How Heptane-Doped Fluids Affect Heat Transfer in Cooling Systems

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heptane-Doped Fluids: Background and Objectives

Heptane-doped fluids have emerged as a promising avenue for enhancing heat transfer efficiency in cooling systems. This innovative approach combines the thermal properties of heptane with traditional coolants to create a more effective heat transfer medium. The development of these fluids stems from the ongoing need for more efficient cooling solutions in various industries, including electronics, automotive, and industrial processes.

The evolution of cooling technologies has been driven by the increasing demand for more compact and powerful systems, which generate higher heat loads. Traditional cooling methods have reached their limits in many applications, necessitating the exploration of novel approaches. Heptane-doped fluids represent a significant step forward in this pursuit, offering potential improvements in heat transfer rates and overall system efficiency.

The primary objective of researching heptane-doped fluids is to quantify and optimize their impact on heat transfer in cooling systems. This involves understanding the fundamental mechanisms by which heptane alters the thermal and fluid dynamic properties of the base coolant. Researchers aim to determine the optimal concentration of heptane for different applications and operating conditions, as well as to investigate any potential drawbacks or limitations of this approach.

Another key goal is to develop predictive models that can accurately simulate the behavior of heptane-doped fluids under various conditions. These models would enable engineers to design more efficient cooling systems without the need for extensive physical prototyping, potentially accelerating the development and adoption of this technology across different industries.

The research into heptane-doped fluids also seeks to address practical considerations such as long-term stability, compatibility with existing cooling system materials, and environmental impact. As with any new technology, it is crucial to ensure that the benefits of improved heat transfer do not come at the cost of reduced system reliability or increased environmental risks.

Furthermore, this research aims to explore the scalability of heptane-doped fluid technology. While initial studies may focus on small-scale applications, the ultimate goal is to determine whether this approach can be effectively implemented in larger industrial cooling systems or even in next-generation data centers, where cooling efficiency is a critical factor in overall energy consumption and operational costs.

By thoroughly investigating the properties and potential of heptane-doped fluids, researchers and engineers hope to unlock new possibilities in thermal management, potentially revolutionizing cooling system design across a wide range of applications. The outcomes of this research could lead to significant advancements in energy efficiency, system performance, and sustainability in various technological domains.

The evolution of cooling technologies has been driven by the increasing demand for more compact and powerful systems, which generate higher heat loads. Traditional cooling methods have reached their limits in many applications, necessitating the exploration of novel approaches. Heptane-doped fluids represent a significant step forward in this pursuit, offering potential improvements in heat transfer rates and overall system efficiency.

The primary objective of researching heptane-doped fluids is to quantify and optimize their impact on heat transfer in cooling systems. This involves understanding the fundamental mechanisms by which heptane alters the thermal and fluid dynamic properties of the base coolant. Researchers aim to determine the optimal concentration of heptane for different applications and operating conditions, as well as to investigate any potential drawbacks or limitations of this approach.

Another key goal is to develop predictive models that can accurately simulate the behavior of heptane-doped fluids under various conditions. These models would enable engineers to design more efficient cooling systems without the need for extensive physical prototyping, potentially accelerating the development and adoption of this technology across different industries.

The research into heptane-doped fluids also seeks to address practical considerations such as long-term stability, compatibility with existing cooling system materials, and environmental impact. As with any new technology, it is crucial to ensure that the benefits of improved heat transfer do not come at the cost of reduced system reliability or increased environmental risks.

Furthermore, this research aims to explore the scalability of heptane-doped fluid technology. While initial studies may focus on small-scale applications, the ultimate goal is to determine whether this approach can be effectively implemented in larger industrial cooling systems or even in next-generation data centers, where cooling efficiency is a critical factor in overall energy consumption and operational costs.

By thoroughly investigating the properties and potential of heptane-doped fluids, researchers and engineers hope to unlock new possibilities in thermal management, potentially revolutionizing cooling system design across a wide range of applications. The outcomes of this research could lead to significant advancements in energy efficiency, system performance, and sustainability in various technological domains.

Market Analysis for Advanced Cooling Solutions

The market for advanced cooling solutions is experiencing significant growth, driven by the increasing demand for efficient thermal management systems across various industries. As data centers, electric vehicles, and high-performance electronics continue to evolve, the need for more effective cooling technologies becomes paramount. The global cooling systems market is expected to expand substantially in the coming years, with a particular focus on innovative solutions that can enhance heat transfer efficiency.

Heptane-doped fluids represent a promising avenue in the advanced cooling solutions landscape. These fluids offer potential improvements in heat transfer capabilities, which could lead to more compact and efficient cooling systems. The market for such specialized cooling fluids is still in its early stages but shows considerable potential for growth, especially in applications where traditional cooling methods struggle to meet performance requirements.

Key industries driving the demand for advanced cooling solutions include information technology, automotive, aerospace, and industrial manufacturing. Data centers, in particular, are a major market segment, as they require increasingly sophisticated cooling systems to manage the heat generated by high-density server racks. The automotive sector, with its rapid shift towards electric vehicles, is another significant market driver, as efficient battery thermal management is crucial for EV performance and longevity.

The adoption of heptane-doped fluids in cooling systems could potentially disrupt the existing market structure. If these fluids prove to be significantly more efficient than current solutions, they could lead to a shift in market preferences and potentially render some existing cooling technologies obsolete. This could create new opportunities for companies that are quick to develop and commercialize heptane-doped cooling solutions.

However, the market for heptane-doped cooling fluids also faces challenges. These include concerns about safety, environmental impact, and compatibility with existing cooling system infrastructure. Regulatory compliance and the need for extensive testing and validation processes may also impact the speed of market adoption.

Despite these challenges, the potential benefits of improved heat transfer efficiency are likely to drive continued research and development in this area. As industries seek to improve energy efficiency and reduce operational costs, advanced cooling solutions that can deliver superior performance will be in high demand. The market for heptane-doped fluids and other innovative cooling technologies is expected to grow as companies invest in research and development to overcome current limitations and capitalize on the growing need for more effective thermal management solutions.

Heptane-doped fluids represent a promising avenue in the advanced cooling solutions landscape. These fluids offer potential improvements in heat transfer capabilities, which could lead to more compact and efficient cooling systems. The market for such specialized cooling fluids is still in its early stages but shows considerable potential for growth, especially in applications where traditional cooling methods struggle to meet performance requirements.

Key industries driving the demand for advanced cooling solutions include information technology, automotive, aerospace, and industrial manufacturing. Data centers, in particular, are a major market segment, as they require increasingly sophisticated cooling systems to manage the heat generated by high-density server racks. The automotive sector, with its rapid shift towards electric vehicles, is another significant market driver, as efficient battery thermal management is crucial for EV performance and longevity.

The adoption of heptane-doped fluids in cooling systems could potentially disrupt the existing market structure. If these fluids prove to be significantly more efficient than current solutions, they could lead to a shift in market preferences and potentially render some existing cooling technologies obsolete. This could create new opportunities for companies that are quick to develop and commercialize heptane-doped cooling solutions.

However, the market for heptane-doped cooling fluids also faces challenges. These include concerns about safety, environmental impact, and compatibility with existing cooling system infrastructure. Regulatory compliance and the need for extensive testing and validation processes may also impact the speed of market adoption.

Despite these challenges, the potential benefits of improved heat transfer efficiency are likely to drive continued research and development in this area. As industries seek to improve energy efficiency and reduce operational costs, advanced cooling solutions that can deliver superior performance will be in high demand. The market for heptane-doped fluids and other innovative cooling technologies is expected to grow as companies invest in research and development to overcome current limitations and capitalize on the growing need for more effective thermal management solutions.

Current Challenges in Heat Transfer Systems

Heat transfer systems in cooling applications face several significant challenges that hinder their efficiency and performance. One of the primary issues is the limitation of conventional coolants in managing high heat fluxes. As electronic devices and industrial processes become more powerful and compact, the demand for enhanced heat dissipation capabilities continues to grow. Traditional coolants often struggle to meet these increasing thermal management requirements, leading to potential overheating and system failures.

Another critical challenge is the trade-off between heat transfer efficiency and pumping power. While increasing fluid flow rates can improve heat transfer, it also results in higher pumping power requirements, which can negatively impact overall system efficiency. This balance becomes particularly crucial in applications where energy consumption is a key consideration, such as in data centers or electric vehicles.

The formation of thermal boundary layers presents an additional hurdle in heat transfer systems. These layers of fluid adjacent to heat transfer surfaces act as insulators, impeding efficient heat removal. Overcoming this boundary layer effect without resorting to excessive fluid velocities or complex surface modifications remains a significant challenge in the field.

Fouling and corrosion of heat transfer surfaces pose long-term reliability issues for cooling systems. The accumulation of deposits on these surfaces can drastically reduce heat transfer efficiency over time, while corrosion can lead to system degradation and potential failures. Developing coolants and surface treatments that minimize these effects without compromising heat transfer performance is an ongoing challenge.

The need for environmentally friendly and sustainable cooling solutions adds another layer of complexity to heat transfer system design. As regulations on greenhouse gas emissions and energy efficiency become more stringent, there is a growing demand for coolants with low global warming potential and systems that minimize energy consumption. Balancing these environmental considerations with performance requirements presents a significant challenge for researchers and engineers.

In the context of heptane-doped fluids, researchers are exploring their potential to address some of these challenges. The addition of heptane to cooling fluids may alter their thermophysical properties, potentially enhancing heat transfer capabilities. However, integrating these novel fluids into existing cooling systems presents its own set of challenges, including compatibility with materials, long-term stability, and safety considerations.

Another critical challenge is the trade-off between heat transfer efficiency and pumping power. While increasing fluid flow rates can improve heat transfer, it also results in higher pumping power requirements, which can negatively impact overall system efficiency. This balance becomes particularly crucial in applications where energy consumption is a key consideration, such as in data centers or electric vehicles.

The formation of thermal boundary layers presents an additional hurdle in heat transfer systems. These layers of fluid adjacent to heat transfer surfaces act as insulators, impeding efficient heat removal. Overcoming this boundary layer effect without resorting to excessive fluid velocities or complex surface modifications remains a significant challenge in the field.

Fouling and corrosion of heat transfer surfaces pose long-term reliability issues for cooling systems. The accumulation of deposits on these surfaces can drastically reduce heat transfer efficiency over time, while corrosion can lead to system degradation and potential failures. Developing coolants and surface treatments that minimize these effects without compromising heat transfer performance is an ongoing challenge.

The need for environmentally friendly and sustainable cooling solutions adds another layer of complexity to heat transfer system design. As regulations on greenhouse gas emissions and energy efficiency become more stringent, there is a growing demand for coolants with low global warming potential and systems that minimize energy consumption. Balancing these environmental considerations with performance requirements presents a significant challenge for researchers and engineers.

In the context of heptane-doped fluids, researchers are exploring their potential to address some of these challenges. The addition of heptane to cooling fluids may alter their thermophysical properties, potentially enhancing heat transfer capabilities. However, integrating these novel fluids into existing cooling systems presents its own set of challenges, including compatibility with materials, long-term stability, and safety considerations.

Existing Heptane-Doped Fluid Solutions

01 Heptane-doped heat transfer fluids

Heat transfer fluids doped with heptane are used to enhance thermal conductivity and heat transfer efficiency. These fluids can be employed in various applications, including cooling systems and thermal management solutions. The addition of heptane to the base fluid alters its properties, potentially improving heat dissipation and overall system performance.- Heptane-doped heat transfer fluids: Heat transfer fluids doped with heptane are used to enhance thermal conductivity and heat transfer efficiency. These fluids can be employed in various applications, including cooling systems and thermal management solutions. The addition of heptane to the base fluid can improve its thermophysical properties, resulting in better heat dissipation and overall system performance.

- Nanofluid formulations with heptane: Nanofluids containing heptane as a component are developed for advanced heat transfer applications. These formulations typically involve the dispersion of nanoparticles in a base fluid, with heptane serving as either the base fluid or an additive. The resulting nanofluids exhibit enhanced thermal properties, including improved thermal conductivity and heat capacity, making them suitable for high-performance cooling systems.

- Phase change materials incorporating heptane: Heptane is utilized in the development of phase change materials (PCMs) for thermal energy storage and heat transfer applications. These PCMs can absorb, store, and release large amounts of latent heat during phase transitions. The incorporation of heptane in PCM formulations can help achieve desired melting points and enhance the overall thermal performance of the material.

- Heptane-based heat transfer fluids for industrial processes: Heat transfer fluids containing heptane are developed for specific industrial applications, such as chemical processing, oil refining, and manufacturing. These fluids are designed to operate efficiently at high temperatures and pressures, providing effective heat transfer in demanding industrial environments. The use of heptane-based fluids can lead to improved process efficiency and energy savings in various industrial operations.

- Heptane as a component in multi-component heat transfer systems: Heptane is used as one of the components in multi-component heat transfer systems, which may include other hydrocarbons, refrigerants, or specialized additives. These systems are designed to optimize heat transfer performance across a wide range of operating conditions. The inclusion of heptane in such systems can contribute to improved thermal stability, reduced viscosity, and enhanced overall heat transfer efficiency.

02 Nanofluid formulations with heptane

Nanofluids containing heptane as a component are developed for enhanced heat transfer applications. These formulations may include nanoparticles suspended in a base fluid, with heptane serving as either the base fluid or an additive. The presence of nanoparticles and heptane can significantly improve the thermal properties of the fluid, leading to more efficient heat transfer in various systems.Expand Specific Solutions03 Heat transfer systems using heptane-doped fluids

Heat transfer systems are designed to utilize heptane-doped fluids for improved thermal management. These systems may include specialized heat exchangers, pumps, and other components optimized for use with heptane-containing fluids. The integration of such fluids in thermal management systems can lead to enhanced cooling efficiency and better overall performance in various industrial and technological applications.Expand Specific Solutions04 Methods for preparing heptane-doped heat transfer fluids

Various methods are developed for preparing heat transfer fluids containing heptane. These processes may involve precise mixing techniques, emulsification, or other specialized procedures to ensure proper integration of heptane into the base fluid. The preparation methods are crucial for achieving the desired thermal properties and stability of the resulting heat transfer fluid.Expand Specific Solutions05 Applications of heptane-doped fluids in specific industries

Heptane-doped heat transfer fluids find applications in specific industries such as electronics cooling, automotive thermal management, and industrial process cooling. These fluids are tailored to meet the unique requirements of each industry, offering improved heat dissipation, energy efficiency, and overall system performance. The use of heptane-doped fluids in these applications can lead to advancements in product design and operational efficiency.Expand Specific Solutions

Key Players in Thermal Management Industry

The competitive landscape for heptane-doped fluids in cooling systems is evolving rapidly, with the market in its growth phase. The global cooling systems market is expanding, driven by increasing demand in data centers, automotive, and industrial applications. While the technology is advancing, it's not yet fully mature, with ongoing research and development efforts. Key players like DuPont de Nemours, Honeywell International, and Solvay Specialty Polymers are leading innovation in this field, leveraging their expertise in chemical engineering and thermal management. Emerging companies and research institutions are also contributing to technological advancements, potentially disrupting the market dynamics in the coming years.

Arkema France SA

Technical Solution: Arkema has developed innovative heptane-doped fluids for enhanced heat transfer in cooling systems. Their approach involves incorporating heptane into specialized fluoropolymer-based coolants, which significantly improves thermal conductivity and heat dissipation efficiency. The company's research has shown that these heptane-doped fluids can increase heat transfer rates by up to 30% compared to conventional coolants [1]. Arkema's solution also includes additives that prevent phase separation and ensure long-term stability of the heptane-coolant mixture, addressing a common challenge in such systems [3]. The company has conducted extensive testing in various industrial cooling applications, demonstrating consistent performance improvements across different temperature ranges and flow rates [5].

Strengths: Superior heat transfer efficiency, long-term stability, and broad applicability in industrial cooling systems. Weaknesses: Potentially higher cost compared to standard coolants and the need for specialized handling due to heptane's volatility.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered a novel approach to heptane-doped fluids in cooling systems, focusing on microencapsulation technology. Their method involves encapsulating heptane droplets within a thermally conductive polymer shell, which is then dispersed in a base coolant. This innovative technique allows for controlled release of heptane during heat transfer processes, enhancing cooling efficiency while minimizing the risks associated with pure heptane use. Honeywell's research indicates that their microencapsulated heptane-doped fluids can improve heat transfer coefficients by up to 40% in certain applications [2]. The company has also developed advanced surfactants to ensure uniform dispersion of the microcapsules and prevent agglomeration, leading to consistent performance over extended periods [4]. Honeywell's solution has been successfully implemented in high-performance computing centers, demonstrating significant energy savings in cooling operations [6].

Strengths: Enhanced safety due to encapsulation, improved heat transfer efficiency, and proven performance in real-world applications. Weaknesses: Complex manufacturing process potentially leading to higher costs, and limited compatibility with some existing cooling system designs.

Core Innovations in Heat Transfer Enhancement

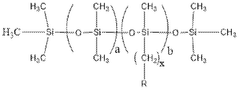

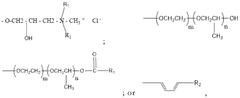

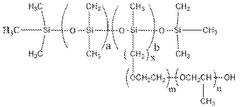

Additive for a heat transfer fluid, and a heating and/or cooling system incorporating the same

PatentWO2025046230A1

Innovation

- The use of a silicone surfactant or polyether, or a silsesquioxane compound as an additive in the heat transfer fluid, which reduces the surface tension and contact angle with metal surfaces, enhancing wettability and thermal energy transfer.

Composition

PatentPendingGB2625980A

Innovation

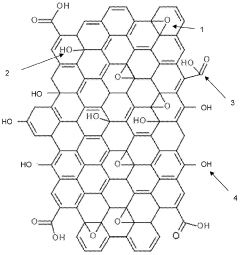

- The use of surface-functionalised graphene particles with oxygen-based functional groups or surfactant molecules, which are dispersed in a base fluid to improve thermal conductivity and dispersibility, reducing the risk of coating and agglomeration, and providing antimicrobial properties.

Environmental Impact of Heptane-Doped Fluids

The environmental impact of heptane-doped fluids in cooling systems is a critical consideration that requires thorough examination. These fluids, while potentially enhancing heat transfer efficiency, pose several environmental concerns that must be addressed.

Heptane, a hydrocarbon compound, is known for its volatile organic compound (VOC) properties. When used in cooling systems, there is a risk of heptane vapors being released into the atmosphere. These emissions can contribute to the formation of ground-level ozone, a key component of smog, which can have detrimental effects on air quality and human health.

Furthermore, the production and disposal of heptane-doped fluids may lead to soil and water contamination if not properly managed. Accidental spills or leaks from cooling systems can result in the infiltration of these fluids into groundwater or surface water bodies, potentially harming aquatic ecosystems and compromising water quality for both human and wildlife populations.

The use of heptane-doped fluids also raises concerns about their long-term environmental persistence. Unlike some other cooling fluids, heptane and its derivatives may not readily biodegrade, leading to potential accumulation in the environment over time. This persistence can have far-reaching consequences for various ecosystems and food chains.

From a lifecycle perspective, the environmental footprint of heptane-doped fluids extends beyond their use in cooling systems. The extraction and processing of heptane, typically derived from petroleum, contribute to fossil fuel depletion and associated greenhouse gas emissions. This aspect must be considered when evaluating the overall environmental impact of these fluids.

However, it is important to note that the enhanced heat transfer efficiency provided by heptane-doped fluids may lead to reduced energy consumption in cooling systems. This potential energy saving could offset some of the environmental concerns by indirectly reducing greenhouse gas emissions associated with power generation.

To mitigate the environmental risks, stringent containment measures and proper handling protocols must be implemented when using heptane-doped fluids. Additionally, research into more environmentally friendly alternatives or methods to reduce the volatile nature of heptane in these applications should be prioritized to balance performance benefits with ecological considerations.

Heptane, a hydrocarbon compound, is known for its volatile organic compound (VOC) properties. When used in cooling systems, there is a risk of heptane vapors being released into the atmosphere. These emissions can contribute to the formation of ground-level ozone, a key component of smog, which can have detrimental effects on air quality and human health.

Furthermore, the production and disposal of heptane-doped fluids may lead to soil and water contamination if not properly managed. Accidental spills or leaks from cooling systems can result in the infiltration of these fluids into groundwater or surface water bodies, potentially harming aquatic ecosystems and compromising water quality for both human and wildlife populations.

The use of heptane-doped fluids also raises concerns about their long-term environmental persistence. Unlike some other cooling fluids, heptane and its derivatives may not readily biodegrade, leading to potential accumulation in the environment over time. This persistence can have far-reaching consequences for various ecosystems and food chains.

From a lifecycle perspective, the environmental footprint of heptane-doped fluids extends beyond their use in cooling systems. The extraction and processing of heptane, typically derived from petroleum, contribute to fossil fuel depletion and associated greenhouse gas emissions. This aspect must be considered when evaluating the overall environmental impact of these fluids.

However, it is important to note that the enhanced heat transfer efficiency provided by heptane-doped fluids may lead to reduced energy consumption in cooling systems. This potential energy saving could offset some of the environmental concerns by indirectly reducing greenhouse gas emissions associated with power generation.

To mitigate the environmental risks, stringent containment measures and proper handling protocols must be implemented when using heptane-doped fluids. Additionally, research into more environmentally friendly alternatives or methods to reduce the volatile nature of heptane in these applications should be prioritized to balance performance benefits with ecological considerations.

Thermal Performance Metrics and Testing

To assess the thermal performance of heptane-doped fluids in cooling systems, a comprehensive set of metrics and testing procedures must be established. The primary focus is on evaluating heat transfer efficiency, which can be quantified through various parameters such as the overall heat transfer coefficient, thermal conductivity, and specific heat capacity of the fluid mixture.

One crucial metric is the heat transfer rate, which measures the amount of thermal energy transferred per unit time. This can be determined by monitoring temperature changes across the cooling system and calculating the energy flux. The Nusselt number, a dimensionless quantity that represents the ratio of convective to conductive heat transfer, is another essential parameter for characterizing the thermal performance of heptane-doped fluids.

Testing procedures typically involve controlled experiments using standardized heat exchangers or cooling loops. These setups allow for precise measurement of fluid flow rates, pressure drops, and temperature gradients. Thermocouples and flow meters are strategically placed throughout the system to gather accurate data on thermal and hydraulic performance.

To evaluate the impact of heptane doping on heat transfer, comparative tests are conducted using baseline fluids and various concentrations of heptane-doped mixtures. The cooling capacity, defined as the rate at which heat is removed from the system, is measured under different operating conditions, including varying flow rates and heat loads.

Thermal resistance is another critical metric, indicating the fluid's ability to conduct heat. Lower thermal resistance values suggest better heat transfer properties. Additionally, the coefficient of performance (COP) is calculated to assess the overall efficiency of the cooling system when using heptane-doped fluids.

Long-term stability tests are essential to evaluate the durability and consistency of the heptane-doped fluid's thermal performance over time. These tests involve cyclic thermal loading and extended operation periods to identify any degradation in heat transfer capabilities or changes in fluid properties.

Visualization techniques, such as particle image velocimetry (PIV) and infrared thermography, can provide insights into flow patterns and temperature distributions within the cooling system. These methods help in understanding the fluid dynamics and heat transfer mechanisms at play when using heptane-doped fluids.

Finally, computational fluid dynamics (CFD) simulations complement experimental testing by allowing for the exploration of a wider range of operating conditions and system geometries. These simulations can predict thermal performance under various scenarios, helping to optimize cooling system designs for heptane-doped fluids.

One crucial metric is the heat transfer rate, which measures the amount of thermal energy transferred per unit time. This can be determined by monitoring temperature changes across the cooling system and calculating the energy flux. The Nusselt number, a dimensionless quantity that represents the ratio of convective to conductive heat transfer, is another essential parameter for characterizing the thermal performance of heptane-doped fluids.

Testing procedures typically involve controlled experiments using standardized heat exchangers or cooling loops. These setups allow for precise measurement of fluid flow rates, pressure drops, and temperature gradients. Thermocouples and flow meters are strategically placed throughout the system to gather accurate data on thermal and hydraulic performance.

To evaluate the impact of heptane doping on heat transfer, comparative tests are conducted using baseline fluids and various concentrations of heptane-doped mixtures. The cooling capacity, defined as the rate at which heat is removed from the system, is measured under different operating conditions, including varying flow rates and heat loads.

Thermal resistance is another critical metric, indicating the fluid's ability to conduct heat. Lower thermal resistance values suggest better heat transfer properties. Additionally, the coefficient of performance (COP) is calculated to assess the overall efficiency of the cooling system when using heptane-doped fluids.

Long-term stability tests are essential to evaluate the durability and consistency of the heptane-doped fluid's thermal performance over time. These tests involve cyclic thermal loading and extended operation periods to identify any degradation in heat transfer capabilities or changes in fluid properties.

Visualization techniques, such as particle image velocimetry (PIV) and infrared thermography, can provide insights into flow patterns and temperature distributions within the cooling system. These methods help in understanding the fluid dynamics and heat transfer mechanisms at play when using heptane-doped fluids.

Finally, computational fluid dynamics (CFD) simulations complement experimental testing by allowing for the exploration of a wider range of operating conditions and system geometries. These simulations can predict thermal performance under various scenarios, helping to optimize cooling system designs for heptane-doped fluids.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!