Heptane's Role in Enhancements of Biodegradable Plastics Stability

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heptane and Biodegradable Plastics: Background and Objectives

Biodegradable plastics have emerged as a promising solution to address the global plastic pollution crisis. These materials, designed to decompose naturally in the environment, offer a sustainable alternative to conventional plastics. However, their widespread adoption has been hindered by challenges related to stability and durability. In recent years, researchers have turned their attention to heptane as a potential agent for enhancing the stability of biodegradable plastics.

The development of biodegradable plastics can be traced back to the 1980s when environmental concerns began to gain prominence. Since then, the field has witnessed significant advancements, with various materials and technologies being explored to create plastics that can break down into harmless substances. Despite these efforts, the inherent instability of many biodegradable plastics has remained a persistent issue, limiting their practical applications.

Heptane, a straight-chain alkane with seven carbon atoms, has traditionally been used as a solvent in various industrial processes. Its potential role in enhancing the stability of biodegradable plastics represents a novel application that could revolutionize the field. The exploration of heptane's capabilities in this context aligns with the broader trend of repurposing existing chemicals for innovative environmental solutions.

The primary objective of investigating heptane's role in enhancing biodegradable plastics stability is to address the key limitations that have impeded the widespread adoption of these materials. By improving stability, researchers aim to extend the shelf life and usability of biodegradable plastics, making them more viable alternatives to conventional plastics across a broader range of applications.

This research direction is driven by the urgent need to reduce plastic pollution while meeting the growing demand for sustainable materials. The potential of heptane to enhance stability could lead to biodegradable plastics that maintain their structural integrity during use but still decompose effectively at the end of their lifecycle. This balance is crucial for the practical implementation of biodegradable plastics in various industries, from packaging to consumer goods.

As we delve into this technological exploration, it is essential to consider the broader implications of enhancing biodegradable plastics stability. Success in this area could accelerate the transition away from petroleum-based plastics, contributing to reduced carbon emissions and environmental pollution. Moreover, it could open up new avenues for innovation in material science and sustainable product design.

The journey to harness heptane's potential in this field is part of a larger narrative of technological evolution in response to environmental challenges. It represents a convergence of chemistry, materials science, and environmental stewardship, highlighting the interdisciplinary nature of modern technological advancements.

The development of biodegradable plastics can be traced back to the 1980s when environmental concerns began to gain prominence. Since then, the field has witnessed significant advancements, with various materials and technologies being explored to create plastics that can break down into harmless substances. Despite these efforts, the inherent instability of many biodegradable plastics has remained a persistent issue, limiting their practical applications.

Heptane, a straight-chain alkane with seven carbon atoms, has traditionally been used as a solvent in various industrial processes. Its potential role in enhancing the stability of biodegradable plastics represents a novel application that could revolutionize the field. The exploration of heptane's capabilities in this context aligns with the broader trend of repurposing existing chemicals for innovative environmental solutions.

The primary objective of investigating heptane's role in enhancing biodegradable plastics stability is to address the key limitations that have impeded the widespread adoption of these materials. By improving stability, researchers aim to extend the shelf life and usability of biodegradable plastics, making them more viable alternatives to conventional plastics across a broader range of applications.

This research direction is driven by the urgent need to reduce plastic pollution while meeting the growing demand for sustainable materials. The potential of heptane to enhance stability could lead to biodegradable plastics that maintain their structural integrity during use but still decompose effectively at the end of their lifecycle. This balance is crucial for the practical implementation of biodegradable plastics in various industries, from packaging to consumer goods.

As we delve into this technological exploration, it is essential to consider the broader implications of enhancing biodegradable plastics stability. Success in this area could accelerate the transition away from petroleum-based plastics, contributing to reduced carbon emissions and environmental pollution. Moreover, it could open up new avenues for innovation in material science and sustainable product design.

The journey to harness heptane's potential in this field is part of a larger narrative of technological evolution in response to environmental challenges. It represents a convergence of chemistry, materials science, and environmental stewardship, highlighting the interdisciplinary nature of modern technological advancements.

Market Analysis for Stable Biodegradable Plastics

The market for stable biodegradable plastics has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. The global biodegradable plastics market was valued at $4.1 billion in 2020 and is projected to reach $7.8 billion by 2026, growing at a CAGR of 11.2% during the forecast period.

The demand for stable biodegradable plastics is particularly strong in packaging, consumer goods, and agriculture sectors. In the packaging industry, which accounts for the largest market share, there is a growing trend towards sustainable packaging solutions. Major food and beverage companies are increasingly adopting biodegradable plastics for their products to meet consumer preferences for eco-friendly alternatives.

The consumer goods sector is another key driver of market growth, with rising demand for biodegradable plastics in disposable cutlery, bags, and other single-use items. The agriculture sector is also showing increased interest in biodegradable mulch films and plant pots, contributing to market expansion.

Geographically, Europe leads the market for stable biodegradable plastics, followed by North America and Asia-Pacific. European countries have implemented stringent regulations on single-use plastics, fostering the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate due to increasing environmental awareness and government initiatives promoting sustainable materials.

However, the market faces challenges related to the higher cost of biodegradable plastics compared to conventional plastics. The price premium ranges from 20% to 100% depending on the type of biodegradable plastic and its application. This cost factor has been a significant barrier to widespread adoption, particularly in price-sensitive markets.

The stability of biodegradable plastics remains a critical concern for many potential users. While improvements have been made, there is still a need for biodegradable plastics that can maintain their structural integrity and functional properties over extended periods before degradation. This is where heptane's role in enhancing biodegradable plastics stability becomes crucial.

Market research indicates that consumers and businesses are willing to pay a premium for biodegradable plastics that offer improved stability without compromising on biodegradability. Industries such as electronics, automotive, and medical devices are showing increased interest in stable biodegradable plastics for components and packaging that require longer shelf life.

As research and development efforts continue to focus on enhancing the stability of biodegradable plastics, the market is expected to expand into new application areas. The successful integration of heptane or similar compounds to improve stability could potentially unlock significant market opportunities and accelerate the transition from conventional plastics to biodegradable alternatives across various industries.

The demand for stable biodegradable plastics is particularly strong in packaging, consumer goods, and agriculture sectors. In the packaging industry, which accounts for the largest market share, there is a growing trend towards sustainable packaging solutions. Major food and beverage companies are increasingly adopting biodegradable plastics for their products to meet consumer preferences for eco-friendly alternatives.

The consumer goods sector is another key driver of market growth, with rising demand for biodegradable plastics in disposable cutlery, bags, and other single-use items. The agriculture sector is also showing increased interest in biodegradable mulch films and plant pots, contributing to market expansion.

Geographically, Europe leads the market for stable biodegradable plastics, followed by North America and Asia-Pacific. European countries have implemented stringent regulations on single-use plastics, fostering the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate due to increasing environmental awareness and government initiatives promoting sustainable materials.

However, the market faces challenges related to the higher cost of biodegradable plastics compared to conventional plastics. The price premium ranges from 20% to 100% depending on the type of biodegradable plastic and its application. This cost factor has been a significant barrier to widespread adoption, particularly in price-sensitive markets.

The stability of biodegradable plastics remains a critical concern for many potential users. While improvements have been made, there is still a need for biodegradable plastics that can maintain their structural integrity and functional properties over extended periods before degradation. This is where heptane's role in enhancing biodegradable plastics stability becomes crucial.

Market research indicates that consumers and businesses are willing to pay a premium for biodegradable plastics that offer improved stability without compromising on biodegradability. Industries such as electronics, automotive, and medical devices are showing increased interest in stable biodegradable plastics for components and packaging that require longer shelf life.

As research and development efforts continue to focus on enhancing the stability of biodegradable plastics, the market is expected to expand into new application areas. The successful integration of heptane or similar compounds to improve stability could potentially unlock significant market opportunities and accelerate the transition from conventional plastics to biodegradable alternatives across various industries.

Current Challenges in Biodegradable Plastics Stability

Biodegradable plastics have emerged as a promising solution to address the global plastic pollution crisis. However, their widespread adoption faces significant challenges, primarily related to their stability and performance compared to conventional plastics. One of the key issues is the rapid degradation of these materials under normal environmental conditions, which can lead to premature breakdown and loss of functionality.

The inherent instability of biodegradable plastics stems from their chemical composition, which is designed to facilitate decomposition by microorganisms. This characteristic, while beneficial for end-of-life disposal, poses problems during the product's intended lifespan. Exposure to moisture, heat, and UV radiation can accelerate the degradation process, resulting in reduced mechanical strength, altered physical properties, and compromised barrier properties.

Another challenge is the variability in degradation rates across different environments. Biodegradable plastics may degrade too quickly in some conditions, while persisting longer than desired in others. This inconsistency makes it difficult to predict and control the material's lifespan, which is crucial for many applications, especially in packaging and consumer goods.

The limited thermal stability of biodegradable plastics also presents obstacles in processing and manufacturing. Many biodegradable polymers have lower melting points and are more sensitive to thermal degradation compared to conventional plastics. This restricts the range of processing techniques that can be employed and may result in reduced production efficiency or increased costs.

Furthermore, the mechanical properties of biodegradable plastics often fall short of those exhibited by traditional petroleum-based plastics. Issues such as lower tensile strength, reduced flexibility, and increased brittleness limit their applicability in certain high-performance applications. This performance gap has hindered the adoption of biodegradable plastics in sectors where durability and long-term reliability are paramount.

The susceptibility of biodegradable plastics to moisture absorption presents additional challenges. Many biodegradable polymers are hydrophilic, leading to water uptake that can cause swelling, dimensional changes, and accelerated hydrolytic degradation. This moisture sensitivity affects not only the material's stability but also its barrier properties, which are critical for packaging applications.

Addressing these stability challenges is crucial for the broader adoption of biodegradable plastics. Research efforts are focused on developing novel formulations and additives to enhance stability without compromising biodegradability. The exploration of new stabilization techniques, such as the incorporation of nanofillers or the development of multi-layer structures, shows promise in improving the overall performance and longevity of biodegradable plastics.

The inherent instability of biodegradable plastics stems from their chemical composition, which is designed to facilitate decomposition by microorganisms. This characteristic, while beneficial for end-of-life disposal, poses problems during the product's intended lifespan. Exposure to moisture, heat, and UV radiation can accelerate the degradation process, resulting in reduced mechanical strength, altered physical properties, and compromised barrier properties.

Another challenge is the variability in degradation rates across different environments. Biodegradable plastics may degrade too quickly in some conditions, while persisting longer than desired in others. This inconsistency makes it difficult to predict and control the material's lifespan, which is crucial for many applications, especially in packaging and consumer goods.

The limited thermal stability of biodegradable plastics also presents obstacles in processing and manufacturing. Many biodegradable polymers have lower melting points and are more sensitive to thermal degradation compared to conventional plastics. This restricts the range of processing techniques that can be employed and may result in reduced production efficiency or increased costs.

Furthermore, the mechanical properties of biodegradable plastics often fall short of those exhibited by traditional petroleum-based plastics. Issues such as lower tensile strength, reduced flexibility, and increased brittleness limit their applicability in certain high-performance applications. This performance gap has hindered the adoption of biodegradable plastics in sectors where durability and long-term reliability are paramount.

The susceptibility of biodegradable plastics to moisture absorption presents additional challenges. Many biodegradable polymers are hydrophilic, leading to water uptake that can cause swelling, dimensional changes, and accelerated hydrolytic degradation. This moisture sensitivity affects not only the material's stability but also its barrier properties, which are critical for packaging applications.

Addressing these stability challenges is crucial for the broader adoption of biodegradable plastics. Research efforts are focused on developing novel formulations and additives to enhance stability without compromising biodegradability. The exploration of new stabilization techniques, such as the incorporation of nanofillers or the development of multi-layer structures, shows promise in improving the overall performance and longevity of biodegradable plastics.

Existing Heptane-based Stabilization Solutions

01 Enhancing stability through additives

Biodegradable plastics can be stabilized by incorporating specific additives. These additives help improve the material's resistance to environmental factors such as heat, light, and moisture, thereby extending the shelf life and usability of the biodegradable plastic products. Common additives include antioxidants, UV stabilizers, and moisture-resistant compounds.- Enhancing stability through additives: Biodegradable plastics can be stabilized by incorporating specific additives. These additives help to improve the material's resistance to environmental factors such as heat, light, and moisture, thereby extending the shelf life and usability of the biodegradable plastic products without compromising their biodegradability.

- Polymer blending for improved stability: Blending different biodegradable polymers or combining biodegradable polymers with non-biodegradable ones can enhance the overall stability of the material. This approach allows for the creation of biodegradable plastics with improved mechanical properties and resistance to degradation during use, while still maintaining their ability to biodegrade under appropriate conditions.

- Modification of molecular structure: Altering the molecular structure of biodegradable polymers through techniques such as crosslinking or copolymerization can significantly improve their stability. These modifications can enhance the material's resistance to hydrolysis and thermal degradation, leading to more durable biodegradable plastics suitable for a wider range of applications.

- Nanocomposite technology: Incorporating nanoparticles or nanofillers into biodegradable plastics can greatly enhance their stability and performance. These nanocomposites often exhibit improved barrier properties, mechanical strength, and thermal stability, while maintaining their biodegradability. This technology allows for the development of more robust biodegradable materials for demanding applications.

- Controlled degradation mechanisms: Developing biodegradable plastics with controlled degradation mechanisms allows for improved stability during use and predictable biodegradation after disposal. This can be achieved through the careful selection of polymer types, additives, and processing methods to create materials that remain stable under normal use conditions but degrade rapidly in specific environments.

02 Polymer blending for improved stability

Blending different biodegradable polymers or combining biodegradable polymers with non-biodegradable ones can enhance the overall stability of the material. This approach allows for the creation of composite materials that maintain biodegradability while exhibiting improved mechanical properties and resistance to environmental degradation.Expand Specific Solutions03 Modification of molecular structure

Altering the molecular structure of biodegradable polymers through techniques such as cross-linking, copolymerization, or grafting can significantly improve their stability. These modifications can enhance the material's resistance to hydrolysis, thermal degradation, and mechanical stress, resulting in more durable biodegradable plastics.Expand Specific Solutions04 Nanocomposite technology

Incorporating nanoparticles or nanofillers into biodegradable plastics can greatly enhance their stability and performance. These nanocomposites often exhibit improved barrier properties, mechanical strength, and thermal stability compared to conventional biodegradable plastics, while maintaining their biodegradability.Expand Specific Solutions05 Controlled degradation mechanisms

Developing biodegradable plastics with controlled degradation mechanisms allows for better stability during use and predictable biodegradation after disposal. This can be achieved through the careful selection of polymer types, additives, and processing conditions to create materials that remain stable under normal use conditions but degrade rapidly in specific environments.Expand Specific Solutions

Key Players in Biodegradable Plastics Industry

The biodegradable plastics market is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size is projected to reach $7.8 billion by 2025, with a CAGR of 9.5%. Technologically, the field is advancing rapidly, with companies like Kingfa Sci. & Tech. Co., Ltd. and CJ CheilJedang Corp. leading innovation in eco-friendly and fully biodegradable plastics. Emerging players such as Timeplast LLC and Samsara Eco Pty Ltd. are developing novel enzymatic recycling technologies, while established firms like Kaneka Corp. and Toagosei Co., Ltd. are expanding their biodegradable polymer portfolios. The involvement of research institutions like East China Normal University and Korea Research Institute of Chemical Technology indicates ongoing efforts to enhance the stability and performance of biodegradable plastics, potentially using heptane as a key component.

Timeplast LLC

Technical Solution: Timeplast LLC has developed a groundbreaking technology that utilizes heptane to enhance the stability and biodegradability of plastics. Their approach involves incorporating heptane into the polymer matrix during the manufacturing process, which creates microscopic tunnels within the plastic structure. These tunnels allow for controlled degradation, enabling the plastic to break down more efficiently in various environments while maintaining its structural integrity during its intended use period[1][3]. The heptane-induced tunnels also facilitate the penetration of microorganisms, accelerating the biodegradation process once the plastic is discarded[2]. This innovative method addresses both the longevity and end-of-life concerns associated with traditional biodegradable plastics.

Strengths: Enhances both stability and biodegradability, allows for customizable degradation rates, and maintains plastic functionality during use. Weaknesses: May require modifications to existing manufacturing processes and potential increased production costs.

Samsara Eco Pty Ltd.

Technical Solution: Samsara Eco has developed an enzymatic recycling technology that can be applied to enhance the stability of biodegradable plastics. While not directly using heptane, their approach complements efforts to improve biodegradable plastic stability. The company's enzyme-based technology breaks down plastics into their basic building blocks, which can then be used to create new, high-quality plastics[4]. This process can be adapted to work with biodegradable plastics enhanced with heptane, potentially creating a closed-loop system for these materials. By ensuring that biodegradable plastics can be effectively recycled, Samsara Eco's technology indirectly contributes to the overall stability and sustainability of these materials in the circular economy[5].

Strengths: Enables true circular economy for plastics, including biodegradable ones. Weaknesses: May require adaptation to work specifically with heptane-enhanced biodegradable plastics.

Innovative Approaches in Heptane-enhanced Stability

Composition for the degradation of plastic

PatentActiveUS20150203666A1

Innovation

- A composition using Nano additives, such as heptane, cellulose, methyl rhenium trioxide, butylated hydroxytoluene, and polyphenol oxidase, which are added to the plastic to create weaker links susceptible to degradation, while maintaining the original molecular structure and stability, and can be programmed to control the degradation time based on the plastic's mass and density.

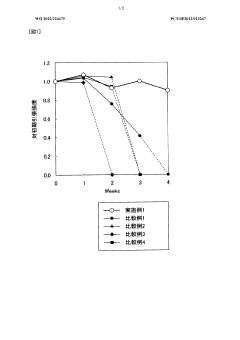

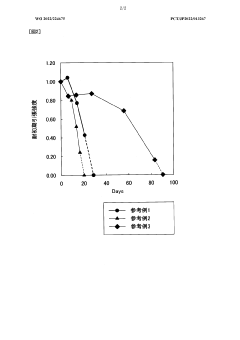

Composition, molded object, container for cosmetic preparation, and container containing cosmetic preparation

PatentWO2022224675A1

Innovation

- A biodegradable plastic composition comprising poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) and a carbodiimide group-containing compound is developed, enhancing hydrolysis and water resistance by combining a specific polymer with an additive that slows down hydrolysis and improves durability.

Environmental Impact Assessment

The environmental impact assessment of heptane's role in enhancing biodegradable plastics stability is a critical aspect of evaluating the overall sustainability of this technological approach. Heptane, a hydrocarbon solvent, is being investigated for its potential to improve the stability and durability of biodegradable plastics. While this advancement may lead to more robust and versatile biodegradable materials, it is essential to consider the environmental implications of incorporating heptane into these plastics.

One primary concern is the potential release of heptane into the environment during the production, use, and disposal of enhanced biodegradable plastics. Heptane is a volatile organic compound (VOC) that can contribute to air pollution and the formation of ground-level ozone when released into the atmosphere. The manufacturing processes involving heptane may require stringent emission control measures to mitigate these environmental risks.

The impact on soil and water ecosystems must also be carefully evaluated. Although biodegradable plastics are designed to break down naturally, the presence of heptane may alter their degradation patterns and potentially introduce this compound into soil and aquatic environments. Research is needed to determine whether heptane-enhanced biodegradable plastics maintain their biodegradability and whether any residual heptane could persist in the environment, potentially affecting microbial communities or aquatic organisms.

Furthermore, the lifecycle assessment of heptane-enhanced biodegradable plastics should consider the sourcing and production of heptane itself. As a petroleum-derived compound, the extraction and refinement of heptane contribute to fossil fuel consumption and associated environmental impacts. This aspect must be weighed against the potential benefits of extended plastic life and reduced overall plastic waste.

The end-of-life management of these enhanced plastics is another crucial consideration. While improved stability may extend the useful life of biodegradable products, it could also potentially complicate existing recycling and composting processes. Assessment of how heptane-treated plastics interact with current waste management systems is necessary to ensure that they do not disrupt established recycling streams or composting facilities.

Lastly, the potential for bioaccumulation of heptane or its breakdown products in food chains should be investigated. If these compounds persist in the environment, there is a possibility of accumulation in organisms, potentially leading to broader ecological impacts. Long-term studies on the environmental fate of heptane in biodegradable plastics are essential to fully understand and mitigate any risks to ecosystems and human health.

One primary concern is the potential release of heptane into the environment during the production, use, and disposal of enhanced biodegradable plastics. Heptane is a volatile organic compound (VOC) that can contribute to air pollution and the formation of ground-level ozone when released into the atmosphere. The manufacturing processes involving heptane may require stringent emission control measures to mitigate these environmental risks.

The impact on soil and water ecosystems must also be carefully evaluated. Although biodegradable plastics are designed to break down naturally, the presence of heptane may alter their degradation patterns and potentially introduce this compound into soil and aquatic environments. Research is needed to determine whether heptane-enhanced biodegradable plastics maintain their biodegradability and whether any residual heptane could persist in the environment, potentially affecting microbial communities or aquatic organisms.

Furthermore, the lifecycle assessment of heptane-enhanced biodegradable plastics should consider the sourcing and production of heptane itself. As a petroleum-derived compound, the extraction and refinement of heptane contribute to fossil fuel consumption and associated environmental impacts. This aspect must be weighed against the potential benefits of extended plastic life and reduced overall plastic waste.

The end-of-life management of these enhanced plastics is another crucial consideration. While improved stability may extend the useful life of biodegradable products, it could also potentially complicate existing recycling and composting processes. Assessment of how heptane-treated plastics interact with current waste management systems is necessary to ensure that they do not disrupt established recycling streams or composting facilities.

Lastly, the potential for bioaccumulation of heptane or its breakdown products in food chains should be investigated. If these compounds persist in the environment, there is a possibility of accumulation in organisms, potentially leading to broader ecological impacts. Long-term studies on the environmental fate of heptane in biodegradable plastics are essential to fully understand and mitigate any risks to ecosystems and human health.

Regulatory Framework for Biodegradable Plastics

The regulatory framework for biodegradable plastics plays a crucial role in shaping the development, production, and use of these materials, including those enhanced with heptane for improved stability. As the global concern for plastic pollution grows, governments and international organizations have been implementing and refining regulations to ensure the proper management of biodegradable plastics throughout their lifecycle.

In the European Union, the European Committee for Standardization (CEN) has established EN 13432 as the standard for biodegradable packaging. This standard specifies requirements for packaging recoverable through composting and biodegradation. It sets criteria for biodegradability, disintegration during biological treatment, effect on the biological treatment process, and effect on the quality of the resulting compost.

The United States has a more fragmented approach, with regulations varying at federal, state, and local levels. The Federal Trade Commission (FTC) has issued guidelines on environmental marketing claims, including those related to biodegradability. These guidelines aim to prevent deceptive marketing practices and ensure that claims about biodegradability are substantiated.

In Asia, countries like Japan and South Korea have implemented their own certification systems for biodegradable plastics. Japan's BiomassPla mark and South Korea's EL724 standard provide frameworks for certifying and labeling biodegradable plastic products.

International standards, such as ISO 17088 and ASTM D6400, provide specifications for compostable plastics. These standards are often referenced in national regulations and help harmonize the global approach to biodegradable plastics management.

The regulatory landscape also addresses the use of additives like heptane in biodegradable plastics. Many jurisdictions require thorough safety assessments and environmental impact studies before approving new additives. The European Food Safety Authority (EFSA) and the U.S. Food and Drug Administration (FDA) play key roles in evaluating the safety of additives used in food-contact materials, including biodegradable plastics.

As research into heptane's role in enhancing biodegradable plastics stability progresses, regulatory bodies are likely to adapt their frameworks to accommodate these innovations. This may involve updating existing standards or creating new ones specifically addressing stability-enhanced biodegradable plastics.

Compliance with these regulations is essential for manufacturers and researchers working on heptane-enhanced biodegradable plastics. It ensures that the developed materials meet safety and environmental standards while providing a clear path for market entry and consumer acceptance.

In the European Union, the European Committee for Standardization (CEN) has established EN 13432 as the standard for biodegradable packaging. This standard specifies requirements for packaging recoverable through composting and biodegradation. It sets criteria for biodegradability, disintegration during biological treatment, effect on the biological treatment process, and effect on the quality of the resulting compost.

The United States has a more fragmented approach, with regulations varying at federal, state, and local levels. The Federal Trade Commission (FTC) has issued guidelines on environmental marketing claims, including those related to biodegradability. These guidelines aim to prevent deceptive marketing practices and ensure that claims about biodegradability are substantiated.

In Asia, countries like Japan and South Korea have implemented their own certification systems for biodegradable plastics. Japan's BiomassPla mark and South Korea's EL724 standard provide frameworks for certifying and labeling biodegradable plastic products.

International standards, such as ISO 17088 and ASTM D6400, provide specifications for compostable plastics. These standards are often referenced in national regulations and help harmonize the global approach to biodegradable plastics management.

The regulatory landscape also addresses the use of additives like heptane in biodegradable plastics. Many jurisdictions require thorough safety assessments and environmental impact studies before approving new additives. The European Food Safety Authority (EFSA) and the U.S. Food and Drug Administration (FDA) play key roles in evaluating the safety of additives used in food-contact materials, including biodegradable plastics.

As research into heptane's role in enhancing biodegradable plastics stability progresses, regulatory bodies are likely to adapt their frameworks to accommodate these innovations. This may involve updating existing standards or creating new ones specifically addressing stability-enhanced biodegradable plastics.

Compliance with these regulations is essential for manufacturers and researchers working on heptane-enhanced biodegradable plastics. It ensures that the developed materials meet safety and environmental standards while providing a clear path for market entry and consumer acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!