How LTPO influences AMOLED's display adaptability?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LTPO AMOLED Evolution

The evolution of LTPO (Low-Temperature Polycrystalline Oxide) AMOLED technology represents a significant advancement in display technology, particularly in terms of enhancing the adaptability of AMOLED displays. This evolution can be traced through several key stages, each marked by notable technological breakthroughs and improvements in display performance.

In the early stages of AMOLED development, displays were primarily based on Low-Temperature Polycrystalline Silicon (LTPS) technology. While LTPS offered good performance, it had limitations in terms of power efficiency and refresh rate adaptability. The introduction of LTPO technology marked a pivotal moment in AMOLED evolution, addressing these limitations and opening up new possibilities for display adaptability.

The first generation of LTPO displays combined LTPS and Oxide TFT technologies, leveraging the strengths of both. This hybrid approach allowed for improved electron mobility and lower power consumption compared to traditional LTPS displays. The key innovation was the ability to dynamically adjust the refresh rate, ranging from as low as 1Hz to 120Hz or higher, depending on the content being displayed.

As LTPO technology matured, subsequent generations brought further refinements and enhancements. The second generation of LTPO displays improved upon the power efficiency and refresh rate range of their predecessors. These displays could transition between refresh rates more smoothly and quickly, resulting in better overall power management and display performance.

The latest iterations of LTPO AMOLED displays have pushed the boundaries even further. Current-generation LTPO displays offer even wider refresh rate ranges, with some capable of operating from 1Hz to 144Hz or even higher. This expanded range allows for unprecedented adaptability, catering to a variety of use cases from static content display to high-frame-rate gaming.

Throughout this evolution, the influence of LTPO on AMOLED's display adaptability has been profound. The technology has enabled displays to dynamically adjust their refresh rates based on the content being shown, significantly reducing power consumption without compromising on visual quality. This adaptability has been particularly beneficial for mobile devices, where battery life is a critical concern.

Moreover, the evolution of LTPO AMOLED has also led to improvements in other aspects of display performance. These include enhanced color accuracy, better brightness control, and reduced motion blur. The technology has also facilitated the development of always-on display features, which leverage the ultra-low refresh rates to show basic information with minimal power draw.

Looking ahead, the LTPO AMOLED evolution is expected to continue, with future generations likely to offer even greater adaptability and efficiency. Potential areas of advancement include further expansion of the refresh rate range, improved power efficiency at all refresh rates, and integration with other emerging display technologies to create even more versatile and high-performance displays.

In the early stages of AMOLED development, displays were primarily based on Low-Temperature Polycrystalline Silicon (LTPS) technology. While LTPS offered good performance, it had limitations in terms of power efficiency and refresh rate adaptability. The introduction of LTPO technology marked a pivotal moment in AMOLED evolution, addressing these limitations and opening up new possibilities for display adaptability.

The first generation of LTPO displays combined LTPS and Oxide TFT technologies, leveraging the strengths of both. This hybrid approach allowed for improved electron mobility and lower power consumption compared to traditional LTPS displays. The key innovation was the ability to dynamically adjust the refresh rate, ranging from as low as 1Hz to 120Hz or higher, depending on the content being displayed.

As LTPO technology matured, subsequent generations brought further refinements and enhancements. The second generation of LTPO displays improved upon the power efficiency and refresh rate range of their predecessors. These displays could transition between refresh rates more smoothly and quickly, resulting in better overall power management and display performance.

The latest iterations of LTPO AMOLED displays have pushed the boundaries even further. Current-generation LTPO displays offer even wider refresh rate ranges, with some capable of operating from 1Hz to 144Hz or even higher. This expanded range allows for unprecedented adaptability, catering to a variety of use cases from static content display to high-frame-rate gaming.

Throughout this evolution, the influence of LTPO on AMOLED's display adaptability has been profound. The technology has enabled displays to dynamically adjust their refresh rates based on the content being shown, significantly reducing power consumption without compromising on visual quality. This adaptability has been particularly beneficial for mobile devices, where battery life is a critical concern.

Moreover, the evolution of LTPO AMOLED has also led to improvements in other aspects of display performance. These include enhanced color accuracy, better brightness control, and reduced motion blur. The technology has also facilitated the development of always-on display features, which leverage the ultra-low refresh rates to show basic information with minimal power draw.

Looking ahead, the LTPO AMOLED evolution is expected to continue, with future generations likely to offer even greater adaptability and efficiency. Potential areas of advancement include further expansion of the refresh rate range, improved power efficiency at all refresh rates, and integration with other emerging display technologies to create even more versatile and high-performance displays.

Market Demand Analysis

The market demand for AMOLED displays with LTPO technology has been steadily increasing, driven by the growing consumer preference for mobile devices with enhanced display quality and energy efficiency. LTPO (Low-Temperature Polycrystalline Oxide) technology has emerged as a game-changer in the AMOLED display industry, significantly improving the adaptability and power consumption of these displays.

The smartphone market, in particular, has shown a strong appetite for LTPO-enabled AMOLED displays. As consumers increasingly rely on their mobile devices for various tasks, from content consumption to productivity, the demand for displays that can adapt to different usage scenarios while conserving battery life has surged. LTPO technology addresses this need by allowing for variable refresh rates, which can dynamically adjust based on the content being displayed.

In the wearables sector, especially smartwatches, LTPO AMOLED displays have become a key differentiator. The ability to switch between high refresh rates for smooth interactions and low refresh rates for always-on displays has made LTPO technology particularly attractive for this market segment. This adaptability not only enhances user experience but also extends battery life, a critical factor in wearable devices.

The automotive industry is another sector showing increased interest in LTPO AMOLED displays. As vehicles become more technologically advanced and incorporate larger, more sophisticated infotainment systems, the need for displays that can adapt to varying light conditions and usage patterns while minimizing power consumption has grown. LTPO technology's ability to optimize display performance based on ambient conditions aligns well with the automotive sector's requirements.

Market analysts predict a compound annual growth rate (CAGR) for LTPO AMOLED displays that outpaces the overall AMOLED market. This growth is attributed to the technology's adoption in premium smartphones, high-end wearables, and luxury vehicles. The demand is further fueled by the ongoing trend towards 5G adoption, which necessitates more power-efficient displays to offset the increased energy consumption of 5G modems.

The enterprise and professional markets are also showing interest in LTPO AMOLED displays, particularly for high-end laptops and tablets. The ability to dynamically adjust refresh rates can significantly benefit users who require both high-performance displays for content creation and energy efficiency for extended battery life during travel or remote work.

As consumers become more environmentally conscious, the energy-saving benefits of LTPO technology are likely to drive further demand. Manufacturers and brands that can offer devices with LTPO AMOLED displays may gain a competitive edge by appealing to eco-friendly consumers and meeting increasingly stringent energy efficiency regulations.

The smartphone market, in particular, has shown a strong appetite for LTPO-enabled AMOLED displays. As consumers increasingly rely on their mobile devices for various tasks, from content consumption to productivity, the demand for displays that can adapt to different usage scenarios while conserving battery life has surged. LTPO technology addresses this need by allowing for variable refresh rates, which can dynamically adjust based on the content being displayed.

In the wearables sector, especially smartwatches, LTPO AMOLED displays have become a key differentiator. The ability to switch between high refresh rates for smooth interactions and low refresh rates for always-on displays has made LTPO technology particularly attractive for this market segment. This adaptability not only enhances user experience but also extends battery life, a critical factor in wearable devices.

The automotive industry is another sector showing increased interest in LTPO AMOLED displays. As vehicles become more technologically advanced and incorporate larger, more sophisticated infotainment systems, the need for displays that can adapt to varying light conditions and usage patterns while minimizing power consumption has grown. LTPO technology's ability to optimize display performance based on ambient conditions aligns well with the automotive sector's requirements.

Market analysts predict a compound annual growth rate (CAGR) for LTPO AMOLED displays that outpaces the overall AMOLED market. This growth is attributed to the technology's adoption in premium smartphones, high-end wearables, and luxury vehicles. The demand is further fueled by the ongoing trend towards 5G adoption, which necessitates more power-efficient displays to offset the increased energy consumption of 5G modems.

The enterprise and professional markets are also showing interest in LTPO AMOLED displays, particularly for high-end laptops and tablets. The ability to dynamically adjust refresh rates can significantly benefit users who require both high-performance displays for content creation and energy efficiency for extended battery life during travel or remote work.

As consumers become more environmentally conscious, the energy-saving benefits of LTPO technology are likely to drive further demand. Manufacturers and brands that can offer devices with LTPO AMOLED displays may gain a competitive edge by appealing to eco-friendly consumers and meeting increasingly stringent energy efficiency regulations.

LTPO Tech Challenges

LTPO (Low-Temperature Polycrystalline Oxide) technology presents several significant challenges in its implementation and optimization for AMOLED displays. One of the primary hurdles is the complexity of the manufacturing process. LTPO requires a combination of LTPS (Low-Temperature Polycrystalline Silicon) and IGZO (Indium Gallium Zinc Oxide) technologies, which necessitates intricate fabrication techniques and precise control over material properties.

The integration of these two technologies introduces challenges in maintaining consistent performance across the entire display panel. Variations in transistor characteristics between LTPS and IGZO regions can lead to non-uniform pixel behavior, potentially affecting image quality and power efficiency. Addressing this issue requires advanced compensation algorithms and fine-tuning of the manufacturing process.

Another significant challenge lies in optimizing the power-saving capabilities of LTPO. While the technology promises substantial energy efficiency improvements, achieving the ideal balance between power savings and display performance is complex. The dynamic refresh rate functionality, a key feature of LTPO, demands sophisticated control systems to seamlessly switch between different refresh rates without compromising visual quality or introducing artifacts.

Thermal management presents an additional hurdle for LTPO implementation. The varying refresh rates and power states can create localized heating issues, potentially impacting the longevity and performance of the display. Developing effective heat dissipation solutions while maintaining the slim profile of modern mobile devices is a critical engineering challenge.

Yield rates in LTPO production also pose a significant concern. The increased complexity of the manufacturing process compared to traditional AMOLED displays can lead to higher defect rates and lower yields, particularly in the early stages of adoption. This challenge has implications for production costs and the widespread implementation of LTPO technology in consumer devices.

Furthermore, the development of driver ICs (Integrated Circuits) capable of fully leveraging LTPO's capabilities is an ongoing challenge. These ICs must efficiently manage the dynamic refresh rate, power states, and compensate for panel variations, all while maintaining high performance and low power consumption.

Lastly, ensuring long-term reliability and consistency of LTPO displays under various usage conditions remains a critical area of focus. The technology must demonstrate robustness against factors such as temperature variations, humidity, and prolonged use to meet the demanding requirements of modern consumer electronics.

The integration of these two technologies introduces challenges in maintaining consistent performance across the entire display panel. Variations in transistor characteristics between LTPS and IGZO regions can lead to non-uniform pixel behavior, potentially affecting image quality and power efficiency. Addressing this issue requires advanced compensation algorithms and fine-tuning of the manufacturing process.

Another significant challenge lies in optimizing the power-saving capabilities of LTPO. While the technology promises substantial energy efficiency improvements, achieving the ideal balance between power savings and display performance is complex. The dynamic refresh rate functionality, a key feature of LTPO, demands sophisticated control systems to seamlessly switch between different refresh rates without compromising visual quality or introducing artifacts.

Thermal management presents an additional hurdle for LTPO implementation. The varying refresh rates and power states can create localized heating issues, potentially impacting the longevity and performance of the display. Developing effective heat dissipation solutions while maintaining the slim profile of modern mobile devices is a critical engineering challenge.

Yield rates in LTPO production also pose a significant concern. The increased complexity of the manufacturing process compared to traditional AMOLED displays can lead to higher defect rates and lower yields, particularly in the early stages of adoption. This challenge has implications for production costs and the widespread implementation of LTPO technology in consumer devices.

Furthermore, the development of driver ICs (Integrated Circuits) capable of fully leveraging LTPO's capabilities is an ongoing challenge. These ICs must efficiently manage the dynamic refresh rate, power states, and compensate for panel variations, all while maintaining high performance and low power consumption.

Lastly, ensuring long-term reliability and consistency of LTPO displays under various usage conditions remains a critical area of focus. The technology must demonstrate robustness against factors such as temperature variations, humidity, and prolonged use to meet the demanding requirements of modern consumer electronics.

Current LTPO Solutions

01 LTPO AMOLED display technology

LTPO (Low-Temperature Polycrystalline Oxide) AMOLED displays combine the benefits of LTPS and oxide TFTs, offering improved power efficiency and variable refresh rates. This technology allows for adaptive refresh rates, enhancing battery life while maintaining high-quality display performance.- LTPO AMOLED display technology: LTPO (Low-Temperature Polycrystalline Oxide) AMOLED displays combine the benefits of LTPS and oxide TFTs, offering improved power efficiency and variable refresh rates. This technology allows for adaptive refresh rates, reducing power consumption when displaying static content while maintaining high refresh rates for dynamic content.

- Adaptive refresh rate control: LTPO AMOLED displays feature adaptive refresh rate control, allowing the display to dynamically adjust its refresh rate based on the content being displayed. This adaptability helps optimize power consumption and improve overall display performance, particularly in mobile devices with varying content types.

- Power efficiency improvements: The LTPO technology in AMOLED displays offers significant power efficiency improvements compared to traditional LTPS displays. By combining oxide and LTPS TFTs, LTPO displays can reduce power consumption, especially during low refresh rate operations, leading to extended battery life in mobile devices.

- Integration with touch and biometric sensors: LTPO AMOLED displays can be integrated with various sensors, including touch and biometric sensors, to enhance device functionality. This integration allows for features such as in-display fingerprint sensors and improved touch response, while maintaining the display's adaptability and power efficiency.

- Manufacturing and fabrication techniques: Advanced manufacturing and fabrication techniques are employed in the production of LTPO AMOLED displays to ensure high yield and performance. These techniques involve specialized processes for combining oxide and LTPS TFTs, as well as optimizing the display structure for improved adaptability and efficiency.

02 Adaptive refresh rate control

LTPO AMOLED displays feature adaptive refresh rate control, allowing the display to dynamically adjust its refresh rate based on content and user interaction. This adaptability helps optimize power consumption and improve overall display performance, particularly in mobile devices.Expand Specific Solutions03 Power efficiency optimization

LTPO technology enables significant power savings in AMOLED displays by allowing for more efficient pixel driving and reduced power consumption during low refresh rate periods. This optimization contributes to extended battery life in devices utilizing LTPO AMOLED displays.Expand Specific Solutions04 Integration with touch and biometric features

LTPO AMOLED displays can be integrated with advanced touch sensing and biometric features, such as under-display fingerprint sensors. This integration enhances the overall functionality and user experience of devices incorporating LTPO AMOLED technology.Expand Specific Solutions05 Compatibility with flexible and foldable designs

LTPO AMOLED technology can be adapted for use in flexible and foldable display designs, allowing for innovative form factors in mobile devices. The adaptability of LTPO technology enables its application in various display configurations while maintaining power efficiency and performance benefits.Expand Specific Solutions

Key LTPO Display Players

The LTPO AMOLED display technology market is in a growth phase, with increasing adoption in high-end smartphones and wearables. The market size is expanding rapidly, driven by consumer demand for energy-efficient, high-performance displays. Technologically, LTPO is maturing, with major players like Samsung Electronics, BOE Technology, and Tianma Microelectronics making significant advancements. These companies are investing heavily in R&D to improve LTPO's efficiency and performance. Other key players, including TCL CSOT and Visionox, are also entering the market, intensifying competition. The technology's maturity is evident in its widespread implementation, but there's still room for innovation in areas such as power consumption and refresh rate variability.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed its own LTPO AMOLED technology, focusing on improving display adaptability and energy efficiency. Their LTPO displays can adjust refresh rates from 1Hz to 120Hz, similar to Samsung's offerings[5]. BOE's implementation includes advanced pixel compensation algorithms to maintain color accuracy across different refresh rates[6]. The company has also introduced a unique "hybrid" LTPO technology that combines the benefits of LTPO with traditional LTPS, potentially offering a more cost-effective solution for manufacturers[7]. BOE's LTPO panels have shown up to 15% reduction in power consumption compared to standard AMOLED displays[8].

Strengths: Cost-effective LTPO solutions, growing market share in AMOLED production. Weaknesses: Still catching up to Samsung in terms of overall display quality and production yield.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered LTPO AMOLED technology, significantly enhancing display adaptability. Their LTPO displays can dynamically adjust refresh rates from 1Hz to 120Hz, optimizing power consumption[1]. Samsung's implementation allows for fine-grained control over individual pixel voltages, enabling precise brightness and color adjustments[2]. This technology has been integrated into their flagship smartphones, demonstrating up to 22% improvement in power efficiency compared to standard AMOLED displays[3]. Samsung's LTPO AMOLED panels also feature improved response times and reduced motion blur, enhancing overall display performance[4].

Strengths: Industry-leading LTPO technology, significant power savings, and enhanced display performance. Weaknesses: Higher production costs and complexity in manufacturing process.

LTPO Core Innovations

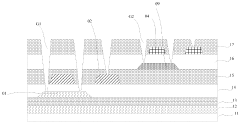

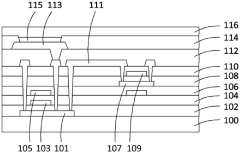

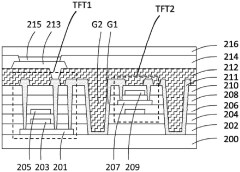

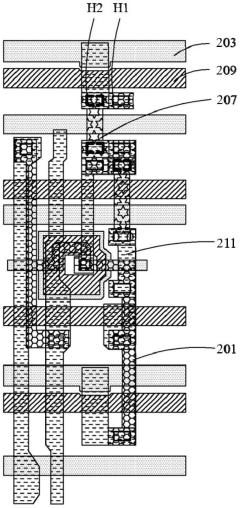

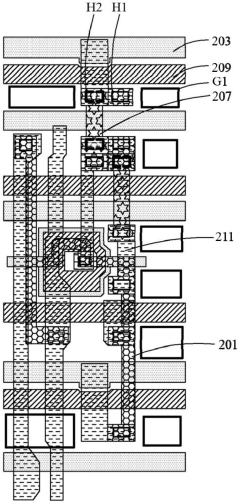

Display substrate, fabrication method therefor, and display device

PatentWO2024000249A1

Innovation

- By using the same layer and the same material for the first active layer and the second active layer in the display substrate, the same patterning process is used to form a via hole exposing the active layer of the second transistor, and the first transistor is connected through the same layer. Make sure the etching depth of the via holes is the same or basically the same.

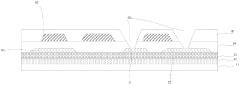

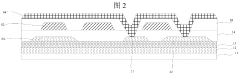

Display Panel

PatentActiveCN112420749B

Innovation

- Low-temperature polysilicon thin film transistors and metal oxide thin film transistors are introduced into the display panel, and a metal barrier layer is formed in the multi-layer insulating layer, covering the groove, and filled with organic layers to improve the barrier effect and bending performance.

Power Efficiency Impact

LTPO (Low-Temperature Polycrystalline Oxide) technology has significantly enhanced the power efficiency of AMOLED displays, revolutionizing the adaptability of these screens in various devices. The integration of LTPO into AMOLED displays has led to substantial improvements in energy consumption, particularly in mobile devices where battery life is a critical factor.

One of the primary advantages of LTPO technology is its ability to dynamically adjust the refresh rate of the display. Traditional AMOLED screens operate at a fixed refresh rate, typically 60Hz or higher, regardless of the content being displayed. This constant high refresh rate consumes unnecessary power, especially when displaying static content. LTPO allows the display to seamlessly switch between high refresh rates (up to 120Hz or more) for smooth animations and low refresh rates (as low as 1Hz) for static content, resulting in significant power savings.

The power efficiency impact of LTPO on AMOLED displays is particularly noticeable in always-on display features. By reducing the refresh rate to 1Hz for static content, LTPO-enabled devices can maintain an always-on display with minimal battery drain. This feature has become increasingly popular in smartphones and smartwatches, providing users with constant access to essential information without significantly impacting battery life.

Furthermore, LTPO technology enables more efficient power management in variable refresh rate scenarios. For instance, when scrolling through a webpage or playing a video game, the display can dynamically adjust its refresh rate to match the content, optimizing power consumption without compromising visual quality. This adaptive refresh rate capability not only conserves energy but also enhances the overall user experience by providing smoother motion and reduced screen tearing.

The power efficiency gains from LTPO technology extend beyond refresh rate management. The low-temperature polycrystalline oxide material used in LTPO displays exhibits lower power leakage compared to traditional LTPS (Low-Temperature Polycrystalline Silicon) backplanes. This inherent characteristic further contributes to reduced power consumption, especially in standby modes or when displaying dark content.

In mobile devices, the implementation of LTPO technology has led to reported battery life improvements of up to 15-20% compared to non-LTPO AMOLED displays. This significant increase in power efficiency has allowed manufacturers to either extend battery life or reduce battery size without compromising on screen-on time, contributing to thinner and lighter device designs.

As LTPO technology continues to evolve, we can expect further refinements in power efficiency. Future developments may include even lower power consumption in ultra-low refresh rate modes, improved color accuracy at variable refresh rates, and enhanced integration with system-level power management features. These advancements will likely cement LTPO's position as a key technology in the ongoing pursuit of more energy-efficient and adaptable display solutions for mobile and wearable devices.

One of the primary advantages of LTPO technology is its ability to dynamically adjust the refresh rate of the display. Traditional AMOLED screens operate at a fixed refresh rate, typically 60Hz or higher, regardless of the content being displayed. This constant high refresh rate consumes unnecessary power, especially when displaying static content. LTPO allows the display to seamlessly switch between high refresh rates (up to 120Hz or more) for smooth animations and low refresh rates (as low as 1Hz) for static content, resulting in significant power savings.

The power efficiency impact of LTPO on AMOLED displays is particularly noticeable in always-on display features. By reducing the refresh rate to 1Hz for static content, LTPO-enabled devices can maintain an always-on display with minimal battery drain. This feature has become increasingly popular in smartphones and smartwatches, providing users with constant access to essential information without significantly impacting battery life.

Furthermore, LTPO technology enables more efficient power management in variable refresh rate scenarios. For instance, when scrolling through a webpage or playing a video game, the display can dynamically adjust its refresh rate to match the content, optimizing power consumption without compromising visual quality. This adaptive refresh rate capability not only conserves energy but also enhances the overall user experience by providing smoother motion and reduced screen tearing.

The power efficiency gains from LTPO technology extend beyond refresh rate management. The low-temperature polycrystalline oxide material used in LTPO displays exhibits lower power leakage compared to traditional LTPS (Low-Temperature Polycrystalline Silicon) backplanes. This inherent characteristic further contributes to reduced power consumption, especially in standby modes or when displaying dark content.

In mobile devices, the implementation of LTPO technology has led to reported battery life improvements of up to 15-20% compared to non-LTPO AMOLED displays. This significant increase in power efficiency has allowed manufacturers to either extend battery life or reduce battery size without compromising on screen-on time, contributing to thinner and lighter device designs.

As LTPO technology continues to evolve, we can expect further refinements in power efficiency. Future developments may include even lower power consumption in ultra-low refresh rate modes, improved color accuracy at variable refresh rates, and enhanced integration with system-level power management features. These advancements will likely cement LTPO's position as a key technology in the ongoing pursuit of more energy-efficient and adaptable display solutions for mobile and wearable devices.

LTPO Manufacturing Costs

The manufacturing costs associated with Low-Temperature Polycrystalline Oxide (LTPO) technology play a crucial role in its adoption and implementation in AMOLED displays. LTPO manufacturing involves several complex processes that contribute to its overall cost structure.

One of the primary factors influencing LTPO manufacturing costs is the specialized equipment required for the fabrication process. The production of LTPO backplanes necessitates advanced lithography tools, deposition systems, and etching equipment. These sophisticated machines come with substantial capital expenditures, which are reflected in the overall manufacturing costs.

Material costs also significantly impact LTPO production expenses. The technology utilizes high-quality oxide semiconductors, such as indium gallium zinc oxide (IGZO), which are more expensive than traditional amorphous silicon. Additionally, the need for high-purity precursor materials and specialized dopants further contributes to the material cost component.

The complexity of the LTPO manufacturing process itself adds to the overall expenses. The fabrication involves multiple steps, including thin-film deposition, patterning, and annealing, each requiring precise control and optimization. This intricate process leads to longer production cycles and potentially lower yields, especially during the initial stages of implementation.

Labor costs associated with LTPO manufacturing are also considerable. The technology demands highly skilled engineers and technicians who are proficient in advanced semiconductor fabrication techniques. The specialized knowledge required for LTPO production commands higher wages, contributing to the overall manufacturing expenses.

Quality control and testing procedures for LTPO panels are more rigorous compared to conventional display technologies. The need for extensive testing to ensure uniform performance and reliability across the display adds to the manufacturing costs. This includes both in-line testing during production and final quality assurance checks.

As with any emerging technology, economies of scale play a significant role in LTPO manufacturing costs. Initially, the production volumes may be lower, resulting in higher per-unit costs. However, as adoption increases and production scales up, it is expected that manufacturing costs will gradually decrease, making LTPO more economically viable for a broader range of applications.

The ongoing research and development efforts to improve LTPO technology also contribute to its overall cost structure. Investments in enhancing performance, increasing yields, and optimizing production processes are necessary to maintain competitiveness in the rapidly evolving display market.

One of the primary factors influencing LTPO manufacturing costs is the specialized equipment required for the fabrication process. The production of LTPO backplanes necessitates advanced lithography tools, deposition systems, and etching equipment. These sophisticated machines come with substantial capital expenditures, which are reflected in the overall manufacturing costs.

Material costs also significantly impact LTPO production expenses. The technology utilizes high-quality oxide semiconductors, such as indium gallium zinc oxide (IGZO), which are more expensive than traditional amorphous silicon. Additionally, the need for high-purity precursor materials and specialized dopants further contributes to the material cost component.

The complexity of the LTPO manufacturing process itself adds to the overall expenses. The fabrication involves multiple steps, including thin-film deposition, patterning, and annealing, each requiring precise control and optimization. This intricate process leads to longer production cycles and potentially lower yields, especially during the initial stages of implementation.

Labor costs associated with LTPO manufacturing are also considerable. The technology demands highly skilled engineers and technicians who are proficient in advanced semiconductor fabrication techniques. The specialized knowledge required for LTPO production commands higher wages, contributing to the overall manufacturing expenses.

Quality control and testing procedures for LTPO panels are more rigorous compared to conventional display technologies. The need for extensive testing to ensure uniform performance and reliability across the display adds to the manufacturing costs. This includes both in-line testing during production and final quality assurance checks.

As with any emerging technology, economies of scale play a significant role in LTPO manufacturing costs. Initially, the production volumes may be lower, resulting in higher per-unit costs. However, as adoption increases and production scales up, it is expected that manufacturing costs will gradually decrease, making LTPO more economically viable for a broader range of applications.

The ongoing research and development efforts to improve LTPO technology also contribute to its overall cost structure. Investments in enhancing performance, increasing yields, and optimizing production processes are necessary to maintain competitiveness in the rapidly evolving display market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!