impact of temperature fluctuations on heptane partitioning. As temperature changes, the solubility and interfacial properties of heptane can shift dramatically, leading to unpredictable phase behavior. This temperature sensitivity makes it difficult to maintain stable emulsions in industrial processes where temperature control may be limited or costly.

Another significant hurdle is the influence of emulsion composition on heptane partitioning. The presence of other hydrocarbons, surfactants, and impurities can significantly alter the phase behavior of heptane. These compositional variations can lead to unexpected changes in emulsion stability and heptane distribution, complicating process design and control.

The formation of complex interfacial structures poses an additional challenge. Heptane molecules can interact with surfactants and other components at the oil-water interface, creating intricate molecular arrangements that are difficult to characterize and predict. These interfacial phenomena can have a profound impact on emulsion stability and heptane partitioning behavior.

Scale-up issues present yet another obstacle in heptane phase partitioning. Laboratory-scale experiments often fail to accurately represent the behavior of large-scale industrial systems. Factors such as mixing dynamics, heat transfer, and interfacial area-to-volume ratios can differ significantly between scales, leading to discrepancies in heptane partitioning behavior.

Furthermore, the development of accurate modeling and simulation tools for heptane partitioning remains a challenge. Current models often struggle to account for the complex interplay of factors affecting phase behavior, limiting their predictive capabilities. This gap in modeling accuracy hampers the ability to optimize processes and design new emulsion systems effectively.

Lastly, the environmental and health concerns associated with heptane usage add another layer of complexity to its phase partitioning challenges. Stricter regulations on volatile organic compounds (VOCs) and the push for more sustainable practices are driving the need for better containment and recovery methods for heptane in emulsion systems.

Existing Methodologies for Heptane Partitioning

01 Separation and purification techniques

Heptane phase partitioning is utilized in various separation and purification processes. This technique exploits the differences in solubility and polarity between compounds to achieve separation. It is particularly useful in extracting and isolating specific components from complex mixtures, such as in the purification of organic compounds or the removal of impurities from industrial products.- Separation and purification techniques: Heptane phase partitioning is utilized in various separation and purification processes. This technique exploits the differences in solubility and polarity between compounds to achieve separation. It is particularly useful in extracting and isolating specific components from complex mixtures, making it valuable in chemical and pharmaceutical industries.

- Analytical applications: Heptane phase partitioning finds applications in analytical chemistry for sample preparation and analysis. It can be used to concentrate analytes, remove interfering substances, or fractionate complex samples prior to further analysis. This method enhances the sensitivity and selectivity of various analytical techniques.

- Extraction of natural products: The technique is employed in the extraction of natural products from plant materials or other biological sources. Heptane, being a non-polar solvent, can effectively extract lipophilic compounds such as essential oils, fatty acids, and certain phytochemicals. This application is relevant in the production of pharmaceuticals, cosmetics, and food additives.

- Environmental remediation: Heptane phase partitioning can be used in environmental remediation processes, particularly for the removal of organic contaminants from soil or water. The method allows for the separation of pollutants based on their affinity for the heptane phase, facilitating their removal from the contaminated medium.

- Microfluidic applications: In microfluidic devices and systems, heptane phase partitioning can be utilized for various purposes such as droplet formation, emulsion stabilization, or creating biphasic flow systems. This application is relevant in fields like drug delivery, chemical synthesis, and analytical chemistry at microscale levels.

02 Analytical applications

Heptane phase partitioning finds applications in analytical chemistry for sample preparation and analysis. It can be used to concentrate analytes of interest, remove interfering substances, or as a pre-treatment step before chromatographic or spectroscopic analysis. This method enhances the sensitivity and accuracy of various analytical techniques, particularly in environmental and pharmaceutical analyses.Expand Specific Solutions03 Extraction of biomolecules

In biotechnology and biochemistry, heptane phase partitioning is employed for the extraction and purification of biomolecules. This technique can be used to isolate proteins, enzymes, or other biological compounds from cell lysates or fermentation broths. The method allows for gentle separation, helping to maintain the biological activity of sensitive molecules.Expand Specific Solutions04 Industrial applications

Heptane phase partitioning is utilized in various industrial processes, including petrochemical refining, polymer production, and pharmaceutical manufacturing. It can be used for the removal of contaminants, the separation of reaction products, or the extraction of valuable compounds from industrial waste streams. This technique offers advantages in terms of efficiency and scalability for large-scale industrial applications.Expand Specific Solutions05 Environmental remediation

Heptane phase partitioning plays a role in environmental remediation efforts, particularly in the treatment of contaminated soil and water. This technique can be used to extract and concentrate pollutants, facilitating their removal or further treatment. It is especially useful for the remediation of sites contaminated with hydrophobic organic compounds, such as oil spills or industrial solvents.Expand Specific Solutions

Key Industry Players in Emulsion Technology

The phase partitioning of heptane in water/oil emulsions represents a complex technological challenge in the oil and gas industry, currently in a mature development stage. The market for this technology is substantial, driven by the global demand for efficient oil-water separation processes. Companies like ExxonMobil, Chevron, and BP are at the forefront of research and development in this field, leveraging their extensive experience in petroleum engineering. BASF and Dow Chemical are also significant players, contributing their expertise in chemical formulations for emulsion stability. The technology's maturity is evident in the advanced solutions offered by these industry leaders, yet ongoing research continues to refine and optimize the process for improved efficiency and environmental sustainability.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed a sophisticated approach to managing heptane partitioning in water/oil emulsions, leveraging their expertise in materials science and chemical engineering. Their technology centers on the development of advanced copolymer surfactants that can precisely control interfacial properties between heptane and water phases[13]. Dow's research includes the use of responsive polymers that undergo conformational changes in response to external stimuli, allowing for dynamic control of emulsion stability[15]. The company has also pioneered the application of microencapsulation techniques to create "smart" emulsion droplets that can release or absorb heptane on demand[17]. This multifaceted approach enables fine-tuned control over phase behavior in complex emulsion systems, with applications ranging from enhanced oil recovery to specialty chemical manufacturing.

Strengths: Extensive polymer expertise, broad application range beyond oil and gas, and strong intellectual property portfolio. Weaknesses: Potentially higher production costs for specialized materials and need for customization for different industry applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant strides in addressing heptane partitioning in water/oil emulsions, particularly in the context of enhanced oil recovery and refinery operations. Their approach combines traditional chemical demulsification with novel acoustic-based separation techniques[8]. Sinopec has developed a series of tailored polymeric surfactants that can effectively stabilize or destabilize heptane-water interfaces depending on specific process requirements[10]. The company's research also extends to the use of magnetic nanoparticles for targeted emulsion manipulation, allowing for remote-controlled phase separation[12]. Sinopec's technology portfolio enables flexible management of emulsion properties across various stages of oil production and processing, from reservoir to refinery.

Strengths: Large-scale implementation capabilities, integration of novel physical separation methods, and adaptability to diverse oil field conditions. Weaknesses: Potential regulatory challenges for new technologies and need for extensive field testing.

Innovative Approaches in Emulsion Stability

Method for separating oil/water emulsions using at least bidentate complexing agents

PatentWO2009130196A1

Innovation

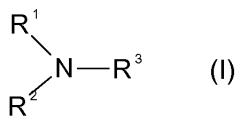

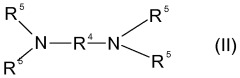

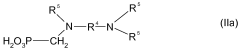

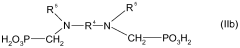

- A process using at least one emulsion breaker in combination with oil-soluble bidentate complexing agents, preferably containing phosphonic acid groups, to enhance the separation of oil-water emulsions by disrupting the oil-water interface and improving solubility in organic phases.

Processes for separation of oil/water emulsions

PatentWO2001074468A3

Innovation

- The process separates oil/water emulsions without using high temperatures or chemical demulsifiers.

- The method creates a water-continuous phase by adding excess water to the emulsion.

- The separation occurs through a simple settling process after creating the water-continuous phase.

Environmental Impact of Heptane Use

The use of heptane in water/oil emulsions raises significant environmental concerns due to its potential impact on ecosystems and human health. When released into the environment, heptane can contaminate soil, water, and air, leading to various ecological disruptions. In aquatic environments, heptane forms a thin film on the water surface, reducing oxygen transfer and affecting aquatic life. This can result in decreased biodiversity and altered ecosystem dynamics.

Heptane's volatility contributes to air pollution, as it readily evaporates and can react with other atmospheric compounds to form ground-level ozone and smog. These secondary pollutants can have detrimental effects on both human respiratory health and plant life. Additionally, the persistence of heptane in soil can lead to long-term contamination, affecting soil microorganisms and potentially entering the food chain through plant uptake.

The bioaccumulation potential of heptane in aquatic organisms is another critical concern. As it moves up the food chain, higher concentrations may be found in predatory species, potentially causing reproductive issues, developmental abnormalities, and other toxic effects. This bioaccumulation can also pose risks to human health through the consumption of contaminated fish and shellfish.

Accidental spills or improper disposal of heptane-containing emulsions can result in acute environmental damage. Such incidents may require extensive and costly cleanup efforts, often with long-lasting ecological consequences. The remediation of heptane-contaminated sites typically involves complex processes such as soil vapor extraction, bioremediation, or chemical oxidation, which can be both time-consuming and resource-intensive.

To mitigate these environmental risks, stringent regulations and best practices for heptane handling, storage, and disposal are essential. Industries using heptane in water/oil emulsions must implement robust containment measures, spill prevention protocols, and proper waste management systems. Furthermore, research into less environmentally harmful alternatives and the development of more efficient recovery and recycling technologies for heptane are crucial for reducing its overall environmental footprint.

As global environmental awareness increases, the continued use of heptane in industrial processes faces growing scrutiny. Regulatory bodies worldwide are implementing stricter guidelines for its use, emphasizing the need for more sustainable practices. This regulatory pressure, combined with potential reputational risks for companies, is driving innovation in greener alternatives and more environmentally friendly emulsion technologies.

Heptane's volatility contributes to air pollution, as it readily evaporates and can react with other atmospheric compounds to form ground-level ozone and smog. These secondary pollutants can have detrimental effects on both human respiratory health and plant life. Additionally, the persistence of heptane in soil can lead to long-term contamination, affecting soil microorganisms and potentially entering the food chain through plant uptake.

The bioaccumulation potential of heptane in aquatic organisms is another critical concern. As it moves up the food chain, higher concentrations may be found in predatory species, potentially causing reproductive issues, developmental abnormalities, and other toxic effects. This bioaccumulation can also pose risks to human health through the consumption of contaminated fish and shellfish.

Accidental spills or improper disposal of heptane-containing emulsions can result in acute environmental damage. Such incidents may require extensive and costly cleanup efforts, often with long-lasting ecological consequences. The remediation of heptane-contaminated sites typically involves complex processes such as soil vapor extraction, bioremediation, or chemical oxidation, which can be both time-consuming and resource-intensive.

To mitigate these environmental risks, stringent regulations and best practices for heptane handling, storage, and disposal are essential. Industries using heptane in water/oil emulsions must implement robust containment measures, spill prevention protocols, and proper waste management systems. Furthermore, research into less environmentally harmful alternatives and the development of more efficient recovery and recycling technologies for heptane are crucial for reducing its overall environmental footprint.

As global environmental awareness increases, the continued use of heptane in industrial processes faces growing scrutiny. Regulatory bodies worldwide are implementing stricter guidelines for its use, emphasizing the need for more sustainable practices. This regulatory pressure, combined with potential reputational risks for companies, is driving innovation in greener alternatives and more environmentally friendly emulsion technologies.

Regulatory Framework for Chemical Emulsions

The regulatory framework for chemical emulsions, particularly those involving heptane in water/oil systems, is complex and multifaceted. Governments and international bodies have established stringent guidelines to ensure the safe handling, transportation, and disposal of these substances. The United States Environmental Protection Agency (EPA) plays a crucial role in regulating chemical emulsions under the Toxic Substances Control Act (TSCA). This act requires manufacturers to report new chemical substances and provides the EPA with authority to require testing of chemicals that may pose environmental or health risks.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of chemical emulsions. REACH mandates that companies register chemical substances manufactured or imported in quantities of one tonne or more per year. For heptane-based emulsions, this often includes providing detailed safety data sheets and risk assessments.

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has been widely adopted to standardize hazard communication. Under GHS, heptane-containing emulsions are typically classified as flammable liquids and may carry additional hazard classifications based on their specific composition and properties.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, require employers to implement safety measures when handling chemical emulsions. This includes providing appropriate personal protective equipment, ensuring proper ventilation, and conducting regular safety training for employees.

Environmental regulations also play a significant role in the management of heptane-based emulsions. The Clean Water Act in the U.S. and similar legislation in other countries set limits on the discharge of oil and oil-like substances into water bodies. Companies must obtain permits and implement spill prevention and control measures to comply with these regulations.

Transportation of chemical emulsions is subject to strict regulations, including those set by the International Maritime Organization (IMO) for sea transport and the International Air Transport Association (IATA) for air transport. These regulations dictate packaging, labeling, and documentation requirements to ensure safe handling during transit.

As environmental concerns grow, many jurisdictions are implementing more stringent regulations on volatile organic compounds (VOCs), which may impact the use of heptane in certain applications. This has led to increased research into alternative, more environmentally friendly emulsion formulations.

Compliance with these diverse regulatory frameworks requires companies to maintain comprehensive documentation, conduct regular audits, and stay informed about evolving regulatory landscapes. Failure to adhere to these regulations can result in significant fines, legal liabilities, and reputational damage.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of chemical emulsions. REACH mandates that companies register chemical substances manufactured or imported in quantities of one tonne or more per year. For heptane-based emulsions, this often includes providing detailed safety data sheets and risk assessments.

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has been widely adopted to standardize hazard communication. Under GHS, heptane-containing emulsions are typically classified as flammable liquids and may carry additional hazard classifications based on their specific composition and properties.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, require employers to implement safety measures when handling chemical emulsions. This includes providing appropriate personal protective equipment, ensuring proper ventilation, and conducting regular safety training for employees.

Environmental regulations also play a significant role in the management of heptane-based emulsions. The Clean Water Act in the U.S. and similar legislation in other countries set limits on the discharge of oil and oil-like substances into water bodies. Companies must obtain permits and implement spill prevention and control measures to comply with these regulations.

Transportation of chemical emulsions is subject to strict regulations, including those set by the International Maritime Organization (IMO) for sea transport and the International Air Transport Association (IATA) for air transport. These regulations dictate packaging, labeling, and documentation requirements to ensure safe handling during transit.

As environmental concerns grow, many jurisdictions are implementing more stringent regulations on volatile organic compounds (VOCs), which may impact the use of heptane in certain applications. This has led to increased research into alternative, more environmentally friendly emulsion formulations.

Compliance with these diverse regulatory frameworks requires companies to maintain comprehensive documentation, conduct regular audits, and stay informed about evolving regulatory landscapes. Failure to adhere to these regulations can result in significant fines, legal liabilities, and reputational damage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!