Role of Heptane in Foam Formation and Stability in Enhanced Oil Recovery

JUL 25, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heptane in EOR: Background and Objectives

Enhanced Oil Recovery (EOR) has become increasingly crucial in the petroleum industry as conventional oil production methods face declining yields. Among the various EOR techniques, foam-assisted methods have gained significant attention due to their potential to improve sweep efficiency and oil displacement. Heptane, a straight-chain alkane with seven carbon atoms, plays a pivotal role in foam formation and stability within EOR processes.

The development of foam-based EOR techniques can be traced back to the 1960s when researchers first recognized the potential of foam to control gas mobility in porous media. Since then, the understanding of foam behavior in oil reservoirs has evolved significantly, with heptane emerging as a key component in recent years. The primary objective of investigating heptane's role in foam formation and stability is to enhance the effectiveness of foam-assisted EOR methods, ultimately leading to increased oil recovery rates and extended reservoir lifespans.

Heptane's importance in EOR stems from its unique properties as a non-polar hydrocarbon. Its molecular structure allows it to interact with both the oil phase and the surfactants used in foam generation, influencing the interfacial properties that govern foam stability. By modulating these interactions, heptane can potentially enhance the foam's ability to withstand high temperatures and salinities often encountered in oil reservoirs.

The technical evolution in this field has seen a shift from simple gas injection methods to more sophisticated foam-based approaches. Early foam EOR techniques focused primarily on surfactant selection and injection strategies. However, recent advancements have highlighted the need for a more comprehensive understanding of the complex interplay between various components, including heptane, in foam systems.

Current research aims to elucidate the mechanisms by which heptane affects foam formation, stability, and propagation in porous media. This includes investigating its impact on foam texture, bubble size distribution, and coalescence rates. Additionally, researchers are exploring how heptane influences the adsorption behavior of surfactants at gas-liquid interfaces, a critical factor in maintaining foam stability under reservoir conditions.

The ultimate goal of this technical research is to develop more efficient and robust foam formulations for EOR applications. By optimizing the role of heptane in these systems, it may be possible to create foams that exhibit enhanced stability, improved mobility control, and greater resistance to adverse reservoir conditions. This, in turn, could lead to significant improvements in oil recovery factors and the economic viability of mature oil fields.

The development of foam-based EOR techniques can be traced back to the 1960s when researchers first recognized the potential of foam to control gas mobility in porous media. Since then, the understanding of foam behavior in oil reservoirs has evolved significantly, with heptane emerging as a key component in recent years. The primary objective of investigating heptane's role in foam formation and stability is to enhance the effectiveness of foam-assisted EOR methods, ultimately leading to increased oil recovery rates and extended reservoir lifespans.

Heptane's importance in EOR stems from its unique properties as a non-polar hydrocarbon. Its molecular structure allows it to interact with both the oil phase and the surfactants used in foam generation, influencing the interfacial properties that govern foam stability. By modulating these interactions, heptane can potentially enhance the foam's ability to withstand high temperatures and salinities often encountered in oil reservoirs.

The technical evolution in this field has seen a shift from simple gas injection methods to more sophisticated foam-based approaches. Early foam EOR techniques focused primarily on surfactant selection and injection strategies. However, recent advancements have highlighted the need for a more comprehensive understanding of the complex interplay between various components, including heptane, in foam systems.

Current research aims to elucidate the mechanisms by which heptane affects foam formation, stability, and propagation in porous media. This includes investigating its impact on foam texture, bubble size distribution, and coalescence rates. Additionally, researchers are exploring how heptane influences the adsorption behavior of surfactants at gas-liquid interfaces, a critical factor in maintaining foam stability under reservoir conditions.

The ultimate goal of this technical research is to develop more efficient and robust foam formulations for EOR applications. By optimizing the role of heptane in these systems, it may be possible to create foams that exhibit enhanced stability, improved mobility control, and greater resistance to adverse reservoir conditions. This, in turn, could lead to significant improvements in oil recovery factors and the economic viability of mature oil fields.

Market Analysis for Heptane-based EOR

The market for heptane-based Enhanced Oil Recovery (EOR) is experiencing significant growth, driven by the increasing global demand for oil and the need to maximize recovery from existing reservoirs. As conventional oil production methods become less effective, EOR techniques, particularly those utilizing heptane-based foams, are gaining traction in the industry.

The global EOR market is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026, with the heptane-based segment showing promising potential. This growth is primarily attributed to the superior performance of heptane in foam formation and stability, which is crucial for effective oil displacement in reservoirs.

North America currently dominates the heptane-based EOR market, accounting for approximately 40% of the global share. This is due to the presence of mature oilfields and a strong focus on technological advancements in the region. The Middle East and Asia-Pacific are emerging as rapidly growing markets, driven by increasing oil production activities and the adoption of advanced EOR techniques.

The demand for heptane in EOR applications is closely tied to crude oil prices. As oil prices recover from recent volatility, investments in EOR projects are expected to rise, further boosting the market for heptane-based solutions. Additionally, the push for more environmentally friendly extraction methods is driving research into optimizing heptane-based foam formulations to reduce chemical usage and improve overall efficiency.

Key market players in the heptane-based EOR sector include major oil and gas companies, as well as specialized chemical manufacturers. These companies are investing heavily in research and development to enhance foam stability and performance, leading to improved oil recovery rates and cost-effectiveness.

The market is also witnessing a trend towards the development of hybrid EOR techniques that combine heptane-based foams with other methods such as gas injection or thermal recovery. This approach aims to leverage the strengths of multiple technologies to achieve higher recovery rates in challenging reservoir conditions.

Despite the positive outlook, the heptane-based EOR market faces challenges such as high initial investment costs and technical complexities associated with foam stability in harsh reservoir environments. However, ongoing research and technological advancements are expected to address these issues, further driving market growth in the coming years.

The global EOR market is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026, with the heptane-based segment showing promising potential. This growth is primarily attributed to the superior performance of heptane in foam formation and stability, which is crucial for effective oil displacement in reservoirs.

North America currently dominates the heptane-based EOR market, accounting for approximately 40% of the global share. This is due to the presence of mature oilfields and a strong focus on technological advancements in the region. The Middle East and Asia-Pacific are emerging as rapidly growing markets, driven by increasing oil production activities and the adoption of advanced EOR techniques.

The demand for heptane in EOR applications is closely tied to crude oil prices. As oil prices recover from recent volatility, investments in EOR projects are expected to rise, further boosting the market for heptane-based solutions. Additionally, the push for more environmentally friendly extraction methods is driving research into optimizing heptane-based foam formulations to reduce chemical usage and improve overall efficiency.

Key market players in the heptane-based EOR sector include major oil and gas companies, as well as specialized chemical manufacturers. These companies are investing heavily in research and development to enhance foam stability and performance, leading to improved oil recovery rates and cost-effectiveness.

The market is also witnessing a trend towards the development of hybrid EOR techniques that combine heptane-based foams with other methods such as gas injection or thermal recovery. This approach aims to leverage the strengths of multiple technologies to achieve higher recovery rates in challenging reservoir conditions.

Despite the positive outlook, the heptane-based EOR market faces challenges such as high initial investment costs and technical complexities associated with foam stability in harsh reservoir environments. However, ongoing research and technological advancements are expected to address these issues, further driving market growth in the coming years.

Current Challenges in Foam EOR

Despite the promising potential of foam-based enhanced oil recovery (EOR) techniques, several significant challenges persist in their widespread implementation and optimization. One of the primary obstacles is the instability of foam in harsh reservoir conditions, particularly in the presence of crude oil and high temperatures. The foam's longevity and effectiveness are often compromised by these factors, leading to reduced sweep efficiency and overall oil recovery.

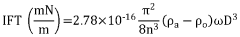

Another critical challenge is the inconsistent foam generation and propagation within heterogeneous reservoir formations. The complex pore structures and varying permeability zones can result in uneven foam distribution, potentially leading to channeling and bypassing of oil-rich regions. This heterogeneity also complicates the prediction and control of foam behavior, making it difficult to design optimal injection strategies.

The selection and formulation of appropriate surfactants for foam generation pose additional challenges. Surfactants must be tailored to specific reservoir conditions, including salinity, temperature, and oil composition. Finding cost-effective surfactants that maintain their foaming ability and stability under these diverse conditions remains a significant hurdle in foam EOR applications.

Furthermore, the interaction between foam and reservoir fluids, particularly crude oil, presents ongoing challenges. The presence of certain oil components can destabilize foam, leading to coalescence and collapse. Understanding and mitigating these oil-foam interactions are crucial for maintaining foam integrity and effectiveness throughout the EOR process.

The optimization of foam quality and texture for maximum oil displacement efficiency is another area of concern. Achieving the right balance between foam stability and mobility control while ensuring adequate oil recovery is a complex task that requires continuous research and refinement.

Lastly, the scaling up of laboratory results to field-scale applications remains a significant challenge. The behavior of foam in core flood experiments often differs from its performance in actual reservoir conditions, making it difficult to accurately predict and optimize field-scale foam EOR operations. Bridging this gap between laboratory findings and field implementation is crucial for the successful deployment of foam EOR technologies.

Another critical challenge is the inconsistent foam generation and propagation within heterogeneous reservoir formations. The complex pore structures and varying permeability zones can result in uneven foam distribution, potentially leading to channeling and bypassing of oil-rich regions. This heterogeneity also complicates the prediction and control of foam behavior, making it difficult to design optimal injection strategies.

The selection and formulation of appropriate surfactants for foam generation pose additional challenges. Surfactants must be tailored to specific reservoir conditions, including salinity, temperature, and oil composition. Finding cost-effective surfactants that maintain their foaming ability and stability under these diverse conditions remains a significant hurdle in foam EOR applications.

Furthermore, the interaction between foam and reservoir fluids, particularly crude oil, presents ongoing challenges. The presence of certain oil components can destabilize foam, leading to coalescence and collapse. Understanding and mitigating these oil-foam interactions are crucial for maintaining foam integrity and effectiveness throughout the EOR process.

The optimization of foam quality and texture for maximum oil displacement efficiency is another area of concern. Achieving the right balance between foam stability and mobility control while ensuring adequate oil recovery is a complex task that requires continuous research and refinement.

Lastly, the scaling up of laboratory results to field-scale applications remains a significant challenge. The behavior of foam in core flood experiments often differs from its performance in actual reservoir conditions, making it difficult to accurately predict and optimize field-scale foam EOR operations. Bridging this gap between laboratory findings and field implementation is crucial for the successful deployment of foam EOR technologies.

Heptane-Foam Interaction Mechanisms

01 Foam formation using heptane and surfactants

Heptane-based foams can be created by combining heptane with suitable surfactants. The surfactants help to stabilize the foam structure by reducing surface tension and creating a barrier between the gas and liquid phases. The choice of surfactant and its concentration are critical factors in determining the foam's stability and properties.- Foam formation using heptane-based compositions: Heptane can be used as a primary component in foam-forming compositions. These compositions often include additional agents such as surfactants or other additives to enhance foam formation and stability. The resulting foam can be used in various applications, including firefighting, oil recovery, and industrial processes.

- Stabilizing agents for heptane-based foams: To improve the stability of heptane-based foams, various stabilizing agents can be incorporated. These may include polymers, nanoparticles, or specialty surfactants that help maintain the foam structure for extended periods. The choice of stabilizing agent depends on the specific application and desired foam properties.

- Environmental and safety considerations for heptane foams: When working with heptane-based foams, it's crucial to consider environmental impact and safety measures. This includes developing formulations with reduced volatile organic compound (VOC) emissions, implementing proper handling procedures, and ensuring compatibility with existing safety protocols in industrial settings.

- Foam generation techniques for heptane-based systems: Various techniques can be employed to generate foam from heptane-based compositions. These may include mechanical agitation, gas injection, or specialized foam-generating devices. The choice of technique affects foam quality, bubble size distribution, and overall stability, which are critical factors in many applications.

- Applications of heptane-based foams: Heptane-based foams find applications in diverse fields such as enhanced oil recovery, fire suppression, insulation, and chemical processing. The specific formulation and foam properties are tailored to meet the requirements of each application, considering factors like expansion ratio, drainage time, and thermal stability.

02 Foam stabilization techniques for heptane-based foams

Various methods can be employed to enhance the stability of heptane foams. These may include the addition of foam stabilizers, such as polymers or nanoparticles, which can strengthen the foam structure and prevent coalescence. Temperature control and pressure regulation can also play a role in maintaining foam stability over extended periods.Expand Specific Solutions03 Heptane foam applications in oil and gas industry

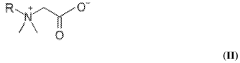

Heptane-based foams find applications in the oil and gas industry, particularly in enhanced oil recovery and well stimulation processes. These foams can be used to improve the efficiency of oil extraction by reducing the mobility of gas or water in reservoirs. The foam's ability to withstand high temperatures and pressures makes it suitable for deep well applications.Expand Specific Solutions04 Characterization and measurement of heptane foam properties

Various techniques and instruments are used to characterize and measure the properties of heptane-based foams. These may include methods for determining foam density, bubble size distribution, drainage rate, and rheological properties. Advanced imaging techniques and computational models can also be employed to study foam structure and behavior under different conditions.Expand Specific Solutions05 Environmental and safety considerations for heptane foams

The use of heptane-based foams requires careful consideration of environmental and safety factors. This includes developing methods for proper handling, storage, and disposal of heptane foams, as well as assessing their potential impact on ecosystems. Research into biodegradable alternatives and environmentally friendly foam formulations is ongoing to address these concerns.Expand Specific Solutions

Key Players in Foam-based EOR

The role of heptane in foam formation and stability for enhanced oil recovery is an emerging area of research in the petroleum industry. The competitive landscape is characterized by a mix of established oil companies, research institutions, and specialized chemical firms. The industry is in a growth phase, with increasing market size driven by the need for more efficient oil extraction methods. Technologically, the field is still developing, with varying levels of maturity among key players. Companies like China Petroleum & Chemical Corp., Saudi Arabian Oil Co., and TotalEnergies SE are leveraging their extensive resources to advance research, while specialized firms such as Dow Global Technologies LLC and Rhodia Operations SASU are contributing innovative chemical solutions. Academic institutions like China University of Petroleum and Southwest Petroleum University are also playing crucial roles in fundamental research and technology development.

China Petroleum & Chemical Corp.

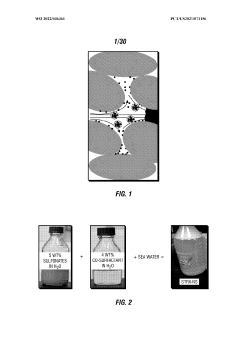

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel foam system incorporating heptane for enhanced oil recovery (EOR). Their approach utilizes a specially formulated surfactant blend that stabilizes heptane-in-water emulsions, creating a robust foam structure. This foam system demonstrates improved stability under high-temperature and high-salinity reservoir conditions [1][3]. The heptane-based foam exhibits a lower interfacial tension with crude oil, facilitating more efficient oil displacement. Sinopec's research indicates that the addition of heptane in optimal concentrations can increase foam half-life by up to 40% compared to conventional aqueous foams [2]. The company has also implemented advanced injection techniques to ensure uniform foam distribution throughout the reservoir, maximizing sweep efficiency and oil recovery rates.

Strengths: Enhanced foam stability in harsh reservoir conditions, improved oil displacement efficiency. Weaknesses: Potential environmental concerns related to heptane use, higher operational costs compared to water-only foams.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has pioneered a heptane-based foam formulation for EOR applications, focusing on its role in foam formation and stability. Their approach involves a proprietary blend of surfactants and polymers that work synergistically with heptane to create a highly stable foam structure. The company's research has shown that incorporating heptane into the foam system can significantly reduce gas mobility and improve sweep efficiency in oil reservoirs [4]. Dow's foam technology utilizes heptane as both a foam-forming agent and a solvent for certain crude oil components, enhancing overall oil recovery. Their studies indicate that heptane-containing foams can maintain stability for up to 72 hours under simulated reservoir conditions, a substantial improvement over conventional foams [5]. Additionally, Dow has developed specialized injection protocols to optimize heptane concentration and foam quality for different reservoir characteristics.

Strengths: Long-lasting foam stability, dual functionality of heptane as foam agent and oil solvent. Weaknesses: Higher initial investment for specialized equipment, potential regulatory challenges in some regions.

Innovations in Heptane-Foam Stability

Enhanced oil recovery method employing a high temperature brine tolerant foam-forming composition

PatentInactiveUS5358045A

Innovation

- A foam-forming composition comprising C10-16 alpha-olefin sulfonate (AOS) surfactants, specifically C10 and C12 AOS, combined with a solubilizing component such as a mixture of alkyl ethoxylates, is injected into the reservoir to enhance brine tolerance and foam propagation, allowing effective recovery of hydrocarbons in formations with high total dissolved solids (TDS) content and elevated temperatures.

3 in 1 foam formulation for enhanced oil recovery including conformance control, ultra-low interfacial tension, and wettability alteration

PatentWO2022036361A1

Innovation

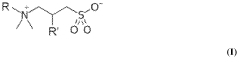

- A nanosurfactant composition comprising sulfonate surfactants, zwitterionic co-surfactants, and mineral oil, formulated to form stable nanoparticles with diameters between 10 nm to 100 nm, which are stable for extended periods at high temperatures and salinity levels, reducing interfacial tension and enhancing oil recovery by efficiently delivering surfactants to oil-water interfaces.

Environmental Impact of Heptane Use

The use of heptane in enhanced oil recovery (EOR) processes, particularly in foam formation and stability, raises significant environmental concerns that warrant careful consideration. Heptane, a hydrocarbon compound, can have various impacts on ecosystems and human health if not properly managed.

One of the primary environmental risks associated with heptane use in EOR is its potential for soil and groundwater contamination. When heptane-containing foams are injected into oil reservoirs, there is a possibility of leakage or migration into surrounding soil and aquifers. This contamination can adversely affect soil microorganisms, plant life, and potentially enter the food chain through agricultural products grown in affected areas.

Aquatic ecosystems are particularly vulnerable to heptane pollution. If heptane-contaminated water reaches rivers, lakes, or coastal areas, it can form a thin film on the water surface, impeding oxygen transfer and disrupting aquatic life. Fish and other marine organisms may suffer from acute toxicity or long-term reproductive issues due to exposure to heptane-polluted waters.

Air quality is another concern related to heptane use in EOR. Volatile organic compounds (VOCs) released during the handling and application of heptane can contribute to smog formation and exacerbate air pollution issues. These emissions may lead to respiratory problems in nearby communities and contribute to the overall degradation of local air quality.

The production and transportation of heptane for EOR purposes also carry environmental risks. Accidental spills during transport or storage can result in immediate environmental damage and require costly cleanup efforts. Moreover, the energy-intensive processes involved in heptane production contribute to greenhouse gas emissions, further impacting global climate change.

From a broader perspective, the reliance on heptane and other hydrocarbon-based chemicals in EOR perpetuates the fossil fuel industry's environmental footprint. This raises questions about the long-term sustainability of such practices in the face of growing global efforts to transition towards cleaner energy sources and reduce carbon emissions.

To mitigate these environmental impacts, industry stakeholders and regulatory bodies must work together to implement stringent safety measures and environmental monitoring protocols. This includes developing more environmentally friendly alternatives to heptane, improving containment and handling procedures, and investing in research to better understand and minimize the ecological footprint of EOR technologies.

One of the primary environmental risks associated with heptane use in EOR is its potential for soil and groundwater contamination. When heptane-containing foams are injected into oil reservoirs, there is a possibility of leakage or migration into surrounding soil and aquifers. This contamination can adversely affect soil microorganisms, plant life, and potentially enter the food chain through agricultural products grown in affected areas.

Aquatic ecosystems are particularly vulnerable to heptane pollution. If heptane-contaminated water reaches rivers, lakes, or coastal areas, it can form a thin film on the water surface, impeding oxygen transfer and disrupting aquatic life. Fish and other marine organisms may suffer from acute toxicity or long-term reproductive issues due to exposure to heptane-polluted waters.

Air quality is another concern related to heptane use in EOR. Volatile organic compounds (VOCs) released during the handling and application of heptane can contribute to smog formation and exacerbate air pollution issues. These emissions may lead to respiratory problems in nearby communities and contribute to the overall degradation of local air quality.

The production and transportation of heptane for EOR purposes also carry environmental risks. Accidental spills during transport or storage can result in immediate environmental damage and require costly cleanup efforts. Moreover, the energy-intensive processes involved in heptane production contribute to greenhouse gas emissions, further impacting global climate change.

From a broader perspective, the reliance on heptane and other hydrocarbon-based chemicals in EOR perpetuates the fossil fuel industry's environmental footprint. This raises questions about the long-term sustainability of such practices in the face of growing global efforts to transition towards cleaner energy sources and reduce carbon emissions.

To mitigate these environmental impacts, industry stakeholders and regulatory bodies must work together to implement stringent safety measures and environmental monitoring protocols. This includes developing more environmentally friendly alternatives to heptane, improving containment and handling procedures, and investing in research to better understand and minimize the ecological footprint of EOR technologies.

Economic Feasibility of Heptane-Foam EOR

The economic feasibility of heptane-foam enhanced oil recovery (EOR) is a critical consideration for oil companies seeking to optimize their production processes. This analysis examines the financial viability of implementing heptane-foam EOR techniques in existing oil fields.

The primary economic advantage of heptane-foam EOR lies in its potential to significantly increase oil recovery rates from mature fields. By improving sweep efficiency and mobilizing residual oil, this technique can extend the productive life of reservoirs that would otherwise be considered economically depleted. This increased recovery translates directly into additional revenue streams for oil companies.

However, the implementation of heptane-foam EOR requires substantial upfront investment. The costs associated with this technique include the procurement of heptane, surfactants, and other chemicals, as well as the necessary infrastructure modifications to existing production facilities. Additionally, specialized equipment for foam generation and injection must be acquired and installed.

Operational expenses for heptane-foam EOR are also a significant factor in its economic feasibility. These include ongoing chemical costs, increased energy consumption for foam generation and injection, and potential increases in water handling and treatment expenses. The complexity of the process may also necessitate additional personnel training or the hiring of specialized staff.

The economic viability of heptane-foam EOR is highly dependent on oil prices. Higher oil prices improve the return on investment for this technique, as the increased production volumes become more valuable. Conversely, in periods of low oil prices, the additional costs associated with heptane-foam EOR may outweigh the benefits of increased recovery.

Environmental regulations and carbon pricing mechanisms also play a role in the economic feasibility of this technique. While heptane-foam EOR can potentially reduce the environmental footprint of oil production by maximizing recovery from existing fields, it may also face scrutiny due to the use of additional chemicals and energy.

The scalability of heptane-foam EOR technology is another important economic consideration. As the technique becomes more widely adopted, economies of scale may reduce implementation costs, making it more accessible to smaller operators and improving overall economic feasibility across the industry.

In conclusion, the economic feasibility of heptane-foam EOR is a complex interplay of increased production potential, implementation costs, operational expenses, oil prices, and regulatory factors. Oil companies must carefully evaluate these aspects in the context of their specific field characteristics and market conditions to determine the viability of this enhanced recovery technique.

The primary economic advantage of heptane-foam EOR lies in its potential to significantly increase oil recovery rates from mature fields. By improving sweep efficiency and mobilizing residual oil, this technique can extend the productive life of reservoirs that would otherwise be considered economically depleted. This increased recovery translates directly into additional revenue streams for oil companies.

However, the implementation of heptane-foam EOR requires substantial upfront investment. The costs associated with this technique include the procurement of heptane, surfactants, and other chemicals, as well as the necessary infrastructure modifications to existing production facilities. Additionally, specialized equipment for foam generation and injection must be acquired and installed.

Operational expenses for heptane-foam EOR are also a significant factor in its economic feasibility. These include ongoing chemical costs, increased energy consumption for foam generation and injection, and potential increases in water handling and treatment expenses. The complexity of the process may also necessitate additional personnel training or the hiring of specialized staff.

The economic viability of heptane-foam EOR is highly dependent on oil prices. Higher oil prices improve the return on investment for this technique, as the increased production volumes become more valuable. Conversely, in periods of low oil prices, the additional costs associated with heptane-foam EOR may outweigh the benefits of increased recovery.

Environmental regulations and carbon pricing mechanisms also play a role in the economic feasibility of this technique. While heptane-foam EOR can potentially reduce the environmental footprint of oil production by maximizing recovery from existing fields, it may also face scrutiny due to the use of additional chemicals and energy.

The scalability of heptane-foam EOR technology is another important economic consideration. As the technique becomes more widely adopted, economies of scale may reduce implementation costs, making it more accessible to smaller operators and improving overall economic feasibility across the industry.

In conclusion, the economic feasibility of heptane-foam EOR is a complex interplay of increased production potential, implementation costs, operational expenses, oil prices, and regulatory factors. Oil companies must carefully evaluate these aspects in the context of their specific field characteristics and market conditions to determine the viability of this enhanced recovery technique.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!