How Isocyanates Support Lightweight Material Advancements?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Tech Evolution

Isocyanates have played a pivotal role in the evolution of lightweight materials, particularly in the development of polyurethanes. The journey of isocyanate technology in this field began in the 1930s with Otto Bayer's groundbreaking discovery of polyurethane chemistry. This innovation laid the foundation for a wide range of applications in lightweight material advancements.

Throughout the 1950s and 1960s, researchers focused on refining isocyanate formulations to enhance the properties of polyurethane foams. This period saw significant improvements in the thermal insulation and structural integrity of these materials, making them increasingly attractive for use in automotive and construction industries.

The 1970s marked a turning point in isocyanate technology with the introduction of microcellular polyurethane systems. These systems allowed for the production of materials with even lower densities while maintaining excellent mechanical properties. This breakthrough opened up new possibilities for lightweight applications in aerospace and transportation sectors.

In the 1980s and 1990s, environmental concerns led to the development of water-blown foam systems, reducing the reliance on ozone-depleting blowing agents. This shift not only addressed ecological issues but also improved the overall performance of isocyanate-based lightweight materials.

The early 2000s saw a focus on enhancing the fire resistance of isocyanate-derived materials. Researchers developed novel flame retardant additives and modified isocyanate chemistries to meet increasingly stringent safety standards, particularly in building and automotive applications.

Recent advancements in the 2010s have centered on the development of bio-based isocyanates. These sustainable alternatives aim to reduce the carbon footprint of polyurethane production while maintaining the high performance of traditional petroleum-based isocyanates.

Current research is exploring the potential of nanocomposite polyurethanes, where isocyanates are combined with nanomaterials to create ultra-lightweight materials with exceptional strength-to-weight ratios. This cutting-edge work promises to push the boundaries of what's possible in aerospace and high-performance automotive applications.

The evolution of isocyanate technology continues to drive innovations in lightweight materials. From improving energy efficiency in buildings to enabling more fuel-efficient vehicles, isocyanates remain at the forefront of material science advancements. As we look to the future, the ongoing refinement of isocyanate chemistry and its integration with other emerging technologies will undoubtedly lead to even more remarkable lightweight solutions.

Throughout the 1950s and 1960s, researchers focused on refining isocyanate formulations to enhance the properties of polyurethane foams. This period saw significant improvements in the thermal insulation and structural integrity of these materials, making them increasingly attractive for use in automotive and construction industries.

The 1970s marked a turning point in isocyanate technology with the introduction of microcellular polyurethane systems. These systems allowed for the production of materials with even lower densities while maintaining excellent mechanical properties. This breakthrough opened up new possibilities for lightweight applications in aerospace and transportation sectors.

In the 1980s and 1990s, environmental concerns led to the development of water-blown foam systems, reducing the reliance on ozone-depleting blowing agents. This shift not only addressed ecological issues but also improved the overall performance of isocyanate-based lightweight materials.

The early 2000s saw a focus on enhancing the fire resistance of isocyanate-derived materials. Researchers developed novel flame retardant additives and modified isocyanate chemistries to meet increasingly stringent safety standards, particularly in building and automotive applications.

Recent advancements in the 2010s have centered on the development of bio-based isocyanates. These sustainable alternatives aim to reduce the carbon footprint of polyurethane production while maintaining the high performance of traditional petroleum-based isocyanates.

Current research is exploring the potential of nanocomposite polyurethanes, where isocyanates are combined with nanomaterials to create ultra-lightweight materials with exceptional strength-to-weight ratios. This cutting-edge work promises to push the boundaries of what's possible in aerospace and high-performance automotive applications.

The evolution of isocyanate technology continues to drive innovations in lightweight materials. From improving energy efficiency in buildings to enabling more fuel-efficient vehicles, isocyanates remain at the forefront of material science advancements. As we look to the future, the ongoing refinement of isocyanate chemistry and its integration with other emerging technologies will undoubtedly lead to even more remarkable lightweight solutions.

Lightweight Material Demand

The demand for lightweight materials has been steadily increasing across various industries, driven by the need for improved energy efficiency, enhanced performance, and reduced environmental impact. In the automotive sector, stringent fuel efficiency regulations and the shift towards electric vehicles have intensified the focus on weight reduction. Lightweight materials play a crucial role in extending the range of electric vehicles and improving the overall efficiency of conventional vehicles.

The aerospace industry has long been at the forefront of lightweight material adoption, with a constant push for materials that offer high strength-to-weight ratios. This demand is fueled by the need to reduce fuel consumption, increase payload capacity, and improve aircraft performance. The construction industry is also experiencing a growing interest in lightweight materials, particularly for high-rise buildings and large-scale infrastructure projects, where weight reduction can lead to significant cost savings and improved structural performance.

In the consumer electronics sector, the trend towards more portable and wearable devices has created a strong demand for lightweight materials that can provide durability and functionality in compact form factors. This extends to the sports and leisure industry, where lightweight materials are sought after for equipment and gear to enhance athletic performance and user comfort.

The global market for lightweight materials is projected to grow substantially in the coming years. This growth is attributed to the increasing adoption of these materials in various end-use industries and the continuous development of new, advanced lightweight solutions. Isocyanates, as key components in the production of polyurethanes, play a significant role in meeting this demand for lightweight materials.

Polyurethanes derived from isocyanates offer a unique combination of properties that make them ideal for lightweight applications. They can be formulated to create foams with varying densities, from rigid structural foams to flexible cushioning materials. This versatility allows for the creation of lightweight components that can replace heavier traditional materials while maintaining or even improving performance characteristics.

The automotive industry, in particular, has been a major driver of demand for isocyanate-based lightweight materials. Polyurethane foams are extensively used in vehicle interiors for seating, headliners, and sound insulation, contributing to weight reduction without compromising comfort or safety. In the aerospace sector, polyurethane composites and foams find applications in interior panels, seating, and insulation, helping to reduce aircraft weight and improve fuel efficiency.

As the push for sustainability grows, there is an increasing focus on developing bio-based and recyclable isocyanates to address environmental concerns while meeting the demand for lightweight materials. This trend is expected to further drive innovation in the isocyanate industry and expand the application of lightweight polyurethane-based materials across various sectors.

The aerospace industry has long been at the forefront of lightweight material adoption, with a constant push for materials that offer high strength-to-weight ratios. This demand is fueled by the need to reduce fuel consumption, increase payload capacity, and improve aircraft performance. The construction industry is also experiencing a growing interest in lightweight materials, particularly for high-rise buildings and large-scale infrastructure projects, where weight reduction can lead to significant cost savings and improved structural performance.

In the consumer electronics sector, the trend towards more portable and wearable devices has created a strong demand for lightweight materials that can provide durability and functionality in compact form factors. This extends to the sports and leisure industry, where lightweight materials are sought after for equipment and gear to enhance athletic performance and user comfort.

The global market for lightweight materials is projected to grow substantially in the coming years. This growth is attributed to the increasing adoption of these materials in various end-use industries and the continuous development of new, advanced lightweight solutions. Isocyanates, as key components in the production of polyurethanes, play a significant role in meeting this demand for lightweight materials.

Polyurethanes derived from isocyanates offer a unique combination of properties that make them ideal for lightweight applications. They can be formulated to create foams with varying densities, from rigid structural foams to flexible cushioning materials. This versatility allows for the creation of lightweight components that can replace heavier traditional materials while maintaining or even improving performance characteristics.

The automotive industry, in particular, has been a major driver of demand for isocyanate-based lightweight materials. Polyurethane foams are extensively used in vehicle interiors for seating, headliners, and sound insulation, contributing to weight reduction without compromising comfort or safety. In the aerospace sector, polyurethane composites and foams find applications in interior panels, seating, and insulation, helping to reduce aircraft weight and improve fuel efficiency.

As the push for sustainability grows, there is an increasing focus on developing bio-based and recyclable isocyanates to address environmental concerns while meeting the demand for lightweight materials. This trend is expected to further drive innovation in the isocyanate industry and expand the application of lightweight polyurethane-based materials across various sectors.

Isocyanate Challenges

Isocyanates, while crucial in lightweight material advancements, face several significant challenges that hinder their widespread adoption and optimal performance. One of the primary concerns is their toxicity and potential health hazards. Exposure to isocyanates can cause respiratory irritation, skin sensitization, and in severe cases, occupational asthma. This necessitates stringent safety measures during production, handling, and application processes, increasing operational costs and complexity.

Environmental concerns also pose a challenge for isocyanate usage. Many isocyanates are derived from petroleum-based sources, raising sustainability issues in an era of increasing environmental consciousness. The production process often involves the use of phosgene, a highly toxic compound, further complicating environmental and safety considerations.

Another significant challenge lies in the reactivity of isocyanates. While their high reactivity is beneficial for rapid polymerization and curing, it also makes them susceptible to moisture and other contaminants. This sensitivity can lead to inconsistent product quality, reduced shelf life, and potential failure of lightweight materials if not properly managed throughout the manufacturing and application processes.

The cost of isocyanates presents an economic challenge, particularly for large-scale applications in lightweight material production. High-quality, specialized isocyanates can be expensive, impacting the overall cost-effectiveness of lightweight materials and potentially limiting their adoption in price-sensitive markets.

Technical limitations also exist in achieving the perfect balance between reactivity, curing time, and final material properties. Formulating isocyanate-based systems that provide optimal strength, flexibility, and durability while maintaining low weight remains a complex task. This challenge is particularly evident in applications requiring specific performance characteristics, such as in automotive or aerospace industries.

Regulatory hurdles further complicate the use of isocyanates in lightweight materials. Stringent regulations regarding their production, transportation, and use, while necessary for safety, can create barriers to innovation and market entry. Compliance with these regulations often requires significant investment in equipment, training, and safety protocols.

Lastly, the development of alternatives to traditional isocyanates presents both a challenge and an opportunity. As research into bio-based and less toxic alternatives progresses, the isocyanate industry must adapt to maintain its relevance in lightweight material advancements. This necessitates ongoing research and development efforts to improve existing isocyanate technologies while exploring new, more sustainable options.

Environmental concerns also pose a challenge for isocyanate usage. Many isocyanates are derived from petroleum-based sources, raising sustainability issues in an era of increasing environmental consciousness. The production process often involves the use of phosgene, a highly toxic compound, further complicating environmental and safety considerations.

Another significant challenge lies in the reactivity of isocyanates. While their high reactivity is beneficial for rapid polymerization and curing, it also makes them susceptible to moisture and other contaminants. This sensitivity can lead to inconsistent product quality, reduced shelf life, and potential failure of lightweight materials if not properly managed throughout the manufacturing and application processes.

The cost of isocyanates presents an economic challenge, particularly for large-scale applications in lightweight material production. High-quality, specialized isocyanates can be expensive, impacting the overall cost-effectiveness of lightweight materials and potentially limiting their adoption in price-sensitive markets.

Technical limitations also exist in achieving the perfect balance between reactivity, curing time, and final material properties. Formulating isocyanate-based systems that provide optimal strength, flexibility, and durability while maintaining low weight remains a complex task. This challenge is particularly evident in applications requiring specific performance characteristics, such as in automotive or aerospace industries.

Regulatory hurdles further complicate the use of isocyanates in lightweight materials. Stringent regulations regarding their production, transportation, and use, while necessary for safety, can create barriers to innovation and market entry. Compliance with these regulations often requires significant investment in equipment, training, and safety protocols.

Lastly, the development of alternatives to traditional isocyanates presents both a challenge and an opportunity. As research into bio-based and less toxic alternatives progresses, the isocyanate industry must adapt to maintain its relevance in lightweight material advancements. This necessitates ongoing research and development efforts to improve existing isocyanate technologies while exploring new, more sustainable options.

Current Isocyanate Solutions

01 Molecular weight control of isocyanates

Controlling the molecular weight of isocyanates is crucial in various applications. This involves techniques to manipulate the chain length and structure of isocyanate compounds, which can affect their reactivity, viscosity, and overall performance in different formulations.- Molecular weight control of isocyanates: Controlling the molecular weight of isocyanates is crucial in various applications. This can be achieved through different polymerization techniques and reaction conditions. The molecular weight affects properties such as viscosity, reactivity, and final product characteristics.

- Isocyanate weight percentage in formulations: The weight percentage of isocyanates in formulations is a critical factor in determining the performance of the final product. Optimal ratios are determined based on the specific application, such as coatings, adhesives, or foams. Balancing isocyanate content with other components is essential for achieving desired properties.

- Low molecular weight isocyanates: Low molecular weight isocyanates are used in various applications due to their high reactivity and low viscosity. These compounds are particularly useful in coatings and adhesives where fast curing and good penetration are required. However, their volatility and potential health hazards necessitate careful handling and formulation.

- High molecular weight isocyanate prepolymers: High molecular weight isocyanate prepolymers are synthesized to reduce volatility and improve handling safety. These prepolymers offer advantages in terms of processing, mechanical properties, and reduced environmental impact. They are commonly used in polyurethane systems for various industrial applications.

- Weight ratio of isocyanates to polyols: The weight ratio of isocyanates to polyols is a critical parameter in polyurethane chemistry. This ratio affects the final properties of the polymer, including hardness, flexibility, and chemical resistance. Optimizing this ratio is essential for tailoring polyurethanes to specific applications and performance requirements.

02 Isocyanate weight percentage in formulations

The weight percentage of isocyanates in various formulations is a critical factor in determining the properties of the final product. Adjusting the isocyanate content can influence characteristics such as curing time, strength, and flexibility of the resulting materials.Expand Specific Solutions03 Weight ratio of isocyanates to other components

The weight ratio between isocyanates and other components in a mixture plays a significant role in the performance of the final product. Optimizing these ratios can lead to improved properties such as adhesion, durability, and chemical resistance.Expand Specific Solutions04 Isocyanate weight in polyurethane production

In polyurethane production, the weight of isocyanates used is a critical factor. Precise control of isocyanate weight can affect the foam density, hardness, and other physical properties of the final polyurethane product.Expand Specific Solutions05 Weight-based dosing of isocyanates

Accurate weight-based dosing of isocyanates is essential in many industrial processes. This involves using specialized equipment and techniques to measure and dispense precise amounts of isocyanates based on their weight, ensuring consistent quality and performance in the final products.Expand Specific Solutions

Key Isocyanate Producers

The isocyanates market for lightweight material advancements is in a growth phase, driven by increasing demand in automotive, aerospace, and construction industries. The global market size is projected to reach $11.8 billion by 2027, with a CAGR of 6.5%. Technologically, isocyanates are mature but evolving, with companies like Wanhua Chemical, BASF, Covestro, and Dow focusing on developing more sustainable and high-performance variants. These industry leaders are investing in R&D to improve isocyanate properties, reduce environmental impact, and expand applications in lightweight materials, positioning themselves at the forefront of innovation in this competitive landscape.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has made significant strides in isocyanate-based lightweight material advancements. Their WANNATE® series of MDI (methylene diphenyl diisocyanate) products are used in the production of high-performance polyurethane foams for automotive and construction applications, offering excellent insulation properties and weight reduction[13]. Wanhua's WANECO® polyurethane systems, incorporating proprietary isocyanate technology, enable the production of lightweight composite materials with enhanced mechanical properties and durability[14]. The company has also developed innovative isocyanate-based binders for lightweight wood composites, reducing formaldehyde emissions while maintaining strength and reducing overall weight in furniture and construction materials[15].

Strengths: Strong R&D capabilities, vertically integrated production, and a growing global presence. Weaknesses: Potential regulatory challenges in different markets and the need for continuous investment in sustainable production methods.

BASF Corp.

Technical Solution: BASF has developed innovative isocyanate-based solutions for lightweight material advancements. Their Elastocoat® C spray system, utilizing modified polyisocyanates, creates a high-performance protective coating for various substrates[1]. This technology enables the production of lightweight composite materials with enhanced durability and weather resistance. BASF's Elastopan® polyurethane systems, incorporating isocyanates, are used in the automotive industry to create lightweight structural components, reducing vehicle weight by up to 30% compared to traditional materials[2]. The company has also introduced Ultramid® Advanced N, a high-performance polyamide that incorporates isocyanate chemistry to achieve superior mechanical properties and thermal stability in lightweight applications[3].

Strengths: Wide range of applications across industries, significant weight reduction capabilities, and improved durability. Weaknesses: Potential environmental concerns related to isocyanate production and handling, and the need for specialized equipment for application.

Isocyanate Innovations

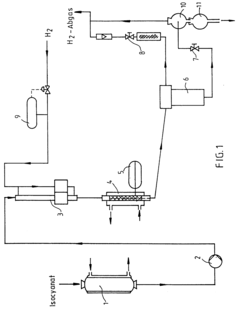

Process for the preparation of isocyanates or isocyanate mixtures and their use for the manufacture of light coloured foams

PatentInactiveEP0676391A1

Innovation

- A process involving the phosgenation of amines or amine mixtures followed by hydrogen treatment using supported catalysts, specifically Shell catalysts with alkali-free, 0.3 to 3 mm sized carriers and metals like platinum, palladium, and gold, to produce isocyanates or isocyanate mixtures with minimal coloring substances.

Non-inflammable building, isolation, furniture production and interior finish materials

PatentInactiveEP0023579A1

Innovation

- The addition of small amounts of moisture-reactive polyfunctional isocyanates to liquid mortar and concrete mixtures enhances fire and water resistance while allowing for quick demolding, and the use of various aggregates and reinforcing fibers, enabling the production of materials that are also sound and heat-insulating, mechanically strong, and aesthetically pleasing.

Environmental Impact

The environmental impact of isocyanates in lightweight material advancements is a critical consideration for sustainable development in various industries. Isocyanates, while instrumental in creating high-performance lightweight materials, pose significant environmental challenges throughout their lifecycle.

During production, isocyanates require energy-intensive processes and often involve the use of fossil fuel-derived raw materials. This contributes to greenhouse gas emissions and resource depletion. Additionally, the manufacturing process can release volatile organic compounds (VOCs) and other pollutants, potentially affecting air quality in surrounding areas.

In the application phase, isocyanate-based lightweight materials offer environmental benefits through improved fuel efficiency in transportation and reduced energy consumption in buildings. However, these advantages must be weighed against the potential risks of isocyanate exposure during installation and use, which can have adverse effects on both human health and ecosystems.

End-of-life management of isocyanate-containing materials presents another environmental challenge. Many of these materials are not easily recyclable or biodegradable, leading to increased waste in landfills or the need for specialized disposal methods. Incineration of these materials can release toxic fumes, including hydrogen cyanide and other harmful substances.

Recent advancements in green chemistry have led to the development of bio-based isocyanates and alternative cross-linking agents, aiming to reduce the environmental footprint of lightweight materials. These innovations focus on utilizing renewable resources and improving the biodegradability of end products.

Efforts are also being made to enhance the recyclability of isocyanate-based materials through the development of reversible chemistries and improved separation techniques. This could significantly reduce waste and promote a more circular economy approach in the use of lightweight materials.

Regulatory bodies worldwide are implementing stricter controls on isocyanate use and disposal, driving industry innovation towards more environmentally friendly alternatives. This includes the promotion of water-based systems and solvent-free technologies that reduce VOC emissions and improve overall environmental performance.

As the demand for lightweight materials continues to grow, balancing their performance benefits with environmental considerations remains a key challenge. Future developments in this field will likely focus on further reducing the environmental impact of isocyanates while maintaining or enhancing the advantageous properties they bring to lightweight materials.

During production, isocyanates require energy-intensive processes and often involve the use of fossil fuel-derived raw materials. This contributes to greenhouse gas emissions and resource depletion. Additionally, the manufacturing process can release volatile organic compounds (VOCs) and other pollutants, potentially affecting air quality in surrounding areas.

In the application phase, isocyanate-based lightweight materials offer environmental benefits through improved fuel efficiency in transportation and reduced energy consumption in buildings. However, these advantages must be weighed against the potential risks of isocyanate exposure during installation and use, which can have adverse effects on both human health and ecosystems.

End-of-life management of isocyanate-containing materials presents another environmental challenge. Many of these materials are not easily recyclable or biodegradable, leading to increased waste in landfills or the need for specialized disposal methods. Incineration of these materials can release toxic fumes, including hydrogen cyanide and other harmful substances.

Recent advancements in green chemistry have led to the development of bio-based isocyanates and alternative cross-linking agents, aiming to reduce the environmental footprint of lightweight materials. These innovations focus on utilizing renewable resources and improving the biodegradability of end products.

Efforts are also being made to enhance the recyclability of isocyanate-based materials through the development of reversible chemistries and improved separation techniques. This could significantly reduce waste and promote a more circular economy approach in the use of lightweight materials.

Regulatory bodies worldwide are implementing stricter controls on isocyanate use and disposal, driving industry innovation towards more environmentally friendly alternatives. This includes the promotion of water-based systems and solvent-free technologies that reduce VOC emissions and improve overall environmental performance.

As the demand for lightweight materials continues to grow, balancing their performance benefits with environmental considerations remains a key challenge. Future developments in this field will likely focus on further reducing the environmental impact of isocyanates while maintaining or enhancing the advantageous properties they bring to lightweight materials.

Safety Regulations

Safety regulations play a crucial role in the advancement of lightweight materials using isocyanates. These regulations are designed to protect workers, consumers, and the environment from potential hazards associated with the production, handling, and use of isocyanate-based products.

In the manufacturing sector, strict guidelines have been established to ensure proper handling and storage of isocyanates. Workers are required to wear appropriate personal protective equipment (PPE), including respirators, gloves, and protective clothing. Ventilation systems must meet specific standards to minimize exposure to isocyanate vapors and aerosols. Regular air quality monitoring and medical surveillance programs are mandatory in many jurisdictions to detect and prevent occupational health issues.

The transportation of isocyanates is subject to rigorous safety protocols. Containers must be properly labeled and sealed, with clear hazard communication. Drivers transporting these materials are required to undergo specialized training and carry appropriate safety documentation. Emergency response plans are mandatory to address potential spills or accidents during transit.

In the construction and automotive industries, where isocyanate-based lightweight materials are commonly used, regulations focus on proper application techniques and curing processes. Spray foam insulation installers, for instance, must be certified and follow strict application guidelines to prevent off-gassing and ensure optimal performance of the final product.

Consumer safety is addressed through product labeling requirements and restrictions on volatile organic compound (VOC) emissions. Many countries have implemented regulations limiting the use of certain isocyanates in consumer products, particularly those intended for indoor use or direct skin contact.

Environmental regulations govern the disposal of isocyanate-containing waste and emissions control during production processes. Manufacturers are required to implement pollution prevention measures and adhere to specific waste management protocols to minimize environmental impact.

As lightweight material technologies advance, safety regulations continue to evolve. Ongoing research into the long-term effects of isocyanate exposure has led to more stringent occupational exposure limits in many countries. Additionally, there is a growing emphasis on developing safer alternatives and improving risk assessment methodologies.

Compliance with these safety regulations is not only a legal requirement but also a driving force for innovation in the isocyanate industry. Manufacturers are investing in research and development to create safer formulations and application methods, which in turn supports the advancement of lightweight materials while prioritizing health and environmental protection.

In the manufacturing sector, strict guidelines have been established to ensure proper handling and storage of isocyanates. Workers are required to wear appropriate personal protective equipment (PPE), including respirators, gloves, and protective clothing. Ventilation systems must meet specific standards to minimize exposure to isocyanate vapors and aerosols. Regular air quality monitoring and medical surveillance programs are mandatory in many jurisdictions to detect and prevent occupational health issues.

The transportation of isocyanates is subject to rigorous safety protocols. Containers must be properly labeled and sealed, with clear hazard communication. Drivers transporting these materials are required to undergo specialized training and carry appropriate safety documentation. Emergency response plans are mandatory to address potential spills or accidents during transit.

In the construction and automotive industries, where isocyanate-based lightweight materials are commonly used, regulations focus on proper application techniques and curing processes. Spray foam insulation installers, for instance, must be certified and follow strict application guidelines to prevent off-gassing and ensure optimal performance of the final product.

Consumer safety is addressed through product labeling requirements and restrictions on volatile organic compound (VOC) emissions. Many countries have implemented regulations limiting the use of certain isocyanates in consumer products, particularly those intended for indoor use or direct skin contact.

Environmental regulations govern the disposal of isocyanate-containing waste and emissions control during production processes. Manufacturers are required to implement pollution prevention measures and adhere to specific waste management protocols to minimize environmental impact.

As lightweight material technologies advance, safety regulations continue to evolve. Ongoing research into the long-term effects of isocyanate exposure has led to more stringent occupational exposure limits in many countries. Additionally, there is a growing emphasis on developing safer alternatives and improving risk assessment methodologies.

Compliance with these safety regulations is not only a legal requirement but also a driving force for innovation in the isocyanate industry. Manufacturers are investing in research and development to create safer formulations and application methods, which in turn supports the advancement of lightweight materials while prioritizing health and environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!