How Heptane Facilitates Synthesis of High-Density Polyethylene

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HDPE Synthesis Background

High-density polyethylene (HDPE) is a versatile thermoplastic polymer with a wide range of applications in various industries. The synthesis of HDPE has evolved significantly since its discovery in the 1950s, driven by the demand for improved material properties and more efficient production processes. The development of HDPE synthesis techniques has been closely linked to advancements in catalysis and polymerization technologies.

The traditional method for HDPE synthesis involves the use of Ziegler-Natta catalysts, which were first developed by Karl Ziegler and Giulio Natta in the 1950s. These catalysts enabled the production of HDPE with high molecular weight and improved mechanical properties. However, the Ziegler-Natta process had limitations in terms of control over polymer structure and molecular weight distribution.

In the 1970s, the introduction of chromium-based Phillips catalysts marked a significant advancement in HDPE synthesis. These catalysts allowed for better control over the polymerization process and resulted in HDPE with enhanced properties, such as improved stiffness and environmental stress crack resistance.

The next major breakthrough came with the development of metallocene catalysts in the 1980s. These single-site catalysts offered unprecedented control over polymer structure, enabling the production of HDPE with tailored properties and narrow molecular weight distributions. Metallocene-catalyzed HDPE exhibited superior mechanical properties and processing characteristics compared to its predecessors.

Recent years have seen further innovations in HDPE synthesis, including the use of post-metallocene catalysts and the development of hybrid catalyst systems. These advancements have focused on improving catalyst activity, enhancing polymer properties, and increasing process efficiency.

The role of heptane in HDPE synthesis has gained attention as researchers and industry professionals seek to optimize the polymerization process. Heptane, a hydrocarbon solvent, has been found to play a crucial role in facilitating the synthesis of high-density polyethylene, particularly in slurry polymerization processes.

Heptane serves as a diluent in the polymerization reaction, helping to control the viscosity of the reaction mixture and prevent agglomeration of polymer particles. Its low boiling point and inert nature make it an ideal medium for HDPE synthesis, allowing for efficient heat transfer and easy separation of the polymer product from the reaction mixture.

Furthermore, heptane influences the morphology and particle size distribution of the resulting HDPE, which can have significant implications for the material's final properties and processability. The use of heptane in HDPE synthesis has contributed to improvements in product quality, process efficiency, and overall economics of production.

As research in this field continues, understanding the intricate role of heptane in HDPE synthesis remains a key focus area. Scientists and engineers are exploring ways to further optimize the use of heptane and similar solvents to enhance HDPE production processes and develop new grades of HDPE with improved performance characteristics.

The traditional method for HDPE synthesis involves the use of Ziegler-Natta catalysts, which were first developed by Karl Ziegler and Giulio Natta in the 1950s. These catalysts enabled the production of HDPE with high molecular weight and improved mechanical properties. However, the Ziegler-Natta process had limitations in terms of control over polymer structure and molecular weight distribution.

In the 1970s, the introduction of chromium-based Phillips catalysts marked a significant advancement in HDPE synthesis. These catalysts allowed for better control over the polymerization process and resulted in HDPE with enhanced properties, such as improved stiffness and environmental stress crack resistance.

The next major breakthrough came with the development of metallocene catalysts in the 1980s. These single-site catalysts offered unprecedented control over polymer structure, enabling the production of HDPE with tailored properties and narrow molecular weight distributions. Metallocene-catalyzed HDPE exhibited superior mechanical properties and processing characteristics compared to its predecessors.

Recent years have seen further innovations in HDPE synthesis, including the use of post-metallocene catalysts and the development of hybrid catalyst systems. These advancements have focused on improving catalyst activity, enhancing polymer properties, and increasing process efficiency.

The role of heptane in HDPE synthesis has gained attention as researchers and industry professionals seek to optimize the polymerization process. Heptane, a hydrocarbon solvent, has been found to play a crucial role in facilitating the synthesis of high-density polyethylene, particularly in slurry polymerization processes.

Heptane serves as a diluent in the polymerization reaction, helping to control the viscosity of the reaction mixture and prevent agglomeration of polymer particles. Its low boiling point and inert nature make it an ideal medium for HDPE synthesis, allowing for efficient heat transfer and easy separation of the polymer product from the reaction mixture.

Furthermore, heptane influences the morphology and particle size distribution of the resulting HDPE, which can have significant implications for the material's final properties and processability. The use of heptane in HDPE synthesis has contributed to improvements in product quality, process efficiency, and overall economics of production.

As research in this field continues, understanding the intricate role of heptane in HDPE synthesis remains a key focus area. Scientists and engineers are exploring ways to further optimize the use of heptane and similar solvents to enhance HDPE production processes and develop new grades of HDPE with improved performance characteristics.

Market Analysis for HDPE

The global High-Density Polyethylene (HDPE) market has been experiencing steady growth, driven by increasing demand across various industries. HDPE, known for its high strength-to-density ratio and chemical resistance, finds extensive applications in packaging, construction, automotive, and consumer goods sectors.

In the packaging industry, HDPE is widely used for producing bottles, containers, and films. The growing e-commerce sector and the shift towards sustainable packaging solutions have further boosted the demand for HDPE. The construction industry utilizes HDPE in pipes, fittings, and geomembranes, benefiting from its durability and resistance to corrosion.

The automotive sector has been incorporating HDPE in vehicle components to reduce weight and improve fuel efficiency. This trend is expected to continue as manufacturers strive to meet stringent emission regulations. In the consumer goods sector, HDPE is used in household products, toys, and personal care packaging, driven by its versatility and recyclability.

Market analysis indicates that Asia-Pacific dominates the HDPE market, with China being the largest consumer and producer. The region's rapid industrialization, urbanization, and growing middle-class population contribute to the increasing demand. North America and Europe follow, with mature markets focusing on technological advancements and sustainable solutions.

The HDPE market is influenced by several factors, including raw material prices, environmental regulations, and technological innovations. The volatility in crude oil prices, a key raw material for HDPE production, impacts the market dynamics. Environmental concerns and plastic waste management issues have led to increased focus on recycling and the development of bio-based alternatives.

Technological advancements in HDPE production, such as the use of heptane as a facilitator in synthesis, are expected to drive market growth. These innovations aim to improve product quality, reduce production costs, and enhance sustainability. The development of metallocene-based HDPE grades with superior properties is also gaining traction in high-performance applications.

The market is characterized by intense competition among major players, leading to continuous product innovations and strategic collaborations. Key market participants are investing in research and development to expand their product portfolios and cater to evolving customer demands. The growing emphasis on circular economy principles is driving investments in recycling infrastructure and the development of recyclable HDPE grades.

In the packaging industry, HDPE is widely used for producing bottles, containers, and films. The growing e-commerce sector and the shift towards sustainable packaging solutions have further boosted the demand for HDPE. The construction industry utilizes HDPE in pipes, fittings, and geomembranes, benefiting from its durability and resistance to corrosion.

The automotive sector has been incorporating HDPE in vehicle components to reduce weight and improve fuel efficiency. This trend is expected to continue as manufacturers strive to meet stringent emission regulations. In the consumer goods sector, HDPE is used in household products, toys, and personal care packaging, driven by its versatility and recyclability.

Market analysis indicates that Asia-Pacific dominates the HDPE market, with China being the largest consumer and producer. The region's rapid industrialization, urbanization, and growing middle-class population contribute to the increasing demand. North America and Europe follow, with mature markets focusing on technological advancements and sustainable solutions.

The HDPE market is influenced by several factors, including raw material prices, environmental regulations, and technological innovations. The volatility in crude oil prices, a key raw material for HDPE production, impacts the market dynamics. Environmental concerns and plastic waste management issues have led to increased focus on recycling and the development of bio-based alternatives.

Technological advancements in HDPE production, such as the use of heptane as a facilitator in synthesis, are expected to drive market growth. These innovations aim to improve product quality, reduce production costs, and enhance sustainability. The development of metallocene-based HDPE grades with superior properties is also gaining traction in high-performance applications.

The market is characterized by intense competition among major players, leading to continuous product innovations and strategic collaborations. Key market participants are investing in research and development to expand their product portfolios and cater to evolving customer demands. The growing emphasis on circular economy principles is driving investments in recycling infrastructure and the development of recyclable HDPE grades.

Heptane in HDPE Production

Heptane plays a crucial role in the synthesis of high-density polyethylene (HDPE), serving as a key component in the production process. This hydrocarbon solvent facilitates the polymerization reaction by providing an inert medium for the ethylene monomers and catalyst to interact effectively. The use of heptane in HDPE production has evolved over time, with continuous improvements in process efficiency and product quality.

In the early stages of HDPE synthesis, researchers discovered that using a hydrocarbon solvent like heptane could significantly enhance the polymerization process. Heptane's low boiling point and chemical inertness made it an ideal choice for maintaining a stable reaction environment. As the technology progressed, manufacturers refined the use of heptane to optimize catalyst activity and control polymer molecular weight distribution.

The role of heptane in HDPE production extends beyond its function as a solvent. It also acts as a heat transfer medium, helping to regulate the temperature of the exothermic polymerization reaction. This temperature control is critical for maintaining consistent product quality and preventing reactor fouling. Additionally, heptane's low viscosity allows for efficient mixing and uniform distribution of catalyst and monomers throughout the reaction vessel.

Recent advancements in HDPE synthesis have focused on improving the efficiency of heptane usage. Researchers have developed novel catalyst systems that require lower heptane-to-ethylene ratios, reducing overall solvent consumption. These innovations not only decrease production costs but also minimize environmental impact by reducing the volume of solvent that needs to be recovered and recycled.

The use of heptane in HDPE production has also enabled the development of specialized grades of polyethylene with enhanced properties. By carefully controlling the heptane concentration and reaction conditions, manufacturers can influence the polymer's crystallinity, molecular weight, and branching characteristics. This level of control allows for the production of HDPE tailored for specific applications, such as high-strength films or durable piping materials.

As environmental concerns grow, the industry is exploring alternatives to traditional heptane-based processes. Some researchers are investigating the use of supercritical carbon dioxide as a replacement for hydrocarbon solvents in polyethylene production. However, heptane remains the preferred choice for many manufacturers due to its proven effectiveness and the substantial investment in existing production infrastructure.

In the early stages of HDPE synthesis, researchers discovered that using a hydrocarbon solvent like heptane could significantly enhance the polymerization process. Heptane's low boiling point and chemical inertness made it an ideal choice for maintaining a stable reaction environment. As the technology progressed, manufacturers refined the use of heptane to optimize catalyst activity and control polymer molecular weight distribution.

The role of heptane in HDPE production extends beyond its function as a solvent. It also acts as a heat transfer medium, helping to regulate the temperature of the exothermic polymerization reaction. This temperature control is critical for maintaining consistent product quality and preventing reactor fouling. Additionally, heptane's low viscosity allows for efficient mixing and uniform distribution of catalyst and monomers throughout the reaction vessel.

Recent advancements in HDPE synthesis have focused on improving the efficiency of heptane usage. Researchers have developed novel catalyst systems that require lower heptane-to-ethylene ratios, reducing overall solvent consumption. These innovations not only decrease production costs but also minimize environmental impact by reducing the volume of solvent that needs to be recovered and recycled.

The use of heptane in HDPE production has also enabled the development of specialized grades of polyethylene with enhanced properties. By carefully controlling the heptane concentration and reaction conditions, manufacturers can influence the polymer's crystallinity, molecular weight, and branching characteristics. This level of control allows for the production of HDPE tailored for specific applications, such as high-strength films or durable piping materials.

As environmental concerns grow, the industry is exploring alternatives to traditional heptane-based processes. Some researchers are investigating the use of supercritical carbon dioxide as a replacement for hydrocarbon solvents in polyethylene production. However, heptane remains the preferred choice for many manufacturers due to its proven effectiveness and the substantial investment in existing production infrastructure.

Current Heptane-Based Methods

01 Measurement of heptane density

Various methods and apparatus are used to measure the density of heptane, which is an important physical property in many industrial applications. These techniques may include pycnometry, hydrometry, or advanced electronic density meters. Accurate measurement of heptane density is crucial for quality control and process optimization in industries such as petrochemicals and fuel production.- Measurement and calculation of heptane density: Various methods are used to measure and calculate the density of heptane, including experimental techniques and theoretical models. These approaches consider factors such as temperature, pressure, and purity of the heptane sample to determine accurate density values.

- Heptane density in separation processes: The density of heptane plays a crucial role in separation processes, particularly in distillation and extraction. Understanding heptane's density helps in designing efficient separation systems and optimizing process parameters for various industrial applications.

- Heptane density in fuel formulations: Heptane's density is an important factor in fuel formulations, especially for gasoline and aviation fuels. The density affects the fuel's energy content, combustion characteristics, and overall performance in engines.

- Influence of temperature on heptane density: Temperature has a significant impact on heptane's density. Understanding this relationship is crucial for accurate measurements and calculations in various applications, including chemical processing and fuel storage.

- Heptane density in polymer and material science: The density of heptane is relevant in polymer and material science applications, such as solvent selection, polymer synthesis, and characterization of materials. It affects the solubility, viscosity, and other properties of polymer solutions and composites.

02 Heptane as a solvent in chemical processes

Heptane is widely used as a solvent in various chemical processes due to its specific density and other properties. Its application ranges from extraction processes to reaction media in organic synthesis. The density of heptane plays a crucial role in determining its effectiveness as a solvent and in the separation of mixtures based on density differences.Expand Specific Solutions03 Density-based separation using heptane

The specific density of heptane is utilized in separation processes, particularly in the petrochemical industry. Density differences between heptane and other hydrocarbons or impurities are exploited to achieve efficient separation in processes such as distillation, liquid-liquid extraction, or density gradient centrifugation.Expand Specific Solutions04 Heptane density in fuel formulations

The density of heptane is a critical factor in fuel formulations, particularly for gasoline and aviation fuels. It affects the energy content, combustion characteristics, and overall performance of the fuel. Precise control and adjustment of heptane density in fuel blends are essential for meeting industry standards and optimizing engine performance.Expand Specific Solutions05 Environmental and safety considerations related to heptane density

The density of heptane is an important parameter in environmental and safety assessments. It influences the behavior of heptane in case of spills or leaks, affecting its spread and potential environmental impact. Understanding heptane density is crucial for developing appropriate handling procedures, storage solutions, and emergency response plans in industries where it is used.Expand Specific Solutions

Key HDPE Manufacturers

The competitive landscape for heptane-facilitated synthesis of high-density polyethylene (HDPE) is characterized by a mature market with significant global players. The industry is in a consolidation phase, with major petrochemical companies dominating the field. Market size for HDPE is substantial, driven by increasing demand in packaging, construction, and automotive sectors. Technologically, the process is well-established, with companies like China Petroleum & Chemical Corp., Saudi Basic Industries Corp., and ExxonMobil Chemical Patents, Inc. leading in innovation. Emerging players such as Univation Technologies LLC and SABIC Global Technologies BV are also making strides in process improvements. The technology's maturity is evident in the involvement of research institutions like King Fahd University of Petroleum & Minerals, indicating a focus on incremental advancements rather than disruptive innovations.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a hybrid slurry-gas phase process for HDPE synthesis that leverages the benefits of heptane. The process begins with a slurry phase reactor using heptane as a diluent, followed by a gas-phase reactor for further polymerization[1]. This two-stage approach allows for precise control over polymer properties and morphology. Sinopec has engineered specialized Ziegler-Natta catalysts that perform optimally in the heptane medium, achieving high activity and selectivity[2]. The company's process incorporates advanced heat recovery systems that utilize the latent heat of heptane vaporization, significantly improving energy efficiency[3]. Sinopec has also implemented a closed-loop heptane recovery system, minimizing solvent losses and environmental impact. The process achieves production rates of up to 400,000 metric tons per year with excellent product consistency[4].

Strengths: Versatile process capable of producing a wide range of HDPE grades, excellent energy efficiency, and high product consistency. Weaknesses: Complexity of managing two reactor systems and potential for inter-reactor fouling.

Saudi Basic Industries Corp.

Technical Solution: Saudi Basic Industries Corp. (SABIC) has developed an advanced loop slurry process for HDPE production utilizing heptane as a diluent. Their technology incorporates a multi-loop reactor system that allows for precise control of residence time and polymer properties[1]. SABIC has engineered proprietary single-site catalysts that exhibit exceptional performance in heptane, enabling the production of HDPE with narrow molecular weight distribution and controlled long-chain branching[2]. The company's process features an innovative heat management system that uses heptane's high heat capacity to maintain optimal reaction temperatures, even at high production rates[3]. SABIC has also implemented advanced polymer particle management techniques, leveraging heptane's properties to control particle size and prevent reactor fouling. The process achieves production rates of up to 550,000 metric tons per year with minimal downtime[4].

Strengths: High production rates, excellent product uniformity, and advanced catalyst technology. Weaknesses: High capital costs associated with multi-loop reactor systems and potential challenges in heptane recovery at large scales.

Heptane Catalysis Mechanisms

process FOR THE POLYMERIZATION OF ETHYLENE

PatentInactiveBR112013007914A2

Innovation

- A process involving a supported chromium oxide catalyst modified with an organic compound containing oxygen and nitrogen, such as saturated heterocyclic compounds or amino alcohols, is used to polymerize ethylene, allowing for variation in molecular weight and distribution while enhancing productivity.

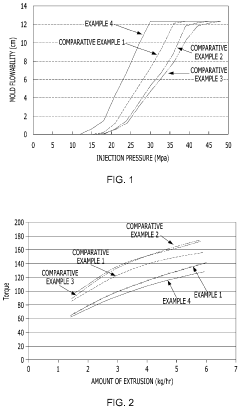

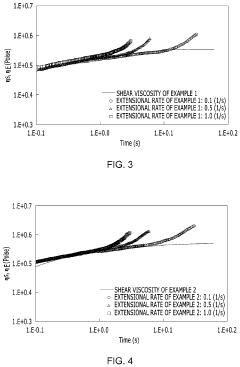

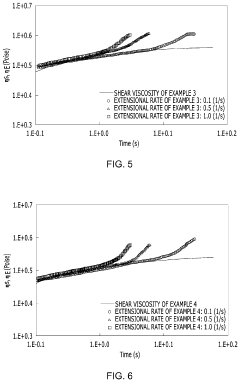

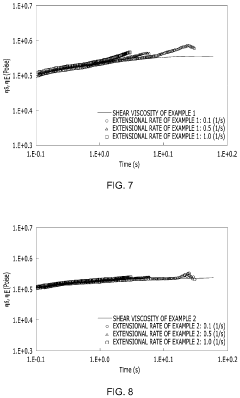

High-density ethylene-based polymer using supported hybrid metallocene catalyst, and manufacturing method therefor

PatentActiveUS10954321B2

Innovation

- A high-density ethylene-based polymer is developed using a supported hybrid metallocene catalyst system comprising specific metallocene compounds and a cocatalyst, which provides a unimodal molecular weight distribution, long chain branched structure, and improved melt flowability, enhancing impact strength, flexural strength, and environmental stress cracking resistance while maintaining high catalyst activity and cost-effectiveness.

Environmental Impact of HDPE

The environmental impact of High-Density Polyethylene (HDPE) production, particularly when facilitated by heptane in the synthesis process, is a complex issue with both positive and negative aspects. The use of heptane as a catalyst in HDPE synthesis has implications for energy efficiency and waste reduction, which can contribute to a more environmentally friendly production process.

One of the primary environmental benefits of using heptane in HDPE synthesis is the potential for increased energy efficiency. Heptane's role as a diluent in the polymerization process allows for better heat transfer and temperature control, which can lead to reduced energy consumption during production. This improved efficiency can result in lower greenhouse gas emissions associated with energy use in manufacturing facilities.

However, the use of heptane also presents environmental challenges. As a volatile organic compound (VOC), heptane can contribute to air pollution if not properly managed. Emissions of heptane during the production process can lead to the formation of ground-level ozone and smog, which have negative impacts on air quality and human health. Strict emission control measures are necessary to mitigate these potential environmental hazards.

The production of HDPE itself has significant environmental implications. While HDPE is a durable and recyclable material, its production relies on fossil fuel resources. The extraction and processing of these raw materials contribute to carbon emissions and environmental degradation. However, the long lifespan and recyclability of HDPE products can offset some of these impacts by reducing the need for frequent replacement and minimizing waste.

Water pollution is another concern in HDPE production. The cooling processes and cleaning of equipment can generate wastewater containing trace amounts of chemicals, including heptane. Proper treatment and disposal of this wastewater are crucial to prevent contamination of local water sources and ecosystems.

On the positive side, advancements in HDPE production techniques, including the use of heptane, have led to improvements in product quality and consistency. This can result in fewer defects and less waste during manufacturing, contributing to overall resource efficiency and waste reduction.

The end-of-life management of HDPE products is a critical aspect of their environmental impact. While HDPE is highly recyclable, the global recycling rates for plastics remain low. Improving recycling infrastructure and promoting circular economy principles can help mitigate the environmental impact of HDPE throughout its lifecycle.

In conclusion, the environmental impact of HDPE production using heptane as a facilitator is multifaceted. While there are potential benefits in terms of energy efficiency and product quality, careful management of emissions, waste, and resource use is essential to minimize negative environmental consequences. Ongoing research and development in sustainable production methods and recycling technologies will be crucial in further reducing the environmental footprint of HDPE.

One of the primary environmental benefits of using heptane in HDPE synthesis is the potential for increased energy efficiency. Heptane's role as a diluent in the polymerization process allows for better heat transfer and temperature control, which can lead to reduced energy consumption during production. This improved efficiency can result in lower greenhouse gas emissions associated with energy use in manufacturing facilities.

However, the use of heptane also presents environmental challenges. As a volatile organic compound (VOC), heptane can contribute to air pollution if not properly managed. Emissions of heptane during the production process can lead to the formation of ground-level ozone and smog, which have negative impacts on air quality and human health. Strict emission control measures are necessary to mitigate these potential environmental hazards.

The production of HDPE itself has significant environmental implications. While HDPE is a durable and recyclable material, its production relies on fossil fuel resources. The extraction and processing of these raw materials contribute to carbon emissions and environmental degradation. However, the long lifespan and recyclability of HDPE products can offset some of these impacts by reducing the need for frequent replacement and minimizing waste.

Water pollution is another concern in HDPE production. The cooling processes and cleaning of equipment can generate wastewater containing trace amounts of chemicals, including heptane. Proper treatment and disposal of this wastewater are crucial to prevent contamination of local water sources and ecosystems.

On the positive side, advancements in HDPE production techniques, including the use of heptane, have led to improvements in product quality and consistency. This can result in fewer defects and less waste during manufacturing, contributing to overall resource efficiency and waste reduction.

The end-of-life management of HDPE products is a critical aspect of their environmental impact. While HDPE is highly recyclable, the global recycling rates for plastics remain low. Improving recycling infrastructure and promoting circular economy principles can help mitigate the environmental impact of HDPE throughout its lifecycle.

In conclusion, the environmental impact of HDPE production using heptane as a facilitator is multifaceted. While there are potential benefits in terms of energy efficiency and product quality, careful management of emissions, waste, and resource use is essential to minimize negative environmental consequences. Ongoing research and development in sustainable production methods and recycling technologies will be crucial in further reducing the environmental footprint of HDPE.

Recycling Technologies for HDPE

Recycling technologies for High-Density Polyethylene (HDPE) have become increasingly important as the world grapples with plastic waste management. HDPE, known for its strength and durability, is widely used in packaging, containers, and various consumer products. However, its persistence in the environment has led to a growing need for effective recycling solutions.

Mechanical recycling remains the most common method for HDPE recycling. This process involves sorting, grinding, washing, and melting the plastic to create new products. While effective for clean and homogeneous HDPE waste, mechanical recycling faces challenges with contaminated or mixed plastic waste. Advanced sorting technologies, such as near-infrared spectroscopy and X-ray fluorescence, have improved the efficiency of this process.

Chemical recycling has emerged as a promising alternative, particularly for contaminated or mixed plastic waste. This approach breaks down HDPE into its chemical components, which can then be used to create new plastics or other chemical products. Pyrolysis, a thermal decomposition process, is one of the most researched chemical recycling methods for HDPE. It converts the plastic into a mixture of hydrocarbons, which can be used as fuel or feedstock for new plastic production.

Solvent-based recycling is another innovative approach gaining traction. This method uses specific solvents to dissolve HDPE, separating it from contaminants and additives. The purified HDPE can then be precipitated and used to create new products. This technique shows promise in maintaining the quality of recycled HDPE, potentially allowing for closed-loop recycling.

Enzymatic recycling, while still in its early stages for HDPE, represents a potential breakthrough in plastic recycling. Researchers are exploring enzymes capable of breaking down HDPE into its monomers, which could then be used to produce new plastic. This bio-based approach could offer a more environmentally friendly alternative to traditional recycling methods.

As recycling technologies advance, there is a growing focus on upcycling HDPE into higher-value products. This includes converting HDPE waste into carbon nanotubes, graphene, or other advanced materials. Such processes not only address the waste problem but also create new economic opportunities in the recycling industry.

The development of these recycling technologies is crucial for creating a circular economy for HDPE. However, challenges remain in scaling up these processes, improving their economic viability, and ensuring the quality of recycled materials meets industry standards. Continued research and investment in these technologies will be essential to address the global plastic waste challenge and promote sustainable use of HDPE.

Mechanical recycling remains the most common method for HDPE recycling. This process involves sorting, grinding, washing, and melting the plastic to create new products. While effective for clean and homogeneous HDPE waste, mechanical recycling faces challenges with contaminated or mixed plastic waste. Advanced sorting technologies, such as near-infrared spectroscopy and X-ray fluorescence, have improved the efficiency of this process.

Chemical recycling has emerged as a promising alternative, particularly for contaminated or mixed plastic waste. This approach breaks down HDPE into its chemical components, which can then be used to create new plastics or other chemical products. Pyrolysis, a thermal decomposition process, is one of the most researched chemical recycling methods for HDPE. It converts the plastic into a mixture of hydrocarbons, which can be used as fuel or feedstock for new plastic production.

Solvent-based recycling is another innovative approach gaining traction. This method uses specific solvents to dissolve HDPE, separating it from contaminants and additives. The purified HDPE can then be precipitated and used to create new products. This technique shows promise in maintaining the quality of recycled HDPE, potentially allowing for closed-loop recycling.

Enzymatic recycling, while still in its early stages for HDPE, represents a potential breakthrough in plastic recycling. Researchers are exploring enzymes capable of breaking down HDPE into its monomers, which could then be used to produce new plastic. This bio-based approach could offer a more environmentally friendly alternative to traditional recycling methods.

As recycling technologies advance, there is a growing focus on upcycling HDPE into higher-value products. This includes converting HDPE waste into carbon nanotubes, graphene, or other advanced materials. Such processes not only address the waste problem but also create new economic opportunities in the recycling industry.

The development of these recycling technologies is crucial for creating a circular economy for HDPE. However, challenges remain in scaling up these processes, improving their economic viability, and ensuring the quality of recycled materials meets industry standards. Continued research and investment in these technologies will be essential to address the global plastic waste challenge and promote sustainable use of HDPE.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!