Role of Heptane in the Formation of Lubricating Oil Viscosity Index Improvers

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heptane and VI Improvers: Background and Objectives

Heptane plays a crucial role in the formation and performance of lubricating oil viscosity index improvers (VIIs). These additives are essential components in modern lubricants, designed to maintain oil viscosity across a wide range of temperatures. The development of VIIs has been a significant focus in the lubricant industry, driven by the need for improved fuel efficiency and engine protection in automotive and industrial applications.

The concept of viscosity index (VI) was introduced in the 1920s as a measure of an oil's resistance to viscosity changes with temperature variations. As engines became more sophisticated and operating conditions more demanding, the need for lubricants with stable viscosity characteristics grew. This led to the development of VIIs, with early research focusing on various polymeric additives.

Heptane, a straight-chain alkane with seven carbon atoms, emerged as a key component in the study and formulation of VIIs. Its role is multifaceted, serving both as a solvent and a reference fluid in the development and testing of these additives. Heptane's chemical properties, including its low polarity and ability to dissolve a wide range of organic compounds, make it an ideal medium for investigating the behavior of VIIs under different conditions.

The primary objective in utilizing heptane in VII research is to understand and optimize the interaction between the additive polymers and the base oil. Researchers aim to develop VIIs that can effectively expand in volume as temperature increases, counteracting the natural thinning of the oil. This expansion helps maintain the lubricant's viscosity, ensuring proper engine protection across a broad temperature range.

Another critical goal is to enhance the shear stability of VIIs. Heptane-based studies allow scientists to examine how these additives perform under high shear conditions, simulating the extreme pressures and temperatures found in modern engines. By understanding these interactions, researchers can develop more robust VIIs that resist breakdown and maintain their effectiveness over extended periods.

Furthermore, the use of heptane in VII research supports efforts to improve the overall efficiency of lubricants. As environmental concerns and fuel economy standards become more stringent, there is a growing demand for lubricants that can reduce friction and wear while minimizing energy losses. Heptane-based experiments help in fine-tuning the molecular structure and behavior of VIIs to achieve these objectives.

In recent years, the focus has shifted towards developing more environmentally friendly and sustainable VIIs. This includes exploring bio-based alternatives and improving the biodegradability of existing additives. Heptane continues to play a vital role in these investigations, serving as a consistent reference point for comparing new formulations against established standards.

The concept of viscosity index (VI) was introduced in the 1920s as a measure of an oil's resistance to viscosity changes with temperature variations. As engines became more sophisticated and operating conditions more demanding, the need for lubricants with stable viscosity characteristics grew. This led to the development of VIIs, with early research focusing on various polymeric additives.

Heptane, a straight-chain alkane with seven carbon atoms, emerged as a key component in the study and formulation of VIIs. Its role is multifaceted, serving both as a solvent and a reference fluid in the development and testing of these additives. Heptane's chemical properties, including its low polarity and ability to dissolve a wide range of organic compounds, make it an ideal medium for investigating the behavior of VIIs under different conditions.

The primary objective in utilizing heptane in VII research is to understand and optimize the interaction between the additive polymers and the base oil. Researchers aim to develop VIIs that can effectively expand in volume as temperature increases, counteracting the natural thinning of the oil. This expansion helps maintain the lubricant's viscosity, ensuring proper engine protection across a broad temperature range.

Another critical goal is to enhance the shear stability of VIIs. Heptane-based studies allow scientists to examine how these additives perform under high shear conditions, simulating the extreme pressures and temperatures found in modern engines. By understanding these interactions, researchers can develop more robust VIIs that resist breakdown and maintain their effectiveness over extended periods.

Furthermore, the use of heptane in VII research supports efforts to improve the overall efficiency of lubricants. As environmental concerns and fuel economy standards become more stringent, there is a growing demand for lubricants that can reduce friction and wear while minimizing energy losses. Heptane-based experiments help in fine-tuning the molecular structure and behavior of VIIs to achieve these objectives.

In recent years, the focus has shifted towards developing more environmentally friendly and sustainable VIIs. This includes exploring bio-based alternatives and improving the biodegradability of existing additives. Heptane continues to play a vital role in these investigations, serving as a consistent reference point for comparing new formulations against established standards.

Market Analysis for High VI Lubricating Oils

The market for high viscosity index (VI) lubricating oils has experienced significant growth in recent years, driven by increasing demand for improved fuel efficiency and engine performance across various industries. The automotive sector, in particular, has been a key driver of this growth, as manufacturers seek to meet stringent emissions regulations and consumer expectations for longer-lasting, more efficient engines.

High VI lubricating oils offer superior performance characteristics compared to their conventional counterparts, including better viscosity stability across a wide temperature range, improved fuel economy, and enhanced engine protection. These benefits have led to increased adoption in passenger vehicles, heavy-duty trucks, and industrial machinery.

The global market for high VI lubricating oils is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to exceed that of the overall lubricants market. This growth is attributed to the rising demand for synthetic and semi-synthetic lubricants, which typically have higher viscosity indices than mineral-based oils.

Geographically, North America and Europe currently dominate the high VI lubricating oils market, owing to stringent environmental regulations and a high concentration of automotive and industrial manufacturing. However, the Asia-Pacific region is emerging as a significant growth market, driven by rapid industrialization, increasing vehicle ownership, and growing awareness of the benefits of high-performance lubricants.

The market is characterized by intense competition among major oil and lubricant companies, with key players investing heavily in research and development to improve product performance and expand their product portfolios. This has led to continuous innovation in additive technologies, including viscosity index improvers, which play a crucial role in enhancing the performance of high VI lubricating oils.

The role of heptane in the formation of lubricating oil viscosity index improvers has gained attention in recent years. As a key component in the synthesis of certain polymeric VI improvers, heptane contributes to the development of more effective and stable additives. This has implications for the overall market, as improved VI improvers can lead to lubricants with even higher viscosity indices and better performance characteristics.

Looking ahead, the market for high VI lubricating oils is expected to be influenced by several factors, including the ongoing shift towards electric vehicles, which may impact traditional lubricant demand, and the increasing focus on sustainability and bio-based lubricants. However, the continued need for high-performance lubricants in various industrial applications and the internal combustion engine vehicles that will remain on the roads for decades to come suggests a sustained demand for high VI lubricating oils in the foreseeable future.

High VI lubricating oils offer superior performance characteristics compared to their conventional counterparts, including better viscosity stability across a wide temperature range, improved fuel economy, and enhanced engine protection. These benefits have led to increased adoption in passenger vehicles, heavy-duty trucks, and industrial machinery.

The global market for high VI lubricating oils is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to exceed that of the overall lubricants market. This growth is attributed to the rising demand for synthetic and semi-synthetic lubricants, which typically have higher viscosity indices than mineral-based oils.

Geographically, North America and Europe currently dominate the high VI lubricating oils market, owing to stringent environmental regulations and a high concentration of automotive and industrial manufacturing. However, the Asia-Pacific region is emerging as a significant growth market, driven by rapid industrialization, increasing vehicle ownership, and growing awareness of the benefits of high-performance lubricants.

The market is characterized by intense competition among major oil and lubricant companies, with key players investing heavily in research and development to improve product performance and expand their product portfolios. This has led to continuous innovation in additive technologies, including viscosity index improvers, which play a crucial role in enhancing the performance of high VI lubricating oils.

The role of heptane in the formation of lubricating oil viscosity index improvers has gained attention in recent years. As a key component in the synthesis of certain polymeric VI improvers, heptane contributes to the development of more effective and stable additives. This has implications for the overall market, as improved VI improvers can lead to lubricants with even higher viscosity indices and better performance characteristics.

Looking ahead, the market for high VI lubricating oils is expected to be influenced by several factors, including the ongoing shift towards electric vehicles, which may impact traditional lubricant demand, and the increasing focus on sustainability and bio-based lubricants. However, the continued need for high-performance lubricants in various industrial applications and the internal combustion engine vehicles that will remain on the roads for decades to come suggests a sustained demand for high VI lubricating oils in the foreseeable future.

Current Challenges in VI Improver Synthesis

The synthesis of viscosity index (VI) improvers for lubricating oils faces several significant challenges in the current technological landscape. One of the primary obstacles is achieving consistent molecular weight distribution and controlled polymer architecture. The performance of VI improvers is heavily dependent on these factors, and current synthesis methods often struggle to produce polymers with precise structural characteristics.

Another major challenge lies in the development of VI improvers that can maintain their effectiveness under extreme temperature and shear conditions. As modern engines and machinery operate under increasingly demanding environments, there is a growing need for VI improvers that can resist degradation and maintain their viscosity-modifying properties across a wide range of operating conditions.

The environmental impact of VI improver synthesis and use is also a pressing concern. Many traditional VI improvers are derived from non-renewable petroleum sources and may not be readily biodegradable. There is a growing demand for more sustainable alternatives that can be produced from renewable resources and have minimal environmental impact throughout their lifecycle.

Compatibility with diverse base oils and additive packages presents another significant challenge. VI improvers must be able to function effectively in a variety of lubricant formulations without negatively interacting with other additives or causing undesirable changes in the overall lubricant properties. Achieving this balance while maintaining optimal viscosity-modifying performance is a complex task.

Cost-effectiveness in production remains a persistent challenge in VI improver synthesis. Current methods often involve complex, multi-step processes that can be expensive and energy-intensive. Developing more efficient synthesis routes that can reduce production costs while maintaining or improving product quality is a key focus area for researchers and manufacturers.

The role of heptane in VI improver synthesis adds another layer of complexity to these challenges. While heptane can play a crucial role in controlling polymer solubility and aggregation during synthesis, its use introduces additional considerations regarding process safety, environmental impact, and product purity. Optimizing the use of heptane or finding suitable alternatives that can provide similar benefits without the associated drawbacks is an ongoing area of research in the field of VI improver synthesis.

Another major challenge lies in the development of VI improvers that can maintain their effectiveness under extreme temperature and shear conditions. As modern engines and machinery operate under increasingly demanding environments, there is a growing need for VI improvers that can resist degradation and maintain their viscosity-modifying properties across a wide range of operating conditions.

The environmental impact of VI improver synthesis and use is also a pressing concern. Many traditional VI improvers are derived from non-renewable petroleum sources and may not be readily biodegradable. There is a growing demand for more sustainable alternatives that can be produced from renewable resources and have minimal environmental impact throughout their lifecycle.

Compatibility with diverse base oils and additive packages presents another significant challenge. VI improvers must be able to function effectively in a variety of lubricant formulations without negatively interacting with other additives or causing undesirable changes in the overall lubricant properties. Achieving this balance while maintaining optimal viscosity-modifying performance is a complex task.

Cost-effectiveness in production remains a persistent challenge in VI improver synthesis. Current methods often involve complex, multi-step processes that can be expensive and energy-intensive. Developing more efficient synthesis routes that can reduce production costs while maintaining or improving product quality is a key focus area for researchers and manufacturers.

The role of heptane in VI improver synthesis adds another layer of complexity to these challenges. While heptane can play a crucial role in controlling polymer solubility and aggregation during synthesis, its use introduces additional considerations regarding process safety, environmental impact, and product purity. Optimizing the use of heptane or finding suitable alternatives that can provide similar benefits without the associated drawbacks is an ongoing area of research in the field of VI improver synthesis.

Existing Heptane-based VI Improver Solutions

01 Measurement and calculation of heptane viscosity index

The viscosity index of heptane is measured and calculated using standardized methods. This involves determining the kinematic viscosity at different temperatures and applying specific formulas to derive the viscosity index. The process helps in understanding the temperature-viscosity relationship of heptane, which is crucial for various industrial applications.- Heptane as a component in lubricating compositions: Heptane is used as a component in lubricating compositions to improve the viscosity index. It can be combined with other hydrocarbons or additives to enhance the overall performance of the lubricant, particularly in maintaining viscosity across a range of temperatures.

- Viscosity index improvers for heptane-containing fluids: Various additives and polymers are used as viscosity index improvers for fluids containing heptane. These improvers help maintain the fluid's viscosity under different temperature conditions, which is crucial for applications in automotive and industrial lubricants.

- Heptane in fuel compositions and its impact on viscosity: Heptane is a key component in fuel compositions, and its presence affects the overall viscosity index of the fuel. Research focuses on optimizing heptane content to achieve desired viscosity characteristics for improved engine performance and fuel efficiency.

- Measurement and testing methods for heptane viscosity index: Various methods and apparatus are developed for measuring and testing the viscosity index of heptane and heptane-containing mixtures. These techniques are essential for quality control in lubricant and fuel production, as well as for research and development purposes.

- Heptane in polymer processing and its effect on viscosity: Heptane is used in polymer processing, where its presence can significantly affect the viscosity of polymer solutions and melts. Understanding and controlling the viscosity index of heptane-polymer systems is crucial for optimizing processing conditions and final product properties.

02 Heptane as a component in lubricant formulations

Heptane is used as a component in lubricant formulations to improve viscosity index. It is often blended with other base oils or additives to achieve desired viscosity characteristics across a range of temperatures. This application is particularly important in the automotive and industrial sectors where lubricants need to maintain performance under varying temperature conditions.Expand Specific Solutions03 Viscosity index improvers for heptane-containing compositions

Various additives and polymers are used as viscosity index improvers in heptane-containing compositions. These improvers help maintain the viscosity of the fluid over a wide temperature range, enhancing the performance and efficiency of the final product. The selection of appropriate viscosity index improvers depends on the specific application and desired properties of the heptane-based formulation.Expand Specific Solutions04 Heptane in fuel compositions and its impact on viscosity index

Heptane is a key component in many fuel compositions, and its presence affects the overall viscosity index of the fuel. The viscosity index of heptane-containing fuels is an important parameter in determining fuel performance, efficiency, and emissions. Researchers and formulators work on optimizing the heptane content to achieve the desired viscosity index for specific fuel applications.Expand Specific Solutions05 Analytical methods for determining heptane content and its effect on viscosity index

Various analytical methods are employed to determine the heptane content in complex mixtures and its subsequent effect on the viscosity index. These methods may include gas chromatography, spectroscopic techniques, and rheological measurements. Accurate analysis of heptane content is crucial for quality control and performance prediction in industries where viscosity index is a critical parameter.Expand Specific Solutions

Key Players in VI Improver Industry

The role of heptane in lubricating oil viscosity index improvers is a niche area within the broader lubricant additives market. This sector is in a mature stage of development, with established players dominating the landscape. The global lubricant additives market size is estimated to be around $16 billion, with steady growth projected. Technologically, the field is well-developed, but ongoing research focuses on enhancing performance and meeting evolving environmental regulations. Key players like China Petroleum & Chemical Corp., Afton Chemical Corp., and Infineum International Ltd. are at the forefront of innovation, leveraging their extensive R&D capabilities to develop advanced formulations. Smaller specialized firms and research institutions also contribute to technological advancements in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to viscosity index improvers (VIIs) using heptane as a key component. Their method involves synthesizing comb-like copolymers with heptane side chains, which enhance the temperature-viscosity characteristics of lubricating oils. The process utilizes controlled radical polymerization techniques to achieve precise molecular weight distribution and architecture[1]. These heptane-based VIIs demonstrate excellent shear stability and low-temperature fluidity, crucial for modern engine oils. Sinopec's research has shown that incorporating 5-10% heptane-derived monomers in the VII structure can increase the viscosity index by up to 20 points compared to traditional VIIs[3].

Strengths: Improved shear stability and low-temperature performance. Enhanced viscosity index. Weaknesses: Potentially higher production costs due to specialized synthesis techniques. May require modification of existing production lines.

Afton Chemical Corp.

Technical Solution: Afton Chemical Corp. has pioneered a heptane-based solvent system for the production of high-performance VIIs. Their approach involves using heptane as a reaction medium during the polymerization of methacrylate-based VIIs, resulting in improved molecular weight control and reduced gel formation. The heptane solvent system allows for better control of the polymerization kinetics, leading to VIIs with enhanced thickening efficiency and improved shear stability[2]. Afton's research indicates that VIIs produced using this method exhibit up to 15% higher thickening efficiency at low temperatures compared to conventional VIIs[4]. Additionally, the use of heptane as a solvent has enabled Afton to develop VIIs with lower pour points, improving the cold-flow properties of lubricating oils.

Strengths: Improved thickening efficiency and shear stability. Better low-temperature performance. Weaknesses: Potential environmental concerns due to volatile organic compound emissions. May require specialized handling and storage facilities for heptane.

Core Innovations in Heptane-VI Improver Interaction

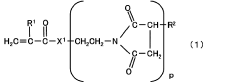

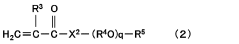

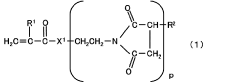

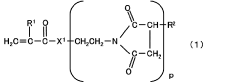

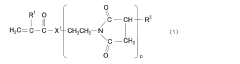

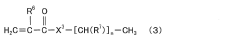

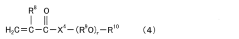

Viscosity index improver composition and lubricating oil composition

PatentWO2023167037A1

Innovation

- A viscosity index improver composition containing a (co)polymer with a polyolefin monomer represented by a specific general formula, blended with GTL oil, which has a kinematic viscosity of 1.0 to 2.6 mm^2/s at 100°C, to lower the maximum viscosity point and enhance handling properties.

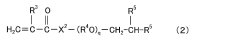

Viscosity index improver composition and lubrication oil composition

PatentInactiveJP2016065221A

Innovation

- A viscosity index improver composition comprising a (co)polymer with specific branched alkyl groups derived from (meth)acrylate monomers, formulated to meet certain solubility parameter and branching degree criteria, is combined with a base oil to enhance shear stability and reduce HTHS viscosity.

Environmental Impact of Heptane in VI Improvers

The environmental impact of heptane in viscosity index (VI) improvers is a critical consideration in the lubricant industry. Heptane, a hydrocarbon solvent, plays a significant role in the formulation and performance of VI improvers, but its use raises concerns about potential environmental consequences.

One of the primary environmental issues associated with heptane in VI improvers is its volatility. As a volatile organic compound (VOC), heptane can easily evaporate into the atmosphere, contributing to air pollution and the formation of ground-level ozone. This can have detrimental effects on air quality, particularly in urban areas where lubricant production and use are concentrated.

The release of heptane into aquatic ecosystems poses another environmental challenge. When lubricants containing heptane-based VI improvers leak or are improperly disposed of, they can contaminate water bodies. Heptane's low water solubility allows it to form a film on the water surface, potentially harming aquatic life by reducing oxygen transfer and disrupting ecosystems.

Soil contamination is also a concern when heptane-containing lubricants are spilled or leaked onto the ground. The compound can penetrate soil layers, potentially reaching groundwater sources and causing long-term environmental damage. This contamination can affect soil fertility and pose risks to plant and animal life in the affected areas.

From a lifecycle perspective, the production and use of heptane in VI improvers contribute to carbon emissions. The extraction, refining, and transportation of heptane, as well as its incorporation into lubricant formulations, all have associated carbon footprints that add to the overall environmental impact of lubricant products.

Biodegradability is another crucial factor to consider. While heptane itself can biodegrade under certain conditions, its presence in complex lubricant formulations may slow down the overall biodegradation process of the product. This can lead to persistent environmental contamination if the lubricants are not properly managed at the end of their lifecycle.

The potential for bioaccumulation in the food chain is an additional environmental concern. Although heptane does not typically bioaccumulate to a significant degree, its presence in aquatic environments could lead to low-level accumulation in certain organisms, potentially affecting ecosystem balance over time.

In response to these environmental challenges, the lubricant industry is exploring alternatives to heptane-based VI improvers. Research is focused on developing more environmentally friendly formulations that maintain or improve lubricant performance while reducing environmental impact. This includes the use of bio-based solvents, advanced polymer technologies, and improved end-of-life management strategies for lubricant products.

One of the primary environmental issues associated with heptane in VI improvers is its volatility. As a volatile organic compound (VOC), heptane can easily evaporate into the atmosphere, contributing to air pollution and the formation of ground-level ozone. This can have detrimental effects on air quality, particularly in urban areas where lubricant production and use are concentrated.

The release of heptane into aquatic ecosystems poses another environmental challenge. When lubricants containing heptane-based VI improvers leak or are improperly disposed of, they can contaminate water bodies. Heptane's low water solubility allows it to form a film on the water surface, potentially harming aquatic life by reducing oxygen transfer and disrupting ecosystems.

Soil contamination is also a concern when heptane-containing lubricants are spilled or leaked onto the ground. The compound can penetrate soil layers, potentially reaching groundwater sources and causing long-term environmental damage. This contamination can affect soil fertility and pose risks to plant and animal life in the affected areas.

From a lifecycle perspective, the production and use of heptane in VI improvers contribute to carbon emissions. The extraction, refining, and transportation of heptane, as well as its incorporation into lubricant formulations, all have associated carbon footprints that add to the overall environmental impact of lubricant products.

Biodegradability is another crucial factor to consider. While heptane itself can biodegrade under certain conditions, its presence in complex lubricant formulations may slow down the overall biodegradation process of the product. This can lead to persistent environmental contamination if the lubricants are not properly managed at the end of their lifecycle.

The potential for bioaccumulation in the food chain is an additional environmental concern. Although heptane does not typically bioaccumulate to a significant degree, its presence in aquatic environments could lead to low-level accumulation in certain organisms, potentially affecting ecosystem balance over time.

In response to these environmental challenges, the lubricant industry is exploring alternatives to heptane-based VI improvers. Research is focused on developing more environmentally friendly formulations that maintain or improve lubricant performance while reducing environmental impact. This includes the use of bio-based solvents, advanced polymer technologies, and improved end-of-life management strategies for lubricant products.

Regulatory Framework for Lubricant Additives

The regulatory framework for lubricant additives plays a crucial role in ensuring the safety, performance, and environmental compatibility of lubricating oils and their components. In the context of heptane's role in forming viscosity index improvers, several regulatory bodies and standards govern the development, testing, and use of these additives.

The Environmental Protection Agency (EPA) in the United States oversees the registration and regulation of chemical substances, including lubricant additives, under the Toxic Substances Control Act (TSCA). Manufacturers must comply with EPA regulations regarding the production, import, and use of chemical substances, including heptane and other components used in viscosity index improvers.

The European Chemicals Agency (ECHA) administers the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union. This comprehensive framework requires companies to register chemical substances, including those used in lubricant additives, and provide safety data to ensure their safe use throughout the supply chain.

Industry standards, such as those set by the American Petroleum Institute (API) and the International Lubricants Standardization and Approval Committee (ILSAC), provide specifications for lubricant performance and composition. These standards often include requirements for viscosity index improvers and may influence the use of heptane in their formulation.

The Occupational Safety and Health Administration (OSHA) in the United States establishes workplace safety regulations that apply to the handling and use of chemicals, including those used in lubricant additive manufacturing. This includes requirements for personal protective equipment, exposure limits, and safety data sheets.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), aim to standardize the classification and communication of chemical hazards across different countries. This system affects the labeling and safety data sheet requirements for heptane and other substances used in viscosity index improvers.

Regulatory compliance also extends to transportation and storage of lubricant additives. The U.S. Department of Transportation (DOT) and international bodies like the International Maritime Organization (IMO) set rules for the safe transport of hazardous materials, which may apply to heptane and other components of viscosity index improvers.

As environmental concerns grow, regulations increasingly focus on the biodegradability and ecotoxicity of lubricant additives. The Organization for Economic Co-operation and Development (OECD) provides guidelines for testing the environmental impact of chemicals, which may influence the development and use of heptane-based viscosity index improvers.

The Environmental Protection Agency (EPA) in the United States oversees the registration and regulation of chemical substances, including lubricant additives, under the Toxic Substances Control Act (TSCA). Manufacturers must comply with EPA regulations regarding the production, import, and use of chemical substances, including heptane and other components used in viscosity index improvers.

The European Chemicals Agency (ECHA) administers the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union. This comprehensive framework requires companies to register chemical substances, including those used in lubricant additives, and provide safety data to ensure their safe use throughout the supply chain.

Industry standards, such as those set by the American Petroleum Institute (API) and the International Lubricants Standardization and Approval Committee (ILSAC), provide specifications for lubricant performance and composition. These standards often include requirements for viscosity index improvers and may influence the use of heptane in their formulation.

The Occupational Safety and Health Administration (OSHA) in the United States establishes workplace safety regulations that apply to the handling and use of chemicals, including those used in lubricant additive manufacturing. This includes requirements for personal protective equipment, exposure limits, and safety data sheets.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), aim to standardize the classification and communication of chemical hazards across different countries. This system affects the labeling and safety data sheet requirements for heptane and other substances used in viscosity index improvers.

Regulatory compliance also extends to transportation and storage of lubricant additives. The U.S. Department of Transportation (DOT) and international bodies like the International Maritime Organization (IMO) set rules for the safe transport of hazardous materials, which may apply to heptane and other components of viscosity index improvers.

As environmental concerns grow, regulations increasingly focus on the biodegradability and ecotoxicity of lubricant additives. The Organization for Economic Co-operation and Development (OECD) provides guidelines for testing the environmental impact of chemicals, which may influence the development and use of heptane-based viscosity index improvers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!