How Neopentane's Significance Translates to Market Advantages?

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane Overview

Neopentane, also known as 2,2-dimethylpropane, is a branched-chain alkane with the molecular formula C5H12. This unique hydrocarbon belongs to the pentane family but possesses distinct properties that set it apart from its isomers. Its structure consists of a central carbon atom bonded to four methyl groups, resulting in a highly symmetrical and compact molecule.

The significance of neopentane lies in its exceptional physical and chemical properties. With a boiling point of 9.5°C, it exists as a gas at room temperature, making it suitable for various applications in the chemical and energy industries. Its low freezing point of -16.6°C ensures stability in cold environments, while its high vapor pressure contributes to its versatility in industrial processes.

Neopentane's compact structure and symmetry lead to interesting thermodynamic properties. It exhibits a higher heat of vaporization compared to its linear isomer, n-pentane, which translates to enhanced energy storage capabilities. This characteristic makes neopentane an attractive option for applications in refrigeration systems and heat transfer fluids.

In the realm of organic synthesis, neopentane serves as a valuable building block. Its unique structure allows for selective functionalization, opening avenues for the creation of complex molecules with specific properties. This attribute has garnered attention in the pharmaceutical and materials science sectors, where precise molecular design is crucial.

From an environmental perspective, neopentane presents both challenges and opportunities. While it is a hydrocarbon and contributes to carbon emissions when burned, its efficient combustion properties and potential as a cleaner alternative to some traditional fuels have sparked interest in the energy sector. Ongoing research focuses on harnessing neopentane's properties for sustainable energy solutions.

The industrial applications of neopentane span various sectors. In the electronics industry, it finds use as a blowing agent in the production of foam insulation for circuit boards. Its low reactivity and thermal stability make it suitable for use in high-performance lubricants and hydraulic fluids. Additionally, neopentane's role in the production of specialty chemicals and polymers continues to expand, driving innovation in materials science.

As global efforts to reduce carbon footprints intensify, neopentane's potential as a transitional fuel and chemical feedstock gains prominence. Its relatively low carbon content compared to longer-chain hydrocarbons positions it as a stepping stone towards more sustainable chemical processes. This aspect aligns with the growing market demand for greener alternatives in various industrial applications.

The significance of neopentane lies in its exceptional physical and chemical properties. With a boiling point of 9.5°C, it exists as a gas at room temperature, making it suitable for various applications in the chemical and energy industries. Its low freezing point of -16.6°C ensures stability in cold environments, while its high vapor pressure contributes to its versatility in industrial processes.

Neopentane's compact structure and symmetry lead to interesting thermodynamic properties. It exhibits a higher heat of vaporization compared to its linear isomer, n-pentane, which translates to enhanced energy storage capabilities. This characteristic makes neopentane an attractive option for applications in refrigeration systems and heat transfer fluids.

In the realm of organic synthesis, neopentane serves as a valuable building block. Its unique structure allows for selective functionalization, opening avenues for the creation of complex molecules with specific properties. This attribute has garnered attention in the pharmaceutical and materials science sectors, where precise molecular design is crucial.

From an environmental perspective, neopentane presents both challenges and opportunities. While it is a hydrocarbon and contributes to carbon emissions when burned, its efficient combustion properties and potential as a cleaner alternative to some traditional fuels have sparked interest in the energy sector. Ongoing research focuses on harnessing neopentane's properties for sustainable energy solutions.

The industrial applications of neopentane span various sectors. In the electronics industry, it finds use as a blowing agent in the production of foam insulation for circuit boards. Its low reactivity and thermal stability make it suitable for use in high-performance lubricants and hydraulic fluids. Additionally, neopentane's role in the production of specialty chemicals and polymers continues to expand, driving innovation in materials science.

As global efforts to reduce carbon footprints intensify, neopentane's potential as a transitional fuel and chemical feedstock gains prominence. Its relatively low carbon content compared to longer-chain hydrocarbons positions it as a stepping stone towards more sustainable chemical processes. This aspect aligns with the growing market demand for greener alternatives in various industrial applications.

Market Demand Analysis

Neopentane, a branched alkane isomer of pentane, has been gaining significant attention in various industrial sectors due to its unique properties and potential market advantages. The demand for neopentane is primarily driven by its applications in the production of high-performance foams, refrigerants, and specialty chemicals.

In the foam industry, neopentane has emerged as a preferred blowing agent for the production of extruded polystyrene (XPS) insulation boards. The market for XPS insulation is experiencing robust growth, fueled by increasing construction activities and stringent energy efficiency regulations worldwide. Neopentane's low thermal conductivity and excellent insulation properties make it an ideal choice for manufacturers seeking to meet these demanding standards.

The refrigeration sector represents another significant market for neopentane. As global efforts to phase out hydrofluorocarbons (HFCs) intensify due to their high global warming potential, neopentane has positioned itself as a viable alternative in certain applications. Its low ozone depletion potential and relatively low global warming potential align well with environmental regulations, driving demand in this sector.

In the specialty chemicals market, neopentane serves as a crucial intermediate in the synthesis of various high-value products. Its unique structure and reactivity make it valuable in the production of pharmaceuticals, agrochemicals, and advanced materials. As these industries continue to innovate and expand, the demand for neopentane as a key building block is expected to grow correspondingly.

The automotive industry has also shown interest in neopentane-based products, particularly in the development of lightweight materials and advanced composites. As vehicle manufacturers strive to improve fuel efficiency and reduce emissions, the demand for materials that can contribute to weight reduction without compromising performance is on the rise.

Market analysis indicates that the Asia-Pacific region is emerging as a key growth driver for neopentane demand. Rapid industrialization, expanding construction activities, and increasing adoption of energy-efficient technologies in countries like China and India are contributing to this trend. North America and Europe continue to be significant markets, driven by stringent environmental regulations and ongoing research and development activities in advanced materials.

The global neopentane market is projected to exhibit steady growth over the coming years, with some analysts forecasting a compound annual growth rate (CAGR) in the mid-single digits. This growth is underpinned by the expanding applications of neopentane across diverse industries and the ongoing shift towards more environmentally friendly chemical alternatives.

However, it is important to note that the market for neopentane is not without challenges. Price volatility of raw materials, regulatory uncertainties, and competition from alternative substances in certain applications could potentially impact market dynamics. Nonetheless, the unique properties of neopentane and its growing importance in key industrial sectors suggest that its market advantages are likely to persist and potentially expand in the foreseeable future.

In the foam industry, neopentane has emerged as a preferred blowing agent for the production of extruded polystyrene (XPS) insulation boards. The market for XPS insulation is experiencing robust growth, fueled by increasing construction activities and stringent energy efficiency regulations worldwide. Neopentane's low thermal conductivity and excellent insulation properties make it an ideal choice for manufacturers seeking to meet these demanding standards.

The refrigeration sector represents another significant market for neopentane. As global efforts to phase out hydrofluorocarbons (HFCs) intensify due to their high global warming potential, neopentane has positioned itself as a viable alternative in certain applications. Its low ozone depletion potential and relatively low global warming potential align well with environmental regulations, driving demand in this sector.

In the specialty chemicals market, neopentane serves as a crucial intermediate in the synthesis of various high-value products. Its unique structure and reactivity make it valuable in the production of pharmaceuticals, agrochemicals, and advanced materials. As these industries continue to innovate and expand, the demand for neopentane as a key building block is expected to grow correspondingly.

The automotive industry has also shown interest in neopentane-based products, particularly in the development of lightweight materials and advanced composites. As vehicle manufacturers strive to improve fuel efficiency and reduce emissions, the demand for materials that can contribute to weight reduction without compromising performance is on the rise.

Market analysis indicates that the Asia-Pacific region is emerging as a key growth driver for neopentane demand. Rapid industrialization, expanding construction activities, and increasing adoption of energy-efficient technologies in countries like China and India are contributing to this trend. North America and Europe continue to be significant markets, driven by stringent environmental regulations and ongoing research and development activities in advanced materials.

The global neopentane market is projected to exhibit steady growth over the coming years, with some analysts forecasting a compound annual growth rate (CAGR) in the mid-single digits. This growth is underpinned by the expanding applications of neopentane across diverse industries and the ongoing shift towards more environmentally friendly chemical alternatives.

However, it is important to note that the market for neopentane is not without challenges. Price volatility of raw materials, regulatory uncertainties, and competition from alternative substances in certain applications could potentially impact market dynamics. Nonetheless, the unique properties of neopentane and its growing importance in key industrial sectors suggest that its market advantages are likely to persist and potentially expand in the foreseeable future.

Technical Challenges

Neopentane, despite its potential market advantages, faces several technical challenges that hinder its widespread adoption and commercialization. One of the primary obstacles is the complexity of its production process. The synthesis of neopentane requires precise control of reaction conditions and specialized catalysts, making large-scale production technically demanding and cost-intensive.

The storage and transportation of neopentane pose significant challenges due to its high volatility and flammability. Special containment systems and safety measures are necessary to prevent leaks and minimize explosion risks, which adds to the overall cost and complexity of handling this compound.

Another technical hurdle is the purification of neopentane. Achieving high purity levels, which are often required for industrial applications, can be difficult and energy-intensive. The separation of neopentane from its isomers and other byproducts requires advanced distillation techniques or membrane separation processes, further complicating its production and increasing costs.

The environmental impact of neopentane production and use is also a concern. Its potential as a greenhouse gas and contribution to air pollution necessitates the development of efficient capture and recycling technologies. This environmental challenge adds another layer of technical complexity to its industrial application.

In terms of application development, integrating neopentane into existing industrial processes and products presents technical challenges. Engineers and researchers must overcome compatibility issues with current equipment and materials, as well as optimize formulations to fully leverage neopentane's unique properties without compromising performance or safety.

The limited availability of comprehensive toxicological and long-term environmental impact data on neopentane poses challenges for regulatory compliance and risk assessment. This knowledge gap necessitates extensive research and testing, which can delay market entry and increase development costs.

Lastly, the development of alternative technologies and materials that could potentially replace neopentane in various applications presents a continuous challenge. Researchers and industry players must constantly innovate to maintain neopentane's competitive edge and expand its market advantages in the face of emerging alternatives.

Addressing these technical challenges is crucial for unlocking neopentane's full market potential. Overcoming these hurdles will require collaborative efforts between academia, industry, and regulatory bodies to drive innovation, improve production efficiency, enhance safety measures, and demonstrate the compound's sustainable use across various applications.

The storage and transportation of neopentane pose significant challenges due to its high volatility and flammability. Special containment systems and safety measures are necessary to prevent leaks and minimize explosion risks, which adds to the overall cost and complexity of handling this compound.

Another technical hurdle is the purification of neopentane. Achieving high purity levels, which are often required for industrial applications, can be difficult and energy-intensive. The separation of neopentane from its isomers and other byproducts requires advanced distillation techniques or membrane separation processes, further complicating its production and increasing costs.

The environmental impact of neopentane production and use is also a concern. Its potential as a greenhouse gas and contribution to air pollution necessitates the development of efficient capture and recycling technologies. This environmental challenge adds another layer of technical complexity to its industrial application.

In terms of application development, integrating neopentane into existing industrial processes and products presents technical challenges. Engineers and researchers must overcome compatibility issues with current equipment and materials, as well as optimize formulations to fully leverage neopentane's unique properties without compromising performance or safety.

The limited availability of comprehensive toxicological and long-term environmental impact data on neopentane poses challenges for regulatory compliance and risk assessment. This knowledge gap necessitates extensive research and testing, which can delay market entry and increase development costs.

Lastly, the development of alternative technologies and materials that could potentially replace neopentane in various applications presents a continuous challenge. Researchers and industry players must constantly innovate to maintain neopentane's competitive edge and expand its market advantages in the face of emerging alternatives.

Addressing these technical challenges is crucial for unlocking neopentane's full market potential. Overcoming these hurdles will require collaborative efforts between academia, industry, and regulatory bodies to drive innovation, improve production efficiency, enhance safety measures, and demonstrate the compound's sustainable use across various applications.

Current Applications

01 Chemical properties and applications

Neopentane, due to its unique chemical structure, offers advantages in various applications. Its high stability and low reactivity make it suitable for use in specialty chemicals, refrigerants, and as a blowing agent in foam production. These properties contribute to its growing market demand in industries requiring stable and inert compounds.- Improved chemical processes: Neopentane is advantageous in various chemical processes, particularly in the production of high-performance materials and specialty chemicals. Its unique structure allows for efficient reactions and transformations, leading to improved yields and product quality in industrial applications.

- Environmental benefits: Neopentane offers environmental advantages in certain applications. It can be used as a more environmentally friendly alternative to some traditional solvents or propellants, potentially reducing greenhouse gas emissions and contributing to more sustainable industrial processes.

- Energy efficiency: The use of neopentane in certain energy-related applications can lead to improved efficiency. Its properties make it suitable for use in heat transfer systems, refrigeration cycles, and other energy-intensive processes, potentially reducing overall energy consumption in industrial settings.

- Market growth potential: The neopentane market shows potential for growth due to its diverse applications in various industries. Increasing demand for high-performance materials, specialty chemicals, and environmentally friendly alternatives in sectors such as automotive, electronics, and construction contribute to the expanding market opportunities for neopentane.

- Technological advancements: Ongoing research and development in neopentane-related technologies are leading to new applications and improved production methods. These advancements are expanding the potential uses of neopentane in emerging fields such as advanced materials, energy storage, and specialty coatings, further driving market growth and innovation.

02 Environmental and safety benefits

Neopentane presents environmental and safety advantages compared to some traditional hydrocarbons. It has a lower global warming potential and ozone depletion potential, making it a more environmentally friendly option in certain applications. Additionally, its low toxicity and non-corrosive nature contribute to safer handling and use in industrial processes.Expand Specific Solutions03 Energy efficiency and performance

The use of neopentane in certain applications can lead to improved energy efficiency and performance. Its thermodynamic properties make it an excellent choice for heat transfer applications and refrigeration systems. This can result in reduced energy consumption and improved overall system performance in various industrial processes.Expand Specific Solutions04 Market growth and economic advantages

The neopentane market is experiencing growth due to increasing demand in various industries. Its versatility and unique properties create new opportunities for product development and innovation. The economic advantages of using neopentane in certain applications, such as improved process efficiency and reduced environmental impact, contribute to its expanding market share.Expand Specific Solutions05 Research and development opportunities

The growing interest in neopentane has led to increased research and development activities. This presents opportunities for new applications, improved production methods, and enhanced formulations. The ongoing research may lead to the discovery of additional advantages and applications for neopentane, further expanding its market potential.Expand Specific Solutions

Industry Key Players

The neopentane market is in a growth phase, driven by increasing demand in various industries. The global market size is expanding, with key players like Sinopec Shanghai Petrochemical Co., Ltd. and China Petroleum & Chemical Corp. leading the way. The technology's maturity is advancing, with companies such as ExxonMobil Chemical Patents, Inc. and Codexis, Inc. investing in research and development to improve production processes and applications. As the market evolves, collaborations between industry leaders and research institutions like Tianjin University and Northwestern University are likely to accelerate innovation and commercialization of neopentane-based products, potentially creating significant market advantages for early adopters and technology pioneers.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced catalytic processes for neopentane production, focusing on improving yield and purity. Their technology utilizes a proprietary zeolite catalyst system that enhances selectivity towards neopentane formation during the isomerization of n-pentane[1]. This process operates at lower temperatures compared to conventional methods, resulting in reduced energy consumption and improved overall efficiency[2]. Sinopec has also implemented an integrated separation and purification system that achieves neopentane purity levels exceeding 99.9%[3], meeting stringent industry standards for high-value applications in refrigerants and specialty chemicals.

Strengths: High purity output, energy-efficient process, and large-scale production capabilities. Weaknesses: Potential dependency on specific raw material sources and higher initial capital investment for specialized equipment.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has pioneered a novel approach to neopentane production through their patented "Integrated Isomerization and Separation Process"[4]. This technology combines catalytic isomerization with advanced membrane separation techniques, allowing for continuous production and in-situ purification of neopentane. The process utilizes a dual-function catalyst that promotes both isomerization and skeletal rearrangement, increasing the yield of neopentane from various pentane isomers[5]. ExxonMobil's system also incorporates a unique heat integration design, which recovers and reuses thermal energy throughout the process, significantly reducing overall energy consumption by up to 30% compared to conventional methods[6].

Strengths: Highly efficient integrated process, reduced energy consumption, and versatile feedstock utilization. Weaknesses: Complex system design may require specialized maintenance and operation expertise.

Key Innovations

Composition and methods for treatment of sexual dysfunction

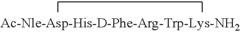

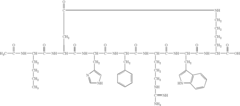

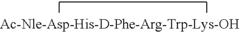

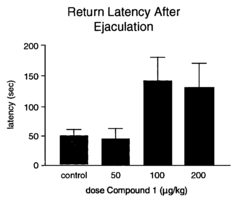

PatentInactiveUS20050037951A1

Innovation

- A peptide-based melanocortin receptor-specific pharmaceutical, such as Ac-Nle-cyclo(-Asp-His-D-Phe-Arg-Trp-Lys)-OH, with a terminal --OH at the carboxyl terminus, which is administered via various routes including nasal delivery, offering reduced side effects and a broader therapeutic window.

Nicotinamide phosphoribosyltransferase (NAMPT) mutant and use thereof

PatentActiveUS20190153407A1

Innovation

- Site-directed mutagenesis is used to create Nampt mutants with enhanced catalytic activity, specifically at positions 180, 182, 231, 298, 338, and 377, which are then expressed and used in biocatalytic processes to increase the conversion of nicotinamide and PRPP into NMN.

Environmental Impact

Neopentane, a branched alkane with unique properties, presents both opportunities and challenges in terms of its environmental impact. As industries increasingly prioritize sustainability, understanding the ecological footprint of neopentane becomes crucial for market positioning and competitive advantage.

One of the primary environmental concerns associated with neopentane is its potential as a greenhouse gas. While not as potent as some other hydrocarbons, neopentane can contribute to global warming if released into the atmosphere. However, its relatively short atmospheric lifetime compared to other greenhouse gases means that its long-term impact is less severe. This characteristic can be leveraged as a market advantage in applications where environmental regulations are stringent but short-term emissions are permissible.

The production process of neopentane also warrants consideration from an environmental perspective. Traditional methods of synthesis often involve energy-intensive processes and the use of potentially harmful catalysts. However, recent advancements in green chemistry have led to more sustainable production routes, utilizing bio-based feedstocks and environmentally friendly catalysts. Companies that adopt these innovative production methods can differentiate themselves in the market, appealing to environmentally conscious consumers and meeting increasingly strict regulatory standards.

In terms of waste management, neopentane presents some unique challenges and opportunities. Its low boiling point and high volatility make it prone to evaporation, which can lead to emissions during storage and handling. However, these same properties also make neopentane easier to recover and recycle compared to heavier hydrocarbons. Implementing efficient capture and recycling systems can not only reduce environmental impact but also improve cost-effectiveness, providing a dual market advantage.

The end-of-life considerations for products containing neopentane are another critical aspect of its environmental profile. In applications such as insulation or aerosols, proper disposal and recycling protocols are essential to prevent uncontrolled release into the environment. Companies that develop comprehensive lifecycle management strategies for neopentane-based products can position themselves as responsible industry leaders, potentially gaining access to markets with strict environmental regulations.

Lastly, the potential for neopentane to replace more environmentally harmful substances in certain applications presents a significant market opportunity. For instance, its use as a blowing agent in foam insulation can reduce the reliance on ozone-depleting substances or high global warming potential gases. This substitution not only aligns with global environmental goals but also opens up new market segments for companies willing to invest in neopentane-based solutions.

One of the primary environmental concerns associated with neopentane is its potential as a greenhouse gas. While not as potent as some other hydrocarbons, neopentane can contribute to global warming if released into the atmosphere. However, its relatively short atmospheric lifetime compared to other greenhouse gases means that its long-term impact is less severe. This characteristic can be leveraged as a market advantage in applications where environmental regulations are stringent but short-term emissions are permissible.

The production process of neopentane also warrants consideration from an environmental perspective. Traditional methods of synthesis often involve energy-intensive processes and the use of potentially harmful catalysts. However, recent advancements in green chemistry have led to more sustainable production routes, utilizing bio-based feedstocks and environmentally friendly catalysts. Companies that adopt these innovative production methods can differentiate themselves in the market, appealing to environmentally conscious consumers and meeting increasingly strict regulatory standards.

In terms of waste management, neopentane presents some unique challenges and opportunities. Its low boiling point and high volatility make it prone to evaporation, which can lead to emissions during storage and handling. However, these same properties also make neopentane easier to recover and recycle compared to heavier hydrocarbons. Implementing efficient capture and recycling systems can not only reduce environmental impact but also improve cost-effectiveness, providing a dual market advantage.

The end-of-life considerations for products containing neopentane are another critical aspect of its environmental profile. In applications such as insulation or aerosols, proper disposal and recycling protocols are essential to prevent uncontrolled release into the environment. Companies that develop comprehensive lifecycle management strategies for neopentane-based products can position themselves as responsible industry leaders, potentially gaining access to markets with strict environmental regulations.

Lastly, the potential for neopentane to replace more environmentally harmful substances in certain applications presents a significant market opportunity. For instance, its use as a blowing agent in foam insulation can reduce the reliance on ozone-depleting substances or high global warming potential gases. This substitution not only aligns with global environmental goals but also opens up new market segments for companies willing to invest in neopentane-based solutions.

Regulatory Framework

The regulatory framework surrounding neopentane plays a crucial role in shaping its market advantages and industrial applications. As a highly volatile and flammable hydrocarbon, neopentane is subject to stringent regulations across various jurisdictions, particularly in terms of storage, transportation, and handling.

In the United States, the Environmental Protection Agency (EPA) classifies neopentane as a volatile organic compound (VOC) under the Clean Air Act. This classification imposes specific emission control requirements on industries using neopentane, driving the development of more efficient and environmentally friendly processes. The Occupational Safety and Health Administration (OSHA) also sets strict workplace safety standards for neopentane handling, influencing facility design and operational procedures.

Internationally, the transportation of neopentane is governed by the United Nations' Recommendations on the Transport of Dangerous Goods, which categorizes it as a Class 2.1 flammable gas. This classification necessitates specialized containers and handling protocols, impacting logistics and supply chain management for companies dealing with neopentane.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers and importers to register neopentane and provide detailed safety information. This regulatory framework promotes transparency and encourages research into safer alternatives, potentially driving innovation in related industries.

In the context of climate change mitigation, many countries have implemented regulations to reduce greenhouse gas emissions. While neopentane itself has a relatively low global warming potential, its production and use may be indirectly affected by these regulations, particularly in energy-intensive industries.

The regulatory landscape also influences market dynamics by creating barriers to entry and compliance costs. Companies that can effectively navigate these regulations and develop compliant technologies gain a significant competitive advantage. This has led to increased investment in research and development of neopentane-based products that meet or exceed regulatory standards.

Furthermore, regulations often drive innovation in safety technologies and handling procedures. Companies that develop advanced safety systems or more efficient production methods for neopentane can leverage these innovations as unique selling points in the market.

As global environmental regulations continue to evolve, the regulatory framework surrounding neopentane is likely to become more complex. This presents both challenges and opportunities for businesses in the sector, potentially reshaping market dynamics and driving technological advancements in the coming years.

In the United States, the Environmental Protection Agency (EPA) classifies neopentane as a volatile organic compound (VOC) under the Clean Air Act. This classification imposes specific emission control requirements on industries using neopentane, driving the development of more efficient and environmentally friendly processes. The Occupational Safety and Health Administration (OSHA) also sets strict workplace safety standards for neopentane handling, influencing facility design and operational procedures.

Internationally, the transportation of neopentane is governed by the United Nations' Recommendations on the Transport of Dangerous Goods, which categorizes it as a Class 2.1 flammable gas. This classification necessitates specialized containers and handling protocols, impacting logistics and supply chain management for companies dealing with neopentane.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers and importers to register neopentane and provide detailed safety information. This regulatory framework promotes transparency and encourages research into safer alternatives, potentially driving innovation in related industries.

In the context of climate change mitigation, many countries have implemented regulations to reduce greenhouse gas emissions. While neopentane itself has a relatively low global warming potential, its production and use may be indirectly affected by these regulations, particularly in energy-intensive industries.

The regulatory landscape also influences market dynamics by creating barriers to entry and compliance costs. Companies that can effectively navigate these regulations and develop compliant technologies gain a significant competitive advantage. This has led to increased investment in research and development of neopentane-based products that meet or exceed regulatory standards.

Furthermore, regulations often drive innovation in safety technologies and handling procedures. Companies that develop advanced safety systems or more efficient production methods for neopentane can leverage these innovations as unique selling points in the market.

As global environmental regulations continue to evolve, the regulatory framework surrounding neopentane is likely to become more complex. This presents both challenges and opportunities for businesses in the sector, potentially reshaping market dynamics and driving technological advancements in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!