Heptane in the Characterization of Asphalt Hardness and Ductility

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heptane in Asphalt Testing: Background and Objectives

The use of heptane in asphalt testing has emerged as a significant area of research in recent years, particularly in the characterization of asphalt hardness and ductility. This field of study has evolved from the broader context of asphalt material science, which has been a crucial aspect of road construction and maintenance for over a century. The development of more precise and reliable testing methods has become increasingly important as the demands on road infrastructure continue to grow.

Historically, asphalt testing has relied on a variety of solvents and techniques to assess the physical properties of bituminous materials. The introduction of heptane as a testing medium represents a shift towards more standardized and reproducible methods. Heptane, a straight-chain alkane with seven carbon atoms, offers unique properties that make it particularly suitable for asphalt analysis.

The primary objective of incorporating heptane in asphalt testing is to enhance the accuracy and consistency of hardness and ductility measurements. These properties are critical in predicting the performance of asphalt under various environmental conditions and traffic loads. By utilizing heptane, researchers aim to develop more refined models of asphalt behavior, which can lead to improved road design and longer-lasting pavements.

Another key goal of this research is to establish a correlation between heptane-based test results and the real-world performance of asphalt mixtures. This involves extensive field studies and laboratory experiments to validate the predictive power of heptane-assisted characterization methods. The ultimate aim is to create a robust set of testing protocols that can be widely adopted by the industry, ensuring better quality control and more efficient use of resources in road construction.

Furthermore, the research into heptane use in asphalt testing aligns with broader trends in materials science and engineering. There is a growing emphasis on developing sustainable and environmentally friendly testing methods. Heptane, being a relatively low-toxicity solvent, fits well within this paradigm, potentially offering a safer alternative to some traditional testing chemicals.

As the field progresses, researchers are also exploring the potential of heptane-based tests to provide insights into other aspects of asphalt performance, such as aging characteristics and resistance to thermal cracking. This expansion of scope reflects the evolving needs of the construction industry and the increasing sophistication of road engineering practices.

Historically, asphalt testing has relied on a variety of solvents and techniques to assess the physical properties of bituminous materials. The introduction of heptane as a testing medium represents a shift towards more standardized and reproducible methods. Heptane, a straight-chain alkane with seven carbon atoms, offers unique properties that make it particularly suitable for asphalt analysis.

The primary objective of incorporating heptane in asphalt testing is to enhance the accuracy and consistency of hardness and ductility measurements. These properties are critical in predicting the performance of asphalt under various environmental conditions and traffic loads. By utilizing heptane, researchers aim to develop more refined models of asphalt behavior, which can lead to improved road design and longer-lasting pavements.

Another key goal of this research is to establish a correlation between heptane-based test results and the real-world performance of asphalt mixtures. This involves extensive field studies and laboratory experiments to validate the predictive power of heptane-assisted characterization methods. The ultimate aim is to create a robust set of testing protocols that can be widely adopted by the industry, ensuring better quality control and more efficient use of resources in road construction.

Furthermore, the research into heptane use in asphalt testing aligns with broader trends in materials science and engineering. There is a growing emphasis on developing sustainable and environmentally friendly testing methods. Heptane, being a relatively low-toxicity solvent, fits well within this paradigm, potentially offering a safer alternative to some traditional testing chemicals.

As the field progresses, researchers are also exploring the potential of heptane-based tests to provide insights into other aspects of asphalt performance, such as aging characteristics and resistance to thermal cracking. This expansion of scope reflects the evolving needs of the construction industry and the increasing sophistication of road engineering practices.

Market Demand for Advanced Asphalt Characterization Methods

The demand for advanced asphalt characterization methods has been steadily increasing in recent years, driven by the growing need for more durable and sustainable road infrastructure. As urbanization continues to expand globally, there is a pressing requirement for high-performance asphalt materials that can withstand increasing traffic loads and diverse environmental conditions. This has led to a significant market opportunity for innovative testing methods that can accurately assess asphalt properties, particularly hardness and ductility.

The use of heptane in asphalt characterization represents a novel approach that addresses several key market needs. Firstly, there is a strong demand for more precise and reliable testing methods that can predict asphalt performance under various conditions. Traditional testing methods often fall short in providing comprehensive data on asphalt behavior, especially in extreme temperatures or under heavy loads. Heptane-based characterization techniques offer the potential for more nuanced analysis of asphalt properties, enabling better prediction of long-term performance and durability.

Furthermore, the construction industry is increasingly focused on sustainability and cost-effectiveness. This has created a market demand for characterization methods that can optimize asphalt mix designs, reducing material waste and improving overall road longevity. Heptane-based testing could potentially allow for more efficient use of resources by providing detailed insights into asphalt composition and behavior, thereby enabling more targeted and effective mix designs.

The market for advanced asphalt testing equipment and services is also expanding, with a particular emphasis on technologies that can streamline the testing process and provide rapid, accurate results. Heptane-based characterization methods align well with this trend, offering the potential for quicker and more comprehensive analysis compared to some traditional techniques. This efficiency is particularly valuable in large-scale infrastructure projects where time and accuracy are critical factors.

Additionally, there is a growing interest in standardization and quality control across the asphalt industry. Regulatory bodies and construction companies are seeking more robust and consistent methods for assessing asphalt quality. The potential for heptane-based characterization to provide standardized, reproducible results could address this market need, potentially leading to wider adoption across the industry.

In conclusion, the market demand for advanced asphalt characterization methods, particularly those focusing on hardness and ductility, is robust and multifaceted. The potential application of heptane in this field aligns well with industry trends towards more precise, efficient, and comprehensive testing methods. As infrastructure development continues to be a priority globally, the market for innovative asphalt characterization techniques is likely to expand further, presenting significant opportunities for research and development in this area.

The use of heptane in asphalt characterization represents a novel approach that addresses several key market needs. Firstly, there is a strong demand for more precise and reliable testing methods that can predict asphalt performance under various conditions. Traditional testing methods often fall short in providing comprehensive data on asphalt behavior, especially in extreme temperatures or under heavy loads. Heptane-based characterization techniques offer the potential for more nuanced analysis of asphalt properties, enabling better prediction of long-term performance and durability.

Furthermore, the construction industry is increasingly focused on sustainability and cost-effectiveness. This has created a market demand for characterization methods that can optimize asphalt mix designs, reducing material waste and improving overall road longevity. Heptane-based testing could potentially allow for more efficient use of resources by providing detailed insights into asphalt composition and behavior, thereby enabling more targeted and effective mix designs.

The market for advanced asphalt testing equipment and services is also expanding, with a particular emphasis on technologies that can streamline the testing process and provide rapid, accurate results. Heptane-based characterization methods align well with this trend, offering the potential for quicker and more comprehensive analysis compared to some traditional techniques. This efficiency is particularly valuable in large-scale infrastructure projects where time and accuracy are critical factors.

Additionally, there is a growing interest in standardization and quality control across the asphalt industry. Regulatory bodies and construction companies are seeking more robust and consistent methods for assessing asphalt quality. The potential for heptane-based characterization to provide standardized, reproducible results could address this market need, potentially leading to wider adoption across the industry.

In conclusion, the market demand for advanced asphalt characterization methods, particularly those focusing on hardness and ductility, is robust and multifaceted. The potential application of heptane in this field aligns well with industry trends towards more precise, efficient, and comprehensive testing methods. As infrastructure development continues to be a priority globally, the market for innovative asphalt characterization techniques is likely to expand further, presenting significant opportunities for research and development in this area.

Current Challenges in Asphalt Hardness and Ductility Testing

The characterization of asphalt hardness and ductility is crucial for ensuring the quality and performance of road pavements. However, current testing methods face several challenges that limit their accuracy, reliability, and efficiency. One of the primary issues is the lack of standardization across different testing procedures, leading to inconsistent results and difficulties in comparing data from various sources.

Traditional testing methods, such as the penetration test and the ductility test, are time-consuming and often require large sample sizes. This not only increases the cost of testing but also limits the frequency of quality control checks during asphalt production and construction. Additionally, these tests are typically conducted at specific temperatures, which may not accurately represent the wide range of environmental conditions that pavements experience in real-world applications.

The use of empirical correlations between laboratory test results and field performance has been a longstanding practice in asphalt characterization. However, these correlations often fail to account for the complex rheological behavior of asphalt under varying loading conditions and temperatures. This discrepancy can lead to inaccurate predictions of pavement performance and premature failures in the field.

Another significant challenge is the inability of current testing methods to fully capture the viscoelastic properties of asphalt. Asphalt binders exhibit both elastic and viscous behavior, which changes with temperature and loading rate. Conventional tests often focus on a single aspect of this behavior, failing to provide a comprehensive understanding of the material's performance across different conditions.

The aging of asphalt binders during production, construction, and service life is another factor that complicates hardness and ductility testing. Current methods struggle to accurately simulate and quantify the effects of long-term aging on asphalt properties, leading to potential overestimation or underestimation of pavement durability.

Furthermore, the increasing use of modified asphalt binders and recycled materials in pavement construction has introduced new variables that are not adequately addressed by traditional testing methods. These materials often exhibit unique rheological properties that require more sophisticated characterization techniques to fully understand and predict their behavior.

The environmental impact of testing procedures is also becoming a growing concern. Many current methods involve the use of solvents and other chemicals that may pose health and environmental risks. There is a pressing need for more sustainable and eco-friendly testing approaches that can provide accurate results without compromising safety or environmental standards.

Traditional testing methods, such as the penetration test and the ductility test, are time-consuming and often require large sample sizes. This not only increases the cost of testing but also limits the frequency of quality control checks during asphalt production and construction. Additionally, these tests are typically conducted at specific temperatures, which may not accurately represent the wide range of environmental conditions that pavements experience in real-world applications.

The use of empirical correlations between laboratory test results and field performance has been a longstanding practice in asphalt characterization. However, these correlations often fail to account for the complex rheological behavior of asphalt under varying loading conditions and temperatures. This discrepancy can lead to inaccurate predictions of pavement performance and premature failures in the field.

Another significant challenge is the inability of current testing methods to fully capture the viscoelastic properties of asphalt. Asphalt binders exhibit both elastic and viscous behavior, which changes with temperature and loading rate. Conventional tests often focus on a single aspect of this behavior, failing to provide a comprehensive understanding of the material's performance across different conditions.

The aging of asphalt binders during production, construction, and service life is another factor that complicates hardness and ductility testing. Current methods struggle to accurately simulate and quantify the effects of long-term aging on asphalt properties, leading to potential overestimation or underestimation of pavement durability.

Furthermore, the increasing use of modified asphalt binders and recycled materials in pavement construction has introduced new variables that are not adequately addressed by traditional testing methods. These materials often exhibit unique rheological properties that require more sophisticated characterization techniques to fully understand and predict their behavior.

The environmental impact of testing procedures is also becoming a growing concern. Many current methods involve the use of solvents and other chemicals that may pose health and environmental risks. There is a pressing need for more sustainable and eco-friendly testing approaches that can provide accurate results without compromising safety or environmental standards.

Existing Heptane-based Asphalt Testing Methods

01 Heptane as a solvent in material processing

Heptane is used as a solvent in various material processing applications, potentially affecting the hardness and ductility of the final product. Its low boiling point and non-polar nature make it suitable for dissolving certain compounds and facilitating material transformations.- Heptane as a solvent in material processing: Heptane is used as a solvent in various material processing applications, potentially affecting the hardness and ductility of the final product. Its low boiling point and non-polar nature make it suitable for dissolving certain compounds and facilitating material transformations.

- Impact of heptane on polymer properties: The use of heptane in polymer processing can influence the hardness and ductility of the resulting materials. It may affect the crystallization process, molecular arrangement, and overall mechanical properties of polymers, leading to changes in their hardness and ductility characteristics.

- Heptane in metal treatment processes: Heptane is utilized in various metal treatment processes, which can impact the hardness and ductility of metal components. It may be involved in cleaning, degreasing, or as a carrier for other substances that modify metal surface properties.

- Heptane's role in composite material fabrication: In the production of composite materials, heptane may be used as a processing aid or solvent, potentially influencing the interfacial properties between matrix and reinforcement. This can affect the overall hardness and ductility of the composite structure.

- Heptane in surface treatment and coating applications: Heptane is employed in surface treatment and coating processes, which can modify the surface properties of materials. These treatments may alter the hardness and ductility of the surface layer, affecting the overall mechanical behavior of the treated components.

02 Impact of heptane on polymer properties

The use of heptane in polymer processing can influence the hardness and ductility of the resulting materials. It may affect the crystallization process, molecular arrangement, and overall mechanical properties of polymers, leading to changes in their hardness and ductility characteristics.Expand Specific Solutions03 Heptane in metal treatment processes

Heptane is utilized in various metal treatment processes, which can impact the hardness and ductility of metal alloys. Its role in cleaning, degreasing, or as a carrier for other substances may indirectly affect the mechanical properties of treated metals.Expand Specific Solutions04 Heptane's role in composite material fabrication

In the production of composite materials, heptane may be used as a processing aid or solvent, potentially influencing the interfacial properties between matrix and reinforcement. This can lead to variations in the hardness and ductility of the final composite product.Expand Specific Solutions05 Heptane in surface treatment and coating applications

Heptane is employed in surface treatment and coating processes, which can alter the surface properties of materials. These treatments may modify the hardness and ductility of the surface layer, affecting the overall mechanical behavior of the treated materials.Expand Specific Solutions

Key Players in Asphalt Testing Industry

The research on Heptane in asphalt characterization is in a developing stage, with growing market potential due to increasing infrastructure demands. The technology's maturity is moderate, with key players like China Petroleum & Chemical Corp. and ExxonMobil Technology & Engineering Co. leading research efforts. Smaller companies such as Sobute New Materials Co., Ltd. and Sichuan Kelutai Transportation Technology Co., Ltd. are also contributing to advancements. The competitive landscape is diverse, including major oil companies, specialized material firms, and academic institutions like the University of Leeds, indicating a collaborative approach to innovation in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach for characterizing asphalt hardness and ductility using heptane as a solvent. Their method involves fractionating asphalt into different components based on solubility in heptane, allowing for precise analysis of asphalt properties[1]. The process includes carefully controlled heptane extraction, followed by chromatographic separation and spectroscopic analysis of the fractions[3]. This technique enables the company to quantify the distribution of asphaltenes, resins, and other components that influence asphalt performance. By correlating the fractionation results with standardized hardness and ductility tests, Sinopec has created predictive models for asphalt behavior under various conditions[5].

Strengths: Highly accurate characterization of asphalt composition; enables tailored asphalt formulations for specific applications. Weaknesses: Process can be time-consuming and requires specialized equipment; may be less suitable for rapid field testing.

Chevron U.S.A., Inc.

Technical Solution: Chevron U.S.A., Inc. has pioneered a heptane-based micro-extraction technique for rapid assessment of asphalt hardness and ductility. Their method utilizes a small sample of asphalt mixed with a precise volume of heptane under controlled temperature conditions[2]. The resulting solution undergoes centrifugation to separate the heptane-soluble and insoluble fractions. Advanced rheological measurements are then performed on these fractions to determine their viscoelastic properties[4]. Chevron has developed proprietary algorithms that correlate these measurements with conventional hardness and ductility tests, allowing for quick and accurate predictions of asphalt performance. This approach also incorporates machine learning models to improve prediction accuracy over time as more data is collected[6].

Strengths: Rapid analysis with minimal sample preparation; highly scalable for high-throughput testing. Weaknesses: May not capture all nuances of asphalt behavior in extreme conditions; requires ongoing calibration and validation.

Core Innovations in Heptane-Asphalt Interaction Analysis

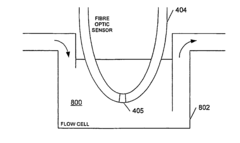

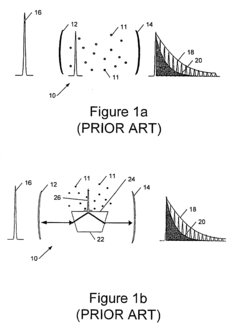

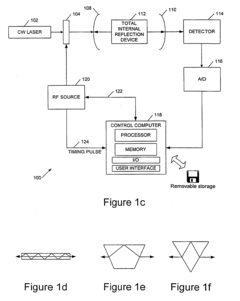

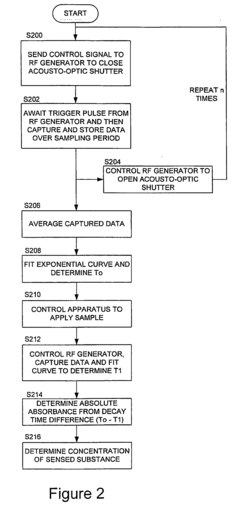

Fluid Monitoring Apparatus and Methods

PatentInactiveUS20110267603A1

Innovation

- The development of a sensor module using evanescent wave techniques, specifically attenuated total internal reflection (ATIR) or other evanescent field sensing apparatus, which includes a fibre optic sensor with a tapered portion to expose the evanescent wave field and a high reflectivity mirror for a two-pass system, allowing for optical determination of fluid conditions.

Asphalt composition

PatentInactiveUS20140305840A1

Innovation

- An asphalt composition incorporating spent adsorbent materials from solvent deasphalting units, including attapulgus clay, alumina, silica, activated carbon, and zeolite catalysts, is integrated with petroleum asphalt, allowing for the recycling and reuse of these materials within the asphalt blending pool, thereby minimizing waste handling demands.

Environmental Impact of Heptane Use in Asphalt Testing

The use of heptane in asphalt testing, while beneficial for characterizing asphalt hardness and ductility, raises significant environmental concerns. Heptane, a volatile organic compound (VOC), can contribute to air pollution and potentially harm human health and ecosystems when released into the environment.

When used in asphalt testing laboratories, heptane emissions can occur during handling, storage, and testing procedures. These emissions contribute to the formation of ground-level ozone, a key component of smog, which can cause respiratory issues and damage vegetation. Additionally, heptane vapors can directly impact indoor air quality in laboratory settings, potentially exposing workers to harmful levels of the chemical.

The disposal of heptane-contaminated materials and waste from asphalt testing also presents environmental challenges. Improper disposal can lead to soil and water contamination, affecting local ecosystems and potentially entering the food chain. Heptane's low water solubility means it can persist in the environment, particularly in soil and sediment, potentially causing long-term ecological impacts.

From a broader perspective, the production and transportation of heptane for asphalt testing purposes contribute to the overall carbon footprint of the construction industry. The petrochemical processes involved in heptane production release greenhouse gases and other pollutants, exacerbating climate change concerns.

To mitigate these environmental impacts, several strategies can be employed. Implementing proper ventilation systems and personal protective equipment in laboratories can reduce worker exposure and minimize indoor air pollution. Adopting closed-loop systems for heptane use and recovery can significantly decrease emissions and waste generation.

Furthermore, exploring alternative, more environmentally friendly solvents or testing methods could potentially reduce or eliminate the need for heptane in asphalt characterization. Research into bio-based solvents or non-solvent based testing techniques could lead to more sustainable practices in the industry.

Regulatory bodies and industry standards organizations play a crucial role in addressing the environmental impact of heptane use. Implementing stricter guidelines for heptane handling, storage, and disposal, as well as encouraging the development and adoption of greener alternatives, can drive positive change in asphalt testing practices.

When used in asphalt testing laboratories, heptane emissions can occur during handling, storage, and testing procedures. These emissions contribute to the formation of ground-level ozone, a key component of smog, which can cause respiratory issues and damage vegetation. Additionally, heptane vapors can directly impact indoor air quality in laboratory settings, potentially exposing workers to harmful levels of the chemical.

The disposal of heptane-contaminated materials and waste from asphalt testing also presents environmental challenges. Improper disposal can lead to soil and water contamination, affecting local ecosystems and potentially entering the food chain. Heptane's low water solubility means it can persist in the environment, particularly in soil and sediment, potentially causing long-term ecological impacts.

From a broader perspective, the production and transportation of heptane for asphalt testing purposes contribute to the overall carbon footprint of the construction industry. The petrochemical processes involved in heptane production release greenhouse gases and other pollutants, exacerbating climate change concerns.

To mitigate these environmental impacts, several strategies can be employed. Implementing proper ventilation systems and personal protective equipment in laboratories can reduce worker exposure and minimize indoor air pollution. Adopting closed-loop systems for heptane use and recovery can significantly decrease emissions and waste generation.

Furthermore, exploring alternative, more environmentally friendly solvents or testing methods could potentially reduce or eliminate the need for heptane in asphalt characterization. Research into bio-based solvents or non-solvent based testing techniques could lead to more sustainable practices in the industry.

Regulatory bodies and industry standards organizations play a crucial role in addressing the environmental impact of heptane use. Implementing stricter guidelines for heptane handling, storage, and disposal, as well as encouraging the development and adoption of greener alternatives, can drive positive change in asphalt testing practices.

Standardization of Heptane-based Asphalt Test Procedures

The standardization of heptane-based asphalt test procedures is crucial for ensuring consistent and reliable results in characterizing asphalt hardness and ductility. This process involves developing and implementing uniform methods for sample preparation, testing conditions, and data analysis across laboratories and research institutions.

One of the primary objectives of standardization is to establish a precise protocol for sample preparation. This includes specifying the optimal concentration of heptane to be used, the mixing time and temperature, and the conditioning period for the asphalt-heptane mixture. By defining these parameters, researchers can minimize variability in test results caused by differences in sample preparation techniques.

Standardization also addresses the testing apparatus and equipment specifications. This encompasses the design and dimensions of testing devices, such as penetrometers for hardness tests and ductilometers for ductility measurements. Calibration procedures for these instruments are also outlined to ensure accuracy and repeatability of results across different laboratories.

Temperature control is another critical aspect of the standardization process. Asphalt properties are highly temperature-dependent, and even small variations can significantly affect test outcomes. Therefore, standardized procedures define precise temperature ranges for conducting tests and specify the use of temperature-controlled chambers or water baths to maintain consistent conditions throughout the testing process.

The standardization effort also focuses on establishing uniform testing protocols. This includes defining the rate of load application in hardness tests, the speed of elongation in ductility tests, and the duration of each test. By standardizing these parameters, researchers can compare results from different studies more effectively and draw more reliable conclusions about asphalt performance.

Data collection and analysis methods are also addressed in the standardization process. This involves specifying the required measurements, the frequency of data collection, and the statistical methods for analyzing and reporting results. Standardized reporting formats ensure that test data is presented consistently across different studies, facilitating easier comparison and meta-analysis of research findings.

Interlaboratory studies play a crucial role in validating and refining standardized procedures. These collaborative efforts involve multiple laboratories performing the same tests on identical samples to assess the reproducibility and repeatability of the methods. The results of these studies help identify potential sources of variability and guide further refinements to the standardized procedures.

One of the primary objectives of standardization is to establish a precise protocol for sample preparation. This includes specifying the optimal concentration of heptane to be used, the mixing time and temperature, and the conditioning period for the asphalt-heptane mixture. By defining these parameters, researchers can minimize variability in test results caused by differences in sample preparation techniques.

Standardization also addresses the testing apparatus and equipment specifications. This encompasses the design and dimensions of testing devices, such as penetrometers for hardness tests and ductilometers for ductility measurements. Calibration procedures for these instruments are also outlined to ensure accuracy and repeatability of results across different laboratories.

Temperature control is another critical aspect of the standardization process. Asphalt properties are highly temperature-dependent, and even small variations can significantly affect test outcomes. Therefore, standardized procedures define precise temperature ranges for conducting tests and specify the use of temperature-controlled chambers or water baths to maintain consistent conditions throughout the testing process.

The standardization effort also focuses on establishing uniform testing protocols. This includes defining the rate of load application in hardness tests, the speed of elongation in ductility tests, and the duration of each test. By standardizing these parameters, researchers can compare results from different studies more effectively and draw more reliable conclusions about asphalt performance.

Data collection and analysis methods are also addressed in the standardization process. This involves specifying the required measurements, the frequency of data collection, and the statistical methods for analyzing and reporting results. Standardized reporting formats ensure that test data is presented consistently across different studies, facilitating easier comparison and meta-analysis of research findings.

Interlaboratory studies play a crucial role in validating and refining standardized procedures. These collaborative efforts involve multiple laboratories performing the same tests on identical samples to assess the reproducibility and repeatability of the methods. The results of these studies help identify potential sources of variability and guide further refinements to the standardized procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!