How Model Predictive Control Reduces Production Waste

SEP 8, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC Technology Evolution and Waste Reduction Goals

Model Predictive Control (MPC) technology has evolved significantly since its theoretical foundations were established in the 1960s. Initially developed as an advanced process control methodology for complex industrial systems, MPC has transformed from a conceptual framework into a practical solution for optimizing manufacturing processes. The evolution began with simple dynamic matrix control algorithms and progressed to incorporate more sophisticated mathematical models capable of handling multiple variables, constraints, and objectives simultaneously.

By the 1980s, MPC had found its first commercial applications in petroleum refineries and petrochemical plants, where it demonstrated remarkable capabilities in reducing variability and improving efficiency. The 1990s witnessed the expansion of MPC into other industries, including pulp and paper, food processing, and automotive manufacturing, as computational power increased and implementation costs decreased.

The technological trajectory of MPC has been characterized by continuous improvements in modeling accuracy, computational efficiency, and integration capabilities. Modern MPC systems leverage advanced machine learning techniques to develop more precise predictive models and adapt to changing process conditions in real-time, representing a significant advancement from earlier static model approaches.

In the context of waste reduction, MPC technology has evolved with increasingly explicit goals to minimize material waste, energy consumption, and quality defects. Early implementations focused primarily on process stabilization, with waste reduction emerging as a secondary benefit. However, contemporary MPC systems directly incorporate waste minimization as a primary optimization objective, reflecting growing environmental concerns and economic pressures.

The waste reduction goals associated with MPC have become more ambitious and multifaceted over time. Current objectives include minimizing raw material usage through precise dosing and mixing, reducing energy waste through optimized heating and cooling cycles, decreasing product defects through tighter quality control, and minimizing transition waste during product changeovers. These goals align with broader industrial sustainability initiatives and circular economy principles.

Recent technological developments have enhanced MPC's waste reduction capabilities through integration with other advanced technologies such as digital twins, Industrial Internet of Things (IIoT) sensors, and artificial intelligence. This integration enables more comprehensive monitoring, more accurate predictions, and more effective interventions to prevent waste generation across the entire production process.

The evolution trajectory suggests that future MPC systems will continue to advance toward more holistic waste reduction approaches, addressing not only immediate production waste but also lifecycle environmental impacts and supply chain inefficiencies. This represents a significant expansion of MPC's scope and potential contribution to industrial sustainability.

By the 1980s, MPC had found its first commercial applications in petroleum refineries and petrochemical plants, where it demonstrated remarkable capabilities in reducing variability and improving efficiency. The 1990s witnessed the expansion of MPC into other industries, including pulp and paper, food processing, and automotive manufacturing, as computational power increased and implementation costs decreased.

The technological trajectory of MPC has been characterized by continuous improvements in modeling accuracy, computational efficiency, and integration capabilities. Modern MPC systems leverage advanced machine learning techniques to develop more precise predictive models and adapt to changing process conditions in real-time, representing a significant advancement from earlier static model approaches.

In the context of waste reduction, MPC technology has evolved with increasingly explicit goals to minimize material waste, energy consumption, and quality defects. Early implementations focused primarily on process stabilization, with waste reduction emerging as a secondary benefit. However, contemporary MPC systems directly incorporate waste minimization as a primary optimization objective, reflecting growing environmental concerns and economic pressures.

The waste reduction goals associated with MPC have become more ambitious and multifaceted over time. Current objectives include minimizing raw material usage through precise dosing and mixing, reducing energy waste through optimized heating and cooling cycles, decreasing product defects through tighter quality control, and minimizing transition waste during product changeovers. These goals align with broader industrial sustainability initiatives and circular economy principles.

Recent technological developments have enhanced MPC's waste reduction capabilities through integration with other advanced technologies such as digital twins, Industrial Internet of Things (IIoT) sensors, and artificial intelligence. This integration enables more comprehensive monitoring, more accurate predictions, and more effective interventions to prevent waste generation across the entire production process.

The evolution trajectory suggests that future MPC systems will continue to advance toward more holistic waste reduction approaches, addressing not only immediate production waste but also lifecycle environmental impacts and supply chain inefficiencies. This represents a significant expansion of MPC's scope and potential contribution to industrial sustainability.

Market Demand for Waste Reduction Solutions

The global market for waste reduction solutions has witnessed significant growth in recent years, driven by increasing environmental concerns, regulatory pressures, and economic incentives. Industrial waste reduction has become a critical focus area for manufacturing companies across various sectors, with Model Predictive Control (MPC) emerging as a promising technological solution to address this challenge.

Manufacturing industries worldwide generate substantial waste, with estimates suggesting that production inefficiencies account for 20-30% of total manufacturing costs. This represents not only a significant economic burden but also contributes to environmental degradation. The demand for advanced waste reduction technologies like MPC is particularly strong in process industries such as chemicals, pharmaceuticals, food and beverage, and pulp and paper, where even small improvements in process efficiency can yield substantial waste reduction.

Market research indicates that the global market for industrial automation solutions focused on waste reduction is growing at a compound annual growth rate of 8.5%, with the MPC segment expanding even faster. This growth is fueled by the dual benefits of cost savings and environmental compliance that MPC technology offers to manufacturers.

Regulatory frameworks worldwide are becoming increasingly stringent regarding waste management and environmental protection. The European Union's Circular Economy Action Plan, China's increasingly strict environmental regulations, and the United States' emphasis on sustainable manufacturing practices are creating strong market pull for technologies that can minimize production waste. Companies are actively seeking solutions that can help them comply with these regulations while maintaining competitive production costs.

Consumer preferences are also driving market demand for waste reduction technologies. The growing consumer awareness about environmental sustainability has led to increased pressure on manufacturers to adopt greener production methods. Companies that can demonstrate reduced waste footprints often gain competitive advantages in consumer markets, further incentivizing investment in technologies like MPC.

From an economic perspective, waste reduction directly impacts the bottom line. Raw materials typically constitute 50-70% of production costs in manufacturing industries. By minimizing waste through precise process control, MPC offers significant cost savings potential. Industry reports suggest that effective implementation of MPC can reduce material waste by 15-25% in many production environments, representing substantial financial benefits.

The COVID-19 pandemic has further accelerated market demand for automation solutions like MPC, as manufacturers seek to build more resilient and efficient production systems. Supply chain disruptions have highlighted the importance of resource efficiency, creating additional market pull for technologies that can optimize material usage and reduce waste.

Manufacturing industries worldwide generate substantial waste, with estimates suggesting that production inefficiencies account for 20-30% of total manufacturing costs. This represents not only a significant economic burden but also contributes to environmental degradation. The demand for advanced waste reduction technologies like MPC is particularly strong in process industries such as chemicals, pharmaceuticals, food and beverage, and pulp and paper, where even small improvements in process efficiency can yield substantial waste reduction.

Market research indicates that the global market for industrial automation solutions focused on waste reduction is growing at a compound annual growth rate of 8.5%, with the MPC segment expanding even faster. This growth is fueled by the dual benefits of cost savings and environmental compliance that MPC technology offers to manufacturers.

Regulatory frameworks worldwide are becoming increasingly stringent regarding waste management and environmental protection. The European Union's Circular Economy Action Plan, China's increasingly strict environmental regulations, and the United States' emphasis on sustainable manufacturing practices are creating strong market pull for technologies that can minimize production waste. Companies are actively seeking solutions that can help them comply with these regulations while maintaining competitive production costs.

Consumer preferences are also driving market demand for waste reduction technologies. The growing consumer awareness about environmental sustainability has led to increased pressure on manufacturers to adopt greener production methods. Companies that can demonstrate reduced waste footprints often gain competitive advantages in consumer markets, further incentivizing investment in technologies like MPC.

From an economic perspective, waste reduction directly impacts the bottom line. Raw materials typically constitute 50-70% of production costs in manufacturing industries. By minimizing waste through precise process control, MPC offers significant cost savings potential. Industry reports suggest that effective implementation of MPC can reduce material waste by 15-25% in many production environments, representing substantial financial benefits.

The COVID-19 pandemic has further accelerated market demand for automation solutions like MPC, as manufacturers seek to build more resilient and efficient production systems. Supply chain disruptions have highlighted the importance of resource efficiency, creating additional market pull for technologies that can optimize material usage and reduce waste.

Current MPC Implementation Challenges

Despite the proven benefits of Model Predictive Control (MPC) in reducing production waste, organizations face significant implementation challenges that hinder widespread adoption. One primary obstacle is the substantial initial investment required for MPC systems, including hardware, software, and integration costs. For many small and medium-sized manufacturers, this financial barrier often outweighs the long-term waste reduction benefits, particularly when operating with limited capital expenditure budgets.

Technical complexity presents another major challenge, as MPC implementation demands specialized expertise in control theory, mathematical modeling, and process engineering. The shortage of qualified personnel with these interdisciplinary skills creates bottlenecks in both implementation and ongoing maintenance. Organizations frequently struggle to recruit and retain staff capable of developing accurate process models and tuning control parameters effectively.

Process model development remains particularly problematic, requiring extensive process knowledge and data collection. Creating high-fidelity models that accurately represent complex manufacturing processes often involves months of development time. Inaccurate models can lead to suboptimal control decisions, potentially increasing rather than reducing waste. Additionally, many industrial processes exhibit nonlinear behaviors and time-varying characteristics that are difficult to capture in standard MPC frameworks.

Integration with existing control systems presents significant technical hurdles. Legacy automation systems, often based on traditional PID controllers, may lack the communication protocols and computational capabilities necessary for seamless MPC integration. This compatibility gap frequently necessitates costly system upgrades or complex middleware solutions to enable effective data exchange between MPC algorithms and plant-floor equipment.

Computational demands constitute another implementation barrier. Real-time optimization calculations in MPC require substantial processing power, especially for complex processes with multiple variables and constraints. This computational intensity can strain existing IT infrastructure and may require dedicated computing resources to maintain acceptable control loop performance without introducing latency issues.

Validation and tuning of MPC systems demand extensive testing periods that can disrupt production schedules. Organizations must balance the need for thorough system verification against production demands, often resulting in compromised implementation approaches. The difficulty in quantifying waste reduction benefits during these early implementation phases further complicates justification for continued investment in MPC technology.

Organizational resistance to change represents a final significant challenge. Operators and production managers accustomed to conventional control methods may exhibit skepticism toward complex algorithmic approaches, particularly when MPC decisions contradict established operational practices. This cultural resistance necessitates comprehensive change management strategies alongside technical implementation plans.

Technical complexity presents another major challenge, as MPC implementation demands specialized expertise in control theory, mathematical modeling, and process engineering. The shortage of qualified personnel with these interdisciplinary skills creates bottlenecks in both implementation and ongoing maintenance. Organizations frequently struggle to recruit and retain staff capable of developing accurate process models and tuning control parameters effectively.

Process model development remains particularly problematic, requiring extensive process knowledge and data collection. Creating high-fidelity models that accurately represent complex manufacturing processes often involves months of development time. Inaccurate models can lead to suboptimal control decisions, potentially increasing rather than reducing waste. Additionally, many industrial processes exhibit nonlinear behaviors and time-varying characteristics that are difficult to capture in standard MPC frameworks.

Integration with existing control systems presents significant technical hurdles. Legacy automation systems, often based on traditional PID controllers, may lack the communication protocols and computational capabilities necessary for seamless MPC integration. This compatibility gap frequently necessitates costly system upgrades or complex middleware solutions to enable effective data exchange between MPC algorithms and plant-floor equipment.

Computational demands constitute another implementation barrier. Real-time optimization calculations in MPC require substantial processing power, especially for complex processes with multiple variables and constraints. This computational intensity can strain existing IT infrastructure and may require dedicated computing resources to maintain acceptable control loop performance without introducing latency issues.

Validation and tuning of MPC systems demand extensive testing periods that can disrupt production schedules. Organizations must balance the need for thorough system verification against production demands, often resulting in compromised implementation approaches. The difficulty in quantifying waste reduction benefits during these early implementation phases further complicates justification for continued investment in MPC technology.

Organizational resistance to change represents a final significant challenge. Operators and production managers accustomed to conventional control methods may exhibit skepticism toward complex algorithmic approaches, particularly when MPC decisions contradict established operational practices. This cultural resistance necessitates comprehensive change management strategies alongside technical implementation plans.

Current MPC Waste Reduction Methodologies

01 Model Predictive Control for Waste Reduction in Manufacturing

Model Predictive Control (MPC) systems can be implemented in manufacturing processes to minimize waste production. These systems use mathematical models to predict future process behavior and optimize control actions accordingly. By anticipating process variations and making proactive adjustments, MPC helps maintain optimal operating conditions, reducing off-spec products and material waste. This approach is particularly effective in continuous production environments where small deviations can lead to significant waste generation.- Model Predictive Control for Waste Reduction in Manufacturing: Model Predictive Control (MPC) systems can be implemented in manufacturing processes to minimize production waste. These systems use mathematical models to predict future process behavior and optimize control actions accordingly. By anticipating process variations and making proactive adjustments, MPC helps maintain optimal operating conditions, reduce off-spec products, and minimize material waste in industrial production environments.

- Real-time Process Optimization for Waste Minimization: Real-time optimization techniques integrated with predictive control frameworks enable continuous monitoring and adjustment of production parameters to minimize waste generation. These systems collect and analyze process data in real-time, identifying inefficiencies and automatically implementing corrective actions. This approach allows for dynamic response to changing conditions, ensuring resource efficiency and reducing waste throughout the production cycle.

- Advanced Control Algorithms for Resource Efficiency: Specialized control algorithms designed for waste reduction incorporate multiple variables and constraints to optimize resource utilization in production processes. These algorithms balance production targets with waste minimization objectives, considering factors such as energy consumption, material usage, and equipment efficiency. By implementing these advanced control strategies, manufacturers can achieve sustainable production with minimal environmental impact.

- Predictive Maintenance to Prevent Production Waste: Predictive maintenance strategies powered by MPC frameworks help prevent equipment failures that lead to production waste. By monitoring equipment health indicators and predicting potential failures before they occur, these systems enable timely maintenance interventions. This proactive approach reduces unplanned downtime, prevents quality issues caused by deteriorating equipment, and minimizes the waste associated with production interruptions.

- Integrated Production Planning and Control Systems: Integrated systems that combine production planning with model predictive control create comprehensive waste management solutions. These systems coordinate production scheduling, inventory management, and process control to optimize material flow and minimize waste throughout the supply chain. By aligning production plans with real-time control strategies, manufacturers can achieve higher resource efficiency and reduce waste across multiple production stages.

02 Real-time Process Optimization for Waste Minimization

Real-time optimization techniques integrated with predictive control frameworks enable continuous adjustment of production parameters to minimize waste. These systems collect and analyze process data in real-time, identifying inefficiencies and automatically implementing corrective actions. By maintaining process variables within optimal ranges, these systems prevent quality issues that would otherwise result in scrapped materials. Advanced algorithms can balance multiple objectives including waste reduction, energy efficiency, and production targets simultaneously.Expand Specific Solutions03 Adaptive MPC Systems for Variable Production Conditions

Adaptive Model Predictive Control systems can automatically adjust their internal models based on changing production conditions, ensuring continued waste reduction even as processes evolve. These systems learn from historical and real-time data to improve prediction accuracy over time. By adapting to changes in raw materials, equipment performance, and environmental conditions, these systems maintain optimal control even when faced with process disturbances or equipment degradation, preventing waste that would otherwise occur during transitional periods.Expand Specific Solutions04 Integration of MPC with Production Planning Systems

Integrating Model Predictive Control with higher-level production planning and scheduling systems creates a comprehensive approach to waste reduction across the entire manufacturing operation. This integration allows production plans to be dynamically adjusted based on actual process performance and constraints. By coordinating production scheduling with process control, manufacturers can minimize changeover waste, reduce inventory levels, and optimize resource utilization. This holistic approach ensures that waste reduction strategies are implemented consistently throughout the production lifecycle.Expand Specific Solutions05 Machine Learning Enhanced MPC for Waste Prediction

Machine learning algorithms can enhance Model Predictive Control systems by improving their ability to predict and prevent waste-generating events. These hybrid systems combine traditional model-based approaches with data-driven techniques to identify complex patterns that may lead to waste production. By analyzing historical waste incidents alongside process data, these systems can identify early warning indicators and implement preventive control actions. This predictive capability is particularly valuable in complex processes where traditional modeling approaches may be insufficient to capture all waste-generating mechanisms.Expand Specific Solutions

Leading MPC Solution Providers and Competitors

Model Predictive Control (MPC) technology is evolving rapidly in waste reduction applications, currently transitioning from early adoption to growth phase. The market is expanding at approximately 8-10% annually, driven by increasing industrial efficiency demands and sustainability regulations. Technologically, MPC implementations show varying maturity levels across industries, with companies like Siemens AG, ABB Group, and Rockwell Automation leading with advanced solutions. Boeing and United Technologies demonstrate successful industrial applications, while IBM and Emerson (Fisher-Rosemount) focus on integrating MPC with AI and cloud technologies. Academic institutions like Zhejiang University and research organizations such as Mitsubishi Electric Research Laboratories are advancing theoretical frameworks, creating a competitive landscape where established industrial automation leaders face emerging specialized optimization providers like Shanshu Technology.

ABB Group

Technical Solution: ABB Group has pioneered Model Predictive Control technology through their ABB Ability Expert Optimizer and Advanced Process Control solutions. Their MPC implementation utilizes dynamic matrix control algorithms with embedded state estimation to handle process disturbances and model uncertainties. ABB's approach focuses on multivariable control with constraint handling capabilities, allowing processes to operate closer to quality and equipment constraints without violations. Their waste reduction strategy employs predictive models to anticipate process deviations before they occur, enabling proactive adjustments rather than reactive corrections. The system continuously optimizes setpoints across multiple process variables while respecting operational constraints, resulting in more consistent product quality and reduced material waste. ABB's MPC technology has been particularly successful in process industries, where it has demonstrated 15-25% reduction in quality variability and up to 20% decrease in raw material consumption. Their implementation includes adaptive models that automatically adjust to changing process conditions, ensuring sustained performance over time.

Strengths: Robust handling of process constraints and disturbances. Excellent integration with existing ABB control systems and extensive industry-specific solution libraries. Weaknesses: Requires significant process knowledge and modeling expertise. Implementation complexity can be challenging for organizations without specialized skills.

Rockwell Automation Technologies, Inc.

Technical Solution: Rockwell Automation has developed a sophisticated Model Predictive Control framework within their PlantPAx Distributed Control System. Their MPC solution employs multivariable control algorithms that simultaneously manage multiple inputs and outputs while respecting operational constraints. The system builds dynamic models of production processes through step testing or analysis of historical data, then uses these models to predict future behavior and optimize control actions. Rockwell's implementation specifically targets waste reduction through several mechanisms: maintaining product quality within tighter specifications, reducing transition waste during product changeovers, and minimizing energy consumption. Their MPC technology includes features like "economic MPC" that directly incorporates waste reduction and production costs into the optimization objective function. Case studies have shown 25-40% reduction in off-spec production and up to 30% decrease in transition waste during grade changes in continuous manufacturing processes.

Strengths: Highly scalable architecture suitable for both small applications and enterprise-wide deployments. Excellent integration with existing Rockwell control systems and visualization tools. Weaknesses: More complex configuration compared to traditional PID control. Requires significant process knowledge for effective implementation and ongoing maintenance.

Key MPC Algorithms and Mathematical Frameworks

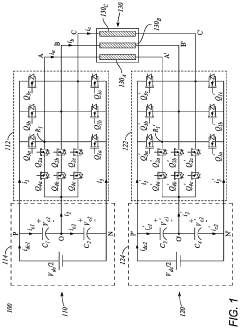

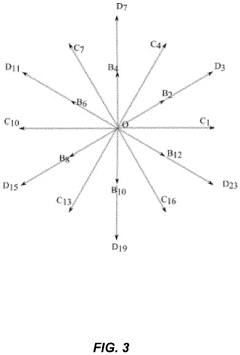

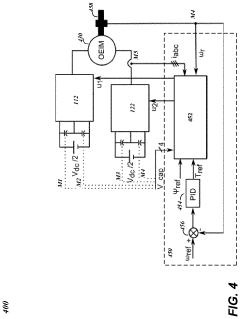

Predictive control method for a multilevel converter

PatentActiveUS20230299698A1

Innovation

- Implementing a reduced switching state model predictive control (MPC) that incorporates common-mode voltage reduction/elimination (CMVR/CMVE) and DC link capacitor balancing, using a set of 219 or 115 reduced switching states to minimize computation time and improve performance, specifically for 5-level dual T-type multilevel converters connected to three-phase open-end induction motors.

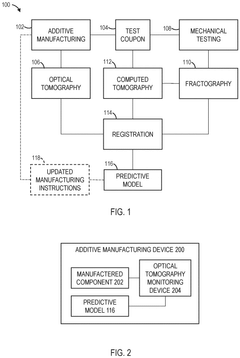

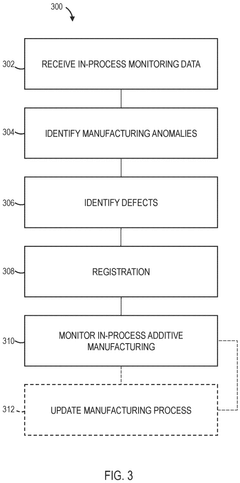

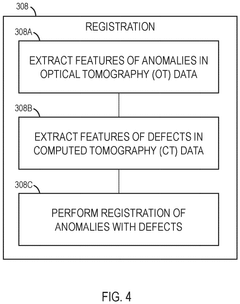

Methods and systems for in-process monitoring of additive manufacturing

PatentPendingEP4600769A1

Innovation

- A predictive model is trained using optical tomography and computed tomography data to identify manufacturing anomalies and defects in a test coupon, enabling in-process monitoring and proactive adjustments to the manufacturing process.

ROI Analysis of MPC Implementation

Implementing Model Predictive Control (MPC) systems represents a significant investment for manufacturing operations, requiring careful financial analysis to justify the expenditure. The return on investment for MPC implementation typically manifests through multiple channels, with waste reduction being a primary driver of financial returns. Comprehensive ROI analyses indicate that MPC systems generally achieve payback periods ranging from 6 months to 2 years, depending on the industry and specific application context.

The initial capital expenditure for MPC implementation includes hardware costs (sensors, controllers, computing infrastructure), software licensing, integration services, and staff training. These upfront costs typically range from $50,000 for simple applications to over $500,000 for complex, facility-wide implementations. However, the operational expenditure reduction often outweighs these initial investments substantially over time.

Waste reduction benefits materialize through several mechanisms. First, MPC systems minimize off-specification production by maintaining process variables within tighter control limits, reducing the volume of products that fail quality checks. Studies across various industries show that MPC implementation typically reduces off-spec production by 20-50%, translating to direct material savings of 2-5% of total production costs.

Energy consumption reduction represents another significant ROI factor. By optimizing process conditions and minimizing unnecessary fluctuations, MPC systems typically reduce energy usage by 2-10% across various manufacturing contexts. This benefit is particularly pronounced in energy-intensive industries such as chemicals, pulp and paper, and metals processing.

Maintenance cost reduction also contributes to ROI through decreased equipment wear. By maintaining smoother operation and reducing process variability, MPC implementations extend equipment life and reduce maintenance frequency. Case studies indicate maintenance cost reductions of 5-15% following MPC implementation, with corresponding increases in equipment uptime.

Productivity improvements further enhance ROI through increased throughput. By operating closer to constraint boundaries while maintaining process stability, MPC systems typically enable throughput increases of 3-8%. This productivity gain often represents the largest single contributor to ROI calculations, particularly in capacity-constrained operations where additional output directly translates to increased revenue.

When calculating comprehensive ROI, organizations must also consider less tangible benefits such as improved regulatory compliance, reduced environmental incidents, and enhanced workforce productivity through automation. While more difficult to quantify, these factors often provide substantial risk mitigation value that should be incorporated into financial analyses through risk-adjusted ROI methodologies.

The initial capital expenditure for MPC implementation includes hardware costs (sensors, controllers, computing infrastructure), software licensing, integration services, and staff training. These upfront costs typically range from $50,000 for simple applications to over $500,000 for complex, facility-wide implementations. However, the operational expenditure reduction often outweighs these initial investments substantially over time.

Waste reduction benefits materialize through several mechanisms. First, MPC systems minimize off-specification production by maintaining process variables within tighter control limits, reducing the volume of products that fail quality checks. Studies across various industries show that MPC implementation typically reduces off-spec production by 20-50%, translating to direct material savings of 2-5% of total production costs.

Energy consumption reduction represents another significant ROI factor. By optimizing process conditions and minimizing unnecessary fluctuations, MPC systems typically reduce energy usage by 2-10% across various manufacturing contexts. This benefit is particularly pronounced in energy-intensive industries such as chemicals, pulp and paper, and metals processing.

Maintenance cost reduction also contributes to ROI through decreased equipment wear. By maintaining smoother operation and reducing process variability, MPC implementations extend equipment life and reduce maintenance frequency. Case studies indicate maintenance cost reductions of 5-15% following MPC implementation, with corresponding increases in equipment uptime.

Productivity improvements further enhance ROI through increased throughput. By operating closer to constraint boundaries while maintaining process stability, MPC systems typically enable throughput increases of 3-8%. This productivity gain often represents the largest single contributor to ROI calculations, particularly in capacity-constrained operations where additional output directly translates to increased revenue.

When calculating comprehensive ROI, organizations must also consider less tangible benefits such as improved regulatory compliance, reduced environmental incidents, and enhanced workforce productivity through automation. While more difficult to quantify, these factors often provide substantial risk mitigation value that should be incorporated into financial analyses through risk-adjusted ROI methodologies.

Environmental Compliance Benefits of MPC Systems

Model Predictive Control (MPC) systems offer significant environmental compliance benefits that extend beyond operational efficiency improvements. As regulatory frameworks worldwide become increasingly stringent regarding emissions, waste management, and resource utilization, MPC technology provides organizations with powerful tools to meet and exceed compliance requirements while maintaining productivity.

MPC systems enable precise adherence to environmental constraints by continuously optimizing process variables within predefined environmental limits. This proactive approach prevents violations before they occur, rather than detecting them after the fact. For instance, in power generation facilities, MPC can maintain optimal combustion conditions that minimize NOx and SOx emissions while maximizing energy output, ensuring continuous compliance with Clean Air Act regulations.

Water treatment facilities implementing MPC have demonstrated remarkable improvements in regulatory compliance. These systems can dynamically adjust chemical dosing and process parameters to maintain effluent quality within permitted ranges despite varying influent conditions. Studies show that MPC-controlled wastewater treatment plants experience up to 85% fewer compliance violations compared to conventionally controlled facilities.

The predictive nature of MPC provides substantial advantages for emissions management in manufacturing. By anticipating process disturbances and making preemptive adjustments, facilities can avoid emission spikes that might otherwise trigger regulatory violations. This capability is particularly valuable in industries with batch processes where transitions between production states often create compliance challenges.

Documentation and reporting capabilities integrated with modern MPC systems streamline regulatory reporting requirements. These systems automatically generate compliance records, creating audit trails that demonstrate continuous adherence to environmental standards. This reduces administrative burden while improving transparency with regulatory agencies and stakeholders.

MPC implementation also supports sustainability certification programs such as ISO 14001 by providing verifiable evidence of continuous environmental performance improvement. Organizations can demonstrate systematic approaches to environmental management through documented optimization of resource utilization and waste reduction, strengthening their position during certification audits.

As carbon pricing mechanisms and emissions trading schemes expand globally, MPC systems offer economic benefits by minimizing emissions-related financial liabilities. The technology enables organizations to operate at the optimal balance point between production efficiency and emissions generation, reducing exposure to carbon taxes or costs associated with purchasing emissions credits.

MPC systems enable precise adherence to environmental constraints by continuously optimizing process variables within predefined environmental limits. This proactive approach prevents violations before they occur, rather than detecting them after the fact. For instance, in power generation facilities, MPC can maintain optimal combustion conditions that minimize NOx and SOx emissions while maximizing energy output, ensuring continuous compliance with Clean Air Act regulations.

Water treatment facilities implementing MPC have demonstrated remarkable improvements in regulatory compliance. These systems can dynamically adjust chemical dosing and process parameters to maintain effluent quality within permitted ranges despite varying influent conditions. Studies show that MPC-controlled wastewater treatment plants experience up to 85% fewer compliance violations compared to conventionally controlled facilities.

The predictive nature of MPC provides substantial advantages for emissions management in manufacturing. By anticipating process disturbances and making preemptive adjustments, facilities can avoid emission spikes that might otherwise trigger regulatory violations. This capability is particularly valuable in industries with batch processes where transitions between production states often create compliance challenges.

Documentation and reporting capabilities integrated with modern MPC systems streamline regulatory reporting requirements. These systems automatically generate compliance records, creating audit trails that demonstrate continuous adherence to environmental standards. This reduces administrative burden while improving transparency with regulatory agencies and stakeholders.

MPC implementation also supports sustainability certification programs such as ISO 14001 by providing verifiable evidence of continuous environmental performance improvement. Organizations can demonstrate systematic approaches to environmental management through documented optimization of resource utilization and waste reduction, strengthening their position during certification audits.

As carbon pricing mechanisms and emissions trading schemes expand globally, MPC systems offer economic benefits by minimizing emissions-related financial liabilities. The technology enables organizations to operate at the optimal balance point between production efficiency and emissions generation, reducing exposure to carbon taxes or costs associated with purchasing emissions credits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!