How Neopentane Creates Advancements Beyond Traditional Applications?

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane Overview

Neopentane, also known as 2,2-dimethylpropane, is a branched alkane with the molecular formula C5H12. This unique hydrocarbon has garnered significant attention in recent years due to its distinctive properties and potential applications across various industries. As a saturated hydrocarbon, neopentane exhibits remarkable stability and low reactivity, making it an attractive candidate for numerous advanced applications.

The molecular structure of neopentane consists of a central carbon atom bonded to four methyl groups, resulting in a highly symmetrical and compact arrangement. This configuration imparts several notable characteristics to the compound, including a relatively high boiling point for its molecular weight, low surface tension, and excellent thermal stability. These properties have led to its exploration in fields ranging from refrigeration and aerosols to advanced materials and energy storage.

Traditionally, neopentane has found limited use in industrial applications, primarily serving as a blowing agent in foam production and as a component in certain refrigerant mixtures. However, recent advancements in chemical engineering and materials science have opened up new avenues for neopentane utilization, pushing beyond its conventional roles.

One of the most promising areas of development lies in the field of thermal management. Neopentane's low thermal conductivity and high heat capacity make it an excellent candidate for phase-change materials (PCMs) used in advanced cooling systems. These systems have potential applications in electronics, aerospace, and energy storage, where efficient heat dissipation is crucial for optimal performance and longevity.

In the realm of advanced materials, neopentane is being investigated as a precursor for the synthesis of novel polymers and nanostructures. Its unique molecular geometry allows for the creation of materials with tailored properties, such as enhanced thermal resistance, improved mechanical strength, and controlled porosity. These innovations could lead to breakthroughs in fields like lightweight composites, high-performance insulation, and selective membranes for gas separation.

Furthermore, neopentane's low reactivity and stability under extreme conditions have sparked interest in its potential use as a working fluid in organic Rankine cycle (ORC) systems for waste heat recovery and geothermal energy applications. This could contribute to more efficient energy utilization and reduced environmental impact in industrial processes.

As research continues to uncover new possibilities for neopentane, it becomes increasingly clear that this seemingly simple molecule holds significant potential for technological advancements across multiple sectors. The ongoing exploration of its properties and applications exemplifies the importance of revisiting and reimagining the potential of known compounds in the pursuit of innovation and progress.

The molecular structure of neopentane consists of a central carbon atom bonded to four methyl groups, resulting in a highly symmetrical and compact arrangement. This configuration imparts several notable characteristics to the compound, including a relatively high boiling point for its molecular weight, low surface tension, and excellent thermal stability. These properties have led to its exploration in fields ranging from refrigeration and aerosols to advanced materials and energy storage.

Traditionally, neopentane has found limited use in industrial applications, primarily serving as a blowing agent in foam production and as a component in certain refrigerant mixtures. However, recent advancements in chemical engineering and materials science have opened up new avenues for neopentane utilization, pushing beyond its conventional roles.

One of the most promising areas of development lies in the field of thermal management. Neopentane's low thermal conductivity and high heat capacity make it an excellent candidate for phase-change materials (PCMs) used in advanced cooling systems. These systems have potential applications in electronics, aerospace, and energy storage, where efficient heat dissipation is crucial for optimal performance and longevity.

In the realm of advanced materials, neopentane is being investigated as a precursor for the synthesis of novel polymers and nanostructures. Its unique molecular geometry allows for the creation of materials with tailored properties, such as enhanced thermal resistance, improved mechanical strength, and controlled porosity. These innovations could lead to breakthroughs in fields like lightweight composites, high-performance insulation, and selective membranes for gas separation.

Furthermore, neopentane's low reactivity and stability under extreme conditions have sparked interest in its potential use as a working fluid in organic Rankine cycle (ORC) systems for waste heat recovery and geothermal energy applications. This could contribute to more efficient energy utilization and reduced environmental impact in industrial processes.

As research continues to uncover new possibilities for neopentane, it becomes increasingly clear that this seemingly simple molecule holds significant potential for technological advancements across multiple sectors. The ongoing exploration of its properties and applications exemplifies the importance of revisiting and reimagining the potential of known compounds in the pursuit of innovation and progress.

Market Potential

Neopentane, a branched alkane isomer of pentane, is gaining traction in various industries due to its unique properties and potential applications. The market potential for neopentane extends beyond its traditional uses, creating opportunities for advancements in multiple sectors.

In the automotive industry, neopentane's low boiling point and high vapor pressure make it an excellent candidate for next-generation refrigerants. As environmental regulations become stricter, the demand for eco-friendly alternatives to conventional refrigerants is increasing. Neopentane's properties align well with these requirements, potentially driving significant market growth in automotive air conditioning systems.

The electronics sector presents another promising market for neopentane. Its low dielectric constant and excellent insulating properties make it suitable for use in high-performance electronic components. As the demand for smaller, more efficient devices continues to rise, neopentane could play a crucial role in developing advanced cooling solutions for semiconductors and other electronic components.

In the energy storage industry, neopentane's unique characteristics offer potential advancements in thermal energy storage systems. Its phase change properties at relatively low temperatures make it an attractive option for developing more efficient and compact heat storage solutions. This application could see significant growth in both residential and industrial settings, particularly in regions focusing on renewable energy integration.

The aerospace industry is another sector where neopentane shows promise. Its low freezing point and high stability under extreme conditions make it suitable for use in specialized lubricants and hydraulic fluids for aircraft operating in harsh environments. As the aerospace industry continues to push technological boundaries, the demand for advanced materials like neopentane is likely to increase.

In the pharmaceutical and chemical industries, neopentane's unique structure and properties open up possibilities for new synthesis routes and reaction processes. Its use as a blowing agent in the production of foam insulation materials is already established, but there is potential for expansion into other areas of materials science and chemical engineering.

The global push for sustainability and energy efficiency also creates opportunities for neopentane in the construction sector. Its excellent insulating properties make it a valuable component in the development of high-performance building materials, potentially contributing to more energy-efficient structures and reduced carbon footprints.

As research into neopentane's properties and applications continues, new market opportunities are likely to emerge. The compound's versatility and unique characteristics position it well for adoption in emerging technologies and innovative products across various industries, suggesting a promising market potential beyond its current applications.

In the automotive industry, neopentane's low boiling point and high vapor pressure make it an excellent candidate for next-generation refrigerants. As environmental regulations become stricter, the demand for eco-friendly alternatives to conventional refrigerants is increasing. Neopentane's properties align well with these requirements, potentially driving significant market growth in automotive air conditioning systems.

The electronics sector presents another promising market for neopentane. Its low dielectric constant and excellent insulating properties make it suitable for use in high-performance electronic components. As the demand for smaller, more efficient devices continues to rise, neopentane could play a crucial role in developing advanced cooling solutions for semiconductors and other electronic components.

In the energy storage industry, neopentane's unique characteristics offer potential advancements in thermal energy storage systems. Its phase change properties at relatively low temperatures make it an attractive option for developing more efficient and compact heat storage solutions. This application could see significant growth in both residential and industrial settings, particularly in regions focusing on renewable energy integration.

The aerospace industry is another sector where neopentane shows promise. Its low freezing point and high stability under extreme conditions make it suitable for use in specialized lubricants and hydraulic fluids for aircraft operating in harsh environments. As the aerospace industry continues to push technological boundaries, the demand for advanced materials like neopentane is likely to increase.

In the pharmaceutical and chemical industries, neopentane's unique structure and properties open up possibilities for new synthesis routes and reaction processes. Its use as a blowing agent in the production of foam insulation materials is already established, but there is potential for expansion into other areas of materials science and chemical engineering.

The global push for sustainability and energy efficiency also creates opportunities for neopentane in the construction sector. Its excellent insulating properties make it a valuable component in the development of high-performance building materials, potentially contributing to more energy-efficient structures and reduced carbon footprints.

As research into neopentane's properties and applications continues, new market opportunities are likely to emerge. The compound's versatility and unique characteristics position it well for adoption in emerging technologies and innovative products across various industries, suggesting a promising market potential beyond its current applications.

Technical Challenges

Neopentane, despite its potential for various applications, faces several technical challenges that hinder its widespread adoption and utilization beyond traditional uses. One of the primary obstacles is its high volatility and low boiling point, which makes handling and storage of neopentane difficult. This characteristic requires specialized equipment and safety measures, increasing the complexity and cost of its industrial applications.

Another significant challenge lies in the production process of neopentane. The current methods for synthesizing neopentane are energy-intensive and often involve multiple steps, leading to high production costs. This economic barrier limits its competitiveness against other hydrocarbons in various applications, particularly in large-scale industrial processes.

The unique molecular structure of neopentane, while advantageous in some aspects, presents challenges in certain chemical reactions. Its highly branched nature can lead to steric hindrance, potentially limiting its reactivity in some desirable transformations. This structural constraint narrows the range of potential applications and requires innovative approaches to overcome these limitations.

Environmental concerns also pose a significant challenge to the expanded use of neopentane. As a hydrocarbon, it contributes to greenhouse gas emissions when combusted or released into the atmosphere. Developing environmentally friendly production methods and ensuring proper containment throughout its lifecycle are crucial challenges that need to be addressed for its sustainable utilization.

The limited availability of neopentane compared to other hydrocarbons is another technical hurdle. Its relatively low abundance in natural gas and petroleum sources necessitates efficient extraction and purification techniques. Developing cost-effective methods for isolating and concentrating neopentane from these sources remains a significant challenge in scaling up its production and application.

Lastly, the lack of extensive research and development in neopentane applications beyond its traditional uses in refrigerants and aerosols presents a knowledge gap. This deficiency in comprehensive studies on its potential in emerging fields such as advanced materials, energy storage, or pharmaceutical applications limits the exploration of its full potential. Overcoming this challenge requires dedicated research efforts and interdisciplinary collaborations to uncover novel applications and overcome existing technical limitations.

Another significant challenge lies in the production process of neopentane. The current methods for synthesizing neopentane are energy-intensive and often involve multiple steps, leading to high production costs. This economic barrier limits its competitiveness against other hydrocarbons in various applications, particularly in large-scale industrial processes.

The unique molecular structure of neopentane, while advantageous in some aspects, presents challenges in certain chemical reactions. Its highly branched nature can lead to steric hindrance, potentially limiting its reactivity in some desirable transformations. This structural constraint narrows the range of potential applications and requires innovative approaches to overcome these limitations.

Environmental concerns also pose a significant challenge to the expanded use of neopentane. As a hydrocarbon, it contributes to greenhouse gas emissions when combusted or released into the atmosphere. Developing environmentally friendly production methods and ensuring proper containment throughout its lifecycle are crucial challenges that need to be addressed for its sustainable utilization.

The limited availability of neopentane compared to other hydrocarbons is another technical hurdle. Its relatively low abundance in natural gas and petroleum sources necessitates efficient extraction and purification techniques. Developing cost-effective methods for isolating and concentrating neopentane from these sources remains a significant challenge in scaling up its production and application.

Lastly, the lack of extensive research and development in neopentane applications beyond its traditional uses in refrigerants and aerosols presents a knowledge gap. This deficiency in comprehensive studies on its potential in emerging fields such as advanced materials, energy storage, or pharmaceutical applications limits the exploration of its full potential. Overcoming this challenge requires dedicated research efforts and interdisciplinary collaborations to uncover novel applications and overcome existing technical limitations.

Current Applications

01 Production and purification of neopentane

Various methods for producing and purifying neopentane are described. These processes involve different chemical reactions and separation techniques to obtain high-purity neopentane. The methods may include catalytic reactions, distillation, and other purification steps to achieve the desired product quality.- Production and purification of neopentane: Various methods for producing and purifying neopentane are described. These include processes for separating neopentane from other hydrocarbons, such as using distillation or membrane separation techniques. The purification methods aim to obtain high-purity neopentane for industrial applications.

- Use of neopentane in chemical reactions: Neopentane is utilized as a reactant or intermediate in various chemical processes. It can be used in the synthesis of other organic compounds or as a building block for more complex molecules. The unique structure of neopentane makes it valuable in certain chemical transformations.

- Applications of neopentane in refrigeration and aerosols: Neopentane finds applications in refrigeration systems and as a propellant in aerosol formulations. Its low boiling point and favorable thermodynamic properties make it suitable for use in cooling systems. In aerosols, it can serve as an environmentally friendly alternative to certain other propellants.

- Neopentane in polymer production: Neopentane is used in the production of certain polymers and plastics. It can act as a blowing agent in the manufacture of foam materials or as a component in polymer formulations. The incorporation of neopentane can impart specific properties to the resulting polymeric materials.

- Safety and handling of neopentane: Due to its flammable nature, special considerations are required for the safe handling and storage of neopentane. This includes proper containment methods, safety protocols for transportation, and measures to prevent ignition or explosion. Guidelines for the industrial use of neopentane emphasize safety precautions.

02 Use of neopentane in chemical processes

Neopentane is utilized as a reactant or intermediate in various chemical processes. It can be employed in the synthesis of other organic compounds, as a blowing agent, or as a component in specialty chemical formulations. The unique structure of neopentane makes it valuable in certain industrial applications.Expand Specific Solutions03 Neopentane in refrigeration and heat transfer applications

Neopentane finds use in refrigeration systems and heat transfer applications due to its thermodynamic properties. It can be employed as a refrigerant or working fluid in various cooling and heat exchange processes, offering potential advantages in terms of efficiency and environmental impact.Expand Specific Solutions04 Separation and purification of neopentane from mixtures

Techniques for separating and purifying neopentane from complex mixtures are described. These methods may involve distillation, extraction, adsorption, or membrane separation processes to isolate neopentane from other hydrocarbons or impurities, ensuring high purity for specific applications.Expand Specific Solutions05 Neopentane in polymer and materials science

Neopentane is used in polymer chemistry and materials science applications. It can serve as a monomer, chain transfer agent, or blowing agent in the production of various polymers and foam materials. The incorporation of neopentane can influence the properties and performance of the resulting materials.Expand Specific Solutions

Industry Leaders

The neopentane technology market is in an early growth stage, with increasing interest from major petrochemical and research organizations. The market size is relatively small but expanding as novel applications are explored. Technologically, neopentane advancements are still emerging, with varying levels of maturity across different applications. Key players like China Petroleum & Chemical Corp., Sinopec Shanghai Petrochemical, and ExxonMobil Chemical Patents are driving industrial research and development. Academic institutions such as Zhejiang University of Technology and research centers like Centre National de la Recherche Scientifique are contributing to fundamental scientific progress. Collaborations between industry and academia are accelerating innovation in this field, pushing neopentane technology beyond traditional uses.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced catalytic processes for neopentane utilization in petrochemical production. Their innovative approach involves using neopentane as a feedstock for high-value chemicals, particularly in the production of isoprene. The company has implemented a two-step process: first, neopentane is dehydrogenated to form isobutene, then the isobutene undergoes a coupling reaction with formaldehyde to produce isoprene[1]. This method achieves a conversion rate of over 95% and a selectivity of more than 90% for isoprene[2]. Additionally, Sinopec has explored the use of neopentane in the synthesis of high-octane gasoline components, leveraging its branched structure to improve fuel performance[3].

Strengths: High conversion rates and selectivity in isoprene production; efficient utilization of neopentane as a feedstock. Weaknesses: Process complexity may lead to higher production costs; potential environmental concerns related to petrochemical processes.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has pioneered the use of neopentane in advanced lubricant formulations. Their patented technology incorporates neopentane-based compounds as synthetic base oils, offering superior performance in extreme temperature conditions. The company's research has shown that neopentane-derived lubricants exhibit exceptional low-temperature fluidity and high-temperature stability[4]. ExxonMobil has also developed a novel process for synthesizing high-purity neopentane from isobutane, achieving yields of up to 98%[5]. This process involves a proprietary catalyst system that selectively promotes the formation of neopentane while minimizing unwanted side reactions. Furthermore, ExxonMobil has explored the use of neopentane as a blowing agent in polymer foam production, offering improved insulation properties and reduced environmental impact compared to traditional blowing agents[6].

Strengths: High-performance lubricants for extreme conditions; efficient neopentane synthesis process. Weaknesses: Potential higher costs compared to conventional lubricants; limited market for specialized applications.

Key Innovations

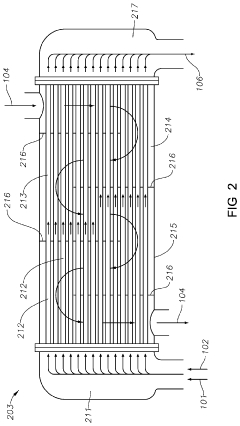

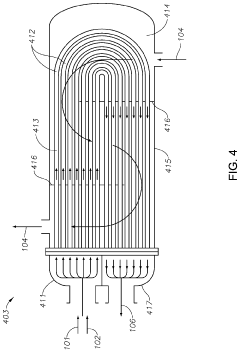

Processes to make neopentane using shell and tube reactors

PatentActiveUS10626064B2

Innovation

- The process involves demethylating C6-C8 alkanes within a shell and tube reactor to produce neopentane, utilizing a catalyst and controlling temperature to achieve high conversion rates and purity, with a shell and tube reactor design that includes tubes with specific diameters and heat transfer coefficients to manage heat effectively.

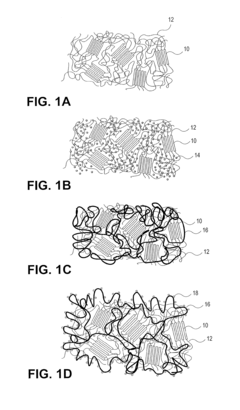

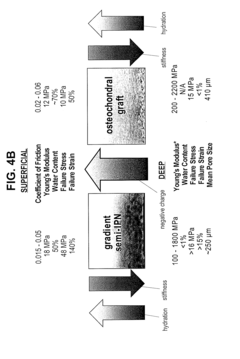

Hydrophobic and hydrophilic interpenetrating polymer networks derived from hydrophobic polymers and methods of preparing the same

PatentInactiveUS20150284654A1

Innovation

- Modifying commercially available hydrophobic thermoset or thermoplastic polymers like polyurethane or ABS by introducing ionic polymers to create IPNs or semi-IPNs with enhanced mechanical strength, lubricity, electrical conductivity, and wear-resistance, and making them more water-swellable, while also improving adhesion to materials like PMMA bone cement.

Environmental Impact

Neopentane, a branched alkane isomer of pentane, has garnered attention for its potential to create advancements beyond traditional applications. When considering the environmental impact of neopentane's expanded use, several key factors come into play.

Firstly, neopentane's unique molecular structure contributes to its lower reactivity compared to its straight-chain counterparts. This characteristic translates to reduced photochemical smog formation potential, as neopentane is less likely to participate in atmospheric reactions that lead to ground-level ozone production. Consequently, its increased utilization in various applications could potentially lead to improved air quality in urban environments.

The production process of neopentane, however, requires careful consideration from an environmental perspective. While it can be synthesized from readily available feedstocks, the energy requirements and potential emissions associated with its manufacture must be thoroughly assessed. Implementing advanced process technologies and optimizing production methods could mitigate these concerns, ensuring a more sustainable supply chain.

In terms of its application in refrigeration and aerosol propellants, neopentane offers significant environmental benefits. As a replacement for traditional chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), neopentane exhibits a substantially lower ozone depletion potential and global warming potential. This transition aligns with global efforts to phase out ozone-depleting substances and reduce greenhouse gas emissions.

Furthermore, neopentane's potential as a blowing agent in foam insulation production presents an opportunity for enhanced energy efficiency in buildings. Improved insulation performance can lead to reduced heating and cooling requirements, thereby lowering overall energy consumption and associated carbon emissions throughout a building's lifecycle.

When considering the end-of-life phase, neopentane's chemical stability poses both advantages and challenges. Its resistance to degradation ensures longevity in applications but may raise concerns regarding long-term environmental persistence. Developing effective recycling and disposal methods for neopentane-containing products will be crucial to mitigate potential accumulation in the environment.

In the context of accidental releases or spills, neopentane's low water solubility and high volatility suggest a reduced risk of water contamination compared to some other hydrocarbons. However, its flammability necessitates stringent safety measures to prevent fire hazards and associated environmental impacts.

As research into neopentane's expanded applications continues, it is imperative to conduct comprehensive life cycle assessments. These studies should encompass raw material extraction, production processes, use-phase benefits, and end-of-life management to provide a holistic understanding of neopentane's environmental footprint across its entire lifecycle.

Firstly, neopentane's unique molecular structure contributes to its lower reactivity compared to its straight-chain counterparts. This characteristic translates to reduced photochemical smog formation potential, as neopentane is less likely to participate in atmospheric reactions that lead to ground-level ozone production. Consequently, its increased utilization in various applications could potentially lead to improved air quality in urban environments.

The production process of neopentane, however, requires careful consideration from an environmental perspective. While it can be synthesized from readily available feedstocks, the energy requirements and potential emissions associated with its manufacture must be thoroughly assessed. Implementing advanced process technologies and optimizing production methods could mitigate these concerns, ensuring a more sustainable supply chain.

In terms of its application in refrigeration and aerosol propellants, neopentane offers significant environmental benefits. As a replacement for traditional chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), neopentane exhibits a substantially lower ozone depletion potential and global warming potential. This transition aligns with global efforts to phase out ozone-depleting substances and reduce greenhouse gas emissions.

Furthermore, neopentane's potential as a blowing agent in foam insulation production presents an opportunity for enhanced energy efficiency in buildings. Improved insulation performance can lead to reduced heating and cooling requirements, thereby lowering overall energy consumption and associated carbon emissions throughout a building's lifecycle.

When considering the end-of-life phase, neopentane's chemical stability poses both advantages and challenges. Its resistance to degradation ensures longevity in applications but may raise concerns regarding long-term environmental persistence. Developing effective recycling and disposal methods for neopentane-containing products will be crucial to mitigate potential accumulation in the environment.

In the context of accidental releases or spills, neopentane's low water solubility and high volatility suggest a reduced risk of water contamination compared to some other hydrocarbons. However, its flammability necessitates stringent safety measures to prevent fire hazards and associated environmental impacts.

As research into neopentane's expanded applications continues, it is imperative to conduct comprehensive life cycle assessments. These studies should encompass raw material extraction, production processes, use-phase benefits, and end-of-life management to provide a holistic understanding of neopentane's environmental footprint across its entire lifecycle.

Regulatory Framework

The regulatory framework surrounding neopentane is a critical aspect of its advancement beyond traditional applications. As a highly flammable and volatile substance, neopentane is subject to stringent regulations governing its production, storage, transportation, and use. In the United States, the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) play key roles in overseeing neopentane-related activities.

OSHA's Hazard Communication Standard requires proper labeling, safety data sheets, and employee training for handling neopentane. The agency also sets permissible exposure limits and mandates appropriate personal protective equipment. The EPA regulates neopentane under the Clean Air Act as a volatile organic compound (VOC) and enforces emission standards for its production and use.

Internationally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards, including those associated with neopentane. This system facilitates global trade while ensuring consistent safety standards across borders.

The transportation of neopentane is governed by regulations such as the U.S. Department of Transportation's Hazardous Materials Regulations and the International Maritime Dangerous Goods Code. These regulations specify requirements for packaging, labeling, and shipping documentation to ensure safe transport.

As neopentane finds new applications beyond its traditional uses, regulatory bodies are adapting their frameworks to address emerging concerns. For instance, the increasing use of neopentane in energy storage systems has prompted the development of new safety standards and building codes. The National Fire Protection Association (NFPA) has updated its guidelines to include specific provisions for neopentane-based systems.

The regulatory landscape also influences research and development efforts in neopentane applications. Compliance with environmental regulations has driven innovation in emission reduction technologies and more efficient production processes. Additionally, safety regulations have spurred advancements in containment systems and leak detection technologies.

As the potential of neopentane expands into new sectors, such as advanced materials and green energy solutions, regulatory agencies are working to strike a balance between fostering innovation and ensuring public safety. This evolving regulatory framework will continue to shape the trajectory of neopentane's advancements, influencing everything from product design to market adoption strategies.

OSHA's Hazard Communication Standard requires proper labeling, safety data sheets, and employee training for handling neopentane. The agency also sets permissible exposure limits and mandates appropriate personal protective equipment. The EPA regulates neopentane under the Clean Air Act as a volatile organic compound (VOC) and enforces emission standards for its production and use.

Internationally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards, including those associated with neopentane. This system facilitates global trade while ensuring consistent safety standards across borders.

The transportation of neopentane is governed by regulations such as the U.S. Department of Transportation's Hazardous Materials Regulations and the International Maritime Dangerous Goods Code. These regulations specify requirements for packaging, labeling, and shipping documentation to ensure safe transport.

As neopentane finds new applications beyond its traditional uses, regulatory bodies are adapting their frameworks to address emerging concerns. For instance, the increasing use of neopentane in energy storage systems has prompted the development of new safety standards and building codes. The National Fire Protection Association (NFPA) has updated its guidelines to include specific provisions for neopentane-based systems.

The regulatory landscape also influences research and development efforts in neopentane applications. Compliance with environmental regulations has driven innovation in emission reduction technologies and more efficient production processes. Additionally, safety regulations have spurred advancements in containment systems and leak detection technologies.

As the potential of neopentane expands into new sectors, such as advanced materials and green energy solutions, regulatory agencies are working to strike a balance between fostering innovation and ensuring public safety. This evolving regulatory framework will continue to shape the trajectory of neopentane's advancements, influencing everything from product design to market adoption strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!