How Isocyanate Materials Facilitate Advanced Product Development?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution

Isocyanates have undergone a remarkable evolution since their discovery in the late 19th century. Initially synthesized as chemical curiosities, these compounds gained significant industrial importance in the 1930s with the development of polyurethanes. The evolution of isocyanates has been closely tied to advancements in polymer chemistry and materials science.

In the early stages, the focus was primarily on diisocyanates, such as toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI). These compounds formed the backbone of the polyurethane industry, enabling the production of flexible and rigid foams, elastomers, and coatings. As the demand for more specialized materials grew, researchers began exploring modifications to these basic isocyanates.

The 1960s and 1970s saw the development of aliphatic isocyanates, which offered improved weatherability and color stability compared to their aromatic counterparts. This breakthrough expanded the application of isocyanate-based materials in exterior coatings and high-performance elastomers. Concurrently, advancements in catalysis and process technology led to more efficient and controlled polymerization reactions, improving the quality and consistency of isocyanate-derived products.

The 1980s and 1990s marked a shift towards environmentally friendly and safer isocyanate technologies. Water-based polyurethane dispersions were developed, reducing the use of volatile organic compounds (VOCs) in coatings and adhesives. Additionally, blocked isocyanates emerged as a solution for improving handling safety and extending pot life in formulations.

In recent years, the evolution of isocyanates has been driven by sustainability concerns and the need for advanced functional materials. Bio-based isocyanates derived from renewable resources have gained attention as alternatives to petroleum-based products. Researchers are also exploring novel isocyanate chemistries, such as non-migrating isocyanates and self-healing polyurethanes, to enhance material performance and longevity.

The miniaturization trend in electronics and the growing demand for high-performance composites have spurred the development of specialized isocyanates. These include low-viscosity variants for improved impregnation of fibers and nanoparticles, as well as isocyanates with tailored reactivity profiles for precise control over curing processes.

As we look to the future, the evolution of isocyanates continues to be shaped by emerging technologies and global challenges. The integration of isocyanate chemistry with nanotechnology and smart materials promises new functionalities, such as self-cleaning surfaces and adaptive structures. Moreover, ongoing research into safer and more sustainable isocyanate alternatives reflects the industry's commitment to addressing health and environmental concerns while maintaining the versatility and performance that have made isocyanates indispensable in advanced product development.

In the early stages, the focus was primarily on diisocyanates, such as toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI). These compounds formed the backbone of the polyurethane industry, enabling the production of flexible and rigid foams, elastomers, and coatings. As the demand for more specialized materials grew, researchers began exploring modifications to these basic isocyanates.

The 1960s and 1970s saw the development of aliphatic isocyanates, which offered improved weatherability and color stability compared to their aromatic counterparts. This breakthrough expanded the application of isocyanate-based materials in exterior coatings and high-performance elastomers. Concurrently, advancements in catalysis and process technology led to more efficient and controlled polymerization reactions, improving the quality and consistency of isocyanate-derived products.

The 1980s and 1990s marked a shift towards environmentally friendly and safer isocyanate technologies. Water-based polyurethane dispersions were developed, reducing the use of volatile organic compounds (VOCs) in coatings and adhesives. Additionally, blocked isocyanates emerged as a solution for improving handling safety and extending pot life in formulations.

In recent years, the evolution of isocyanates has been driven by sustainability concerns and the need for advanced functional materials. Bio-based isocyanates derived from renewable resources have gained attention as alternatives to petroleum-based products. Researchers are also exploring novel isocyanate chemistries, such as non-migrating isocyanates and self-healing polyurethanes, to enhance material performance and longevity.

The miniaturization trend in electronics and the growing demand for high-performance composites have spurred the development of specialized isocyanates. These include low-viscosity variants for improved impregnation of fibers and nanoparticles, as well as isocyanates with tailored reactivity profiles for precise control over curing processes.

As we look to the future, the evolution of isocyanates continues to be shaped by emerging technologies and global challenges. The integration of isocyanate chemistry with nanotechnology and smart materials promises new functionalities, such as self-cleaning surfaces and adaptive structures. Moreover, ongoing research into safer and more sustainable isocyanate alternatives reflects the industry's commitment to addressing health and environmental concerns while maintaining the versatility and performance that have made isocyanates indispensable in advanced product development.

Market Applications

Isocyanate materials have found extensive applications across various industries, driving advanced product development in numerous sectors. In the automotive industry, these materials play a crucial role in manufacturing lightweight components, contributing to improved fuel efficiency and reduced emissions. Isocyanate-based polyurethanes are widely used in car seats, dashboards, and interior trim, offering superior comfort, durability, and aesthetics. The construction sector heavily relies on isocyanate materials for insulation purposes, enhancing energy efficiency in buildings through spray foam insulation and rigid foam boards.

The footwear industry has embraced isocyanate-based materials for producing high-performance athletic shoes and comfortable casual footwear. These materials provide excellent cushioning, flexibility, and durability, meeting the demands of modern consumers. In the furniture industry, isocyanate-based foams are essential for creating comfortable and long-lasting upholstery, mattresses, and cushions. The ability to mold these materials into complex shapes has revolutionized furniture design and manufacturing processes.

Isocyanate materials have also made significant inroads in the medical field. They are used in the production of medical devices, prosthetics, and wound dressings, leveraging their biocompatibility and versatile properties. The electronics industry utilizes isocyanate-based coatings and adhesives for protecting sensitive components and ensuring the reliability of electronic devices in challenging environments.

The packaging industry benefits from isocyanate materials in the form of flexible and rigid packaging solutions. These materials offer excellent barrier properties, protecting goods from moisture, oxygen, and other external factors. In the aerospace sector, isocyanate-based composites contribute to the development of lightweight yet strong structural components, improving fuel efficiency and performance of aircraft.

The marine industry employs isocyanate materials in boat construction, particularly in the manufacturing of fiberglass reinforced plastics and coatings that provide excellent resistance to water and harsh marine environments. In the sports and leisure sector, these materials are used in the production of equipment such as surfboards, skis, and protective gear, offering a combination of strength, flexibility, and impact resistance.

As environmental concerns grow, the development of bio-based and recyclable isocyanate materials is gaining traction. This trend is opening up new market opportunities in sustainable product development across various industries. The versatility and adaptability of isocyanate materials continue to drive innovation in product design and manufacturing processes, enabling the creation of advanced products that meet evolving consumer demands and regulatory requirements.

The footwear industry has embraced isocyanate-based materials for producing high-performance athletic shoes and comfortable casual footwear. These materials provide excellent cushioning, flexibility, and durability, meeting the demands of modern consumers. In the furniture industry, isocyanate-based foams are essential for creating comfortable and long-lasting upholstery, mattresses, and cushions. The ability to mold these materials into complex shapes has revolutionized furniture design and manufacturing processes.

Isocyanate materials have also made significant inroads in the medical field. They are used in the production of medical devices, prosthetics, and wound dressings, leveraging their biocompatibility and versatile properties. The electronics industry utilizes isocyanate-based coatings and adhesives for protecting sensitive components and ensuring the reliability of electronic devices in challenging environments.

The packaging industry benefits from isocyanate materials in the form of flexible and rigid packaging solutions. These materials offer excellent barrier properties, protecting goods from moisture, oxygen, and other external factors. In the aerospace sector, isocyanate-based composites contribute to the development of lightweight yet strong structural components, improving fuel efficiency and performance of aircraft.

The marine industry employs isocyanate materials in boat construction, particularly in the manufacturing of fiberglass reinforced plastics and coatings that provide excellent resistance to water and harsh marine environments. In the sports and leisure sector, these materials are used in the production of equipment such as surfboards, skis, and protective gear, offering a combination of strength, flexibility, and impact resistance.

As environmental concerns grow, the development of bio-based and recyclable isocyanate materials is gaining traction. This trend is opening up new market opportunities in sustainable product development across various industries. The versatility and adaptability of isocyanate materials continue to drive innovation in product design and manufacturing processes, enabling the creation of advanced products that meet evolving consumer demands and regulatory requirements.

Technical Challenges

The development of isocyanate materials for advanced product applications faces several significant technical challenges. One of the primary obstacles is the inherent reactivity of isocyanates, which can lead to uncontrolled polymerization and compromised product quality. This reactivity, while essential for the formation of polyurethanes, requires precise control to achieve desired material properties and performance characteristics.

Another major challenge lies in the toxicity of isocyanates, particularly during the manufacturing process. Exposure to isocyanates can cause severe respiratory issues and skin irritation, necessitating stringent safety measures and protective equipment. This not only complicates production but also raises concerns about long-term environmental and health impacts, potentially limiting widespread adoption in certain applications.

The moisture sensitivity of isocyanates presents additional difficulties in both processing and storage. Exposure to ambient humidity can trigger unwanted reactions, leading to product defects and reduced shelf life. This sensitivity demands specialized handling and storage conditions, increasing production costs and complexity.

Furthermore, the optimization of isocyanate-based formulations for specific applications remains a significant challenge. Achieving the right balance of properties such as strength, flexibility, thermal stability, and chemical resistance often requires extensive experimentation and fine-tuning. This process can be time-consuming and resource-intensive, particularly when developing materials for novel or highly specialized applications.

The environmental impact of isocyanate production and disposal is another critical concern. Many isocyanates are derived from petroleum-based feedstocks, raising sustainability issues. Additionally, the end-of-life management of isocyanate-containing products poses challenges due to the difficulty in recycling or biodegrading these materials.

Scaling up production while maintaining consistent quality presents its own set of challenges. The sensitive nature of isocyanate reactions means that processes that work well in laboratory settings may not translate directly to large-scale manufacturing. Ensuring uniform mixing, controlling reaction rates, and managing heat generation during polymerization are critical factors that become increasingly complex at industrial scales.

Lastly, regulatory compliance and evolving standards pose ongoing challenges for isocyanate material development. Stricter regulations on chemical use, emissions, and worker safety require continuous adaptation of production processes and product formulations. This regulatory landscape can impact innovation timelines and market entry strategies for new isocyanate-based products.

Another major challenge lies in the toxicity of isocyanates, particularly during the manufacturing process. Exposure to isocyanates can cause severe respiratory issues and skin irritation, necessitating stringent safety measures and protective equipment. This not only complicates production but also raises concerns about long-term environmental and health impacts, potentially limiting widespread adoption in certain applications.

The moisture sensitivity of isocyanates presents additional difficulties in both processing and storage. Exposure to ambient humidity can trigger unwanted reactions, leading to product defects and reduced shelf life. This sensitivity demands specialized handling and storage conditions, increasing production costs and complexity.

Furthermore, the optimization of isocyanate-based formulations for specific applications remains a significant challenge. Achieving the right balance of properties such as strength, flexibility, thermal stability, and chemical resistance often requires extensive experimentation and fine-tuning. This process can be time-consuming and resource-intensive, particularly when developing materials for novel or highly specialized applications.

The environmental impact of isocyanate production and disposal is another critical concern. Many isocyanates are derived from petroleum-based feedstocks, raising sustainability issues. Additionally, the end-of-life management of isocyanate-containing products poses challenges due to the difficulty in recycling or biodegrading these materials.

Scaling up production while maintaining consistent quality presents its own set of challenges. The sensitive nature of isocyanate reactions means that processes that work well in laboratory settings may not translate directly to large-scale manufacturing. Ensuring uniform mixing, controlling reaction rates, and managing heat generation during polymerization are critical factors that become increasingly complex at industrial scales.

Lastly, regulatory compliance and evolving standards pose ongoing challenges for isocyanate material development. Stricter regulations on chemical use, emissions, and worker safety require continuous adaptation of production processes and product formulations. This regulatory landscape can impact innovation timelines and market entry strategies for new isocyanate-based products.

Current Solutions

01 Synthesis and production of isocyanate compounds

Various methods and processes for synthesizing and producing isocyanate compounds are described. These include novel reaction pathways, catalysts, and production techniques to improve yield, purity, and efficiency in the manufacture of isocyanates for industrial applications.- Synthesis and modification of isocyanate compounds: This category focuses on the development of new isocyanate compounds and methods to modify existing ones. It includes techniques for synthesizing novel isocyanate structures, improving their properties, and enhancing their reactivity for various applications.

- Isocyanate-based polyurethane formulations: This area covers the formulation of polyurethane materials using isocyanates as key components. It includes the development of specific polyurethane compositions for various applications, such as coatings, adhesives, foams, and elastomers.

- Isocyanate curing and cross-linking processes: This category deals with the curing and cross-linking mechanisms of isocyanate-containing materials. It includes studies on reaction kinetics, curing agents, and methods to control and optimize the curing process for improved material properties.

- Environmental and safety considerations in isocyanate handling: This area focuses on addressing environmental and safety concerns related to isocyanate materials. It includes the development of low-emission isocyanates, safer handling procedures, and methods to reduce the environmental impact of isocyanate-based products.

- Isocyanate-free alternatives and substitutes: This category explores the development of alternative materials and technologies that can replace traditional isocyanate-based systems. It includes research on bio-based materials, non-isocyanate polyurethanes, and other innovative approaches to achieve similar properties without using isocyanates.

02 Isocyanate-based polymer formulations

Development of polymer formulations using isocyanates as key components. These formulations are used in various applications such as coatings, adhesives, sealants, and elastomers. The focus is on improving properties like durability, flexibility, and chemical resistance of the resulting polymers.Expand Specific Solutions03 Isocyanate curing systems and hardeners

Innovations in curing systems and hardeners for isocyanate-based materials. This includes the development of new curing agents, catalysts, and techniques to enhance the curing process, resulting in improved material properties and performance in various applications.Expand Specific Solutions04 Isocyanate-free alternatives and substitutes

Research and development of alternative materials and technologies to replace traditional isocyanate-based systems. This includes the exploration of bio-based materials, non-toxic substitutes, and novel chemistries to address environmental and health concerns associated with isocyanates.Expand Specific Solutions05 Isocyanate processing and handling techniques

Advancements in processing and handling techniques for isocyanate materials. This encompasses improved safety measures, storage methods, and application technologies to enhance efficiency and reduce risks associated with working with isocyanates in industrial settings.Expand Specific Solutions

Industry Leaders

The isocyanate materials market is in a mature growth stage, with a global market size estimated to exceed $30 billion by 2025. The technology's maturity is evident in its widespread application across industries like automotive, construction, and electronics. Key players such as Wanhua Chemical, BASF, and Covestro are driving innovation in advanced product development. These companies are focusing on improving performance characteristics, sustainability, and cost-effectiveness of isocyanate-based products. The competitive landscape is characterized by intense R&D activities, strategic partnerships, and a growing emphasis on eco-friendly formulations. Emerging players like Momentive Performance Materials and UBE Corp are also making significant contributions, particularly in specialty applications and niche markets.

Wanhua Chemical Group Co., Ltd.

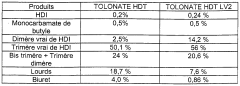

Technical Solution: Wanhua Chemical has made significant strides in isocyanate technology, particularly in the production of methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI). Their innovative WANNATE® series of MDI products offers improved reactivity and processing characteristics for various polyurethane applications[7]. Wanhua has also developed eco-friendly water-blown foam systems that reduce the environmental impact of polyurethane production[8]. In the coatings industry, their aliphatic isocyanates provide excellent durability and color stability for high-performance coatings. Wanhua's continuous investment in R&D has led to breakthroughs in isocyanate production efficiency and product quality[9].

Strengths: Leading global producer of isocyanates with vertically integrated production. Strong focus on sustainability and eco-friendly solutions. Weaknesses: Potential overcapacity in the isocyanate market. Geopolitical risks associated with global trade tensions.

BASF Corp.

Technical Solution: BASF has developed innovative isocyanate-based materials for advanced product development. Their Elastollan® thermoplastic polyurethane (TPU) combines the durability of rubber with the processability of thermoplastics[1]. This material, derived from isocyanates, offers excellent abrasion resistance, high elasticity, and good low-temperature flexibility. BASF has also introduced Elastopan®, a polyurethane system for automotive applications, which provides superior noise and vibration dampening properties[2]. In the construction sector, BASF's Elastospray® roofing systems, based on spray polyurethane foam (SPF) technology, offer excellent insulation and weatherproofing capabilities[3].

Strengths: Wide range of applications across industries, from automotive to construction. High performance materials with customizable properties. Weaknesses: Potential environmental concerns related to isocyanate production and use. Dependency on petrochemical feedstocks.

Key Patents Analysis

Polymers and Their Use as Coatings

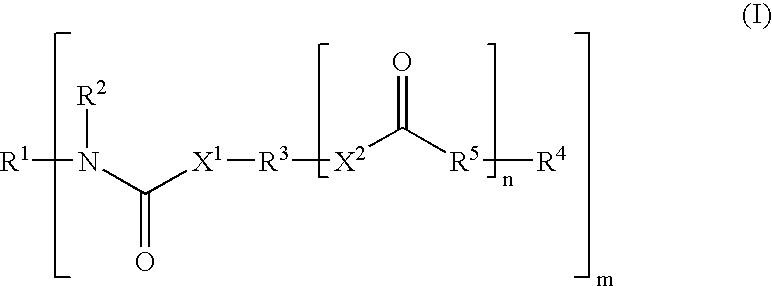

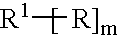

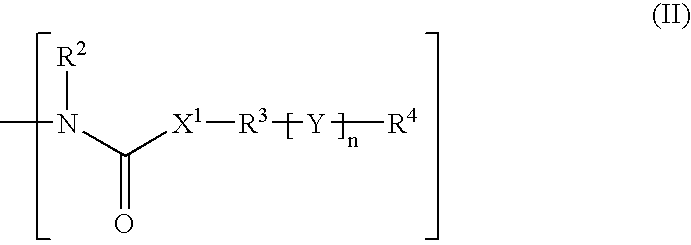

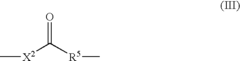

PatentInactiveUS20080026154A1

Innovation

- A process involving the polymerization of lactones or lactams with urethane diols or polyols to create novel polyester diols or polyols, which can then be cross-linked without isocyanates, allowing for the production of polyurethanes with improved flexibility and chemical resistance.

Modified isocyanates

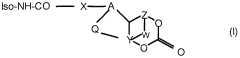

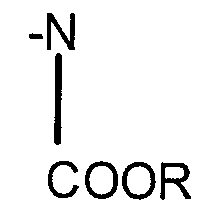

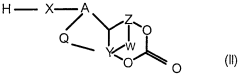

PatentWO2000020477A1

Innovation

- Development of modified isocyanate derivatives with a crosslinking functional group that remains stable and reacts only under specific conditions, allowing for controlled crosslinking reactions without releasing isocyanate functions prematurely, using cyclic carbonates to form stable polyisocyanates that can react with nucleophilic compounds to create coatings and foams.

Environmental Impact

Isocyanate materials, while offering significant benefits in advanced product development, also pose notable environmental concerns. The production and use of isocyanates can contribute to air pollution, particularly through the release of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). These emissions can lead to the formation of ground-level ozone and smog, negatively impacting air quality and human health.

Water contamination is another critical environmental issue associated with isocyanates. Improper disposal or accidental spills can result in these chemicals entering water systems, potentially harming aquatic ecosystems and contaminating drinking water sources. The persistence of some isocyanate compounds in the environment further exacerbates this problem, as they may not readily degrade and can accumulate in soil and water over time.

The energy-intensive nature of isocyanate production also contributes to its environmental footprint. The manufacturing process often relies heavily on fossil fuels, leading to significant greenhouse gas emissions and contributing to climate change. Additionally, the raw materials used in isocyanate production, such as petroleum-based feedstocks, further increase the carbon footprint of these materials.

Waste management presents another environmental challenge. Unused or expired isocyanate products, as well as materials containing isocyanates, require special handling and disposal procedures to prevent environmental contamination. Improper disposal can lead to soil pollution and potential groundwater contamination, posing risks to both ecosystems and human health.

However, it's important to note that efforts are being made to mitigate these environmental impacts. Research into bio-based isocyanates and more sustainable production methods is ongoing, aiming to reduce the reliance on petroleum-based raw materials and decrease overall environmental impact. Additionally, improved waste management practices and stricter regulations on emissions and disposal are being implemented in many regions to minimize the environmental footprint of isocyanate materials.

The development of more environmentally friendly alternatives to traditional isocyanates is also gaining traction. These include non-isocyanate polyurethanes (NIPUs) and other novel materials that aim to provide similar performance characteristics while reducing environmental risks. As the industry continues to evolve, balancing the benefits of isocyanate materials in advanced product development with their environmental impact remains a key challenge and area of focus for researchers and manufacturers alike.

Water contamination is another critical environmental issue associated with isocyanates. Improper disposal or accidental spills can result in these chemicals entering water systems, potentially harming aquatic ecosystems and contaminating drinking water sources. The persistence of some isocyanate compounds in the environment further exacerbates this problem, as they may not readily degrade and can accumulate in soil and water over time.

The energy-intensive nature of isocyanate production also contributes to its environmental footprint. The manufacturing process often relies heavily on fossil fuels, leading to significant greenhouse gas emissions and contributing to climate change. Additionally, the raw materials used in isocyanate production, such as petroleum-based feedstocks, further increase the carbon footprint of these materials.

Waste management presents another environmental challenge. Unused or expired isocyanate products, as well as materials containing isocyanates, require special handling and disposal procedures to prevent environmental contamination. Improper disposal can lead to soil pollution and potential groundwater contamination, posing risks to both ecosystems and human health.

However, it's important to note that efforts are being made to mitigate these environmental impacts. Research into bio-based isocyanates and more sustainable production methods is ongoing, aiming to reduce the reliance on petroleum-based raw materials and decrease overall environmental impact. Additionally, improved waste management practices and stricter regulations on emissions and disposal are being implemented in many regions to minimize the environmental footprint of isocyanate materials.

The development of more environmentally friendly alternatives to traditional isocyanates is also gaining traction. These include non-isocyanate polyurethanes (NIPUs) and other novel materials that aim to provide similar performance characteristics while reducing environmental risks. As the industry continues to evolve, balancing the benefits of isocyanate materials in advanced product development with their environmental impact remains a key challenge and area of focus for researchers and manufacturers alike.

Safety Regulations

Safety regulations play a crucial role in the development and application of isocyanate materials in advanced product manufacturing. These regulations are designed to protect workers, consumers, and the environment from potential hazards associated with isocyanate exposure.

In the United States, the Occupational Safety and Health Administration (OSHA) has established stringent guidelines for handling isocyanates in industrial settings. These regulations mandate the use of personal protective equipment (PPE), including respiratory protection, gloves, and protective clothing. Additionally, OSHA requires employers to implement comprehensive hazard communication programs and provide thorough training to employees working with isocyanates.

The Environmental Protection Agency (EPA) also regulates isocyanates under the Toxic Substances Control Act (TSCA). This legislation aims to control the production, use, and disposal of isocyanate-containing materials to minimize environmental impact. Manufacturers must adhere to strict reporting and record-keeping requirements, as well as implement measures to prevent accidental releases.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register substances and provide detailed safety information. The regulation also imposes restrictions on certain isocyanates, mandating specific risk management measures and authorizations for their use in certain applications.

Japan has implemented the Chemical Substances Control Law, which regulates the manufacture, import, and use of isocyanates. This law requires manufacturers to conduct safety assessments and report potential risks associated with these materials.

To ensure compliance with these regulations, companies developing advanced products using isocyanate materials must invest in robust safety management systems. This includes implementing engineering controls, such as ventilation systems and enclosed production processes, to minimize worker exposure. Regular monitoring of workplace air quality and medical surveillance of employees are also essential components of a comprehensive safety program.

The development of safer alternatives and improved formulations has become a key focus in the isocyanate industry. Manufacturers are exploring low-VOC (volatile organic compound) formulations and water-based systems to reduce potential health and environmental risks. Additionally, research into bio-based isocyanates derived from renewable resources is gaining traction as a more sustainable option.

As regulations continue to evolve, companies must stay informed about changes in safety requirements across different regions. This may involve participating in industry associations, engaging with regulatory bodies, and investing in ongoing employee training and education programs. By prioritizing safety and regulatory compliance, manufacturers can ensure the responsible development and use of isocyanate materials in advanced product applications.

In the United States, the Occupational Safety and Health Administration (OSHA) has established stringent guidelines for handling isocyanates in industrial settings. These regulations mandate the use of personal protective equipment (PPE), including respiratory protection, gloves, and protective clothing. Additionally, OSHA requires employers to implement comprehensive hazard communication programs and provide thorough training to employees working with isocyanates.

The Environmental Protection Agency (EPA) also regulates isocyanates under the Toxic Substances Control Act (TSCA). This legislation aims to control the production, use, and disposal of isocyanate-containing materials to minimize environmental impact. Manufacturers must adhere to strict reporting and record-keeping requirements, as well as implement measures to prevent accidental releases.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register substances and provide detailed safety information. The regulation also imposes restrictions on certain isocyanates, mandating specific risk management measures and authorizations for their use in certain applications.

Japan has implemented the Chemical Substances Control Law, which regulates the manufacture, import, and use of isocyanates. This law requires manufacturers to conduct safety assessments and report potential risks associated with these materials.

To ensure compliance with these regulations, companies developing advanced products using isocyanate materials must invest in robust safety management systems. This includes implementing engineering controls, such as ventilation systems and enclosed production processes, to minimize worker exposure. Regular monitoring of workplace air quality and medical surveillance of employees are also essential components of a comprehensive safety program.

The development of safer alternatives and improved formulations has become a key focus in the isocyanate industry. Manufacturers are exploring low-VOC (volatile organic compound) formulations and water-based systems to reduce potential health and environmental risks. Additionally, research into bio-based isocyanates derived from renewable resources is gaining traction as a more sustainable option.

As regulations continue to evolve, companies must stay informed about changes in safety requirements across different regions. This may involve participating in industry associations, engaging with regulatory bodies, and investing in ongoing employee training and education programs. By prioritizing safety and regulatory compliance, manufacturers can ensure the responsible development and use of isocyanate materials in advanced product applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!