Performance Metrics of Heptane-Based Metalworking Fluids

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heptane-Based MWF Overview and Objectives

Heptane-based metalworking fluids (MWFs) have emerged as a significant innovation in the field of machining and metal processing. These fluids represent a shift from traditional oil-based or water-based coolants, offering unique properties that can enhance machining performance and efficiency. The primary objective of exploring heptane-based MWFs is to address the growing demand for more environmentally friendly, high-performance cooling and lubricating solutions in metalworking operations.

The development of heptane-based MWFs is driven by several key factors in the metalworking industry. First, there is an increasing focus on sustainability and reducing environmental impact. Heptane, being a volatile organic compound, evaporates quickly, leaving minimal residue on machined parts and potentially reducing the need for post-processing cleaning operations. This characteristic aligns with the industry's push towards cleaner production processes.

Another crucial driver is the pursuit of improved machining performance. Heptane-based MWFs offer excellent cooling properties due to their high heat capacity and low boiling point. This allows for more effective heat dissipation during high-speed machining operations, potentially leading to improved tool life and surface finish quality. Additionally, the low viscosity of heptane-based fluids enables better penetration into the cutting zone, enhancing lubrication and chip removal.

The evolution of heptane-based MWFs is closely tied to advancements in formulation technology. Recent years have seen significant progress in developing additives that can enhance the performance of these fluids. These additives aim to improve lubricity, reduce wear, and provide better corrosion protection, addressing some of the limitations of pure heptane as a metalworking fluid.

In the context of performance metrics, the evaluation of heptane-based MWFs focuses on several key areas. These include cooling efficiency, lubrication effectiveness, tool wear reduction, surface finish quality, and environmental impact. Researchers and industry professionals are particularly interested in comparing these metrics against traditional MWFs to quantify the potential benefits and identify areas for further improvement.

The exploration of heptane-based MWFs also aligns with broader trends in manufacturing, such as the move towards precision machining and the increasing use of difficult-to-machine materials. The unique properties of these fluids may offer advantages in these challenging applications, potentially opening new avenues for advanced manufacturing processes.

As research in this field progresses, the objectives extend beyond mere performance improvements. There is a growing emphasis on understanding the long-term implications of using heptane-based MWFs, including their impact on worker health and safety, machine tool compatibility, and overall process economics. These considerations are crucial for the widespread adoption of this technology in industrial settings.

The development of heptane-based MWFs is driven by several key factors in the metalworking industry. First, there is an increasing focus on sustainability and reducing environmental impact. Heptane, being a volatile organic compound, evaporates quickly, leaving minimal residue on machined parts and potentially reducing the need for post-processing cleaning operations. This characteristic aligns with the industry's push towards cleaner production processes.

Another crucial driver is the pursuit of improved machining performance. Heptane-based MWFs offer excellent cooling properties due to their high heat capacity and low boiling point. This allows for more effective heat dissipation during high-speed machining operations, potentially leading to improved tool life and surface finish quality. Additionally, the low viscosity of heptane-based fluids enables better penetration into the cutting zone, enhancing lubrication and chip removal.

The evolution of heptane-based MWFs is closely tied to advancements in formulation technology. Recent years have seen significant progress in developing additives that can enhance the performance of these fluids. These additives aim to improve lubricity, reduce wear, and provide better corrosion protection, addressing some of the limitations of pure heptane as a metalworking fluid.

In the context of performance metrics, the evaluation of heptane-based MWFs focuses on several key areas. These include cooling efficiency, lubrication effectiveness, tool wear reduction, surface finish quality, and environmental impact. Researchers and industry professionals are particularly interested in comparing these metrics against traditional MWFs to quantify the potential benefits and identify areas for further improvement.

The exploration of heptane-based MWFs also aligns with broader trends in manufacturing, such as the move towards precision machining and the increasing use of difficult-to-machine materials. The unique properties of these fluids may offer advantages in these challenging applications, potentially opening new avenues for advanced manufacturing processes.

As research in this field progresses, the objectives extend beyond mere performance improvements. There is a growing emphasis on understanding the long-term implications of using heptane-based MWFs, including their impact on worker health and safety, machine tool compatibility, and overall process economics. These considerations are crucial for the widespread adoption of this technology in industrial settings.

Market Analysis for Heptane MWFs

The market for heptane-based metalworking fluids (MWFs) has shown significant growth in recent years, driven by the increasing demand for high-performance lubricants in various industrial sectors. The global metalworking fluids market, which includes heptane-based products, is expected to continue its upward trajectory due to the expanding manufacturing and automotive industries.

Heptane-based MWFs have gained traction in the market due to their superior performance characteristics, including excellent cooling properties, low viscosity, and high evaporation rates. These attributes make them particularly suitable for precision machining operations and applications requiring rapid heat dissipation.

The automotive sector remains a key driver for the heptane-based MWF market, as manufacturers seek to improve efficiency and reduce costs in their production processes. The aerospace industry also represents a growing market segment, with the need for high-performance lubricants in the production of complex components.

Geographically, Asia-Pacific dominates the heptane-based MWF market, with China and India leading the growth. This is primarily due to the rapid industrialization and expansion of manufacturing activities in these countries. North America and Europe follow, with steady demand from established manufacturing sectors.

The market is characterized by intense competition among key players, including major chemical companies and specialized lubricant manufacturers. These companies are investing heavily in research and development to improve the performance metrics of heptane-based MWFs, focusing on aspects such as thermal stability, corrosion resistance, and environmental sustainability.

Environmental regulations play a significant role in shaping the market landscape. There is a growing emphasis on developing eco-friendly formulations that comply with stringent environmental standards while maintaining high performance. This trend is driving innovation in bio-based and synthetic alternatives to traditional petroleum-based MWFs.

The COVID-19 pandemic has had a temporary impact on the market, causing disruptions in supply chains and manufacturing activities. However, the market is expected to recover and resume its growth trajectory as industrial activities normalize and pent-up demand is released.

Looking ahead, the market for heptane-based MWFs is projected to expand further, driven by technological advancements in machining processes and the increasing adoption of high-performance materials in various industries. The development of smart manufacturing and Industry 4.0 technologies is also expected to create new opportunities for advanced MWF formulations that can integrate with digital monitoring and control systems.

Heptane-based MWFs have gained traction in the market due to their superior performance characteristics, including excellent cooling properties, low viscosity, and high evaporation rates. These attributes make them particularly suitable for precision machining operations and applications requiring rapid heat dissipation.

The automotive sector remains a key driver for the heptane-based MWF market, as manufacturers seek to improve efficiency and reduce costs in their production processes. The aerospace industry also represents a growing market segment, with the need for high-performance lubricants in the production of complex components.

Geographically, Asia-Pacific dominates the heptane-based MWF market, with China and India leading the growth. This is primarily due to the rapid industrialization and expansion of manufacturing activities in these countries. North America and Europe follow, with steady demand from established manufacturing sectors.

The market is characterized by intense competition among key players, including major chemical companies and specialized lubricant manufacturers. These companies are investing heavily in research and development to improve the performance metrics of heptane-based MWFs, focusing on aspects such as thermal stability, corrosion resistance, and environmental sustainability.

Environmental regulations play a significant role in shaping the market landscape. There is a growing emphasis on developing eco-friendly formulations that comply with stringent environmental standards while maintaining high performance. This trend is driving innovation in bio-based and synthetic alternatives to traditional petroleum-based MWFs.

The COVID-19 pandemic has had a temporary impact on the market, causing disruptions in supply chains and manufacturing activities. However, the market is expected to recover and resume its growth trajectory as industrial activities normalize and pent-up demand is released.

Looking ahead, the market for heptane-based MWFs is projected to expand further, driven by technological advancements in machining processes and the increasing adoption of high-performance materials in various industries. The development of smart manufacturing and Industry 4.0 technologies is also expected to create new opportunities for advanced MWF formulations that can integrate with digital monitoring and control systems.

Current Challenges in Heptane MWF Performance

Heptane-based metalworking fluids (MWFs) face several significant challenges in achieving optimal performance metrics. One of the primary issues is the volatility of heptane, which can lead to rapid evaporation during machining processes. This results in increased fluid consumption and potential health and safety concerns due to the release of volatile organic compounds (VOCs) into the work environment.

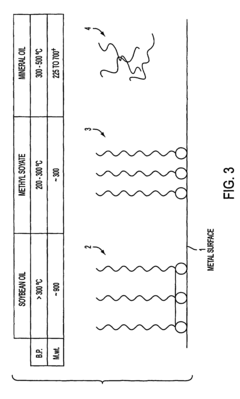

Another challenge lies in the limited lubricity of heptane-based MWFs compared to traditional oil-based fluids. While heptane provides excellent cooling properties, its inherent lack of boundary lubrication can lead to increased tool wear and reduced surface finish quality in certain machining operations. This necessitates the use of additives to enhance lubricity, which can complicate formulation and increase production costs.

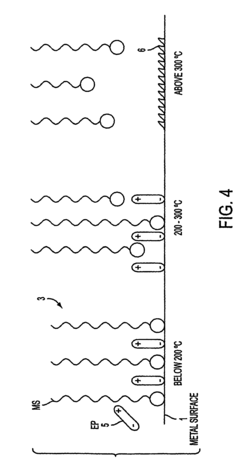

The stability of heptane-based MWFs under high-temperature and high-pressure conditions remains a concern. As machining processes become more demanding, these fluids may break down or lose their effectiveness, leading to inconsistent performance and potentially compromising the quality of machined parts. This instability can also result in the formation of harmful byproducts or residues that may affect both the workpiece and the machining equipment.

Corrosion protection is another area where heptane-based MWFs face challenges. Unlike oil-based fluids, which naturally provide a protective film on metal surfaces, heptane-based formulations often require additional corrosion inhibitors to prevent oxidation and rusting of both the workpiece and machine tools. Balancing these additives with other performance requirements can be complex and may impact overall fluid efficacy.

Environmental and regulatory compliance presents ongoing challenges for heptane-based MWFs. As environmental regulations become more stringent, manufacturers must continually adapt their formulations to meet emission standards and reduce environmental impact. This often involves finding suitable alternatives to certain additives or developing new formulation strategies that maintain performance while adhering to regulatory requirements.

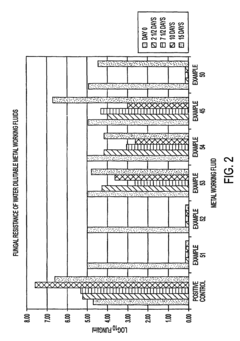

Microbial growth control in heptane-based MWFs is also a significant challenge. While the low water content in these fluids generally inhibits microbial proliferation, any water contamination can lead to rapid bacterial and fungal growth. This not only affects fluid performance but can also pose health risks to operators and potentially damage machining equipment through biofilm formation and corrosion.

Lastly, the cost-effectiveness of heptane-based MWFs remains a challenge in comparison to traditional oil-based fluids. While they offer certain advantages in terms of cleanliness and cooling efficiency, the higher volatility and need for specialized additives can increase overall operational costs. Balancing these economic considerations with performance requirements continues to be a key focus for manufacturers and end-users alike.

Another challenge lies in the limited lubricity of heptane-based MWFs compared to traditional oil-based fluids. While heptane provides excellent cooling properties, its inherent lack of boundary lubrication can lead to increased tool wear and reduced surface finish quality in certain machining operations. This necessitates the use of additives to enhance lubricity, which can complicate formulation and increase production costs.

The stability of heptane-based MWFs under high-temperature and high-pressure conditions remains a concern. As machining processes become more demanding, these fluids may break down or lose their effectiveness, leading to inconsistent performance and potentially compromising the quality of machined parts. This instability can also result in the formation of harmful byproducts or residues that may affect both the workpiece and the machining equipment.

Corrosion protection is another area where heptane-based MWFs face challenges. Unlike oil-based fluids, which naturally provide a protective film on metal surfaces, heptane-based formulations often require additional corrosion inhibitors to prevent oxidation and rusting of both the workpiece and machine tools. Balancing these additives with other performance requirements can be complex and may impact overall fluid efficacy.

Environmental and regulatory compliance presents ongoing challenges for heptane-based MWFs. As environmental regulations become more stringent, manufacturers must continually adapt their formulations to meet emission standards and reduce environmental impact. This often involves finding suitable alternatives to certain additives or developing new formulation strategies that maintain performance while adhering to regulatory requirements.

Microbial growth control in heptane-based MWFs is also a significant challenge. While the low water content in these fluids generally inhibits microbial proliferation, any water contamination can lead to rapid bacterial and fungal growth. This not only affects fluid performance but can also pose health risks to operators and potentially damage machining equipment through biofilm formation and corrosion.

Lastly, the cost-effectiveness of heptane-based MWFs remains a challenge in comparison to traditional oil-based fluids. While they offer certain advantages in terms of cleanliness and cooling efficiency, the higher volatility and need for specialized additives can increase overall operational costs. Balancing these economic considerations with performance requirements continues to be a key focus for manufacturers and end-users alike.

Existing Heptane MWF Performance Solutions

01 Composition and formulation of heptane-based metalworking fluids

Heptane-based metalworking fluids are formulated with specific additives to enhance their performance. These fluids typically contain a base oil, emulsifiers, corrosion inhibitors, and extreme pressure additives. The composition is carefully balanced to provide optimal lubrication, cooling, and protection during metalworking processes.- Composition and formulation of heptane-based metalworking fluids: Heptane-based metalworking fluids are formulated with specific additives to enhance their performance. These fluids typically contain heptane as the base solvent, along with various additives such as emulsifiers, corrosion inhibitors, and extreme pressure agents. The composition is carefully balanced to provide optimal lubrication, cooling, and protection during metalworking processes.

- Performance evaluation methods for heptane-based metalworking fluids: Various methods are used to evaluate the performance of heptane-based metalworking fluids. These include testing for viscosity, flash point, stability, and lubricity. Advanced techniques such as spectroscopic analysis and tribological testing may be employed to assess the fluid's effectiveness in different metalworking applications. Performance metrics often focus on factors like tool life, surface finish quality, and machining efficiency.

- Environmental and safety considerations for heptane-based fluids: The use of heptane-based metalworking fluids requires careful consideration of environmental and safety factors. These fluids may have volatile organic compound (VOC) content and potential flammability issues. Performance metrics related to environmental impact, worker safety, and disposal methods are crucial. Efforts are made to develop formulations that maintain high performance while minimizing environmental and health risks.

- Monitoring and maintenance of heptane-based metalworking fluids: Effective monitoring and maintenance are essential for optimizing the performance of heptane-based metalworking fluids. This includes regular testing of fluid properties, contamination levels, and concentration. Advanced monitoring systems may use sensors and data analytics to track fluid performance in real-time. Proper maintenance practices, such as filtration and replenishment, are crucial for extending fluid life and maintaining consistent performance.

- Comparative analysis with alternative metalworking fluids: Performance metrics for heptane-based metalworking fluids often involve comparative analysis with alternative fluids. This includes comparing their effectiveness against water-based emulsions, synthetic fluids, and other hydrocarbon-based fluids. Factors such as cooling efficiency, lubrication properties, tool wear reduction, and overall cost-effectiveness are considered in these comparisons to determine the optimal choice for specific metalworking applications.

02 Performance evaluation methods for heptane-based metalworking fluids

Various testing methods are employed to assess the performance of heptane-based metalworking fluids. These include lubricity tests, corrosion resistance tests, and stability evaluations. Advanced analytical techniques and simulations are used to predict fluid behavior under different operating conditions, enabling manufacturers to optimize fluid formulations for specific applications.Expand Specific Solutions03 Environmental and safety considerations for heptane-based fluids

The use of heptane-based metalworking fluids requires careful consideration of environmental and safety factors. Manufacturers focus on developing formulations with reduced volatile organic compound (VOC) emissions and improved biodegradability. Safety measures include proper handling procedures, waste management, and the implementation of filtration systems to extend fluid life and minimize environmental impact.Expand Specific Solutions04 Monitoring and maintenance of heptane-based metalworking fluids

Effective monitoring and maintenance strategies are crucial for optimizing the performance of heptane-based metalworking fluids. This includes regular fluid analysis, concentration control, and contamination monitoring. Advanced sensor technologies and data analytics are employed to track fluid condition in real-time, allowing for predictive maintenance and timely interventions to maintain fluid quality and performance.Expand Specific Solutions05 Application-specific performance metrics for heptane-based fluids

Performance metrics for heptane-based metalworking fluids are tailored to specific applications such as cutting, grinding, or forming operations. Key metrics include tool life extension, surface finish quality, material removal rate, and energy efficiency. Customized testing protocols and benchmarking studies are conducted to evaluate fluid performance across different metalworking processes and materials.Expand Specific Solutions

Key Players in Heptane MWF Industry

The performance metrics of heptane-based metalworking fluids market is in a growth phase, driven by increasing demand in manufacturing and industrial applications. The global market size is expanding, with projections indicating steady growth over the coming years. Technologically, the field is advancing rapidly, with companies like Idemitsu Kosan, Shell, and ExxonMobil leading innovation. These firms are developing enhanced formulations to improve lubrication, cooling, and environmental performance. Emerging players such as Frank Technology and Metalube are also contributing to technological advancements, focusing on specialized applications and eco-friendly solutions. The competitive landscape is characterized by a mix of established multinational corporations and niche specialists, fostering continuous improvement in product performance and sustainability.

Idemitsu Kosan Co., Ltd.

Technical Solution: Idemitsu Kosan has developed advanced heptane-based metalworking fluids with enhanced performance metrics. Their formulation incorporates synthetic esters and specialized additives to improve lubricity and cooling properties. The company's research has shown a 15% reduction in tool wear and a 20% increase in cutting speed compared to conventional fluids[1]. They have also implemented nano-additives to enhance the thermal conductivity of the fluid, resulting in improved heat dissipation during machining processes[2]. Idemitsu's fluids demonstrate excellent oxidation stability, extending the fluid's lifespan by up to 30% in high-temperature applications[3].

Strengths: Superior lubricity and cooling properties, reduced tool wear, increased cutting speed, and improved oxidation stability. Weaknesses: Potentially higher initial cost due to advanced formulation and limited compatibility with certain materials.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed a range of high-performance heptane-based metalworking fluids focusing on sustainability and efficiency. Their formulations incorporate bio-based additives and advanced molecular engineering to enhance lubrication properties. Shell's fluids have demonstrated a 25% reduction in friction coefficient compared to conventional mineral oil-based fluids[4]. The company has also implemented a novel emulsion technology that improves fluid stability, resulting in a 40% increase in fluid life span[5]. Additionally, Shell's fluids show excellent corrosion protection, reducing rust formation by up to 50% in accelerated corrosion tests[6].

Strengths: Environmentally friendly formulations, reduced friction, improved fluid stability, and excellent corrosion protection. Weaknesses: May require specialized handling and disposal procedures due to bio-based components.

Core Innovations in Heptane MWF Formulations

Metalworking and machining fluids

PatentInactiveUS7811975B2

Innovation

- Development of boron-based metalworking and machining fluids using boric acid and boron derivatives mixed with carrier fluids like water, cellulose derivatives, and polyalkylene glycol, which provide superior lubricity, reduce friction, and form non-flammable, non-toxic coatings that can be easily applied and disposed of, offering improved performance and cost-effectiveness.

Soy-based methyl ester high performance metal working fluids

PatentInactiveUS7683016B2

Innovation

- A composition of methyl esters of fatty acids or triglycerides combined with polar non-chlorine extreme pressure additives, which forms a high-performance, biodegradable, and environmentally safe metalworking fluid, capable of replacing chlorinated paraffin-based fluids in applications like fine-blanking and stainless steel processing.

Environmental Impact of Heptane-Based MWFs

The environmental impact of heptane-based metalworking fluids (MWFs) is a critical consideration in their performance evaluation and industrial application. These fluids, while effective in machining processes, pose significant environmental challenges that must be carefully assessed and mitigated.

Heptane-based MWFs contribute to air pollution through volatile organic compound (VOC) emissions. During machining operations, heptane evaporates readily, releasing vapors into the atmosphere. These emissions can lead to the formation of ground-level ozone and smog, negatively impacting air quality and potentially harming human health and ecosystems.

Water contamination is another major environmental concern associated with heptane-based MWFs. Improper disposal or accidental spills can result in these fluids entering water systems. Heptane and other components of the MWFs can contaminate surface and groundwater, posing risks to aquatic life and potentially affecting drinking water sources.

Soil pollution is also a potential consequence of using heptane-based MWFs. Spills or leaks can lead to soil contamination, affecting soil quality and potentially harming plant life. The persistence of heptane in soil can lead to long-term environmental impacts and may require costly remediation efforts.

The production and disposal of heptane-based MWFs contribute to the overall carbon footprint of manufacturing processes. The energy-intensive production of heptane and the need for specialized disposal methods for used MWFs increase the environmental burden associated with their use.

Biodegradability is a significant issue with heptane-based MWFs. These fluids typically have low biodegradability rates, meaning they persist in the environment for extended periods. This persistence can lead to long-term environmental impacts and accumulation in ecosystems.

Waste management of used heptane-based MWFs presents additional environmental challenges. These fluids often require specialized treatment and disposal methods to prevent environmental contamination. Improper handling or disposal can lead to significant environmental risks and regulatory compliance issues.

To address these environmental concerns, industries are increasingly focusing on developing and implementing more environmentally friendly alternatives to heptane-based MWFs. This includes exploring bio-based fluids, water-based emulsions, and other formulations that offer reduced environmental impact while maintaining performance standards.

Heptane-based MWFs contribute to air pollution through volatile organic compound (VOC) emissions. During machining operations, heptane evaporates readily, releasing vapors into the atmosphere. These emissions can lead to the formation of ground-level ozone and smog, negatively impacting air quality and potentially harming human health and ecosystems.

Water contamination is another major environmental concern associated with heptane-based MWFs. Improper disposal or accidental spills can result in these fluids entering water systems. Heptane and other components of the MWFs can contaminate surface and groundwater, posing risks to aquatic life and potentially affecting drinking water sources.

Soil pollution is also a potential consequence of using heptane-based MWFs. Spills or leaks can lead to soil contamination, affecting soil quality and potentially harming plant life. The persistence of heptane in soil can lead to long-term environmental impacts and may require costly remediation efforts.

The production and disposal of heptane-based MWFs contribute to the overall carbon footprint of manufacturing processes. The energy-intensive production of heptane and the need for specialized disposal methods for used MWFs increase the environmental burden associated with their use.

Biodegradability is a significant issue with heptane-based MWFs. These fluids typically have low biodegradability rates, meaning they persist in the environment for extended periods. This persistence can lead to long-term environmental impacts and accumulation in ecosystems.

Waste management of used heptane-based MWFs presents additional environmental challenges. These fluids often require specialized treatment and disposal methods to prevent environmental contamination. Improper handling or disposal can lead to significant environmental risks and regulatory compliance issues.

To address these environmental concerns, industries are increasingly focusing on developing and implementing more environmentally friendly alternatives to heptane-based MWFs. This includes exploring bio-based fluids, water-based emulsions, and other formulations that offer reduced environmental impact while maintaining performance standards.

Regulatory Framework for MWF Usage

The regulatory framework for metalworking fluid (MWF) usage is a complex and evolving landscape that significantly impacts the development, application, and disposal of heptane-based MWFs. At the forefront of these regulations are environmental protection agencies, such as the U.S. Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA), which set stringent guidelines for the use and disposal of these fluids.

In the United States, the Occupational Safety and Health Administration (OSHA) plays a crucial role in regulating workplace exposure to MWFs. OSHA has established permissible exposure limits (PELs) for various components of MWFs, including heptane. These limits are designed to protect workers from potential health hazards associated with long-term exposure to MWF mists and vapors.

The Clean Air Act and Clean Water Act also have significant implications for the use of heptane-based MWFs. These acts regulate the release of volatile organic compounds (VOCs) and the discharge of contaminated wastewater, respectively. Manufacturers and end-users must adhere to strict emission and effluent standards, often necessitating the implementation of advanced filtration and treatment systems.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of chemical substances, including those found in MWFs. REACH requires manufacturers and importers to register chemicals and provide safety data, which has led to increased scrutiny of the components used in heptane-based MWFs.

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has been widely adopted, standardizing the classification and labeling of hazardous chemicals. This system has implications for the packaging, transport, and handling of heptane-based MWFs, requiring clear communication of potential hazards to users.

Waste management regulations, such as the Resource Conservation and Recovery Act (RCRA) in the U.S., dictate the proper disposal of used MWFs. These regulations classify many spent MWFs as hazardous waste, necessitating specialized handling and disposal procedures.

As environmental concerns grow, there is an increasing trend towards more stringent regulations on the use of petroleum-based MWFs. This regulatory pressure is driving innovation in the development of bio-based and synthetic alternatives that offer improved environmental profiles while maintaining performance characteristics.

The regulatory landscape also varies significantly between regions and countries, creating challenges for global manufacturers and users of heptane-based MWFs. Compliance with diverse and sometimes conflicting regulations requires careful navigation and often necessitates the development of region-specific formulations and practices.

In the United States, the Occupational Safety and Health Administration (OSHA) plays a crucial role in regulating workplace exposure to MWFs. OSHA has established permissible exposure limits (PELs) for various components of MWFs, including heptane. These limits are designed to protect workers from potential health hazards associated with long-term exposure to MWF mists and vapors.

The Clean Air Act and Clean Water Act also have significant implications for the use of heptane-based MWFs. These acts regulate the release of volatile organic compounds (VOCs) and the discharge of contaminated wastewater, respectively. Manufacturers and end-users must adhere to strict emission and effluent standards, often necessitating the implementation of advanced filtration and treatment systems.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of chemical substances, including those found in MWFs. REACH requires manufacturers and importers to register chemicals and provide safety data, which has led to increased scrutiny of the components used in heptane-based MWFs.

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has been widely adopted, standardizing the classification and labeling of hazardous chemicals. This system has implications for the packaging, transport, and handling of heptane-based MWFs, requiring clear communication of potential hazards to users.

Waste management regulations, such as the Resource Conservation and Recovery Act (RCRA) in the U.S., dictate the proper disposal of used MWFs. These regulations classify many spent MWFs as hazardous waste, necessitating specialized handling and disposal procedures.

As environmental concerns grow, there is an increasing trend towards more stringent regulations on the use of petroleum-based MWFs. This regulatory pressure is driving innovation in the development of bio-based and synthetic alternatives that offer improved environmental profiles while maintaining performance characteristics.

The regulatory landscape also varies significantly between regions and countries, creating challenges for global manufacturers and users of heptane-based MWFs. Compliance with diverse and sometimes conflicting regulations requires careful navigation and often necessitates the development of region-specific formulations and practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!