How Isocyanates Align with Circular Economy Objectives?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanates and Circular Economy: Background and Objectives

Isocyanates, a class of highly reactive chemicals, have been integral to various industries for decades, particularly in the production of polyurethanes. As the global focus shifts towards sustainability and circular economy principles, the role of isocyanates in this new paradigm requires careful examination. The circular economy concept aims to eliminate waste, maximize resource efficiency, and promote regenerative practices, challenging traditional linear economic models.

The evolution of isocyanate technology has been marked by significant milestones since its discovery in the 1930s. Initially used in niche applications, isocyanates quickly became essential in the manufacture of foams, coatings, adhesives, and elastomers. The versatility of these compounds has led to their widespread adoption across automotive, construction, furniture, and electronics industries, among others.

However, the increasing emphasis on environmental sustainability has prompted a reevaluation of isocyanate usage. The primary challenge lies in aligning the production and lifecycle of isocyanate-based products with circular economy objectives. This involves addressing issues such as resource consumption, energy efficiency, product longevity, and end-of-life management.

The technical goals in this context are multifaceted. Firstly, there is a push towards developing bio-based isocyanates, reducing reliance on fossil fuel-derived raw materials. Secondly, improving the recyclability and biodegradability of isocyanate-based products is crucial for closing the material loop. Thirdly, enhancing the durability and repairability of these products aligns with the circular economy's principle of extending product lifecycles.

Another significant objective is the reduction of waste and emissions associated with isocyanate production and use. This includes minimizing the release of volatile organic compounds (VOCs) and developing safer handling procedures to protect workers and the environment. Additionally, there is a growing focus on creating isocyanate-free alternatives that can match or exceed the performance of traditional isocyanate-based products.

The alignment of isocyanates with circular economy objectives also necessitates innovations in product design. This involves creating products that are easier to disassemble, recycle, or biodegrade at the end of their useful life. It also requires the development of new business models that prioritize product-as-a-service concepts, encouraging manufacturers to take responsibility for the entire lifecycle of their products.

As we explore the intersection of isocyanates and the circular economy, it becomes clear that achieving these objectives will require collaborative efforts across the value chain. This includes raw material suppliers, manufacturers, end-users, and waste management entities working together to create closed-loop systems. The journey towards aligning isocyanates with circular economy principles represents both a significant challenge and an opportunity for innovation in materials science and industrial processes.

The evolution of isocyanate technology has been marked by significant milestones since its discovery in the 1930s. Initially used in niche applications, isocyanates quickly became essential in the manufacture of foams, coatings, adhesives, and elastomers. The versatility of these compounds has led to their widespread adoption across automotive, construction, furniture, and electronics industries, among others.

However, the increasing emphasis on environmental sustainability has prompted a reevaluation of isocyanate usage. The primary challenge lies in aligning the production and lifecycle of isocyanate-based products with circular economy objectives. This involves addressing issues such as resource consumption, energy efficiency, product longevity, and end-of-life management.

The technical goals in this context are multifaceted. Firstly, there is a push towards developing bio-based isocyanates, reducing reliance on fossil fuel-derived raw materials. Secondly, improving the recyclability and biodegradability of isocyanate-based products is crucial for closing the material loop. Thirdly, enhancing the durability and repairability of these products aligns with the circular economy's principle of extending product lifecycles.

Another significant objective is the reduction of waste and emissions associated with isocyanate production and use. This includes minimizing the release of volatile organic compounds (VOCs) and developing safer handling procedures to protect workers and the environment. Additionally, there is a growing focus on creating isocyanate-free alternatives that can match or exceed the performance of traditional isocyanate-based products.

The alignment of isocyanates with circular economy objectives also necessitates innovations in product design. This involves creating products that are easier to disassemble, recycle, or biodegrade at the end of their useful life. It also requires the development of new business models that prioritize product-as-a-service concepts, encouraging manufacturers to take responsibility for the entire lifecycle of their products.

As we explore the intersection of isocyanates and the circular economy, it becomes clear that achieving these objectives will require collaborative efforts across the value chain. This includes raw material suppliers, manufacturers, end-users, and waste management entities working together to create closed-loop systems. The journey towards aligning isocyanates with circular economy principles represents both a significant challenge and an opportunity for innovation in materials science and industrial processes.

Market Demand for Sustainable Isocyanate Solutions

The market demand for sustainable isocyanate solutions has been steadily growing in recent years, driven by increasing environmental concerns and regulatory pressures. Isocyanates, widely used in the production of polyurethanes, have traditionally been associated with environmental and health risks. However, the shift towards circular economy principles has created a significant opportunity for sustainable alternatives.

Consumer awareness and preference for eco-friendly products have been key drivers in this market trend. End-users across various industries, including automotive, construction, and furniture, are actively seeking materials that align with sustainability goals. This has led to a surge in demand for bio-based and recyclable isocyanate alternatives that can maintain or improve upon the performance characteristics of traditional isocyanates.

The construction sector, in particular, has shown a strong interest in sustainable isocyanate solutions. With the global push for green buildings and energy-efficient structures, there is a growing need for insulation materials and adhesives that meet both performance and environmental criteria. Sustainable isocyanates offer improved thermal insulation properties while reducing the carbon footprint of buildings.

In the automotive industry, the demand for lightweight materials to improve fuel efficiency has intersected with sustainability requirements. Manufacturers are looking for isocyanate-based components that are not only lighter but also recyclable or biodegradable at the end of the vehicle's life cycle. This has opened up new market opportunities for innovative isocyanate formulations that can be easily disassembled and reprocessed.

The packaging industry has also emerged as a significant market for sustainable isocyanate solutions. With the increasing focus on reducing plastic waste, there is a growing demand for biodegradable packaging materials that can maintain the protective properties of traditional plastics. Isocyanate-based biodegradable films and coatings are gaining traction in this sector.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for sustainable isocyanate solutions. This is primarily due to rapid industrialization, stringent environmental regulations, and increasing adoption of green technologies in countries like China and India. North America and Europe continue to be significant markets, driven by established environmental policies and consumer preferences for sustainable products.

The market demand is further bolstered by collaborations between chemical companies and end-users to develop tailored sustainable solutions. These partnerships are accelerating the development and adoption of circular economy-aligned isocyanate products, creating a positive feedback loop that further stimulates market growth and innovation in this sector.

Consumer awareness and preference for eco-friendly products have been key drivers in this market trend. End-users across various industries, including automotive, construction, and furniture, are actively seeking materials that align with sustainability goals. This has led to a surge in demand for bio-based and recyclable isocyanate alternatives that can maintain or improve upon the performance characteristics of traditional isocyanates.

The construction sector, in particular, has shown a strong interest in sustainable isocyanate solutions. With the global push for green buildings and energy-efficient structures, there is a growing need for insulation materials and adhesives that meet both performance and environmental criteria. Sustainable isocyanates offer improved thermal insulation properties while reducing the carbon footprint of buildings.

In the automotive industry, the demand for lightweight materials to improve fuel efficiency has intersected with sustainability requirements. Manufacturers are looking for isocyanate-based components that are not only lighter but also recyclable or biodegradable at the end of the vehicle's life cycle. This has opened up new market opportunities for innovative isocyanate formulations that can be easily disassembled and reprocessed.

The packaging industry has also emerged as a significant market for sustainable isocyanate solutions. With the increasing focus on reducing plastic waste, there is a growing demand for biodegradable packaging materials that can maintain the protective properties of traditional plastics. Isocyanate-based biodegradable films and coatings are gaining traction in this sector.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for sustainable isocyanate solutions. This is primarily due to rapid industrialization, stringent environmental regulations, and increasing adoption of green technologies in countries like China and India. North America and Europe continue to be significant markets, driven by established environmental policies and consumer preferences for sustainable products.

The market demand is further bolstered by collaborations between chemical companies and end-users to develop tailored sustainable solutions. These partnerships are accelerating the development and adoption of circular economy-aligned isocyanate products, creating a positive feedback loop that further stimulates market growth and innovation in this sector.

Current Challenges in Isocyanate Circularity

The circular economy objectives for isocyanates face several significant challenges that hinder their full implementation. One of the primary obstacles is the complex chemical nature of isocyanates, which makes them difficult to recycle or reuse without compromising their performance characteristics. Isocyanates are highly reactive compounds, and once they are incorporated into polyurethane products, they undergo irreversible chemical reactions, making it challenging to recover them in their original form.

Another major challenge is the lack of efficient and cost-effective recycling technologies specifically designed for isocyanate-based materials. Current recycling methods often result in downcycling, where the recovered materials have lower quality and limited applications compared to virgin isocyanates. This limitation reduces the economic viability of recycling efforts and discourages widespread adoption of circular practices in the industry.

The presence of additives, fillers, and other components in isocyanate-containing products further complicates the recycling process. Separating these various materials to obtain pure isocyanates or their precursors is technically challenging and often energy-intensive, which can offset the environmental benefits of recycling.

Safety concerns also pose a significant challenge in isocyanate circularity. Isocyanates are known for their potential health hazards, particularly respiratory sensitization. Handling and processing recycled isocyanates require stringent safety measures, which can increase operational costs and complexity for recycling facilities.

The global supply chain and diverse applications of isocyanates create logistical challenges for implementing circular economy practices. Collecting, sorting, and transporting used isocyanate-containing products from various sources to centralized recycling facilities can be both economically and environmentally costly.

Regulatory frameworks and standards for recycled isocyanates are still evolving, creating uncertainty for manufacturers and recyclers. The lack of clear guidelines on the use of recycled isocyanates in different applications can hinder investment in circular economy initiatives.

Lastly, market acceptance of recycled isocyanates remains a challenge. Many industries have strict quality requirements, and there may be hesitation to use recycled materials in high-performance applications. Overcoming this perception barrier and demonstrating the reliability and consistency of recycled isocyanates is crucial for closing the loop in their lifecycle.

Another major challenge is the lack of efficient and cost-effective recycling technologies specifically designed for isocyanate-based materials. Current recycling methods often result in downcycling, where the recovered materials have lower quality and limited applications compared to virgin isocyanates. This limitation reduces the economic viability of recycling efforts and discourages widespread adoption of circular practices in the industry.

The presence of additives, fillers, and other components in isocyanate-containing products further complicates the recycling process. Separating these various materials to obtain pure isocyanates or their precursors is technically challenging and often energy-intensive, which can offset the environmental benefits of recycling.

Safety concerns also pose a significant challenge in isocyanate circularity. Isocyanates are known for their potential health hazards, particularly respiratory sensitization. Handling and processing recycled isocyanates require stringent safety measures, which can increase operational costs and complexity for recycling facilities.

The global supply chain and diverse applications of isocyanates create logistical challenges for implementing circular economy practices. Collecting, sorting, and transporting used isocyanate-containing products from various sources to centralized recycling facilities can be both economically and environmentally costly.

Regulatory frameworks and standards for recycled isocyanates are still evolving, creating uncertainty for manufacturers and recyclers. The lack of clear guidelines on the use of recycled isocyanates in different applications can hinder investment in circular economy initiatives.

Lastly, market acceptance of recycled isocyanates remains a challenge. Many industries have strict quality requirements, and there may be hesitation to use recycled materials in high-performance applications. Overcoming this perception barrier and demonstrating the reliability and consistency of recycled isocyanates is crucial for closing the loop in their lifecycle.

Existing Circular Solutions for Isocyanates

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel reaction pathways, catalysts, and production techniques to improve yield, purity, and efficiency in isocyanate manufacturing.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel reaction pathways, catalysts, and production techniques to improve yield, purity, and efficiency in isocyanate manufacturing.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents discuss various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.

- Isocyanate-based catalysts and reaction modifiers: Several patents focus on the development of isocyanate-based catalysts and reaction modifiers. These compounds are used to enhance chemical reactions, improve product properties, or catalyze specific transformations in various industrial processes.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, patents address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer formulations for industrial use.

- Isocyanate-free alternatives and substitutes: Some patents explore alternatives to traditional isocyanates, aiming to develop more environmentally friendly or less hazardous options. This includes novel chemistries, bio-based substitutes, and alternative crosslinking agents for various applications.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.Expand Specific Solutions03 Isocyanate-based catalysts and reaction modifiers

Several patents focus on the development of isocyanate-based catalysts and reaction modifiers. These compounds are used to enhance chemical reactions, improve product properties, or facilitate specific industrial processes.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, patents in this category address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer formulations for various applications.Expand Specific Solutions05 Isocyanate-free alternatives and substitutes

Some patents describe the development of isocyanate-free alternatives or substitutes for traditional isocyanate-based products. These innovations aim to address environmental and health concerns associated with isocyanates while maintaining similar performance characteristics.Expand Specific Solutions

Key Players in Isocyanate Production and Recycling

The isocyanates market is in a mature growth stage, with a global market size estimated at over $30 billion. The technology's maturity is evident in the involvement of major chemical companies like BASF, Wanhua Chemical, Covestro, and Mitsui Chemicals, who have established production capabilities and product portfolios. However, the industry faces challenges in aligning with circular economy objectives, driving research into bio-based alternatives and recycling technologies. Companies are investing in sustainable production methods and exploring new applications to maintain growth. The competitive landscape is characterized by ongoing innovation efforts to improve environmental performance and meet evolving regulatory standards, with a focus on developing more sustainable isocyanate products.

BASF Corp.

Technical Solution: BASF has developed a novel approach to align isocyanates with circular economy objectives through their ChemCycling™ project. This initiative focuses on chemical recycling of plastic waste, including polyurethanes made from isocyanates. The process involves converting plastic waste into pyrolysis oil, which is then used as a feedstock for new chemical products, including isocyanates[1]. BASF has also introduced bio-based isocyanates, derived from renewable raw materials, reducing the reliance on fossil resources[2]. Additionally, they have developed water-based polyurethane systems that significantly reduce VOC emissions and improve the overall environmental footprint of isocyanate-based products[3].

Strengths: Innovative recycling technology, bio-based alternatives, and reduced environmental impact. Weaknesses: Potential high costs associated with new technologies and the need for extensive waste collection and sorting infrastructure.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has made significant strides in aligning isocyanates with circular economy principles. They have developed a proprietary technology called "RENUVA™" for recycling polyurethane foam waste back into its original polyol and isocyanate components[4]. This closed-loop system allows for the reuse of materials that would otherwise end up in landfills. Wanhua has also invested in bio-based isocyanates, utilizing plant-based feedstocks to reduce the carbon footprint of their products[5]. Furthermore, they have implemented energy-efficient production processes that minimize waste and emissions during isocyanate manufacturing[6].

Strengths: Advanced recycling technology, bio-based alternatives, and improved production efficiency. Weaknesses: Dependence on the availability of suitable waste streams and potential quality variations in recycled materials.

Innovative Approaches to Isocyanate Recycling and Reuse

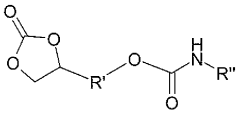

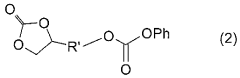

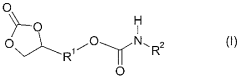

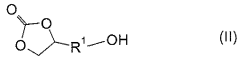

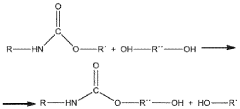

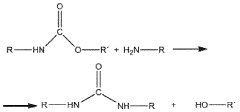

Method for producing carbonate-terminated urethanes

PatentWO2008142100A1

Innovation

- A process involving the reaction of compounds with isocyanates, avoiding the formation of phenol as a secondary component, resulting in an atom-economical complete yield without further secondary components.

Method for isocyanate and polyurethane production with improved sustainability

PatentWO2021089737A1

Innovation

- A process that recycles polyurethane waste through pyrolysis and reverse water gas shift reaction, utilizing renewable energy for hydrogen and oxygen production, and closed-loop carbon dioxide recycling to produce isocyanates and polyurethanes, reducing fossil raw material use and carbon emissions.

Environmental Impact Assessment of Circular Isocyanate Practices

The environmental impact assessment of circular isocyanate practices is crucial for evaluating the alignment of isocyanates with circular economy objectives. This assessment encompasses various aspects of the isocyanate lifecycle, from production to disposal, and considers the potential benefits and challenges of implementing circular practices.

One of the primary environmental concerns associated with traditional isocyanate production is the use of fossil fuel-based raw materials. Circular practices aim to address this issue by exploring alternative feedstocks, such as bio-based materials or recycled content. By reducing reliance on non-renewable resources, circular isocyanate production can significantly lower carbon emissions and overall environmental footprint.

The manufacturing process of isocyanates also presents opportunities for improvement through circular practices. Implementing closed-loop systems and optimizing production efficiency can minimize waste generation and energy consumption. Additionally, the recovery and reuse of solvents and by-products can further reduce the environmental impact of isocyanate production.

In the application phase, circular isocyanate practices focus on extending product lifespans and improving recyclability. This may involve designing products with easier disassembly, using mono-material components, or developing reversible chemistries that allow for efficient material recovery at the end of life. Such approaches can significantly reduce waste and conserve resources.

End-of-life management is a critical aspect of the environmental impact assessment for circular isocyanate practices. Traditional disposal methods, such as incineration or landfilling, can lead to harmful emissions and soil contamination. Circular practices aim to establish effective collection and recycling systems for isocyanate-based products, potentially through chemical recycling processes that break down polymers into their constituent monomers for reuse.

Water and soil pollution risks associated with isocyanates are also addressed through circular practices. By implementing more efficient production methods and closed-loop systems, the potential for accidental releases and environmental contamination can be minimized. Furthermore, the development of safer, less toxic alternatives to traditional isocyanates aligns with circular economy principles and can reduce overall environmental risks.

The assessment also considers the potential for reducing greenhouse gas emissions through circular isocyanate practices. This includes not only the direct emissions from production but also the indirect emissions associated with transportation and energy use throughout the supply chain. By localizing production, optimizing logistics, and transitioning to renewable energy sources, circular practices can contribute to significant reductions in the carbon footprint of isocyanate-based products.

One of the primary environmental concerns associated with traditional isocyanate production is the use of fossil fuel-based raw materials. Circular practices aim to address this issue by exploring alternative feedstocks, such as bio-based materials or recycled content. By reducing reliance on non-renewable resources, circular isocyanate production can significantly lower carbon emissions and overall environmental footprint.

The manufacturing process of isocyanates also presents opportunities for improvement through circular practices. Implementing closed-loop systems and optimizing production efficiency can minimize waste generation and energy consumption. Additionally, the recovery and reuse of solvents and by-products can further reduce the environmental impact of isocyanate production.

In the application phase, circular isocyanate practices focus on extending product lifespans and improving recyclability. This may involve designing products with easier disassembly, using mono-material components, or developing reversible chemistries that allow for efficient material recovery at the end of life. Such approaches can significantly reduce waste and conserve resources.

End-of-life management is a critical aspect of the environmental impact assessment for circular isocyanate practices. Traditional disposal methods, such as incineration or landfilling, can lead to harmful emissions and soil contamination. Circular practices aim to establish effective collection and recycling systems for isocyanate-based products, potentially through chemical recycling processes that break down polymers into their constituent monomers for reuse.

Water and soil pollution risks associated with isocyanates are also addressed through circular practices. By implementing more efficient production methods and closed-loop systems, the potential for accidental releases and environmental contamination can be minimized. Furthermore, the development of safer, less toxic alternatives to traditional isocyanates aligns with circular economy principles and can reduce overall environmental risks.

The assessment also considers the potential for reducing greenhouse gas emissions through circular isocyanate practices. This includes not only the direct emissions from production but also the indirect emissions associated with transportation and energy use throughout the supply chain. By localizing production, optimizing logistics, and transitioning to renewable energy sources, circular practices can contribute to significant reductions in the carbon footprint of isocyanate-based products.

Regulatory Framework for Circular Isocyanate Management

The regulatory framework for circular isocyanate management is a critical component in aligning isocyanates with circular economy objectives. As governments and international organizations increasingly prioritize sustainability and resource efficiency, the regulatory landscape for isocyanates is evolving to support circular economy principles.

At the forefront of this regulatory shift is the European Union's Circular Economy Action Plan, which sets ambitious targets for waste reduction and resource efficiency across various industries. Within this framework, specific regulations are being developed to address the unique challenges posed by isocyanates in the circular economy context.

One key aspect of the regulatory framework is the implementation of Extended Producer Responsibility (EPR) schemes for isocyanate-containing products. These schemes require manufacturers to take responsibility for the entire lifecycle of their products, including collection, recycling, and disposal. This approach incentivizes the design of products that are easier to recycle and promotes the development of more efficient recycling technologies for isocyanates.

Regulations are also being put in place to encourage the use of recycled isocyanates in new products. For instance, the European Chemicals Agency (ECHA) is working on guidelines for the safe use of recycled materials containing isocyanates, addressing concerns about potential contamination and ensuring the quality of recycled content.

Furthermore, regulatory bodies are focusing on the development of standards for the safe handling and recycling of isocyanate-containing waste. These standards aim to minimize environmental and health risks associated with isocyanate recycling processes while maximizing resource recovery.

The regulatory framework also includes measures to promote transparency and traceability in the isocyanate supply chain. This includes requirements for detailed product labeling and the implementation of digital tracking systems to monitor the flow of isocyanates throughout their lifecycle.

To support the transition to a circular economy for isocyanates, regulatory bodies are also providing incentives for research and development in innovative recycling technologies. This includes funding programs and tax incentives for companies investing in circular economy solutions for isocyanates.

As the regulatory framework continues to evolve, it is expected to drive significant changes in the isocyanate industry, pushing manufacturers towards more sustainable practices and encouraging the development of circular business models. This regulatory push, combined with market demands for sustainable products, is likely to accelerate the alignment of isocyanates with circular economy objectives in the coming years.

At the forefront of this regulatory shift is the European Union's Circular Economy Action Plan, which sets ambitious targets for waste reduction and resource efficiency across various industries. Within this framework, specific regulations are being developed to address the unique challenges posed by isocyanates in the circular economy context.

One key aspect of the regulatory framework is the implementation of Extended Producer Responsibility (EPR) schemes for isocyanate-containing products. These schemes require manufacturers to take responsibility for the entire lifecycle of their products, including collection, recycling, and disposal. This approach incentivizes the design of products that are easier to recycle and promotes the development of more efficient recycling technologies for isocyanates.

Regulations are also being put in place to encourage the use of recycled isocyanates in new products. For instance, the European Chemicals Agency (ECHA) is working on guidelines for the safe use of recycled materials containing isocyanates, addressing concerns about potential contamination and ensuring the quality of recycled content.

Furthermore, regulatory bodies are focusing on the development of standards for the safe handling and recycling of isocyanate-containing waste. These standards aim to minimize environmental and health risks associated with isocyanate recycling processes while maximizing resource recovery.

The regulatory framework also includes measures to promote transparency and traceability in the isocyanate supply chain. This includes requirements for detailed product labeling and the implementation of digital tracking systems to monitor the flow of isocyanates throughout their lifecycle.

To support the transition to a circular economy for isocyanates, regulatory bodies are also providing incentives for research and development in innovative recycling technologies. This includes funding programs and tax incentives for companies investing in circular economy solutions for isocyanates.

As the regulatory framework continues to evolve, it is expected to drive significant changes in the isocyanate industry, pushing manufacturers towards more sustainable practices and encouraging the development of circular business models. This regulatory push, combined with market demands for sustainable products, is likely to accelerate the alignment of isocyanates with circular economy objectives in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!