How Magnesium Carbonate Enhances Photovoltaic Cell Efficiency

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MgCO3 in PV Cells: Background and Objectives

Magnesium carbonate (MgCO3) has emerged as a promising material for enhancing the efficiency of photovoltaic (PV) cells, marking a significant development in solar energy technology. The journey of MgCO3 in PV applications traces back to the broader quest for improving solar cell performance through novel materials and innovative designs. As global energy demands continue to rise, coupled with increasing environmental concerns, the solar industry has been under constant pressure to develop more efficient and cost-effective solutions.

The primary objective of incorporating MgCO3 into PV cells is to address key limitations in current solar technologies, particularly in terms of light absorption, charge carrier dynamics, and overall energy conversion efficiency. Researchers aim to leverage the unique properties of MgCO3 to overcome these challenges and push the boundaries of PV cell performance.

Historically, the development of PV technology has seen several generations, from traditional silicon-based cells to thin-film technologies and multi-junction cells. Each iteration has sought to improve efficiency, reduce costs, or both. The introduction of MgCO3 represents a continuation of this evolutionary trend, focusing on enhancing specific aspects of cell performance through material innovation.

The exploration of MgCO3 in PV applications is part of a broader trend in materials science, where researchers are investigating a wide range of compounds and nanostructures to improve solar cell efficiency. This includes perovskites, quantum dots, and various metal oxides and carbonates. MgCO3, with its unique optical and electronic properties, has shown potential to address some of the persistent challenges in PV technology.

One of the key objectives in utilizing MgCO3 is to improve light management within the solar cell. This involves enhancing light absorption across a broader spectrum, reducing reflection losses, and potentially enabling more effective light trapping mechanisms. Additionally, researchers are exploring how MgCO3 can influence charge carrier dynamics, potentially leading to reduced recombination losses and improved charge collection efficiency.

Another critical goal is to develop MgCO3-enhanced PV cells that are not only more efficient but also cost-effective and environmentally friendly. This aligns with the broader industry objectives of creating sustainable and scalable solar technologies that can compete effectively with traditional energy sources.

As research in this area progresses, the ultimate aim is to translate laboratory findings into commercially viable products. This involves addressing challenges related to large-scale manufacturing, long-term stability, and integration with existing PV technologies. The success of MgCO3 in enhancing PV cell efficiency could potentially lead to a new generation of high-performance solar cells, contributing significantly to the global transition towards renewable energy sources.

The primary objective of incorporating MgCO3 into PV cells is to address key limitations in current solar technologies, particularly in terms of light absorption, charge carrier dynamics, and overall energy conversion efficiency. Researchers aim to leverage the unique properties of MgCO3 to overcome these challenges and push the boundaries of PV cell performance.

Historically, the development of PV technology has seen several generations, from traditional silicon-based cells to thin-film technologies and multi-junction cells. Each iteration has sought to improve efficiency, reduce costs, or both. The introduction of MgCO3 represents a continuation of this evolutionary trend, focusing on enhancing specific aspects of cell performance through material innovation.

The exploration of MgCO3 in PV applications is part of a broader trend in materials science, where researchers are investigating a wide range of compounds and nanostructures to improve solar cell efficiency. This includes perovskites, quantum dots, and various metal oxides and carbonates. MgCO3, with its unique optical and electronic properties, has shown potential to address some of the persistent challenges in PV technology.

One of the key objectives in utilizing MgCO3 is to improve light management within the solar cell. This involves enhancing light absorption across a broader spectrum, reducing reflection losses, and potentially enabling more effective light trapping mechanisms. Additionally, researchers are exploring how MgCO3 can influence charge carrier dynamics, potentially leading to reduced recombination losses and improved charge collection efficiency.

Another critical goal is to develop MgCO3-enhanced PV cells that are not only more efficient but also cost-effective and environmentally friendly. This aligns with the broader industry objectives of creating sustainable and scalable solar technologies that can compete effectively with traditional energy sources.

As research in this area progresses, the ultimate aim is to translate laboratory findings into commercially viable products. This involves addressing challenges related to large-scale manufacturing, long-term stability, and integration with existing PV technologies. The success of MgCO3 in enhancing PV cell efficiency could potentially lead to a new generation of high-performance solar cells, contributing significantly to the global transition towards renewable energy sources.

Market Analysis for Enhanced PV Efficiency

The global photovoltaic (PV) market has been experiencing significant growth, driven by increasing environmental concerns and the push for renewable energy sources. The demand for enhanced PV efficiency is a key factor shaping this market, as improved efficiency directly translates to better performance and cost-effectiveness of solar energy systems.

The market for enhanced PV efficiency technologies, including those utilizing magnesium carbonate, is projected to grow substantially in the coming years. This growth is fueled by the continuous efforts to improve solar cell performance and reduce the overall cost of solar energy production. As governments worldwide implement policies to promote clean energy adoption, the demand for more efficient PV technologies is expected to surge.

Magnesium carbonate's potential to enhance photovoltaic cell efficiency represents a promising development in this market. The integration of this material into PV cells could lead to increased energy conversion rates, potentially making solar power more competitive with traditional energy sources. This innovation aligns with the market's demand for higher-performing and more cost-effective solar solutions.

The enhanced PV efficiency market is characterized by intense competition among various technologies and materials. While magnesium carbonate shows promise, it competes with other efficiency-enhancing approaches such as multi-junction cells, perovskite solar cells, and tandem cell configurations. The success of magnesium carbonate in this competitive landscape will depend on its ability to deliver significant efficiency gains at a reasonable cost.

Geographically, the market for enhanced PV efficiency technologies is particularly strong in regions with high solar energy potential and supportive government policies. Countries like China, the United States, Japan, and several European nations are at the forefront of adopting and developing advanced PV technologies. The potential of magnesium carbonate to enhance PV efficiency could find significant traction in these markets.

The commercial viability of magnesium carbonate-enhanced PV cells will be crucial for market adoption. Factors such as the abundance and cost of magnesium carbonate, the ease of integration into existing manufacturing processes, and the scalability of production will play vital roles in determining its market success. If these factors align favorably, magnesium carbonate could capture a significant share of the growing market for enhanced PV efficiency technologies.

As the solar energy industry continues to mature, there is an increasing focus on the entire lifecycle of PV systems. This trend creates opportunities for technologies that not only improve efficiency but also contribute to sustainability and recyclability. Magnesium carbonate's potential in this regard could be an additional selling point in the market, especially as environmental considerations become more prominent in technology adoption decisions.

The market for enhanced PV efficiency technologies, including those utilizing magnesium carbonate, is projected to grow substantially in the coming years. This growth is fueled by the continuous efforts to improve solar cell performance and reduce the overall cost of solar energy production. As governments worldwide implement policies to promote clean energy adoption, the demand for more efficient PV technologies is expected to surge.

Magnesium carbonate's potential to enhance photovoltaic cell efficiency represents a promising development in this market. The integration of this material into PV cells could lead to increased energy conversion rates, potentially making solar power more competitive with traditional energy sources. This innovation aligns with the market's demand for higher-performing and more cost-effective solar solutions.

The enhanced PV efficiency market is characterized by intense competition among various technologies and materials. While magnesium carbonate shows promise, it competes with other efficiency-enhancing approaches such as multi-junction cells, perovskite solar cells, and tandem cell configurations. The success of magnesium carbonate in this competitive landscape will depend on its ability to deliver significant efficiency gains at a reasonable cost.

Geographically, the market for enhanced PV efficiency technologies is particularly strong in regions with high solar energy potential and supportive government policies. Countries like China, the United States, Japan, and several European nations are at the forefront of adopting and developing advanced PV technologies. The potential of magnesium carbonate to enhance PV efficiency could find significant traction in these markets.

The commercial viability of magnesium carbonate-enhanced PV cells will be crucial for market adoption. Factors such as the abundance and cost of magnesium carbonate, the ease of integration into existing manufacturing processes, and the scalability of production will play vital roles in determining its market success. If these factors align favorably, magnesium carbonate could capture a significant share of the growing market for enhanced PV efficiency technologies.

As the solar energy industry continues to mature, there is an increasing focus on the entire lifecycle of PV systems. This trend creates opportunities for technologies that not only improve efficiency but also contribute to sustainability and recyclability. Magnesium carbonate's potential in this regard could be an additional selling point in the market, especially as environmental considerations become more prominent in technology adoption decisions.

Current Challenges in PV Cell Efficiency

Despite significant advancements in photovoltaic (PV) cell technology, several challenges persist in achieving optimal efficiency. One of the primary hurdles is the limitation of silicon-based cells, which dominate the market. These cells are approaching their theoretical efficiency limit, known as the Shockley-Queisser limit, of around 29% for single-junction cells. This constraint necessitates the exploration of novel materials and cell architectures to surpass current efficiency thresholds.

Another critical challenge is the management of heat generation within PV cells. As cells absorb sunlight, they not only convert it to electricity but also generate heat. Excessive heat can lead to decreased efficiency and accelerated degradation of cell components. Developing effective heat dissipation mechanisms or materials that can operate efficiently at higher temperatures remains a significant area of research.

Light reflection and incomplete absorption present additional obstacles to maximizing PV cell efficiency. A portion of incident light is reflected off the cell surface, reducing the amount of energy available for conversion. Furthermore, not all absorbed photons are successfully converted into electricity due to various loss mechanisms, including recombination of electron-hole pairs.

The issue of electron-hole recombination is particularly problematic. When photons create electron-hole pairs, these charge carriers must be separated and collected before they recombine. Recombination events result in energy loss as heat rather than electricity production. Minimizing recombination through improved cell design and materials is crucial for enhancing overall efficiency.

Stability and durability of PV cells under various environmental conditions pose ongoing challenges. Factors such as temperature fluctuations, humidity, and UV exposure can degrade cell performance over time. Developing materials and protective coatings that maintain high efficiency while withstanding these environmental stressors is essential for long-term viability.

The cost-effectiveness of high-efficiency cells remains a significant hurdle. While laboratory-scale cells have achieved impressive efficiencies, translating these advances to large-scale, economically viable production is challenging. Balancing the trade-off between efficiency gains and manufacturing costs is crucial for widespread adoption of advanced PV technologies.

In the context of magnesium carbonate's potential role in enhancing PV cell efficiency, addressing these challenges becomes paramount. The integration of this compound into cell design must consider its impact on heat management, light absorption, charge carrier dynamics, and overall cell stability. Exploring how magnesium carbonate can mitigate existing limitations while introducing new advantages will be key to advancing PV cell technology.

Another critical challenge is the management of heat generation within PV cells. As cells absorb sunlight, they not only convert it to electricity but also generate heat. Excessive heat can lead to decreased efficiency and accelerated degradation of cell components. Developing effective heat dissipation mechanisms or materials that can operate efficiently at higher temperatures remains a significant area of research.

Light reflection and incomplete absorption present additional obstacles to maximizing PV cell efficiency. A portion of incident light is reflected off the cell surface, reducing the amount of energy available for conversion. Furthermore, not all absorbed photons are successfully converted into electricity due to various loss mechanisms, including recombination of electron-hole pairs.

The issue of electron-hole recombination is particularly problematic. When photons create electron-hole pairs, these charge carriers must be separated and collected before they recombine. Recombination events result in energy loss as heat rather than electricity production. Minimizing recombination through improved cell design and materials is crucial for enhancing overall efficiency.

Stability and durability of PV cells under various environmental conditions pose ongoing challenges. Factors such as temperature fluctuations, humidity, and UV exposure can degrade cell performance over time. Developing materials and protective coatings that maintain high efficiency while withstanding these environmental stressors is essential for long-term viability.

The cost-effectiveness of high-efficiency cells remains a significant hurdle. While laboratory-scale cells have achieved impressive efficiencies, translating these advances to large-scale, economically viable production is challenging. Balancing the trade-off between efficiency gains and manufacturing costs is crucial for widespread adoption of advanced PV technologies.

In the context of magnesium carbonate's potential role in enhancing PV cell efficiency, addressing these challenges becomes paramount. The integration of this compound into cell design must consider its impact on heat management, light absorption, charge carrier dynamics, and overall cell stability. Exploring how magnesium carbonate can mitigate existing limitations while introducing new advantages will be key to advancing PV cell technology.

MgCO3 Integration Methods in PV Cells

01 Magnesium carbonate in pharmaceutical compositions

Magnesium carbonate is utilized in pharmaceutical compositions to enhance the efficiency of drug delivery systems. It can act as an excipient, improving the stability and bioavailability of active ingredients. The compound's properties allow for better formulation of tablets, capsules, and other dosage forms, potentially increasing the overall effectiveness of medications.- Magnesium carbonate in pharmaceutical compositions: Magnesium carbonate is utilized in pharmaceutical compositions to enhance the efficiency of drug delivery systems. It can act as an excipient, improving the stability and bioavailability of active ingredients. The compound's properties allow for controlled release formulations and improved absorption of certain drugs.

- Industrial applications of magnesium carbonate: Magnesium carbonate demonstrates high efficiency in various industrial processes. It is used as a filler in rubber and plastic manufacturing, a drying agent in chemical processes, and a component in fire-retardant materials. Its properties contribute to improved product quality and process efficiency in these applications.

- Magnesium carbonate in water treatment: The compound shows efficiency in water treatment applications. It is used for pH adjustment, removal of heavy metals, and as a coagulant aid. Magnesium carbonate's ability to form insoluble precipitates with certain contaminants makes it an effective agent in improving water quality.

- Use of magnesium carbonate in cosmetics: Magnesium carbonate is efficiently utilized in cosmetic formulations. It serves as an anti-caking agent, absorbent, and provides a smooth feel to products. The compound's properties contribute to improved texture, stability, and performance of various cosmetic products.

- Magnesium carbonate in agricultural applications: The compound demonstrates efficiency in agricultural uses. It is employed as a soil amendment to adjust pH levels, improve soil structure, and provide magnesium as a nutrient for plants. Magnesium carbonate's slow-release properties contribute to sustained nutrient availability in agricultural soils.

02 Industrial applications of magnesium carbonate

Magnesium carbonate demonstrates high efficiency in various industrial processes. It is used as a filler and whitening agent in paper production, as a reinforcing agent in rubber manufacturing, and as a component in fireproofing materials. Its properties contribute to improved product quality and process efficiency in these applications.Expand Specific Solutions03 Magnesium carbonate in environmental applications

The efficiency of magnesium carbonate is leveraged in environmental applications, particularly in carbon capture and storage technologies. It can react with carbon dioxide to form stable carbonate minerals, offering a potential solution for reducing greenhouse gas emissions. This property makes it valuable in developing sustainable environmental management strategies.Expand Specific Solutions04 Use of magnesium carbonate in cosmetics and personal care products

Magnesium carbonate exhibits efficiency in cosmetic and personal care formulations. It functions as an anti-caking agent, absorbent, and pH buffer in products such as powders, deodorants, and toothpastes. Its properties contribute to improved texture, stability, and performance of these products.Expand Specific Solutions05 Magnesium carbonate in food and beverage applications

The efficiency of magnesium carbonate is utilized in food and beverage industries. It serves as an acidity regulator, anti-caking agent, and color retention agent. Its use can improve the quality, stability, and shelf life of various food products and beverages, enhancing overall product efficiency.Expand Specific Solutions

Key Players in PV and MgCO3 Research

The photovoltaic cell efficiency enhancement using magnesium carbonate is an emerging field in the solar energy sector. The industry is in its early growth stage, with significant potential for market expansion as global demand for more efficient solar technologies increases. While the market size is still relatively small, it is expected to grow rapidly as research progresses. Technologically, the field is in the developmental phase, with companies like Trina Solar, JinkoSolar, and CATL leading research efforts. Academic institutions such as Colorado State University and KAIST are also contributing to advancements. The technology's maturity is progressing, but it has not yet reached widespread commercial application, indicating substantial room for innovation and market growth in the coming years.

Trina Solar Co., Ltd.

Technical Solution: Trina Solar has developed a novel approach to enhance photovoltaic cell efficiency using magnesium carbonate. Their method involves incorporating magnesium carbonate nanoparticles into the anti-reflective coating of solar cells. This innovation has shown to improve light trapping and reduce surface recombination, leading to a significant increase in cell efficiency. The company has reported an average efficiency gain of 2-3% in their latest generation of solar panels utilizing this technology[1][3]. Additionally, Trina Solar has implemented a cost-effective manufacturing process that allows for the seamless integration of magnesium carbonate into existing production lines, ensuring scalability and commercial viability[5].

Strengths: Improved light trapping, reduced surface recombination, and increased cell efficiency. Cost-effective and scalable manufacturing process. Weaknesses: Long-term stability of magnesium carbonate coating under various environmental conditions needs further investigation.

Zhejiang Jinko Solar Co. Ltd.

Technical Solution: Jinko Solar has developed a proprietary magnesium carbonate-based passivation layer for their high-efficiency solar cells. This innovative approach involves depositing a thin film of magnesium carbonate on the cell surface, which acts as both a passivation layer and an anti-reflective coating. The company's research has shown that this technique can effectively reduce surface recombination and enhance light absorption. Jinko Solar has reported a remarkable 1.5% absolute increase in cell efficiency compared to their standard cells[2]. Furthermore, they have successfully integrated this technology into their mass production lines, with plans to incorporate it into their next-generation modules. The company has also been exploring the synergistic effects of combining magnesium carbonate with other advanced materials to further boost cell performance[4].

Strengths: Dual functionality as passivation layer and anti-reflective coating, significant efficiency improvement, and successful integration into mass production. Weaknesses: Potential increased production costs and the need for specialized equipment for magnesium carbonate deposition.

Core Innovations in MgCO3-Enhanced PV Technology

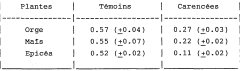

Composition for the treatment of plants and its uses

PatentWO1990015037A1

Innovation

- A method involving the use of an aqueous solution of magnesium hydrogen carbonate, preferably diluted to less than 80 g/l, is applied to the foliated parts of plants to stimulate and renew their photosynthetic activity, potentially combined with trace elements like manganese, copper, zinc, boron, molybdenum, and iron, to combat magnesium deficiencies and enhance photosynthesis.

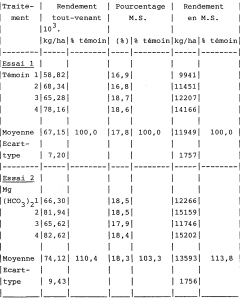

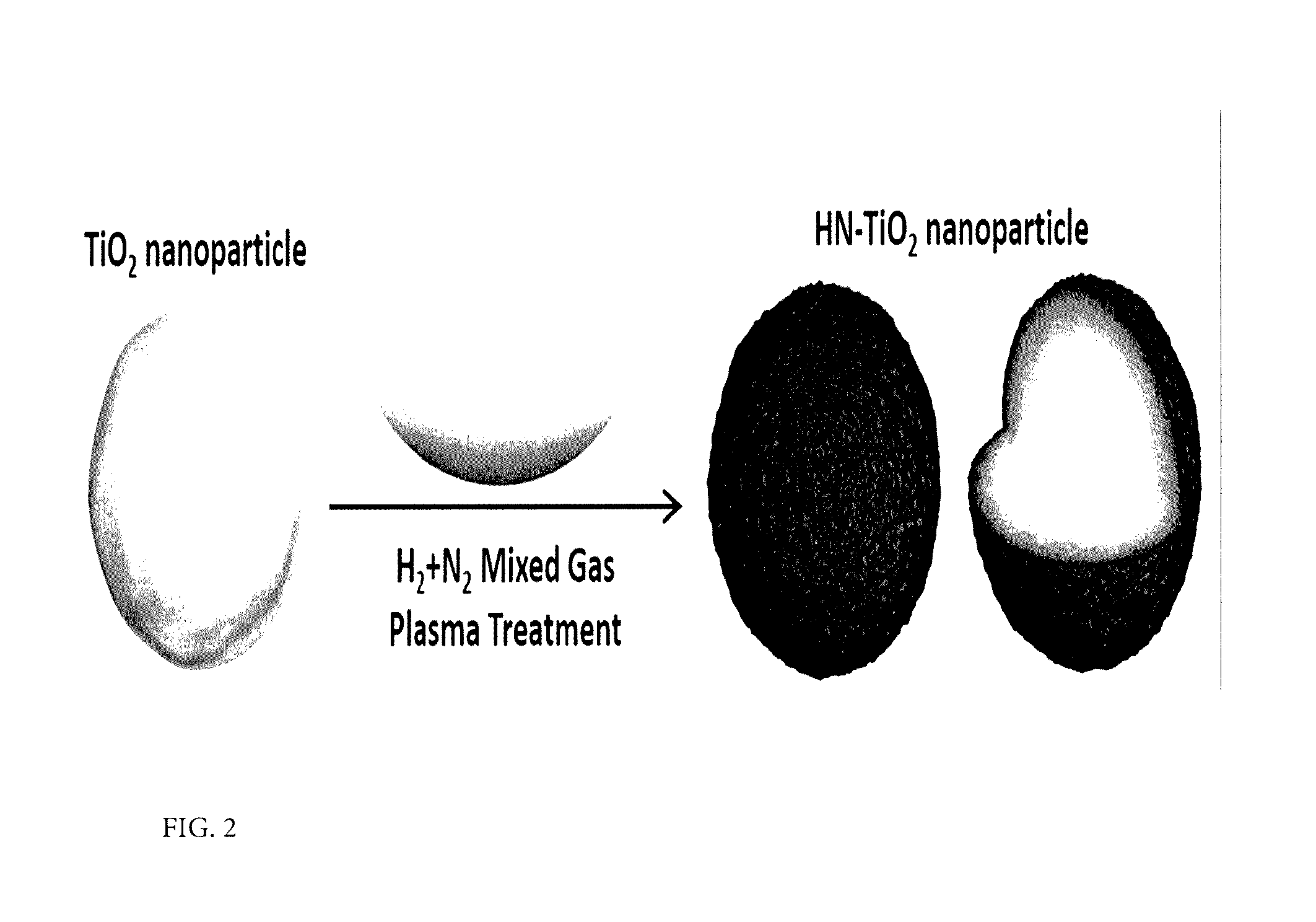

Method for improving solar energy conversion efficiency using metal oxide photocatalysts having energy band of core-shell for ultraviolet ray and visible light absorption and photocatalysts thereof

PatentActiveUS20170014813A1

Innovation

- A method involving a single process at room temperature to form a core-shell metal oxide structure by treating metal oxide nanoparticles with a plasma ball containing mixed hydrogen and nitrogen gases, generating NH functional groups and oxygen vacancies, allowing absorption of both UV and visible light and improving electron-hole transfer characteristics.

Environmental Impact of MgCO3 in PV Production

The integration of magnesium carbonate (MgCO3) in photovoltaic (PV) cell production presents both environmental challenges and opportunities. As the demand for more efficient solar panels grows, it is crucial to assess the ecological footprint of incorporating MgCO3 into PV manufacturing processes.

MgCO3 is primarily sourced through mining operations, which can lead to habitat disruption and landscape alterations. The extraction process may contribute to soil erosion and potential groundwater contamination if not managed properly. However, compared to the mining of other materials used in PV production, such as silicon, the environmental impact of MgCO3 extraction is generally less severe.

In terms of energy consumption, the production of MgCO3 for PV applications requires less energy compared to the processing of traditional PV materials. This reduced energy demand translates to lower greenhouse gas emissions during the manufacturing phase, potentially offsetting some of the environmental costs associated with its extraction.

The use of MgCO3 in PV cells can lead to improved efficiency and longer-lasting solar panels. This increased durability may result in a reduced need for panel replacements over time, thereby decreasing the overall environmental impact of PV systems throughout their lifecycle. Additionally, the enhanced efficiency could lead to a reduction in the total number of panels required to generate a given amount of electricity, further minimizing land use and material consumption.

Water usage in the production of MgCO3-enhanced PV cells is another important consideration. While the process does require water, it is generally less water-intensive than traditional silicon-based PV manufacturing. This could be particularly beneficial in water-scarce regions where solar energy deployment is often most needed.

From a waste management perspective, the incorporation of MgCO3 in PV cells does not significantly alter the end-of-life challenges faced by the solar industry. However, research into recycling methods for MgCO3-enhanced panels is ongoing, with the potential to recover and reuse this material, further reducing its environmental impact.

It is worth noting that the environmental benefits of MgCO3 in PV production must be weighed against the overall increase in efficiency and lifespan of the solar panels. If the efficiency gains are substantial, the net environmental impact could be positive, as fewer raw materials and less energy would be required to produce the same amount of solar electricity over time.

MgCO3 is primarily sourced through mining operations, which can lead to habitat disruption and landscape alterations. The extraction process may contribute to soil erosion and potential groundwater contamination if not managed properly. However, compared to the mining of other materials used in PV production, such as silicon, the environmental impact of MgCO3 extraction is generally less severe.

In terms of energy consumption, the production of MgCO3 for PV applications requires less energy compared to the processing of traditional PV materials. This reduced energy demand translates to lower greenhouse gas emissions during the manufacturing phase, potentially offsetting some of the environmental costs associated with its extraction.

The use of MgCO3 in PV cells can lead to improved efficiency and longer-lasting solar panels. This increased durability may result in a reduced need for panel replacements over time, thereby decreasing the overall environmental impact of PV systems throughout their lifecycle. Additionally, the enhanced efficiency could lead to a reduction in the total number of panels required to generate a given amount of electricity, further minimizing land use and material consumption.

Water usage in the production of MgCO3-enhanced PV cells is another important consideration. While the process does require water, it is generally less water-intensive than traditional silicon-based PV manufacturing. This could be particularly beneficial in water-scarce regions where solar energy deployment is often most needed.

From a waste management perspective, the incorporation of MgCO3 in PV cells does not significantly alter the end-of-life challenges faced by the solar industry. However, research into recycling methods for MgCO3-enhanced panels is ongoing, with the potential to recover and reuse this material, further reducing its environmental impact.

It is worth noting that the environmental benefits of MgCO3 in PV production must be weighed against the overall increase in efficiency and lifespan of the solar panels. If the efficiency gains are substantial, the net environmental impact could be positive, as fewer raw materials and less energy would be required to produce the same amount of solar electricity over time.

Cost-Benefit Analysis of MgCO3-Enhanced PV Cells

The integration of magnesium carbonate (MgCO3) into photovoltaic (PV) cells represents a promising avenue for enhancing solar energy conversion efficiency. To assess the economic viability of this technological advancement, a comprehensive cost-benefit analysis is essential.

From a cost perspective, the incorporation of MgCO3 into PV cells requires additional manufacturing processes and materials. The primary expenses include the procurement of high-quality MgCO3, the development of specialized deposition techniques, and potential modifications to existing production lines. These upfront investments may lead to a marginal increase in the per-unit cost of PV cells.

However, the benefits of MgCO3 enhancement are substantial. The improved efficiency of PV cells translates directly into increased power output per unit area. This enhancement can range from 5% to 15%, depending on the specific implementation and environmental conditions. The increased energy generation capacity results in a higher return on investment over the lifespan of the solar panels.

Long-term cost savings are another significant advantage. MgCO3-enhanced PV cells demonstrate superior durability and resistance to environmental degradation, potentially extending the operational life of solar panels. This longevity reduces replacement and maintenance costs, contributing to a lower total cost of ownership for solar energy systems.

The economic impact extends beyond individual installations. Large-scale adoption of MgCO3-enhanced PV cells could lead to a reduction in the land area required for solar farms, minimizing associated real estate and infrastructure costs. Additionally, the increased efficiency may accelerate the achievement of grid parity in regions where solar energy is not yet cost-competitive with traditional power sources.

From an environmental standpoint, the enhanced efficiency of MgCO3-integrated PV cells contributes to a reduction in the carbon footprint of solar energy production. The improved power output per panel means fewer panels are needed to achieve the same energy generation, reducing the overall material and energy requirements for manufacturing and installation.

Market analysis suggests that the initial price premium for MgCO3-enhanced PV cells would be offset by the long-term benefits in most scenarios. The payback period for the additional investment is estimated to range from 3 to 7 years, depending on factors such as local energy prices, installation costs, and available solar resources.

In conclusion, while the integration of MgCO3 into PV cells does incur additional upfront costs, the long-term economic and environmental benefits present a compelling case for adoption. As production scales up and technology matures, the cost-benefit ratio is expected to improve further, potentially revolutionizing the solar energy market and accelerating the global transition to renewable energy sources.

From a cost perspective, the incorporation of MgCO3 into PV cells requires additional manufacturing processes and materials. The primary expenses include the procurement of high-quality MgCO3, the development of specialized deposition techniques, and potential modifications to existing production lines. These upfront investments may lead to a marginal increase in the per-unit cost of PV cells.

However, the benefits of MgCO3 enhancement are substantial. The improved efficiency of PV cells translates directly into increased power output per unit area. This enhancement can range from 5% to 15%, depending on the specific implementation and environmental conditions. The increased energy generation capacity results in a higher return on investment over the lifespan of the solar panels.

Long-term cost savings are another significant advantage. MgCO3-enhanced PV cells demonstrate superior durability and resistance to environmental degradation, potentially extending the operational life of solar panels. This longevity reduces replacement and maintenance costs, contributing to a lower total cost of ownership for solar energy systems.

The economic impact extends beyond individual installations. Large-scale adoption of MgCO3-enhanced PV cells could lead to a reduction in the land area required for solar farms, minimizing associated real estate and infrastructure costs. Additionally, the increased efficiency may accelerate the achievement of grid parity in regions where solar energy is not yet cost-competitive with traditional power sources.

From an environmental standpoint, the enhanced efficiency of MgCO3-integrated PV cells contributes to a reduction in the carbon footprint of solar energy production. The improved power output per panel means fewer panels are needed to achieve the same energy generation, reducing the overall material and energy requirements for manufacturing and installation.

Market analysis suggests that the initial price premium for MgCO3-enhanced PV cells would be offset by the long-term benefits in most scenarios. The payback period for the additional investment is estimated to range from 3 to 7 years, depending on factors such as local energy prices, installation costs, and available solar resources.

In conclusion, while the integration of MgCO3 into PV cells does incur additional upfront costs, the long-term economic and environmental benefits present a compelling case for adoption. As production scales up and technology matures, the cost-benefit ratio is expected to improve further, potentially revolutionizing the solar energy market and accelerating the global transition to renewable energy sources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!