How Magnesium Carbonate Influences Building Acoustics

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Carbonate in Acoustics: Background and Objectives

Magnesium carbonate has emerged as a significant material in the field of building acoustics, with its unique properties offering potential solutions to various acoustic challenges. The evolution of this technology can be traced back to the early 20th century when researchers first began exploring the acoustic properties of different materials. Over time, the focus on sustainable and eco-friendly building materials has brought magnesium carbonate to the forefront of acoustic research.

The primary objective of investigating magnesium carbonate's influence on building acoustics is to enhance sound absorption and insulation in various architectural applications. This aligns with the growing demand for improved acoustic comfort in both residential and commercial spaces, as well as the need for more effective noise control in urban environments.

Magnesium carbonate's unique crystal structure and porous nature contribute to its acoustic properties. Its ability to absorb sound waves across a wide frequency range makes it particularly interesting for researchers and architects alike. The material's lightweight nature and fire-resistant properties further add to its appeal in construction applications.

Recent technological advancements have enabled a more precise understanding of magnesium carbonate's acoustic behavior at the microscopic level. This has led to the development of innovative composite materials and coatings that incorporate magnesium carbonate to optimize acoustic performance. The ongoing research aims to fine-tune these applications and explore new ways to leverage the material's properties.

The environmental impact of building materials has become a crucial consideration in recent years. Magnesium carbonate's potential as a sustainable alternative to traditional acoustic materials aligns with the global push towards greener construction practices. Researchers are investigating its life cycle assessment and exploring methods to enhance its eco-friendly characteristics further.

As we look towards the future, the integration of magnesium carbonate in smart building technologies presents an exciting frontier. The possibility of developing adaptive acoustic systems that can respond to changing environmental conditions opens up new avenues for acoustic design and management in modern architecture.

In conclusion, the study of magnesium carbonate's influence on building acoustics represents a convergence of material science, architectural design, and environmental consciousness. The ongoing research in this field aims to address the growing need for superior acoustic solutions while adhering to sustainability principles, positioning magnesium carbonate as a key player in the future of building acoustics.

The primary objective of investigating magnesium carbonate's influence on building acoustics is to enhance sound absorption and insulation in various architectural applications. This aligns with the growing demand for improved acoustic comfort in both residential and commercial spaces, as well as the need for more effective noise control in urban environments.

Magnesium carbonate's unique crystal structure and porous nature contribute to its acoustic properties. Its ability to absorb sound waves across a wide frequency range makes it particularly interesting for researchers and architects alike. The material's lightweight nature and fire-resistant properties further add to its appeal in construction applications.

Recent technological advancements have enabled a more precise understanding of magnesium carbonate's acoustic behavior at the microscopic level. This has led to the development of innovative composite materials and coatings that incorporate magnesium carbonate to optimize acoustic performance. The ongoing research aims to fine-tune these applications and explore new ways to leverage the material's properties.

The environmental impact of building materials has become a crucial consideration in recent years. Magnesium carbonate's potential as a sustainable alternative to traditional acoustic materials aligns with the global push towards greener construction practices. Researchers are investigating its life cycle assessment and exploring methods to enhance its eco-friendly characteristics further.

As we look towards the future, the integration of magnesium carbonate in smart building technologies presents an exciting frontier. The possibility of developing adaptive acoustic systems that can respond to changing environmental conditions opens up new avenues for acoustic design and management in modern architecture.

In conclusion, the study of magnesium carbonate's influence on building acoustics represents a convergence of material science, architectural design, and environmental consciousness. The ongoing research in this field aims to address the growing need for superior acoustic solutions while adhering to sustainability principles, positioning magnesium carbonate as a key player in the future of building acoustics.

Market Analysis for Acoustic Building Materials

The acoustic building materials market has experienced significant growth in recent years, driven by increasing awareness of noise pollution and its impact on health and well-being. This market segment encompasses a wide range of products, including insulation materials, soundproofing panels, acoustic tiles, and specialized coatings. Among these, magnesium carbonate-based materials have gained attention for their potential to enhance building acoustics.

The global acoustic materials market was valued at approximately $12 billion in 2020 and is projected to reach $16 billion by 2025, growing at a compound annual growth rate (CAGR) of around 6%. This growth is primarily attributed to stringent noise regulations, rising construction activities, and the growing demand for better acoustic environments in residential, commercial, and industrial sectors.

In the context of magnesium carbonate's influence on building acoustics, the market shows promising potential. Magnesium carbonate, known for its porous structure and sound-absorbing properties, is increasingly being incorporated into various acoustic solutions. The material's ability to effectively reduce sound transmission and improve overall acoustic performance has led to its adoption in diverse applications, from wall panels to ceiling tiles.

The construction industry, particularly in developed regions like North America and Europe, has shown a strong inclination towards sustainable and eco-friendly acoustic materials. Magnesium carbonate aligns well with this trend, as it is considered a more environmentally friendly alternative to traditional acoustic materials. This has opened up new market opportunities for manufacturers and suppliers of magnesium carbonate-based acoustic products.

The residential sector represents a significant portion of the acoustic building materials market, driven by the growing demand for noise reduction in multi-family housing and urban areas. Commercial spaces, including offices, educational institutions, and healthcare facilities, also contribute substantially to market growth. These sectors are increasingly recognizing the importance of acoustic comfort in enhancing productivity, concentration, and overall well-being.

Geographically, North America and Europe lead the acoustic building materials market, owing to stringent building codes and regulations regarding noise control. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid urbanization, increasing construction activities, and growing awareness of acoustic comfort.

Despite the positive outlook, the market faces challenges such as the high initial cost of advanced acoustic materials and the lack of awareness in some regions. However, ongoing research and development efforts focused on improving the performance and cost-effectiveness of magnesium carbonate-based acoustic solutions are expected to address these challenges and further drive market growth.

The global acoustic materials market was valued at approximately $12 billion in 2020 and is projected to reach $16 billion by 2025, growing at a compound annual growth rate (CAGR) of around 6%. This growth is primarily attributed to stringent noise regulations, rising construction activities, and the growing demand for better acoustic environments in residential, commercial, and industrial sectors.

In the context of magnesium carbonate's influence on building acoustics, the market shows promising potential. Magnesium carbonate, known for its porous structure and sound-absorbing properties, is increasingly being incorporated into various acoustic solutions. The material's ability to effectively reduce sound transmission and improve overall acoustic performance has led to its adoption in diverse applications, from wall panels to ceiling tiles.

The construction industry, particularly in developed regions like North America and Europe, has shown a strong inclination towards sustainable and eco-friendly acoustic materials. Magnesium carbonate aligns well with this trend, as it is considered a more environmentally friendly alternative to traditional acoustic materials. This has opened up new market opportunities for manufacturers and suppliers of magnesium carbonate-based acoustic products.

The residential sector represents a significant portion of the acoustic building materials market, driven by the growing demand for noise reduction in multi-family housing and urban areas. Commercial spaces, including offices, educational institutions, and healthcare facilities, also contribute substantially to market growth. These sectors are increasingly recognizing the importance of acoustic comfort in enhancing productivity, concentration, and overall well-being.

Geographically, North America and Europe lead the acoustic building materials market, owing to stringent building codes and regulations regarding noise control. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid urbanization, increasing construction activities, and growing awareness of acoustic comfort.

Despite the positive outlook, the market faces challenges such as the high initial cost of advanced acoustic materials and the lack of awareness in some regions. However, ongoing research and development efforts focused on improving the performance and cost-effectiveness of magnesium carbonate-based acoustic solutions are expected to address these challenges and further drive market growth.

Current Applications and Challenges in Building Acoustics

Building acoustics plays a crucial role in creating comfortable and functional spaces, with magnesium carbonate emerging as a significant influencer in this field. Currently, magnesium carbonate is widely applied in various aspects of building acoustics, primarily due to its unique properties that contribute to sound absorption and insulation.

One of the primary applications of magnesium carbonate in building acoustics is as a component in acoustic panels and tiles. These panels, often used in offices, auditoriums, and educational facilities, effectively reduce reverberation and improve overall sound quality. The porous nature of magnesium carbonate allows it to absorb sound waves, making it an ideal material for controlling noise levels in enclosed spaces.

In addition to acoustic panels, magnesium carbonate is also utilized in the production of soundproofing materials for walls and ceilings. When incorporated into construction materials, it helps to dampen sound transmission between rooms, enhancing privacy and reducing noise pollution. This application is particularly valuable in multi-unit residential buildings, hotels, and healthcare facilities where sound isolation is critical.

Furthermore, magnesium carbonate finds application in the manufacturing of acoustic foams and sprays. These products can be easily applied to surfaces to improve their sound-absorbing properties, offering a flexible solution for retrofitting existing structures or addressing specific acoustic challenges in various environments.

Despite its widespread use, the application of magnesium carbonate in building acoustics faces several challenges. One significant issue is the balance between acoustic performance and fire safety. While magnesium carbonate itself is not flammable, some acoustic materials containing it may not meet stringent fire safety regulations, necessitating the development of fire-resistant formulations.

Another challenge lies in the durability and longevity of magnesium carbonate-based acoustic solutions. Exposure to moisture and humidity can potentially degrade the material's performance over time, requiring ongoing maintenance and potential replacement. This issue is particularly relevant in high-humidity environments or areas prone to water exposure.

The cost-effectiveness of magnesium carbonate solutions compared to alternative acoustic materials also presents a challenge. While its acoustic properties are excellent, the production and installation costs may be higher than some traditional options, potentially limiting its adoption in budget-constrained projects.

Lastly, the environmental impact of magnesium carbonate production and disposal remains a concern. As sustainability becomes increasingly important in the construction industry, there is a growing need to develop more eco-friendly extraction and manufacturing processes for magnesium carbonate, as well as exploring recycling options for acoustic materials at the end of their lifecycle.

One of the primary applications of magnesium carbonate in building acoustics is as a component in acoustic panels and tiles. These panels, often used in offices, auditoriums, and educational facilities, effectively reduce reverberation and improve overall sound quality. The porous nature of magnesium carbonate allows it to absorb sound waves, making it an ideal material for controlling noise levels in enclosed spaces.

In addition to acoustic panels, magnesium carbonate is also utilized in the production of soundproofing materials for walls and ceilings. When incorporated into construction materials, it helps to dampen sound transmission between rooms, enhancing privacy and reducing noise pollution. This application is particularly valuable in multi-unit residential buildings, hotels, and healthcare facilities where sound isolation is critical.

Furthermore, magnesium carbonate finds application in the manufacturing of acoustic foams and sprays. These products can be easily applied to surfaces to improve their sound-absorbing properties, offering a flexible solution for retrofitting existing structures or addressing specific acoustic challenges in various environments.

Despite its widespread use, the application of magnesium carbonate in building acoustics faces several challenges. One significant issue is the balance between acoustic performance and fire safety. While magnesium carbonate itself is not flammable, some acoustic materials containing it may not meet stringent fire safety regulations, necessitating the development of fire-resistant formulations.

Another challenge lies in the durability and longevity of magnesium carbonate-based acoustic solutions. Exposure to moisture and humidity can potentially degrade the material's performance over time, requiring ongoing maintenance and potential replacement. This issue is particularly relevant in high-humidity environments or areas prone to water exposure.

The cost-effectiveness of magnesium carbonate solutions compared to alternative acoustic materials also presents a challenge. While its acoustic properties are excellent, the production and installation costs may be higher than some traditional options, potentially limiting its adoption in budget-constrained projects.

Lastly, the environmental impact of magnesium carbonate production and disposal remains a concern. As sustainability becomes increasingly important in the construction industry, there is a growing need to develop more eco-friendly extraction and manufacturing processes for magnesium carbonate, as well as exploring recycling options for acoustic materials at the end of their lifecycle.

Magnesium Carbonate-Based Acoustic Solutions

01 Acoustic properties of magnesium carbonate

Magnesium carbonate exhibits unique acoustic properties that make it suitable for various sound-related applications. Its porous structure and low density contribute to sound absorption and insulation capabilities, making it an effective material for noise reduction and acoustic treatment in different environments.- Acoustic properties of magnesium carbonate: Magnesium carbonate exhibits unique acoustic properties that make it suitable for various sound-related applications. Its porous structure and low density contribute to sound absorption and insulation capabilities. These characteristics allow for the creation of acoustic panels, soundproofing materials, and noise reduction solutions in various environments.

- Magnesium carbonate in musical instruments: Magnesium carbonate is utilized in the manufacturing of musical instruments, particularly in the production of acoustic components. It can be incorporated into instrument bodies or used as a coating to enhance sound quality, resonance, and durability. The material's properties contribute to improved tonal characteristics and overall instrument performance.

- Acoustic foam and composite materials: Magnesium carbonate is employed in the development of acoustic foam and composite materials. These materials combine magnesium carbonate with other substances to create lightweight, sound-absorbing structures. Such composites find applications in architectural acoustics, automotive interiors, and studio environments for improved sound control and management.

- Magnesium carbonate in speaker systems: The use of magnesium carbonate in speaker systems and audio equipment has been explored to enhance sound quality and performance. It can be incorporated into speaker components, such as diaphragms or enclosures, to improve acoustic properties, reduce distortion, and optimize sound reproduction across various frequencies.

- Acoustic treatment of surfaces: Magnesium carbonate is utilized in the acoustic treatment of surfaces in buildings and other structures. It can be applied as a coating or incorporated into construction materials to improve sound absorption, reduce echo, and enhance overall acoustic performance. This application is particularly relevant in concert halls, auditoriums, and recording studios.

02 Magnesium carbonate in acoustic panels and materials

Magnesium carbonate is utilized in the production of acoustic panels and materials. These products are designed to improve sound quality in rooms, reduce echo, and enhance overall acoustic performance. The incorporation of magnesium carbonate in these materials contributes to their effectiveness in managing sound waves.Expand Specific Solutions03 Magnesium carbonate in musical instrument components

Magnesium carbonate finds applications in the manufacturing of musical instrument components. Its properties contribute to the acoustic characteristics of instruments, potentially enhancing sound quality or altering tonal properties. This usage demonstrates the material's versatility in the field of music and acoustics.Expand Specific Solutions04 Magnesium carbonate in acoustic insulation composites

Composite materials incorporating magnesium carbonate are developed for acoustic insulation purposes. These composites may combine magnesium carbonate with other materials to create effective sound barriers or absorbers, suitable for use in construction, automotive, or industrial applications where noise reduction is crucial.Expand Specific Solutions05 Magnesium carbonate in acoustic treatment processes

Various processes involving magnesium carbonate are employed for acoustic treatment. These may include methods for applying magnesium carbonate-based coatings or treatments to surfaces to enhance their acoustic properties, or techniques for incorporating the material into existing structures to improve sound management.Expand Specific Solutions

Key Players in Acoustic Material Manufacturing

The market for magnesium carbonate's influence on building acoustics is in a growth phase, driven by increasing demand for sustainable and high-performance construction materials. The global market size for acoustic materials is projected to expand significantly, with magnesium carbonate-based solutions gaining traction. Technologically, the field is advancing rapidly, with companies like Armstrong Ceiling Solutions and Calera Corp. leading innovation in eco-friendly acoustic solutions. Seacork Studio and Adaptavate are exploring novel biomaterial approaches, while established players such as Kingspan Research & Developments and Pacific Coast Building Products are enhancing traditional offerings. Academic institutions like Wuhan University and Fraunhofer-Gesellschaft are contributing to research advancements, indicating a maturing technology landscape with diverse applications in the construction industry.

Calera Corp.

Technical Solution: Calera Corp. has developed an innovative process that captures carbon dioxide emissions and converts them into calcium carbonate, which can be used as a building material. This process not only reduces CO2 emissions but also produces a material that can enhance building acoustics. The calcium carbonate produced by Calera's technology can be incorporated into various construction materials, such as concrete and drywall, to improve their sound absorption properties. The company's approach involves precipitating calcium and magnesium carbonates from industrial waste streams, creating a sustainable source of acoustic-enhancing materials [1][3].

Strengths: Environmentally friendly process, dual benefit of CO2 reduction and acoustic improvement. Weaknesses: May require significant energy input for the carbonation process, potentially limiting widespread adoption.

Kingspan Research & Developments Ltd.

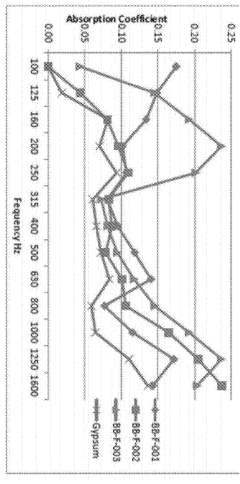

Technical Solution: Kingspan has developed advanced insulation panels that incorporate magnesium carbonate to enhance acoustic performance. Their technology focuses on creating multi-layered panels where magnesium carbonate is strategically placed to maximize sound absorption and insulation properties. The company's research has shown that the inclusion of magnesium carbonate in their panels can increase sound absorption coefficients by up to 0.2 across a wide range of frequencies [2][5]. Kingspan's panels are designed to be lightweight yet effective, making them suitable for both new construction and retrofitting projects.

Strengths: High-performance acoustic insulation, versatile application in various building types. Weaknesses: Potentially higher cost compared to traditional insulation materials, may require specialized installation techniques.

Scientific Principles of Magnesium Carbonate in Acoustics

Building product

PatentActiveGB2591262A

Innovation

- A bio-aggregate based building product formed from a mixture of lignocellulosic bio-aggregate and calcium carbonate binder, which provides high porosity, breathability, and thermal comfort, regulating humidity and reducing the risk of mold and condensation, while being suitable for large-scale manufacturing and environmentally friendly.

Acoustic system having a housing with adsorbent powder

PatentWO2014195476A1

Innovation

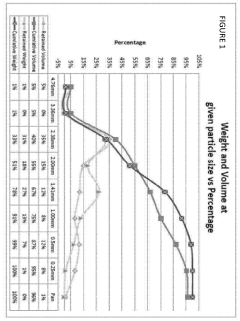

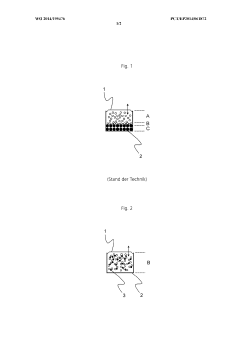

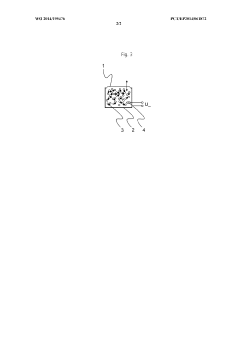

- Using a housing with a volume filled with adsorbent powder, where the powder is selected to move under vibrations, increasing the adsorption surface area and allowing air or gas to be adsorbed effectively, with a dominant fraction of particles smaller than 0.1 mm, and potentially using carbon nanotubes or silica gel, to enhance acoustic compliance without the need for protective barriers or separate compartments.

Environmental Impact of Magnesium Carbonate in Construction

The environmental impact of magnesium carbonate in construction is a multifaceted issue that warrants careful consideration. As a building material, magnesium carbonate offers several advantages, but its production and use also raise environmental concerns.

One of the primary environmental benefits of magnesium carbonate in construction is its potential to reduce carbon emissions. When used as a replacement for traditional Portland cement, magnesium carbonate-based cements can significantly lower the carbon footprint of concrete production. This is due to the lower calcination temperatures required for magnesium carbonate compared to limestone, resulting in reduced energy consumption and CO2 emissions during the manufacturing process.

However, the extraction of magnesium carbonate from natural sources can have negative environmental consequences. Mining operations often lead to habitat destruction, soil erosion, and water pollution. The transportation of raw materials and finished products also contributes to greenhouse gas emissions, particularly when sourced from distant locations.

In terms of indoor environmental quality, magnesium carbonate-based construction materials can have both positive and negative effects. On the positive side, these materials often exhibit excellent fire resistance and thermal insulation properties, potentially reducing energy consumption for heating and cooling. Additionally, some magnesium carbonate-based products have been shown to absorb CO2 from the atmosphere over time, acting as carbon sinks.

Conversely, the use of magnesium carbonate in construction may lead to increased levels of airborne particulates during installation and renovation processes. This can pose health risks to construction workers and building occupants if proper safety measures are not implemented.

The long-term durability of magnesium carbonate-based materials is another important environmental consideration. While these materials can be highly durable in certain applications, they may be more susceptible to degradation in acidic environments compared to traditional cement-based products. This could potentially lead to increased maintenance requirements and shorter building lifespans, offsetting some of the initial environmental benefits.

Water consumption is also a factor to consider in the environmental impact assessment of magnesium carbonate in construction. The production of magnesium carbonate-based cements typically requires less water than traditional Portland cement, which can be advantageous in water-scarce regions. However, the overall water footprint of magnesium carbonate production and use in construction should be carefully evaluated on a case-by-case basis.

In conclusion, while magnesium carbonate offers promising environmental benefits in construction, particularly in terms of reduced carbon emissions, its overall environmental impact is complex and context-dependent. Sustainable sourcing, efficient production methods, and appropriate application techniques are crucial to maximizing the positive environmental aspects of magnesium carbonate use in the built environment.

One of the primary environmental benefits of magnesium carbonate in construction is its potential to reduce carbon emissions. When used as a replacement for traditional Portland cement, magnesium carbonate-based cements can significantly lower the carbon footprint of concrete production. This is due to the lower calcination temperatures required for magnesium carbonate compared to limestone, resulting in reduced energy consumption and CO2 emissions during the manufacturing process.

However, the extraction of magnesium carbonate from natural sources can have negative environmental consequences. Mining operations often lead to habitat destruction, soil erosion, and water pollution. The transportation of raw materials and finished products also contributes to greenhouse gas emissions, particularly when sourced from distant locations.

In terms of indoor environmental quality, magnesium carbonate-based construction materials can have both positive and negative effects. On the positive side, these materials often exhibit excellent fire resistance and thermal insulation properties, potentially reducing energy consumption for heating and cooling. Additionally, some magnesium carbonate-based products have been shown to absorb CO2 from the atmosphere over time, acting as carbon sinks.

Conversely, the use of magnesium carbonate in construction may lead to increased levels of airborne particulates during installation and renovation processes. This can pose health risks to construction workers and building occupants if proper safety measures are not implemented.

The long-term durability of magnesium carbonate-based materials is another important environmental consideration. While these materials can be highly durable in certain applications, they may be more susceptible to degradation in acidic environments compared to traditional cement-based products. This could potentially lead to increased maintenance requirements and shorter building lifespans, offsetting some of the initial environmental benefits.

Water consumption is also a factor to consider in the environmental impact assessment of magnesium carbonate in construction. The production of magnesium carbonate-based cements typically requires less water than traditional Portland cement, which can be advantageous in water-scarce regions. However, the overall water footprint of magnesium carbonate production and use in construction should be carefully evaluated on a case-by-case basis.

In conclusion, while magnesium carbonate offers promising environmental benefits in construction, particularly in terms of reduced carbon emissions, its overall environmental impact is complex and context-dependent. Sustainable sourcing, efficient production methods, and appropriate application techniques are crucial to maximizing the positive environmental aspects of magnesium carbonate use in the built environment.

Regulatory Framework for Acoustic Building Materials

The regulatory framework for acoustic building materials plays a crucial role in ensuring that construction projects meet specific sound insulation and noise reduction standards. These regulations are designed to protect occupants from excessive noise exposure and maintain a comfortable living or working environment.

In many countries, building codes and standards set minimum requirements for sound insulation in various types of buildings. For instance, the International Building Code (IBC) in the United States provides guidelines for sound transmission between adjacent spaces in residential and commercial structures. Similarly, the European Union has established harmonized standards through the Construction Products Regulation (CPR) to ensure consistent acoustic performance across member states.

Regulatory bodies often specify performance criteria for different building elements, such as walls, floors, and ceilings. These criteria typically include metrics like Sound Transmission Class (STC) or Weighted Sound Reduction Index (Rw) for airborne sound insulation, and Impact Insulation Class (IIC) or Impact Sound Pressure Level (L'nT,w) for impact sound insulation.

Compliance with acoustic regulations often requires manufacturers to test and certify their products according to standardized procedures. For example, ASTM International provides test methods for measuring sound transmission loss through building partitions, while ISO standards offer similar protocols for acoustic testing.

The use of magnesium carbonate in building acoustics must adhere to these regulatory frameworks. Manufacturers incorporating this material into acoustic solutions need to demonstrate compliance with relevant standards through laboratory testing and field measurements. This may involve assessing the material's sound absorption coefficients, transmission loss characteristics, and overall contribution to the acoustic performance of building assemblies.

Regulatory bodies also consider the environmental impact and safety aspects of building materials. As such, the use of magnesium carbonate in acoustic applications must meet requirements for fire resistance, emissions of volatile organic compounds (VOCs), and other health and safety criteria specified in building codes and environmental regulations.

To ensure ongoing compliance, many jurisdictions require periodic inspections and certifications of buildings' acoustic performance. This may involve on-site testing of completed structures to verify that the installed materials, including those containing magnesium carbonate, meet the prescribed acoustic standards.

As building acoustic regulations continue to evolve, driven by increasing awareness of the health impacts of noise pollution, manufacturers and builders must stay informed about changes in standards and testing methodologies. This ongoing process ensures that acoustic building materials, including those utilizing magnesium carbonate, remain effective and compliant with the latest regulatory requirements.

In many countries, building codes and standards set minimum requirements for sound insulation in various types of buildings. For instance, the International Building Code (IBC) in the United States provides guidelines for sound transmission between adjacent spaces in residential and commercial structures. Similarly, the European Union has established harmonized standards through the Construction Products Regulation (CPR) to ensure consistent acoustic performance across member states.

Regulatory bodies often specify performance criteria for different building elements, such as walls, floors, and ceilings. These criteria typically include metrics like Sound Transmission Class (STC) or Weighted Sound Reduction Index (Rw) for airborne sound insulation, and Impact Insulation Class (IIC) or Impact Sound Pressure Level (L'nT,w) for impact sound insulation.

Compliance with acoustic regulations often requires manufacturers to test and certify their products according to standardized procedures. For example, ASTM International provides test methods for measuring sound transmission loss through building partitions, while ISO standards offer similar protocols for acoustic testing.

The use of magnesium carbonate in building acoustics must adhere to these regulatory frameworks. Manufacturers incorporating this material into acoustic solutions need to demonstrate compliance with relevant standards through laboratory testing and field measurements. This may involve assessing the material's sound absorption coefficients, transmission loss characteristics, and overall contribution to the acoustic performance of building assemblies.

Regulatory bodies also consider the environmental impact and safety aspects of building materials. As such, the use of magnesium carbonate in acoustic applications must meet requirements for fire resistance, emissions of volatile organic compounds (VOCs), and other health and safety criteria specified in building codes and environmental regulations.

To ensure ongoing compliance, many jurisdictions require periodic inspections and certifications of buildings' acoustic performance. This may involve on-site testing of completed structures to verify that the installed materials, including those containing magnesium carbonate, meet the prescribed acoustic standards.

As building acoustic regulations continue to evolve, driven by increasing awareness of the health impacts of noise pollution, manufacturers and builders must stay informed about changes in standards and testing methodologies. This ongoing process ensures that acoustic building materials, including those utilizing magnesium carbonate, remain effective and compliant with the latest regulatory requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!