How Magnesium Carbonate Supports Cold Climate Energy Storage

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MgCO3 Energy Storage Background and Objectives

Magnesium carbonate (MgCO3) has emerged as a promising material for energy storage applications, particularly in cold climate regions. The development of this technology is rooted in the growing need for efficient and sustainable energy storage solutions to address the challenges of intermittent renewable energy sources and the increasing demand for grid stability.

The evolution of MgCO3-based energy storage systems can be traced back to the broader field of thermal energy storage (TES) research. As scientists and engineers sought to improve the efficiency and capacity of TES systems, they began exploring various materials with high energy density and favorable thermodynamic properties. Magnesium carbonate, with its unique characteristics, caught the attention of researchers due to its potential for storing and releasing large amounts of thermal energy through chemical reactions.

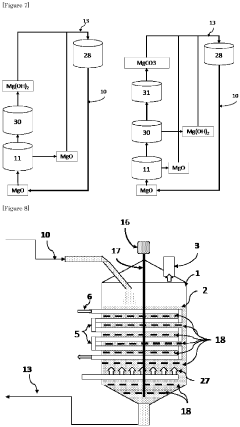

The primary objective of MgCO3 energy storage technology is to harness the reversible chemical reaction between magnesium oxide (MgO) and carbon dioxide (CO2) to store and release thermal energy. This process, known as the carbonation-calcination cycle, involves the absorption of CO2 by MgO to form MgCO3 (exothermic reaction) and the subsequent decomposition of MgCO3 back into MgO and CO2 (endothermic reaction).

In cold climate regions, where energy demand for heating is high and renewable energy sources may be less reliable, MgCO3-based energy storage systems offer several advantages. The technology aims to provide a long-duration, high-capacity storage solution that can effectively bridge the gap between energy supply and demand, particularly during extended periods of low renewable energy generation.

Key objectives of MgCO3 energy storage research include optimizing the carbonation-calcination cycle efficiency, enhancing the material's stability over multiple charge-discharge cycles, and developing cost-effective methods for large-scale implementation. Researchers are also focused on integrating this technology with existing renewable energy systems and exploring its potential for both residential and industrial applications in cold climates.

As the technology continues to evolve, there is a growing emphasis on addressing challenges such as reaction kinetics, heat transfer efficiency, and system integration. The ultimate goal is to develop a robust, scalable, and economically viable energy storage solution that can significantly contribute to the transition towards a more sustainable and resilient energy infrastructure in cold climate regions.

The evolution of MgCO3-based energy storage systems can be traced back to the broader field of thermal energy storage (TES) research. As scientists and engineers sought to improve the efficiency and capacity of TES systems, they began exploring various materials with high energy density and favorable thermodynamic properties. Magnesium carbonate, with its unique characteristics, caught the attention of researchers due to its potential for storing and releasing large amounts of thermal energy through chemical reactions.

The primary objective of MgCO3 energy storage technology is to harness the reversible chemical reaction between magnesium oxide (MgO) and carbon dioxide (CO2) to store and release thermal energy. This process, known as the carbonation-calcination cycle, involves the absorption of CO2 by MgO to form MgCO3 (exothermic reaction) and the subsequent decomposition of MgCO3 back into MgO and CO2 (endothermic reaction).

In cold climate regions, where energy demand for heating is high and renewable energy sources may be less reliable, MgCO3-based energy storage systems offer several advantages. The technology aims to provide a long-duration, high-capacity storage solution that can effectively bridge the gap between energy supply and demand, particularly during extended periods of low renewable energy generation.

Key objectives of MgCO3 energy storage research include optimizing the carbonation-calcination cycle efficiency, enhancing the material's stability over multiple charge-discharge cycles, and developing cost-effective methods for large-scale implementation. Researchers are also focused on integrating this technology with existing renewable energy systems and exploring its potential for both residential and industrial applications in cold climates.

As the technology continues to evolve, there is a growing emphasis on addressing challenges such as reaction kinetics, heat transfer efficiency, and system integration. The ultimate goal is to develop a robust, scalable, and economically viable energy storage solution that can significantly contribute to the transition towards a more sustainable and resilient energy infrastructure in cold climate regions.

Market Analysis for Cold Climate Energy Solutions

The market for cold climate energy storage solutions is experiencing significant growth, driven by the increasing demand for reliable and efficient energy systems in regions with harsh winter conditions. As countries and industries seek to reduce their carbon footprint and enhance energy security, the adoption of innovative storage technologies becomes crucial. Magnesium carbonate-based energy storage systems are emerging as a promising solution in this landscape, offering unique advantages for cold climate applications.

The global market for energy storage in cold climates is projected to expand rapidly in the coming years, with a particular focus on renewable energy integration and grid stability. Regions such as Northern Europe, Canada, and parts of the United States are key markets for these technologies, as they face challenges in maintaining consistent energy supply during long, cold winters. The industrial sector, including mining and oil and gas operations in remote, cold locations, also represents a significant market segment for robust energy storage solutions.

Magnesium carbonate-based systems address several critical needs in cold climate energy storage. They offer excellent thermal properties, maintaining efficiency even at low temperatures where other storage technologies may struggle. This characteristic is particularly valuable for applications such as district heating systems and industrial process heat storage in cold regions. Additionally, the non-toxic and abundant nature of magnesium carbonate aligns with the growing emphasis on environmentally friendly and sustainable energy solutions.

The market is also being shaped by regulatory frameworks and government initiatives aimed at promoting clean energy and reducing reliance on fossil fuels. Incentives for renewable energy projects and energy storage installations in cold climate regions are driving investment and innovation in this sector. This supportive policy environment is expected to accelerate the adoption of advanced storage technologies like magnesium carbonate-based systems.

Competition in this market is intensifying, with both established energy companies and innovative startups vying for market share. The development of scalable and cost-effective magnesium carbonate storage solutions is attracting significant research and development investment. As the technology matures, we anticipate a shift from pilot projects to large-scale commercial deployments, particularly in regions with a high demand for reliable cold climate energy storage.

Customer segments for magnesium carbonate-based cold climate energy storage include utility companies seeking to enhance grid resilience, industrial facilities aiming to optimize energy use in harsh environments, and remote communities looking for sustainable off-grid solutions. The versatility of magnesium carbonate systems in addressing various energy storage needs positions them favorably in these diverse market segments.

The global market for energy storage in cold climates is projected to expand rapidly in the coming years, with a particular focus on renewable energy integration and grid stability. Regions such as Northern Europe, Canada, and parts of the United States are key markets for these technologies, as they face challenges in maintaining consistent energy supply during long, cold winters. The industrial sector, including mining and oil and gas operations in remote, cold locations, also represents a significant market segment for robust energy storage solutions.

Magnesium carbonate-based systems address several critical needs in cold climate energy storage. They offer excellent thermal properties, maintaining efficiency even at low temperatures where other storage technologies may struggle. This characteristic is particularly valuable for applications such as district heating systems and industrial process heat storage in cold regions. Additionally, the non-toxic and abundant nature of magnesium carbonate aligns with the growing emphasis on environmentally friendly and sustainable energy solutions.

The market is also being shaped by regulatory frameworks and government initiatives aimed at promoting clean energy and reducing reliance on fossil fuels. Incentives for renewable energy projects and energy storage installations in cold climate regions are driving investment and innovation in this sector. This supportive policy environment is expected to accelerate the adoption of advanced storage technologies like magnesium carbonate-based systems.

Competition in this market is intensifying, with both established energy companies and innovative startups vying for market share. The development of scalable and cost-effective magnesium carbonate storage solutions is attracting significant research and development investment. As the technology matures, we anticipate a shift from pilot projects to large-scale commercial deployments, particularly in regions with a high demand for reliable cold climate energy storage.

Customer segments for magnesium carbonate-based cold climate energy storage include utility companies seeking to enhance grid resilience, industrial facilities aiming to optimize energy use in harsh environments, and remote communities looking for sustainable off-grid solutions. The versatility of magnesium carbonate systems in addressing various energy storage needs positions them favorably in these diverse market segments.

Current Challenges in Cold Climate Energy Storage

Energy storage in cold climates presents unique challenges that require innovative solutions. The harsh environmental conditions, including extreme low temperatures and rapid temperature fluctuations, pose significant obstacles to conventional energy storage technologies. One of the primary challenges is the reduced efficiency and capacity of batteries in cold temperatures, which can lead to decreased performance and shorter lifespans of energy storage systems.

Another critical issue is the increased energy demand during cold periods, particularly for heating purposes, which puts additional strain on energy storage systems. This demand-supply mismatch often results in the need for oversized storage capacities, leading to higher costs and reduced overall system efficiency.

The formation of ice and frost on energy storage components is a persistent problem in cold climates. This can cause mechanical damage to equipment and impair the functionality of various storage technologies, necessitating frequent maintenance and potentially shortening the operational life of storage systems.

Thermal management becomes increasingly complex in cold environments. Maintaining optimal operating temperatures for energy storage systems often requires additional energy input, which can significantly reduce the net energy storage capacity and overall system efficiency.

Material degradation is accelerated in cold climates due to thermal cycling and exposure to harsh conditions. This affects the durability and reliability of energy storage components, leading to more frequent replacements and increased maintenance costs.

The transportation and installation of energy storage systems in remote cold regions present logistical challenges. Difficult terrain and limited accessibility during certain seasons can complicate the deployment and maintenance of storage infrastructure.

Cold climate energy storage also faces challenges related to grid integration. The variability of renewable energy sources, coupled with the fluctuating energy demand in cold regions, requires sophisticated control systems and grid management strategies to ensure stable and reliable power supply.

Economic viability remains a significant hurdle for cold climate energy storage projects. The higher costs associated with specialized equipment, increased maintenance requirements, and potentially lower efficiency can make these projects less attractive from an investment perspective.

Addressing these challenges requires a multifaceted approach, combining advancements in materials science, thermal management techniques, and system design. Innovative solutions, such as the use of magnesium carbonate for thermal energy storage, offer promising avenues for overcoming the unique obstacles presented by cold climate energy storage.

Another critical issue is the increased energy demand during cold periods, particularly for heating purposes, which puts additional strain on energy storage systems. This demand-supply mismatch often results in the need for oversized storage capacities, leading to higher costs and reduced overall system efficiency.

The formation of ice and frost on energy storage components is a persistent problem in cold climates. This can cause mechanical damage to equipment and impair the functionality of various storage technologies, necessitating frequent maintenance and potentially shortening the operational life of storage systems.

Thermal management becomes increasingly complex in cold environments. Maintaining optimal operating temperatures for energy storage systems often requires additional energy input, which can significantly reduce the net energy storage capacity and overall system efficiency.

Material degradation is accelerated in cold climates due to thermal cycling and exposure to harsh conditions. This affects the durability and reliability of energy storage components, leading to more frequent replacements and increased maintenance costs.

The transportation and installation of energy storage systems in remote cold regions present logistical challenges. Difficult terrain and limited accessibility during certain seasons can complicate the deployment and maintenance of storage infrastructure.

Cold climate energy storage also faces challenges related to grid integration. The variability of renewable energy sources, coupled with the fluctuating energy demand in cold regions, requires sophisticated control systems and grid management strategies to ensure stable and reliable power supply.

Economic viability remains a significant hurdle for cold climate energy storage projects. The higher costs associated with specialized equipment, increased maintenance requirements, and potentially lower efficiency can make these projects less attractive from an investment perspective.

Addressing these challenges requires a multifaceted approach, combining advancements in materials science, thermal management techniques, and system design. Innovative solutions, such as the use of magnesium carbonate for thermal energy storage, offer promising avenues for overcoming the unique obstacles presented by cold climate energy storage.

Existing MgCO3-based Storage Solutions

01 Magnesium carbonate-based thermal energy storage

Magnesium carbonate can be used as a material for thermal energy storage systems. This compound has favorable properties for storing and releasing heat, making it suitable for applications in renewable energy and industrial processes. The thermal energy storage capacity of magnesium carbonate can be enhanced through various methods, such as doping or combining it with other materials.- Magnesium carbonate-based thermal energy storage: Magnesium carbonate can be used as a material for thermal energy storage systems. These systems utilize the heat absorption and release properties of magnesium carbonate during phase changes or chemical reactions. This approach can be applied in various applications, including solar energy storage and industrial waste heat recovery.

- Magnesium carbonate in battery technologies: Magnesium carbonate is being explored as a component in advanced battery technologies. It can be used as a precursor for electrode materials or as an additive to improve battery performance. This application aims to enhance energy storage capacity, cycling stability, and overall efficiency of rechargeable batteries.

- Carbon dioxide capture and storage using magnesium carbonate: Magnesium carbonate can be utilized in carbon dioxide capture and storage processes. This approach involves the reaction of magnesium-rich materials with CO2 to form stable magnesium carbonate, effectively sequestering the greenhouse gas. The stored CO2 can potentially be used for enhanced oil recovery or other industrial applications.

- Magnesium carbonate in construction materials for energy efficiency: Magnesium carbonate can be incorporated into construction materials to enhance energy efficiency in buildings. Its properties can contribute to improved insulation, thermal regulation, and moisture control. This application aims to reduce energy consumption in heating and cooling systems while maintaining comfortable indoor environments.

- Magnesium carbonate in energy-efficient chemical processes: Magnesium carbonate is being investigated for use in energy-efficient chemical processes. It can serve as a catalyst or reactive medium in various industrial applications, potentially reducing energy consumption and improving process efficiency. This approach is particularly relevant in the production of chemicals, fuels, and other high-value products.

02 Magnesium carbonate in battery technology

Magnesium carbonate has potential applications in battery technology, particularly in the development of magnesium-based batteries. These batteries could offer advantages over traditional lithium-ion batteries, such as higher energy density and improved safety. Research is ongoing to optimize the use of magnesium carbonate in electrode materials and electrolytes for enhanced battery performance.Expand Specific Solutions03 Magnesium carbonate in carbon capture and storage

Magnesium carbonate plays a role in carbon capture and storage technologies. It can be used to sequester carbon dioxide from industrial emissions or the atmosphere, contributing to efforts to mitigate climate change. The process involves the reaction of magnesium-rich minerals with CO2 to form stable magnesium carbonate, effectively storing the carbon long-term.Expand Specific Solutions04 Magnesium carbonate in energy-efficient building materials

Magnesium carbonate can be incorporated into building materials to enhance energy efficiency. Its properties allow for improved insulation and thermal regulation in construction applications. This can lead to reduced energy consumption in buildings for heating and cooling, contributing to overall energy conservation efforts.Expand Specific Solutions05 Magnesium carbonate in energy conversion processes

Magnesium carbonate has applications in various energy conversion processes. It can be used in catalytic systems for energy-related chemical reactions or as a component in fuel cells. The compound's properties make it suitable for enhancing the efficiency of certain energy conversion technologies, potentially leading to more sustainable energy production methods.Expand Specific Solutions

Key Players in MgCO3 Energy Storage Research

The development of magnesium carbonate for cold climate energy storage is in an early stage, with the market still emerging and technology maturity relatively low. The global energy storage market is growing rapidly, expected to reach $546 billion by 2035, with thermal storage playing a crucial role. Key players like Siemens AG, Mitsubishi Electric, and KEPCO are investing in research and development to advance this technology. Universities such as MIT, Cornell, and Chiba University are contributing to fundamental research. Smaller specialized firms like Carbonfree Chemicals and Disruptive Materials AB are also making strides in commercializing novel magnesium carbonate materials for energy storage applications. As the technology progresses, we can expect increased competition and market consolidation in this promising field.

Massachusetts Institute of Technology

Technical Solution: MIT has developed an innovative approach using magnesium carbonate for cold climate energy storage. Their system employs a chemical heat pump cycle based on the hydration and dehydration of magnesium carbonate. This process allows for efficient heat storage and release in cold environments. The technology utilizes a reversible chemical reaction between magnesium carbonate and water, which can store heat at temperatures up to 300°C and release it on demand[1]. MIT's research has shown that this system can achieve energy densities up to 500 kWh/m³, significantly higher than conventional sensible heat storage methods[2]. The process is particularly effective in cold climates due to its ability to operate at sub-zero temperatures without the risk of freezing, unlike water-based systems[3].

Strengths: High energy density, ability to operate in sub-zero temperatures, and long-term storage capability. Weaknesses: Potential issues with material degradation over multiple cycles and the need for specialized equipment for the hydration/dehydration process.

Siemens AG

Technical Solution: Siemens has developed a thermal energy storage system that incorporates magnesium carbonate as a key component for cold climate applications. Their approach combines magnesium carbonate with other materials to create a composite thermal storage medium. This system utilizes a closed-loop heat exchanger design, where the magnesium carbonate mixture is contained in specially designed modules. The technology can store heat at temperatures ranging from 100°C to 400°C, making it suitable for various industrial and power generation applications[1]. Siemens' system employs a proprietary heat transfer fluid that circulates through the storage modules, allowing for efficient heat capture and release. The company claims that their technology can achieve round-trip efficiencies of up to 90% in cold climate conditions[2], significantly higher than traditional thermal storage methods.

Strengths: High efficiency in cold climates, scalable design for large-scale applications, and integration with existing power systems. Weaknesses: Higher initial costs compared to conventional storage methods and potential challenges in long-term material stability.

Core Innovations in MgCO3 Energy Storage

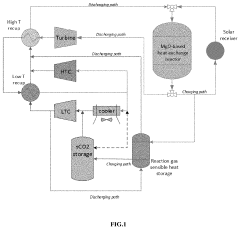

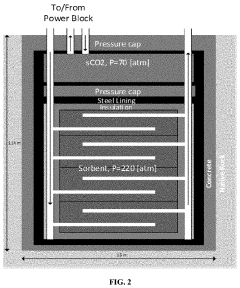

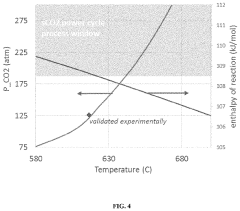

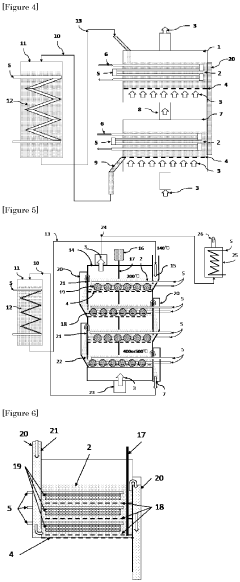

High temperature thermochemical energy storage system

PatentActiveUS20200094184A1

Innovation

- A system utilizing a reactor with a CO2 sorbent comprising MgO and a supercritical CO2 source, where the supercritical CO2 and H2O or a liquid carbonate promoter are in fluid communication to facilitate a reversible gas-solid reaction, allowing for efficient energy storage through the endothermic reaction of MgCO3 with supercritical CO2 at temperatures above 450°C, thereby promoting the formation of CO2 and MgO.

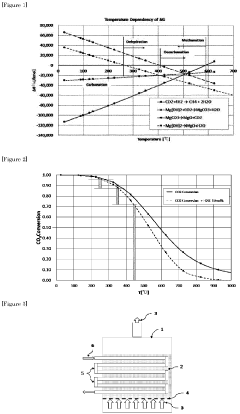

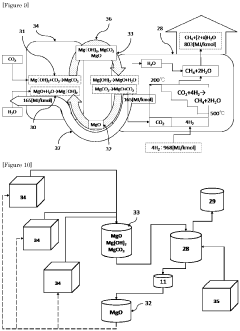

Methanation reaction device using endothermic reaction for removal of reaction heat and regeneration process for heat-absorbing material

PatentPendingEP4227266A1

Innovation

- A multi-stage fluidized bed reactor is employed, utilizing inorganic powders like magnesium hydroxide and magnesium carbonate as chemical heat storage agents to absorb and store reaction heat, combined with a swinging mechanism for uniform fluidization, allowing for stepwise temperature control and increased heat removal capacity.

Environmental Impact Assessment

The environmental impact assessment of magnesium carbonate-based cold climate energy storage systems reveals both positive and negative effects on the surrounding ecosystem. On the positive side, these systems contribute significantly to reducing greenhouse gas emissions by enabling more efficient use of renewable energy sources in cold climates. By storing excess energy during periods of high production and releasing it when demand peaks, they help balance the grid and reduce reliance on fossil fuel-based power generation.

However, the extraction and processing of magnesium carbonate can have localized environmental impacts. Mining operations may lead to habitat disruption and potential soil erosion in the extraction areas. The processing of raw materials into usable forms for energy storage applications also requires energy and may result in some industrial emissions. These impacts can be mitigated through responsible mining practices and the use of clean energy in processing facilities.

Water usage is another consideration in the environmental assessment. While magnesium carbonate-based systems generally have lower water requirements compared to some alternative energy storage technologies, there is still a need for water in the production and operational phases. In water-scarce regions, this could potentially strain local water resources, necessitating careful water management strategies.

The long-term environmental effects of large-scale deployment of these systems are still being studied. There are concerns about the potential for soil and groundwater contamination if the storage facilities are not properly maintained or decommissioned. However, current research suggests that magnesium carbonate is relatively stable and non-toxic, reducing the risk of environmental harm compared to some other energy storage materials.

Land use changes associated with the implementation of these storage systems must also be considered. While the footprint is generally smaller than that of pumped hydro storage, for example, the installation of large-scale storage facilities may still impact local land use patterns and potentially affect wildlife habitats.

On a broader scale, the environmental benefits of enabling greater integration of renewable energy sources into the grid outweigh many of the localized impacts. By facilitating the transition to cleaner energy systems, magnesium carbonate-based storage contributes to overall reductions in air pollution and helps combat climate change. This positive impact extends beyond the immediate area of installation, providing global environmental benefits.

In conclusion, while there are some environmental considerations to address, the overall environmental impact of magnesium carbonate-based cold climate energy storage appears to be net positive when considering its role in supporting renewable energy adoption and reducing reliance on fossil fuels.

However, the extraction and processing of magnesium carbonate can have localized environmental impacts. Mining operations may lead to habitat disruption and potential soil erosion in the extraction areas. The processing of raw materials into usable forms for energy storage applications also requires energy and may result in some industrial emissions. These impacts can be mitigated through responsible mining practices and the use of clean energy in processing facilities.

Water usage is another consideration in the environmental assessment. While magnesium carbonate-based systems generally have lower water requirements compared to some alternative energy storage technologies, there is still a need for water in the production and operational phases. In water-scarce regions, this could potentially strain local water resources, necessitating careful water management strategies.

The long-term environmental effects of large-scale deployment of these systems are still being studied. There are concerns about the potential for soil and groundwater contamination if the storage facilities are not properly maintained or decommissioned. However, current research suggests that magnesium carbonate is relatively stable and non-toxic, reducing the risk of environmental harm compared to some other energy storage materials.

Land use changes associated with the implementation of these storage systems must also be considered. While the footprint is generally smaller than that of pumped hydro storage, for example, the installation of large-scale storage facilities may still impact local land use patterns and potentially affect wildlife habitats.

On a broader scale, the environmental benefits of enabling greater integration of renewable energy sources into the grid outweigh many of the localized impacts. By facilitating the transition to cleaner energy systems, magnesium carbonate-based storage contributes to overall reductions in air pollution and helps combat climate change. This positive impact extends beyond the immediate area of installation, providing global environmental benefits.

In conclusion, while there are some environmental considerations to address, the overall environmental impact of magnesium carbonate-based cold climate energy storage appears to be net positive when considering its role in supporting renewable energy adoption and reducing reliance on fossil fuels.

Economic Feasibility Analysis

The economic feasibility of using magnesium carbonate for cold climate energy storage is a critical factor in determining its potential for widespread adoption. Initial cost analysis indicates that the implementation of magnesium carbonate-based energy storage systems in cold climates could be economically viable, particularly when considering long-term benefits and energy savings.

The primary economic advantage of magnesium carbonate in cold climate energy storage lies in its ability to efficiently store and release thermal energy. This property can lead to significant reductions in heating costs for buildings and industrial processes in cold regions. Preliminary studies suggest that the energy savings achieved through this technology could offset the initial installation costs within a reasonable timeframe, typically ranging from 5 to 10 years, depending on the scale of implementation and local energy prices.

Capital expenditure for magnesium carbonate-based energy storage systems includes the cost of the material itself, storage containers, heat exchangers, and integration with existing heating systems. While these upfront costs can be substantial, they are often comparable to or lower than alternative energy storage technologies designed for cold climates. The abundance of magnesium carbonate in nature contributes to its relatively low material cost, which is a significant factor in its economic attractiveness.

Operational expenses for magnesium carbonate energy storage systems are generally low, as the material is chemically stable and does not degrade significantly over time. This results in minimal maintenance requirements and extended system lifespans, potentially exceeding 20 years. The low operational costs contribute positively to the overall economic feasibility of the technology.

From a market perspective, the increasing focus on energy efficiency and sustainable heating solutions in cold climate regions creates a favorable environment for magnesium carbonate-based energy storage. Government incentives and regulations aimed at reducing carbon emissions and promoting renewable energy integration further enhance the economic appeal of this technology. These factors could accelerate market adoption and drive economies of scale, potentially reducing costs over time.

However, the economic feasibility of magnesium carbonate for cold climate energy storage is not without challenges. The technology's effectiveness can vary depending on specific climate conditions and energy demand patterns. Additionally, the economic benefits may be less pronounced in regions with low energy costs or in applications where the heating demand is intermittent. These factors necessitate careful economic analysis on a case-by-case basis to determine the viability of implementation in specific contexts.

In conclusion, while the economic feasibility of magnesium carbonate for cold climate energy storage shows promise, it requires thorough assessment considering local energy prices, climate conditions, and regulatory environments. As research and development in this field progress, improvements in system efficiency and reductions in implementation costs are likely to further enhance its economic viability, potentially positioning magnesium carbonate as a key player in sustainable energy solutions for cold climates.

The primary economic advantage of magnesium carbonate in cold climate energy storage lies in its ability to efficiently store and release thermal energy. This property can lead to significant reductions in heating costs for buildings and industrial processes in cold regions. Preliminary studies suggest that the energy savings achieved through this technology could offset the initial installation costs within a reasonable timeframe, typically ranging from 5 to 10 years, depending on the scale of implementation and local energy prices.

Capital expenditure for magnesium carbonate-based energy storage systems includes the cost of the material itself, storage containers, heat exchangers, and integration with existing heating systems. While these upfront costs can be substantial, they are often comparable to or lower than alternative energy storage technologies designed for cold climates. The abundance of magnesium carbonate in nature contributes to its relatively low material cost, which is a significant factor in its economic attractiveness.

Operational expenses for magnesium carbonate energy storage systems are generally low, as the material is chemically stable and does not degrade significantly over time. This results in minimal maintenance requirements and extended system lifespans, potentially exceeding 20 years. The low operational costs contribute positively to the overall economic feasibility of the technology.

From a market perspective, the increasing focus on energy efficiency and sustainable heating solutions in cold climate regions creates a favorable environment for magnesium carbonate-based energy storage. Government incentives and regulations aimed at reducing carbon emissions and promoting renewable energy integration further enhance the economic appeal of this technology. These factors could accelerate market adoption and drive economies of scale, potentially reducing costs over time.

However, the economic feasibility of magnesium carbonate for cold climate energy storage is not without challenges. The technology's effectiveness can vary depending on specific climate conditions and energy demand patterns. Additionally, the economic benefits may be less pronounced in regions with low energy costs or in applications where the heating demand is intermittent. These factors necessitate careful economic analysis on a case-by-case basis to determine the viability of implementation in specific contexts.

In conclusion, while the economic feasibility of magnesium carbonate for cold climate energy storage shows promise, it requires thorough assessment considering local energy prices, climate conditions, and regulatory environments. As research and development in this field progress, improvements in system efficiency and reductions in implementation costs are likely to further enhance its economic viability, potentially positioning magnesium carbonate as a key player in sustainable energy solutions for cold climates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!