How Isocyanates Define New Frontiers in Healthcare?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution in Healthcare

Isocyanates have undergone a remarkable evolution in healthcare, transforming from industrial chemicals to versatile components in medical applications. Initially developed for polyurethane production, these compounds have found their way into various healthcare sectors, revolutionizing patient care and treatment methodologies.

The journey of isocyanates in healthcare began in the mid-20th century when researchers discovered their potential in biomaterials. Early applications focused on developing biocompatible polyurethanes for medical devices, such as catheters and artificial heart valves. These materials offered superior mechanical properties and durability compared to traditional options, marking a significant advancement in medical technology.

As research progressed, the 1980s and 1990s saw a surge in isocyanate-based biomaterials for tissue engineering and regenerative medicine. Scientists explored their use in creating scaffolds for cell growth and tissue regeneration, opening new avenues for treating injuries and degenerative conditions. This period also witnessed the development of isocyanate-derived hydrogels, which found applications in drug delivery systems and wound dressings.

The turn of the millennium brought about a paradigm shift in isocyanate utilization within healthcare. Researchers began focusing on modifying isocyanate chemistry to enhance biocompatibility and reduce potential toxicity concerns. This led to the creation of novel biodegradable polyurethanes and shape-memory polymers, expanding their applications in minimally invasive surgical procedures and personalized medicine.

In recent years, the integration of nanotechnology with isocyanate chemistry has pushed the boundaries of healthcare innovation. Nanostructured isocyanate-based materials have shown promise in targeted drug delivery, biosensors, and advanced imaging techniques. These developments have significantly improved diagnostic accuracy and treatment efficacy across various medical fields.

The evolution of isocyanates in healthcare has also been marked by a growing emphasis on sustainability and environmental considerations. Researchers are now exploring bio-based isocyanates derived from renewable resources, aligning with the global push towards greener technologies in the medical sector.

As we look to the future, the trajectory of isocyanates in healthcare continues to ascend. Emerging trends include their application in 3D bioprinting, smart materials for responsive drug release, and advanced wound care solutions. The ongoing research into isocyanate chemistry promises to unlock new frontiers in personalized medicine, regenerative therapies, and non-invasive diagnostic tools, further cementing their role as a cornerstone of modern healthcare innovation.

The journey of isocyanates in healthcare began in the mid-20th century when researchers discovered their potential in biomaterials. Early applications focused on developing biocompatible polyurethanes for medical devices, such as catheters and artificial heart valves. These materials offered superior mechanical properties and durability compared to traditional options, marking a significant advancement in medical technology.

As research progressed, the 1980s and 1990s saw a surge in isocyanate-based biomaterials for tissue engineering and regenerative medicine. Scientists explored their use in creating scaffolds for cell growth and tissue regeneration, opening new avenues for treating injuries and degenerative conditions. This period also witnessed the development of isocyanate-derived hydrogels, which found applications in drug delivery systems and wound dressings.

The turn of the millennium brought about a paradigm shift in isocyanate utilization within healthcare. Researchers began focusing on modifying isocyanate chemistry to enhance biocompatibility and reduce potential toxicity concerns. This led to the creation of novel biodegradable polyurethanes and shape-memory polymers, expanding their applications in minimally invasive surgical procedures and personalized medicine.

In recent years, the integration of nanotechnology with isocyanate chemistry has pushed the boundaries of healthcare innovation. Nanostructured isocyanate-based materials have shown promise in targeted drug delivery, biosensors, and advanced imaging techniques. These developments have significantly improved diagnostic accuracy and treatment efficacy across various medical fields.

The evolution of isocyanates in healthcare has also been marked by a growing emphasis on sustainability and environmental considerations. Researchers are now exploring bio-based isocyanates derived from renewable resources, aligning with the global push towards greener technologies in the medical sector.

As we look to the future, the trajectory of isocyanates in healthcare continues to ascend. Emerging trends include their application in 3D bioprinting, smart materials for responsive drug release, and advanced wound care solutions. The ongoing research into isocyanate chemistry promises to unlock new frontiers in personalized medicine, regenerative therapies, and non-invasive diagnostic tools, further cementing their role as a cornerstone of modern healthcare innovation.

Market Demand Analysis

The market demand for isocyanates in healthcare is experiencing significant growth, driven by their versatile applications in medical devices, pharmaceuticals, and biotechnology. Isocyanates, known for their reactive properties and ability to form strong chemical bonds, are increasingly utilized in the development of advanced medical materials and drug delivery systems.

In the medical device sector, isocyanates play a crucial role in the production of polyurethane-based products such as catheters, wound dressings, and implants. The growing prevalence of chronic diseases and the aging population have led to an increased demand for these medical devices, consequently boosting the market for isocyanates in healthcare. The global medical device market is projected to expand steadily, with a particular emphasis on minimally invasive procedures and personalized medicine, both of which rely heavily on innovative materials derived from isocyanates.

The pharmaceutical industry is another key driver of isocyanate demand in healthcare. Isocyanates are utilized in the synthesis of various drug molecules and in the development of novel drug delivery systems. The trend towards targeted drug delivery and controlled-release formulations has further amplified the need for isocyanate-based materials. As the pharmaceutical industry continues to invest in research and development for more effective and efficient drug delivery methods, the demand for specialized isocyanate compounds is expected to rise.

Biotechnology applications represent an emerging frontier for isocyanates in healthcare. These compounds are being explored for their potential in tissue engineering, regenerative medicine, and biosensors. The growing interest in personalized medicine and the development of biocompatible materials have opened new avenues for isocyanate applications in this field. As biotechnology research advances, the demand for specialized isocyanate-based materials is likely to increase, particularly in areas such as 3D bioprinting and artificial organ development.

The market demand for isocyanates in healthcare is also influenced by regulatory trends and safety considerations. As healthcare providers and patients become more conscious of material safety, there is a growing emphasis on developing safer, more biocompatible isocyanate-based products. This trend is driving innovation in isocyanate chemistry, focusing on reducing potential health risks associated with certain isocyanate compounds while maintaining their beneficial properties.

Geographically, North America and Europe currently lead the market for isocyanates in healthcare, owing to their advanced healthcare infrastructure and significant investments in medical research. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in demand, driven by improving healthcare access and increasing investments in medical technology.

In the medical device sector, isocyanates play a crucial role in the production of polyurethane-based products such as catheters, wound dressings, and implants. The growing prevalence of chronic diseases and the aging population have led to an increased demand for these medical devices, consequently boosting the market for isocyanates in healthcare. The global medical device market is projected to expand steadily, with a particular emphasis on minimally invasive procedures and personalized medicine, both of which rely heavily on innovative materials derived from isocyanates.

The pharmaceutical industry is another key driver of isocyanate demand in healthcare. Isocyanates are utilized in the synthesis of various drug molecules and in the development of novel drug delivery systems. The trend towards targeted drug delivery and controlled-release formulations has further amplified the need for isocyanate-based materials. As the pharmaceutical industry continues to invest in research and development for more effective and efficient drug delivery methods, the demand for specialized isocyanate compounds is expected to rise.

Biotechnology applications represent an emerging frontier for isocyanates in healthcare. These compounds are being explored for their potential in tissue engineering, regenerative medicine, and biosensors. The growing interest in personalized medicine and the development of biocompatible materials have opened new avenues for isocyanate applications in this field. As biotechnology research advances, the demand for specialized isocyanate-based materials is likely to increase, particularly in areas such as 3D bioprinting and artificial organ development.

The market demand for isocyanates in healthcare is also influenced by regulatory trends and safety considerations. As healthcare providers and patients become more conscious of material safety, there is a growing emphasis on developing safer, more biocompatible isocyanate-based products. This trend is driving innovation in isocyanate chemistry, focusing on reducing potential health risks associated with certain isocyanate compounds while maintaining their beneficial properties.

Geographically, North America and Europe currently lead the market for isocyanates in healthcare, owing to their advanced healthcare infrastructure and significant investments in medical research. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in demand, driven by improving healthcare access and increasing investments in medical technology.

Technical Challenges

The development of isocyanates in healthcare faces several significant technical challenges that need to be addressed to fully realize their potential. One of the primary obstacles is the high reactivity of isocyanates, which can lead to uncontrolled polymerization and unwanted side reactions. This reactivity, while beneficial for certain applications, poses difficulties in maintaining stability during storage and handling, potentially compromising the efficacy and safety of healthcare products.

Another critical challenge lies in the biocompatibility of isocyanate-based materials. While some isocyanates have shown promise in biomedical applications, concerns remain about their potential toxicity and long-term effects on human tissues. Researchers must develop innovative strategies to mitigate these risks, such as creating novel isocyanate derivatives or incorporating protective mechanisms to prevent harmful interactions with biological systems.

The controlled release of active compounds from isocyanate-based materials presents another technical hurdle. Achieving precise and sustained drug delivery profiles requires fine-tuning of the material's degradation rate and release kinetics. This challenge is particularly relevant in the development of advanced drug delivery systems and tissue engineering scaffolds, where the timing and dosage of therapeutic agents are crucial for optimal treatment outcomes.

Furthermore, the scalability and reproducibility of isocyanate-based healthcare products pose significant challenges. Ensuring consistent quality and performance across large-scale production batches is essential for regulatory approval and commercial viability. This requires the development of robust manufacturing processes and quality control measures that can accommodate the unique properties of isocyanate chemistry.

The environmental impact of isocyanate production and disposal is another area of concern. As healthcare applications expand, there is a growing need for more sustainable and eco-friendly synthesis routes for isocyanates, as well as improved end-of-life management strategies for isocyanate-based products. This challenge intersects with broader industry efforts to reduce the carbon footprint and environmental impact of healthcare materials.

Lastly, the integration of isocyanate-based materials with existing healthcare technologies and infrastructure presents technical challenges. Compatibility with sterilization methods, imaging techniques, and other medical devices must be carefully evaluated and optimized. Additionally, the development of standardized testing protocols and regulatory guidelines specific to isocyanate-based healthcare products is necessary to ensure their safe and effective implementation in clinical settings.

Another critical challenge lies in the biocompatibility of isocyanate-based materials. While some isocyanates have shown promise in biomedical applications, concerns remain about their potential toxicity and long-term effects on human tissues. Researchers must develop innovative strategies to mitigate these risks, such as creating novel isocyanate derivatives or incorporating protective mechanisms to prevent harmful interactions with biological systems.

The controlled release of active compounds from isocyanate-based materials presents another technical hurdle. Achieving precise and sustained drug delivery profiles requires fine-tuning of the material's degradation rate and release kinetics. This challenge is particularly relevant in the development of advanced drug delivery systems and tissue engineering scaffolds, where the timing and dosage of therapeutic agents are crucial for optimal treatment outcomes.

Furthermore, the scalability and reproducibility of isocyanate-based healthcare products pose significant challenges. Ensuring consistent quality and performance across large-scale production batches is essential for regulatory approval and commercial viability. This requires the development of robust manufacturing processes and quality control measures that can accommodate the unique properties of isocyanate chemistry.

The environmental impact of isocyanate production and disposal is another area of concern. As healthcare applications expand, there is a growing need for more sustainable and eco-friendly synthesis routes for isocyanates, as well as improved end-of-life management strategies for isocyanate-based products. This challenge intersects with broader industry efforts to reduce the carbon footprint and environmental impact of healthcare materials.

Lastly, the integration of isocyanate-based materials with existing healthcare technologies and infrastructure presents technical challenges. Compatibility with sterilization methods, imaging techniques, and other medical devices must be carefully evaluated and optimized. Additionally, the development of standardized testing protocols and regulatory guidelines specific to isocyanate-based healthcare products is necessary to ensure their safe and effective implementation in clinical settings.

Current Isocyanate Applications

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel reaction pathways, catalysts, and production techniques to improve yield, purity, and efficiency in isocyanate manufacturing.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The search results cover various applications, including coatings, adhesives, foams, and elastomers, highlighting the versatility of isocyanates in material science.

- Isocyanate-based catalysts and reaction modifiers: Some patents focus on the use of isocyanates as catalysts or reaction modifiers in various chemical processes. These applications leverage the unique reactivity of isocyanate groups to enhance or control specific reactions.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, several patents address safety concerns and handling procedures. These include methods for reducing toxicity, improving storage stability, and developing safer formulations for industrial use.

- Novel isocyanate compounds and derivatives: Research into new isocyanate compounds and their derivatives is ongoing. Patents in this category describe novel molecular structures, isocyanate-based polymers, and functionalized isocyanates with unique properties or applications.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various formulations, curing methods, and applications of isocyanate-based polymers in coatings, adhesives, and other materials.Expand Specific Solutions03 Isocyanate-modified compounds and materials

This category covers the modification of various compounds and materials using isocyanates. These modifications can impart new properties or enhance existing characteristics of the base materials, leading to improved performance in specific applications.Expand Specific Solutions04 Handling and safety measures for isocyanates

Given the reactive nature of isocyanates, several patents focus on methods for safe handling, storage, and use of these compounds. This includes techniques for reducing exposure risks, improving stability, and managing potential hazards associated with isocyanate-containing materials.Expand Specific Solutions05 Isocyanate-free alternatives and substitutes

Some patents describe the development of isocyanate-free alternatives or substitutes for traditional isocyanate-based systems. These innovations aim to address environmental and health concerns associated with isocyanates while maintaining similar performance characteristics in various applications.Expand Specific Solutions

Key Industry Players

The isocyanates market in healthcare is in a growth phase, driven by increasing applications in medical devices, wound care, and drug delivery systems. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, isocyanates are evolving from basic applications to more advanced, biocompatible formulations. Key players like Wanhua Chemical, BASF, and Asahi Kasei are leading innovation, developing specialized isocyanates for medical use. Academic institutions such as Rutgers University and Sichuan University are contributing to research advancements, while companies like Ethicon and Agios Pharmaceuticals are exploring novel healthcare applications, indicating a maturing but still-developing technological landscape.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed innovative isocyanate-based materials for healthcare applications. Their technology focuses on creating biocompatible polyurethane foams and coatings with enhanced properties. These materials exhibit improved moisture resistance, durability, and flexibility, making them suitable for wound dressings, medical device coatings, and orthopedic supports[1]. Wanhua's isocyanate-derived products also demonstrate antimicrobial properties, potentially reducing infection risks in medical settings[2]. The company has invested in research to minimize potential health risks associated with isocyanate exposure during manufacturing and application processes[3].

Strengths: Advanced material engineering, wide range of healthcare applications, focus on safety improvements. Weaknesses: Potential health concerns related to isocyanate exposure, regulatory challenges in some markets.

BASF Corp.

Technical Solution: BASF has pioneered the development of low-emission isocyanates for healthcare applications. Their technology focuses on creating safer, more sustainable isocyanate-based materials with reduced volatile organic compound (VOC) emissions[1]. BASF's innovative approach includes the development of water-based polyurethane dispersions, which offer improved biocompatibility and reduced environmental impact[2]. These materials find applications in medical textiles, wound care products, and drug delivery systems. BASF has also invested in the development of bio-based isocyanates, derived from renewable resources, to address sustainability concerns in healthcare materials[3]. Their research extends to the creation of shape-memory polyurethanes, which have potential applications in minimally invasive surgical devices and smart implants[4].

Strengths: Strong focus on sustainability and safety, diverse range of healthcare applications, innovative bio-based solutions. Weaknesses: Higher production costs for some advanced materials, potential regulatory hurdles for novel applications.

Breakthrough Isocyanate Research

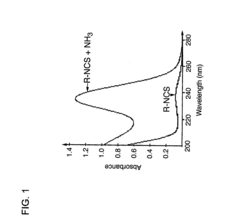

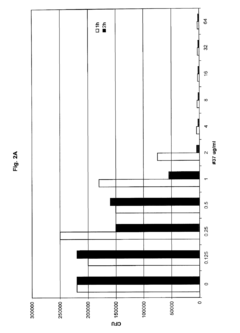

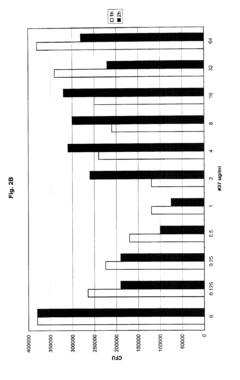

Isothiocyanate compounds, pharmaceutical compositions, and uses thereof

PatentInactiveUS20150246887A1

Innovation

- Development of novel isothiocyanate (ITC) compounds with anti-microbial and anti-cancer activity, formulated into pharmaceutical compositions for oral administration, which can inhibit microbial growth and treat infections, as well as methods for using these compounds in food and wood preservation.

Novel isocyanate and isothiocyanate compounds for cancer treatment

PatentInactiveEP2758367A1

Innovation

- Development of novel isocyanate and isothiocyanate compounds with specific structural modifications, such as those in formula (1), which reduce toxicity and enhance cytostatic activity, allowing for targeted therapy with fewer side effects.

Regulatory Framework

The regulatory framework surrounding isocyanates in healthcare applications is complex and multifaceted, reflecting the potential risks and benefits associated with these versatile compounds. Regulatory bodies worldwide have established stringent guidelines to ensure the safe use of isocyanates in medical devices, pharmaceuticals, and other healthcare products.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing the use of isocyanates in healthcare. The FDA's regulatory approach focuses on evaluating the safety and efficacy of products containing isocyanates through rigorous pre-market approval processes and post-market surveillance. For medical devices incorporating isocyanates, manufacturers must demonstrate compliance with the FDA's Quality System Regulation (QSR) and provide extensive safety data.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which set high standards for products containing isocyanates. These regulations emphasize risk management, clinical evaluation, and post-market surveillance. Manufacturers must obtain CE marking to indicate compliance with EU health, safety, and environmental protection standards.

Occupational safety regulations also play a significant role in the healthcare sector's use of isocyanates. The Occupational Safety and Health Administration (OSHA) in the U.S. and the European Agency for Safety and Health at Work (EU-OSHA) have established exposure limits and safety protocols for workers handling isocyanates in healthcare settings.

Environmental regulations further impact the use of isocyanates in healthcare. The Environmental Protection Agency (EPA) in the U.S. and the European Chemicals Agency (ECHA) under the REACH regulation monitor and control the production, use, and disposal of isocyanates to minimize environmental impact.

As research continues to uncover new applications for isocyanates in healthcare, regulatory frameworks are evolving to keep pace. Emerging areas of focus include the development of bio-based isocyanates and the use of isocyanates in advanced drug delivery systems. Regulatory bodies are working to establish guidelines that balance innovation with safety concerns, particularly in areas such as nanotechnology and personalized medicine where isocyanates show promising potential.

The global nature of the healthcare industry necessitates harmonization of regulatory approaches. International organizations like the International Organization for Standardization (ISO) and the International Medical Device Regulators Forum (IMDRF) are working to develop consistent standards and guidelines for isocyanate use in healthcare products across different regions.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing the use of isocyanates in healthcare. The FDA's regulatory approach focuses on evaluating the safety and efficacy of products containing isocyanates through rigorous pre-market approval processes and post-market surveillance. For medical devices incorporating isocyanates, manufacturers must demonstrate compliance with the FDA's Quality System Regulation (QSR) and provide extensive safety data.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which set high standards for products containing isocyanates. These regulations emphasize risk management, clinical evaluation, and post-market surveillance. Manufacturers must obtain CE marking to indicate compliance with EU health, safety, and environmental protection standards.

Occupational safety regulations also play a significant role in the healthcare sector's use of isocyanates. The Occupational Safety and Health Administration (OSHA) in the U.S. and the European Agency for Safety and Health at Work (EU-OSHA) have established exposure limits and safety protocols for workers handling isocyanates in healthcare settings.

Environmental regulations further impact the use of isocyanates in healthcare. The Environmental Protection Agency (EPA) in the U.S. and the European Chemicals Agency (ECHA) under the REACH regulation monitor and control the production, use, and disposal of isocyanates to minimize environmental impact.

As research continues to uncover new applications for isocyanates in healthcare, regulatory frameworks are evolving to keep pace. Emerging areas of focus include the development of bio-based isocyanates and the use of isocyanates in advanced drug delivery systems. Regulatory bodies are working to establish guidelines that balance innovation with safety concerns, particularly in areas such as nanotechnology and personalized medicine where isocyanates show promising potential.

The global nature of the healthcare industry necessitates harmonization of regulatory approaches. International organizations like the International Organization for Standardization (ISO) and the International Medical Device Regulators Forum (IMDRF) are working to develop consistent standards and guidelines for isocyanate use in healthcare products across different regions.

Environmental Impact Assessment

The environmental impact of isocyanates in healthcare applications is a critical consideration as these compounds gain prominence in medical innovations. Isocyanates, while offering significant benefits in healthcare, also pose potential risks to the environment throughout their lifecycle.

During the production phase, isocyanate manufacturing processes can release volatile organic compounds (VOCs) and other pollutants into the air and water. These emissions may contribute to air quality degradation and water contamination if not properly managed. Stringent regulations and advanced manufacturing techniques are essential to mitigate these environmental risks.

In healthcare settings, the use of isocyanate-based products, such as polyurethane foams in medical devices or coatings on implants, raises concerns about potential leaching and degradation. As these materials come into contact with bodily fluids or are exposed to various environmental conditions, there is a risk of isocyanate residues or breakdown products entering the ecosystem.

Disposal of isocyanate-containing medical waste presents another environmental challenge. Improper disposal methods can lead to soil and groundwater contamination. Healthcare facilities must implement robust waste management protocols to ensure safe handling and disposal of these materials.

However, the environmental impact of isocyanates in healthcare is not entirely negative. Their unique properties enable the development of more durable and efficient medical devices, potentially reducing the overall environmental footprint of healthcare products. For instance, isocyanate-based materials can extend the lifespan of medical equipment, reducing the need for frequent replacements and associated waste.

Furthermore, ongoing research focuses on developing bio-based and environmentally friendly isocyanates. These innovations aim to reduce reliance on petroleum-derived raw materials and minimize the environmental impact of isocyanate production and use in healthcare applications.

To fully assess the environmental impact, lifecycle analyses of isocyanate-based healthcare products are crucial. These studies should consider raw material extraction, manufacturing processes, product use, and end-of-life disposal. Such comprehensive evaluations can guide the development of more sustainable isocyanate applications in healthcare.

Balancing the environmental concerns with the potential healthcare benefits of isocyanates requires a multifaceted approach. This includes investing in cleaner production technologies, implementing strict environmental controls, and fostering innovation in eco-friendly isocyanate alternatives. As the healthcare sector continues to explore new frontiers with isocyanates, integrating environmental stewardship into research and development processes will be paramount for sustainable progress.

During the production phase, isocyanate manufacturing processes can release volatile organic compounds (VOCs) and other pollutants into the air and water. These emissions may contribute to air quality degradation and water contamination if not properly managed. Stringent regulations and advanced manufacturing techniques are essential to mitigate these environmental risks.

In healthcare settings, the use of isocyanate-based products, such as polyurethane foams in medical devices or coatings on implants, raises concerns about potential leaching and degradation. As these materials come into contact with bodily fluids or are exposed to various environmental conditions, there is a risk of isocyanate residues or breakdown products entering the ecosystem.

Disposal of isocyanate-containing medical waste presents another environmental challenge. Improper disposal methods can lead to soil and groundwater contamination. Healthcare facilities must implement robust waste management protocols to ensure safe handling and disposal of these materials.

However, the environmental impact of isocyanates in healthcare is not entirely negative. Their unique properties enable the development of more durable and efficient medical devices, potentially reducing the overall environmental footprint of healthcare products. For instance, isocyanate-based materials can extend the lifespan of medical equipment, reducing the need for frequent replacements and associated waste.

Furthermore, ongoing research focuses on developing bio-based and environmentally friendly isocyanates. These innovations aim to reduce reliance on petroleum-derived raw materials and minimize the environmental impact of isocyanate production and use in healthcare applications.

To fully assess the environmental impact, lifecycle analyses of isocyanate-based healthcare products are crucial. These studies should consider raw material extraction, manufacturing processes, product use, and end-of-life disposal. Such comprehensive evaluations can guide the development of more sustainable isocyanate applications in healthcare.

Balancing the environmental concerns with the potential healthcare benefits of isocyanates requires a multifaceted approach. This includes investing in cleaner production technologies, implementing strict environmental controls, and fostering innovation in eco-friendly isocyanate alternatives. As the healthcare sector continues to explore new frontiers with isocyanates, integrating environmental stewardship into research and development processes will be paramount for sustainable progress.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!