How PETG Assists in Autonomous Systems Development

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG in Autonomous Systems: Background and Objectives

Polyethylene terephthalate glycol (PETG) has emerged as a crucial material in the development of autonomous systems, revolutionizing various aspects of this rapidly evolving field. The journey of PETG in autonomous systems began with its unique properties that make it an ideal candidate for numerous applications. This thermoplastic polymer, known for its durability, flexibility, and chemical resistance, has found its way into the heart of autonomous technology development.

The evolution of PETG in autonomous systems can be traced back to the early 2000s when researchers and engineers started exploring alternative materials for sensor housings and protective casings. As autonomous systems became more sophisticated, the demand for materials that could withstand harsh environments while maintaining optical clarity and structural integrity increased. PETG's ability to meet these requirements positioned it as a frontrunner in the field.

The primary objective of incorporating PETG into autonomous systems is to enhance their overall performance, reliability, and safety. By leveraging PETG's unique characteristics, developers aim to create more robust and efficient autonomous platforms capable of operating in diverse environments. This material plays a crucial role in protecting sensitive components, improving sensor accuracy, and ensuring the longevity of autonomous systems.

One of the key areas where PETG has made significant contributions is in the development of LiDAR (Light Detection and Ranging) systems. These sensors are fundamental to autonomous vehicles and robots, providing crucial 3D mapping and obstacle detection capabilities. PETG's optical clarity and impact resistance make it an ideal material for LiDAR housings, allowing for accurate data collection while protecting the delicate internal components from environmental factors.

Furthermore, PETG has found applications in the construction of autonomous drones and unmanned aerial vehicles (UAVs). Its lightweight nature and high strength-to-weight ratio enable the creation of durable yet efficient drone bodies and propeller guards. This has led to increased flight times, improved maneuverability, and enhanced safety features in autonomous aerial systems.

The integration of PETG in autonomous systems extends beyond vehicular applications. In industrial automation, PETG is utilized in the fabrication of robotic arm components, conveyor systems, and protective enclosures for autonomous machinery. Its chemical resistance and ease of sterilization make it particularly valuable in autonomous systems deployed in healthcare and pharmaceutical settings.

As the field of autonomous systems continues to advance, the role of PETG is expected to expand further. Researchers are exploring new ways to leverage this versatile material, including the development of smart PETG composites that can adapt to changing environmental conditions. The ongoing research aims to push the boundaries of what is possible in autonomous system design, with PETG playing a pivotal role in shaping the future of this technology.

The evolution of PETG in autonomous systems can be traced back to the early 2000s when researchers and engineers started exploring alternative materials for sensor housings and protective casings. As autonomous systems became more sophisticated, the demand for materials that could withstand harsh environments while maintaining optical clarity and structural integrity increased. PETG's ability to meet these requirements positioned it as a frontrunner in the field.

The primary objective of incorporating PETG into autonomous systems is to enhance their overall performance, reliability, and safety. By leveraging PETG's unique characteristics, developers aim to create more robust and efficient autonomous platforms capable of operating in diverse environments. This material plays a crucial role in protecting sensitive components, improving sensor accuracy, and ensuring the longevity of autonomous systems.

One of the key areas where PETG has made significant contributions is in the development of LiDAR (Light Detection and Ranging) systems. These sensors are fundamental to autonomous vehicles and robots, providing crucial 3D mapping and obstacle detection capabilities. PETG's optical clarity and impact resistance make it an ideal material for LiDAR housings, allowing for accurate data collection while protecting the delicate internal components from environmental factors.

Furthermore, PETG has found applications in the construction of autonomous drones and unmanned aerial vehicles (UAVs). Its lightweight nature and high strength-to-weight ratio enable the creation of durable yet efficient drone bodies and propeller guards. This has led to increased flight times, improved maneuverability, and enhanced safety features in autonomous aerial systems.

The integration of PETG in autonomous systems extends beyond vehicular applications. In industrial automation, PETG is utilized in the fabrication of robotic arm components, conveyor systems, and protective enclosures for autonomous machinery. Its chemical resistance and ease of sterilization make it particularly valuable in autonomous systems deployed in healthcare and pharmaceutical settings.

As the field of autonomous systems continues to advance, the role of PETG is expected to expand further. Researchers are exploring new ways to leverage this versatile material, including the development of smart PETG composites that can adapt to changing environmental conditions. The ongoing research aims to push the boundaries of what is possible in autonomous system design, with PETG playing a pivotal role in shaping the future of this technology.

Market Demand Analysis for PETG in Autonomous Systems

The market demand for PETG (Polyethylene Terephthalate Glycol) in autonomous systems development is experiencing significant growth, driven by the rapid expansion of the autonomous technology sector. As autonomous vehicles, drones, and robotics continue to advance, the need for high-performance materials like PETG has become increasingly apparent.

PETG's unique properties make it particularly suitable for various applications in autonomous systems. Its excellent impact resistance, clarity, and ease of fabrication have positioned it as a preferred material for sensor housings, protective covers, and structural components in autonomous vehicles and robots. The material's ability to withstand harsh environmental conditions while maintaining optical clarity is crucial for the reliable operation of sensors and cameras, which are essential in autonomous navigation and object detection.

The automotive industry, a major driver of autonomous technology, has shown a growing interest in PETG for use in both interior and exterior components of self-driving vehicles. Market analysts project that the global autonomous vehicle market will reach substantial valuations in the coming years, indirectly boosting the demand for PETG in this sector.

In the drone industry, another rapidly growing segment of autonomous systems, PETG is being increasingly utilized for lightweight yet durable body parts and protective casings. The material's resistance to UV radiation and chemicals makes it ideal for outdoor applications, where drones are frequently deployed.

The robotics sector, encompassing industrial, service, and collaborative robots, is also contributing to the rising demand for PETG. As robots become more sophisticated and are deployed in diverse environments, the need for materials that can ensure both functionality and safety has grown. PETG's properties align well with these requirements, particularly in applications where transparency and impact resistance are critical.

Furthermore, the medical and healthcare industries are exploring autonomous systems for various applications, from surgical robots to autonomous delivery systems within hospitals. PETG's biocompatibility and sterilization capabilities make it an attractive option for these sensitive environments, potentially opening up new market opportunities.

As the autonomous systems market continues to evolve, the demand for PETG is expected to grow in parallel. Manufacturers and material suppliers are likely to invest in research and development to further enhance PETG's properties and tailor them specifically for autonomous system applications. This trend is expected to drive innovation in material science and potentially lead to the development of specialized PETG formulations optimized for specific autonomous technology requirements.

PETG's unique properties make it particularly suitable for various applications in autonomous systems. Its excellent impact resistance, clarity, and ease of fabrication have positioned it as a preferred material for sensor housings, protective covers, and structural components in autonomous vehicles and robots. The material's ability to withstand harsh environmental conditions while maintaining optical clarity is crucial for the reliable operation of sensors and cameras, which are essential in autonomous navigation and object detection.

The automotive industry, a major driver of autonomous technology, has shown a growing interest in PETG for use in both interior and exterior components of self-driving vehicles. Market analysts project that the global autonomous vehicle market will reach substantial valuations in the coming years, indirectly boosting the demand for PETG in this sector.

In the drone industry, another rapidly growing segment of autonomous systems, PETG is being increasingly utilized for lightweight yet durable body parts and protective casings. The material's resistance to UV radiation and chemicals makes it ideal for outdoor applications, where drones are frequently deployed.

The robotics sector, encompassing industrial, service, and collaborative robots, is also contributing to the rising demand for PETG. As robots become more sophisticated and are deployed in diverse environments, the need for materials that can ensure both functionality and safety has grown. PETG's properties align well with these requirements, particularly in applications where transparency and impact resistance are critical.

Furthermore, the medical and healthcare industries are exploring autonomous systems for various applications, from surgical robots to autonomous delivery systems within hospitals. PETG's biocompatibility and sterilization capabilities make it an attractive option for these sensitive environments, potentially opening up new market opportunities.

As the autonomous systems market continues to evolve, the demand for PETG is expected to grow in parallel. Manufacturers and material suppliers are likely to invest in research and development to further enhance PETG's properties and tailor them specifically for autonomous system applications. This trend is expected to drive innovation in material science and potentially lead to the development of specialized PETG formulations optimized for specific autonomous technology requirements.

Current State and Challenges of PETG in Autonomous Development

The current state of PETG (Polyethylene Terephthalate Glycol) in autonomous systems development is characterized by both significant advancements and notable challenges. PETG has emerged as a promising material in this field due to its unique properties, including high impact resistance, clarity, and ease of fabrication.

In terms of advancements, PETG has found applications in various components of autonomous systems. It is increasingly used in the production of sensor housings, protective covers for cameras and LiDAR systems, and structural elements of autonomous vehicles. The material's durability and weather resistance make it particularly suitable for outdoor applications, where autonomous systems often operate.

One of the key areas where PETG has shown promise is in the development of lightweight, yet robust, enclosures for electronic components in autonomous systems. This application helps in reducing the overall weight of the system while maintaining necessary protection against environmental factors.

However, the integration of PETG in autonomous systems development faces several challenges. One primary concern is the material's limited heat resistance compared to some other engineering plastics. This can be problematic in scenarios where autonomous systems generate significant heat during operation, potentially leading to deformation or degradation of PETG components.

Another challenge lies in the recyclability of PETG when used in complex autonomous system assemblies. While PETG is recyclable, the presence of other materials and electronic components in these systems can complicate the recycling process, raising environmental concerns.

The manufacturing processes for PETG components in autonomous systems also present challenges. Achieving the precise tolerances required for certain autonomous system components can be difficult with PETG, particularly in large-scale production scenarios.

Furthermore, the long-term durability of PETG in autonomous systems exposed to harsh environmental conditions, such as extreme temperatures or chemical exposure, is still under investigation. This uncertainty poses challenges for developers aiming to ensure the longevity and reliability of their autonomous systems.

Despite these challenges, ongoing research and development efforts are focused on enhancing PETG's properties and manufacturing techniques to better suit the demands of autonomous systems. Innovations in material science are exploring ways to improve PETG's heat resistance and durability without compromising its beneficial properties.

In conclusion, while PETG has made significant inroads in autonomous systems development, offering valuable properties for certain applications, it also faces notable challenges that need to be addressed for its wider adoption and more effective utilization in this rapidly evolving field.

In terms of advancements, PETG has found applications in various components of autonomous systems. It is increasingly used in the production of sensor housings, protective covers for cameras and LiDAR systems, and structural elements of autonomous vehicles. The material's durability and weather resistance make it particularly suitable for outdoor applications, where autonomous systems often operate.

One of the key areas where PETG has shown promise is in the development of lightweight, yet robust, enclosures for electronic components in autonomous systems. This application helps in reducing the overall weight of the system while maintaining necessary protection against environmental factors.

However, the integration of PETG in autonomous systems development faces several challenges. One primary concern is the material's limited heat resistance compared to some other engineering plastics. This can be problematic in scenarios where autonomous systems generate significant heat during operation, potentially leading to deformation or degradation of PETG components.

Another challenge lies in the recyclability of PETG when used in complex autonomous system assemblies. While PETG is recyclable, the presence of other materials and electronic components in these systems can complicate the recycling process, raising environmental concerns.

The manufacturing processes for PETG components in autonomous systems also present challenges. Achieving the precise tolerances required for certain autonomous system components can be difficult with PETG, particularly in large-scale production scenarios.

Furthermore, the long-term durability of PETG in autonomous systems exposed to harsh environmental conditions, such as extreme temperatures or chemical exposure, is still under investigation. This uncertainty poses challenges for developers aiming to ensure the longevity and reliability of their autonomous systems.

Despite these challenges, ongoing research and development efforts are focused on enhancing PETG's properties and manufacturing techniques to better suit the demands of autonomous systems. Innovations in material science are exploring ways to improve PETG's heat resistance and durability without compromising its beneficial properties.

In conclusion, while PETG has made significant inroads in autonomous systems development, offering valuable properties for certain applications, it also faces notable challenges that need to be addressed for its wider adoption and more effective utilization in this rapidly evolving field.

Existing PETG Solutions for Autonomous Systems

01 Composition and properties of PETG

PETG is a copolyester derived from polyethylene terephthalate (PET) with added glycol. It offers improved clarity, toughness, and chemical resistance compared to standard PET. PETG is known for its ease of processing, good impact strength, and ability to be thermoformed.- Composition and properties of PETG: PETG is a copolyester derived from polyethylene terephthalate (PET) with added glycol. It offers improved clarity, toughness, and chemical resistance compared to standard PET. PETG is known for its ease of processing, good impact strength, and ability to be thermoformed.

- Applications of PETG in packaging: PETG is widely used in packaging applications due to its excellent transparency, durability, and food-safe properties. It is commonly used for bottles, containers, and trays in food, beverage, and pharmaceutical industries. PETG packaging offers good barrier properties and can be easily molded into various shapes.

- PETG in 3D printing and additive manufacturing: PETG has gained popularity as a filament material for 3D printing due to its ease of use, good layer adhesion, and minimal warping. It offers a balance between strength and flexibility, making it suitable for various 3D printing applications, including prototypes, functional parts, and decorative items.

- PETG blends and composites: Researchers have explored blending PETG with other materials or incorporating additives to enhance its properties. These blends and composites can improve characteristics such as heat resistance, mechanical strength, or specific functionalities, expanding the range of applications for PETG-based materials.

- Recycling and sustainability of PETG: As environmental concerns grow, efforts have been made to improve the recyclability and sustainability of PETG. This includes developing methods for efficient recycling of PETG products, exploring bio-based alternatives, and creating PETG formulations with enhanced biodegradability or reduced environmental impact.

02 Applications of PETG in packaging

PETG is widely used in packaging applications due to its excellent transparency, barrier properties, and formability. It is commonly used for food containers, beverage bottles, cosmetic packaging, and pharmaceutical blister packs. PETG's ability to maintain clarity and toughness makes it suitable for various packaging designs.Expand Specific Solutions03 PETG in 3D printing and additive manufacturing

PETG has gained popularity in 3D printing due to its ease of use, good layer adhesion, and minimal warping. It offers a balance between the ease of printing found in PLA and the strength and durability of ABS. PETG filaments are used in various 3D printing applications, including prototyping and functional parts.Expand Specific Solutions04 PETG blends and composites

PETG can be blended with other polymers or reinforced with additives to enhance its properties. These blends and composites can improve characteristics such as heat resistance, mechanical strength, or specific functionalities. Research in this area focuses on developing new materials with tailored properties for various applications.Expand Specific Solutions05 Processing and manufacturing of PETG products

PETG can be processed using various manufacturing techniques, including injection molding, extrusion, and thermoforming. Its low processing temperature and good melt stability make it suitable for a wide range of production methods. Innovations in processing techniques aim to improve efficiency, reduce cycle times, and enhance product quality.Expand Specific Solutions

Key Players in PETG and Autonomous Systems Industries

The development of autonomous systems using PETG is in its early stages, with the market showing significant growth potential. The technology's maturity varies across different applications, with companies like Siemens Medical Solutions USA and Intel Corp. leading in medical and computing sectors respectively. Texas Instruments and NXP Semiconductors are advancing PETG applications in embedded systems, while automotive giants like GM Global Technology Operations are exploring its use in autonomous vehicles. The market is characterized by a mix of established tech firms and specialized startups, indicating a competitive landscape with diverse innovation sources. As the technology evolves, collaborations between industry leaders and research institutions like The Hong Kong University of Science & Technology are likely to accelerate progress and market expansion.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has integrated PETG into their autonomous systems development, focusing on its application in high-performance, miniaturized sensor modules. Their approach leverages PETG's excellent dielectric properties and low moisture absorption to create highly reliable, compact housings for their advanced mmWave radar sensors used in autonomous vehicles[8]. TI has also developed a proprietary PETG-based thermal management solution for their AI processors, utilizing the material's thermal conductivity to efficiently dissipate heat in confined spaces[10]. Additionally, the company has implemented PETG in their sensor fusion units, taking advantage of its electromagnetic shielding properties to minimize interference between different sensor types[12].

Strengths: Excellent dielectric properties, efficient thermal management in compact designs, and effective electromagnetic shielding. Weaknesses: Higher material costs and potential limitations in high-temperature automotive environments.

Intel Corp.

Technical Solution: Intel has incorporated PETG into their autonomous systems development, focusing on its application in flexible printed circuit boards (FPCBs) for sensor arrays. Their approach utilizes PETG's thermal stability and dimensional accuracy to create highly reliable, thin-film substrates for advanced sensor integration[2]. Intel's proprietary PETG-based FPCBs offer improved signal integrity and reduced electromagnetic interference, crucial for the complex sensor networks in autonomous systems[4]. Additionally, Intel has developed a novel PETG-based encapsulation technique for their neuromorphic computing chips used in autonomous decision-making processes, enhancing their durability and thermal efficiency[6].

Strengths: Improved signal integrity, reduced electromagnetic interference, and enhanced durability for neuromorphic chips. Weaknesses: Higher production costs and potential limitations in extreme temperature environments.

Core Innovations in PETG for Autonomous Applications

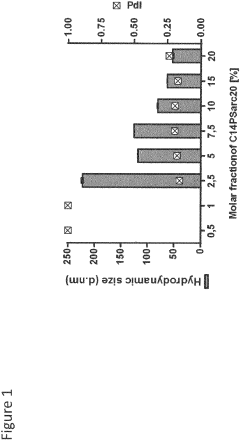

RNA particles comprising polysarcosine

PatentPendingUS20230241223A1

Innovation

- The development of RNA particles using polysarcosine-lipid conjugates, which are biodegradable and allow for controlled size and surface property modulation, avoiding the use of PEGylation to enhance delivery efficiency while minimizing immune responses.

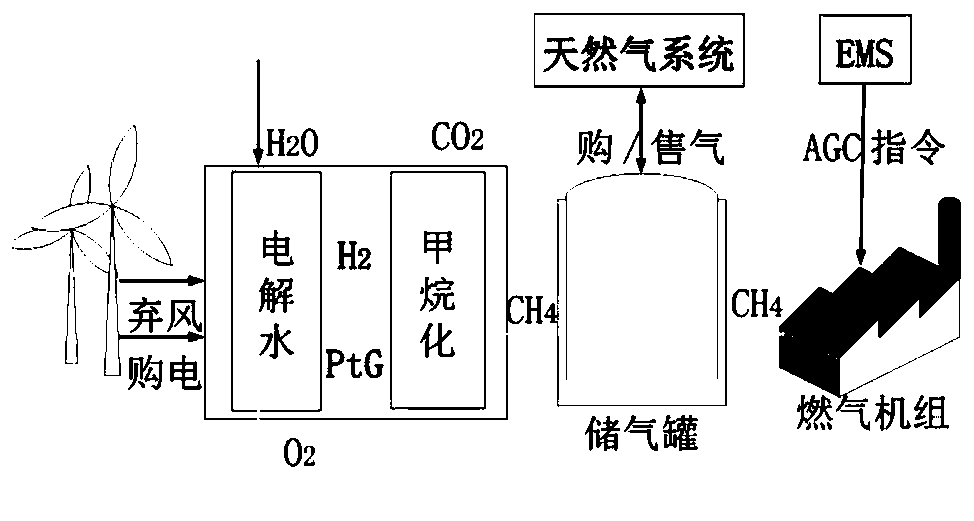

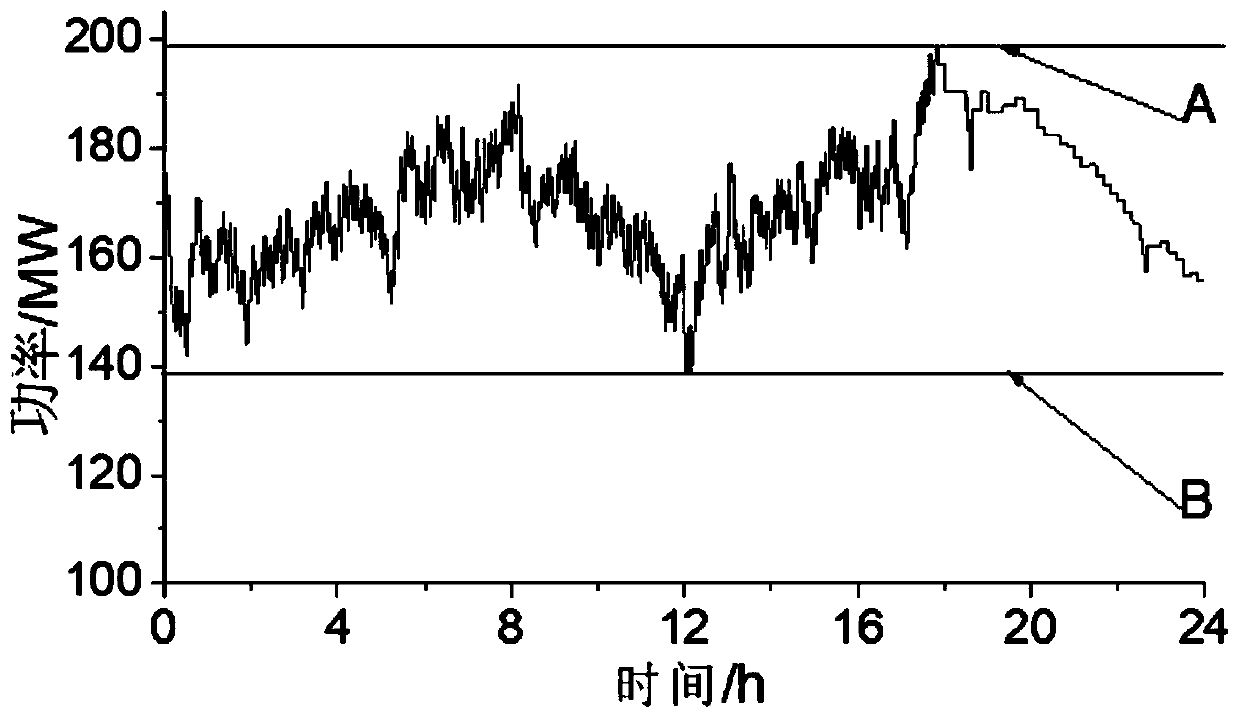

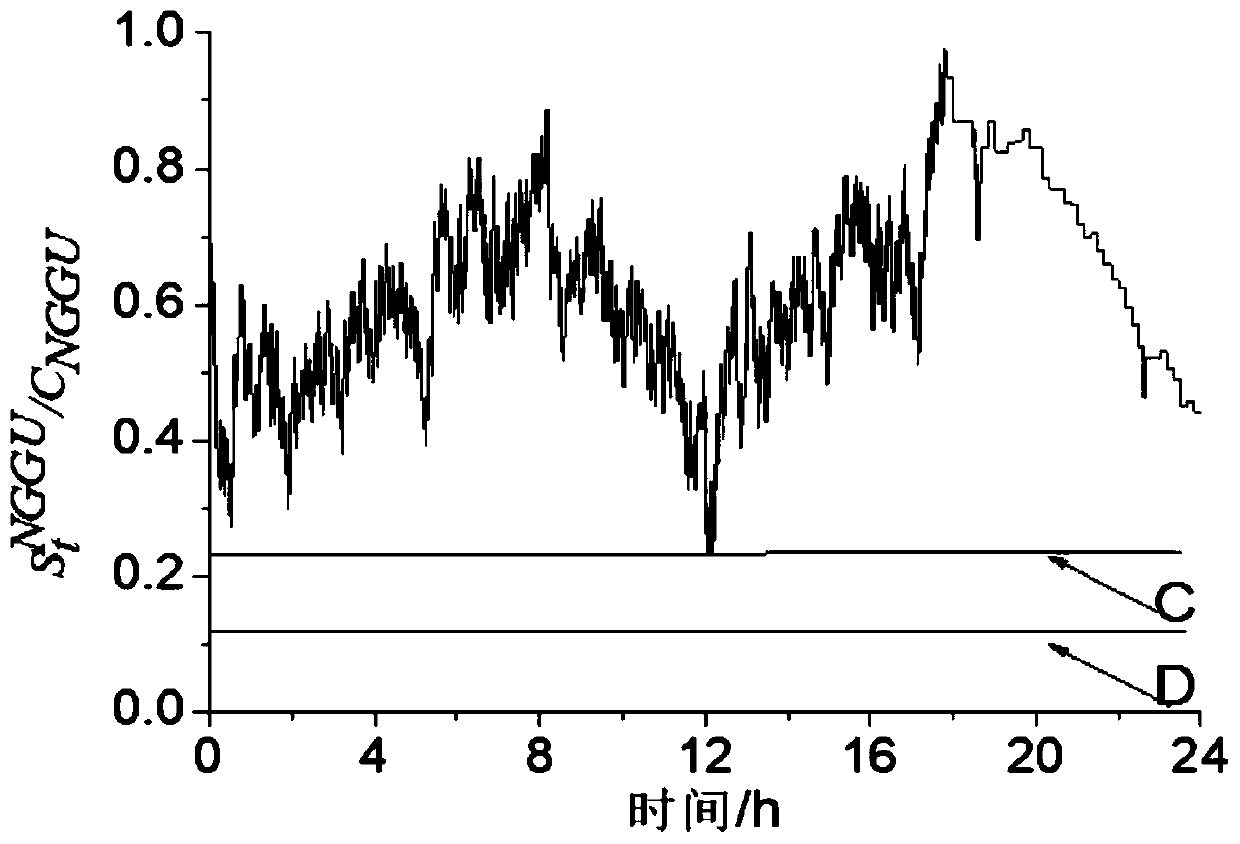

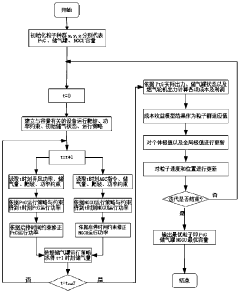

Electricity-to-gas conversion-gas storage-gas turbine capacity optimal configuration method and system with wind curtailment participating in power grid frequency modulation

PatentActiveCN110829504A

Innovation

- Build PtG equipment on the side of the wind farm, use gas storage tanks for large-capacity storage, and participate in frequency regulation through gas turbine power generation. Formulate a joint operation strategy, establish a cost-benefit model, and optimize capacity allocation through particle swarm optimization algorithms to maximize net income. .

Environmental Impact of PETG in Autonomous Technologies

The integration of PETG (Polyethylene Terephthalate Glycol) in autonomous systems development has significant environmental implications that warrant careful consideration. As autonomous technologies continue to advance, the use of PETG in various components and structures has become increasingly prevalent. This material offers several advantages in terms of durability, flexibility, and cost-effectiveness, which contribute to the overall efficiency of autonomous systems.

However, the environmental impact of PETG in these applications is a complex issue that requires a multifaceted analysis. One of the primary concerns is the material's end-of-life management. While PETG is recyclable, the recycling process for components used in autonomous systems can be challenging due to the complexity of the assemblies and the potential contamination from other materials. This may lead to increased waste if proper recycling infrastructure and processes are not in place.

On the positive side, the use of PETG in autonomous technologies can contribute to overall environmental benefits. For instance, in autonomous vehicles, PETG components can help reduce the overall weight of the vehicle, leading to improved fuel efficiency and reduced emissions. Similarly, in drone technologies, PETG's lightweight properties can extend flight times and reduce energy consumption, potentially decreasing the environmental footprint of these operations.

The production of PETG itself has environmental considerations. While it is generally considered to have a lower environmental impact compared to some other plastics, the manufacturing process still requires energy and resources. However, advancements in production techniques and the increasing use of renewable energy in manufacturing could mitigate some of these concerns in the future.

Another aspect to consider is the potential for PETG to replace more environmentally harmful materials in autonomous systems. Its durability and resistance to various environmental factors mean that components made from PETG may have longer lifespans, reducing the need for frequent replacements and the associated resource consumption and waste generation.

The use of PETG in autonomous systems also intersects with broader environmental goals. As these technologies are often developed with the aim of improving efficiency and reducing human error, they have the potential to contribute to more sustainable practices in various industries. For example, autonomous agricultural systems using PETG components could optimize resource use and reduce waste in farming practices.

In conclusion, while PETG offers numerous benefits in the development of autonomous systems, its environmental impact is a nuanced issue. The material's properties contribute to the efficiency and effectiveness of these technologies, potentially leading to broader environmental benefits. However, challenges related to recycling and end-of-life management need to be addressed to fully realize the potential of PETG as an environmentally friendly option in autonomous technologies.

However, the environmental impact of PETG in these applications is a complex issue that requires a multifaceted analysis. One of the primary concerns is the material's end-of-life management. While PETG is recyclable, the recycling process for components used in autonomous systems can be challenging due to the complexity of the assemblies and the potential contamination from other materials. This may lead to increased waste if proper recycling infrastructure and processes are not in place.

On the positive side, the use of PETG in autonomous technologies can contribute to overall environmental benefits. For instance, in autonomous vehicles, PETG components can help reduce the overall weight of the vehicle, leading to improved fuel efficiency and reduced emissions. Similarly, in drone technologies, PETG's lightweight properties can extend flight times and reduce energy consumption, potentially decreasing the environmental footprint of these operations.

The production of PETG itself has environmental considerations. While it is generally considered to have a lower environmental impact compared to some other plastics, the manufacturing process still requires energy and resources. However, advancements in production techniques and the increasing use of renewable energy in manufacturing could mitigate some of these concerns in the future.

Another aspect to consider is the potential for PETG to replace more environmentally harmful materials in autonomous systems. Its durability and resistance to various environmental factors mean that components made from PETG may have longer lifespans, reducing the need for frequent replacements and the associated resource consumption and waste generation.

The use of PETG in autonomous systems also intersects with broader environmental goals. As these technologies are often developed with the aim of improving efficiency and reducing human error, they have the potential to contribute to more sustainable practices in various industries. For example, autonomous agricultural systems using PETG components could optimize resource use and reduce waste in farming practices.

In conclusion, while PETG offers numerous benefits in the development of autonomous systems, its environmental impact is a nuanced issue. The material's properties contribute to the efficiency and effectiveness of these technologies, potentially leading to broader environmental benefits. However, challenges related to recycling and end-of-life management need to be addressed to fully realize the potential of PETG as an environmentally friendly option in autonomous technologies.

Standardization and Regulatory Considerations for PETG Use

As the adoption of PETG (Polyethylene Terephthalate Glycol) in autonomous systems development continues to grow, the need for standardization and regulatory frameworks becomes increasingly critical. These considerations are essential to ensure the safe, reliable, and consistent use of PETG across various applications in autonomous technologies.

Standardization efforts for PETG in autonomous systems are primarily focused on establishing uniform quality control measures, performance metrics, and testing protocols. Industry bodies and standards organizations are working collaboratively to develop guidelines that address the unique properties of PETG, such as its durability, transparency, and chemical resistance. These standards aim to provide manufacturers and developers with clear benchmarks for material selection, processing, and implementation in autonomous system components.

Regulatory considerations for PETG use in autonomous systems encompass a wide range of aspects, including safety, environmental impact, and compatibility with existing regulations. Regulatory bodies are actively reviewing and updating existing frameworks to accommodate the specific characteristics of PETG and its applications in autonomous technologies. This includes assessing the material's long-term stability, potential for degradation, and any potential health or environmental risks associated with its use in autonomous systems.

One key area of focus for regulators is the integration of PETG components in safety-critical systems of autonomous vehicles and robots. Guidelines are being developed to ensure that PETG-based parts meet stringent safety requirements, particularly in areas such as impact resistance, fire safety, and structural integrity. These regulations aim to minimize risks and enhance the overall safety of autonomous systems that incorporate PETG materials.

Environmental regulations are also a significant consideration in the use of PETG for autonomous systems. As sustainability becomes increasingly important, regulators are examining the lifecycle impact of PETG, including its production, use, and end-of-life disposal or recycling. This has led to the development of guidelines for eco-friendly manufacturing processes and the promotion of recycling initiatives for PETG components in autonomous systems.

Interoperability and compatibility standards are another crucial aspect of PETG regulation in autonomous systems. As these systems often involve complex interactions between various components and materials, ensuring that PETG-based parts can seamlessly integrate with other materials and technologies is essential. Standards are being established to define interface specifications, connection methods, and compatibility requirements for PETG components in autonomous system architectures.

As the field of autonomous systems continues to evolve rapidly, regulatory bodies and standards organizations are adopting agile approaches to keep pace with technological advancements. This includes establishing mechanisms for regular review and updates of PETG-related standards and regulations, ensuring they remain relevant and effective in addressing emerging challenges and opportunities in autonomous system development.

Standardization efforts for PETG in autonomous systems are primarily focused on establishing uniform quality control measures, performance metrics, and testing protocols. Industry bodies and standards organizations are working collaboratively to develop guidelines that address the unique properties of PETG, such as its durability, transparency, and chemical resistance. These standards aim to provide manufacturers and developers with clear benchmarks for material selection, processing, and implementation in autonomous system components.

Regulatory considerations for PETG use in autonomous systems encompass a wide range of aspects, including safety, environmental impact, and compatibility with existing regulations. Regulatory bodies are actively reviewing and updating existing frameworks to accommodate the specific characteristics of PETG and its applications in autonomous technologies. This includes assessing the material's long-term stability, potential for degradation, and any potential health or environmental risks associated with its use in autonomous systems.

One key area of focus for regulators is the integration of PETG components in safety-critical systems of autonomous vehicles and robots. Guidelines are being developed to ensure that PETG-based parts meet stringent safety requirements, particularly in areas such as impact resistance, fire safety, and structural integrity. These regulations aim to minimize risks and enhance the overall safety of autonomous systems that incorporate PETG materials.

Environmental regulations are also a significant consideration in the use of PETG for autonomous systems. As sustainability becomes increasingly important, regulators are examining the lifecycle impact of PETG, including its production, use, and end-of-life disposal or recycling. This has led to the development of guidelines for eco-friendly manufacturing processes and the promotion of recycling initiatives for PETG components in autonomous systems.

Interoperability and compatibility standards are another crucial aspect of PETG regulation in autonomous systems. As these systems often involve complex interactions between various components and materials, ensuring that PETG-based parts can seamlessly integrate with other materials and technologies is essential. Standards are being established to define interface specifications, connection methods, and compatibility requirements for PETG components in autonomous system architectures.

As the field of autonomous systems continues to evolve rapidly, regulatory bodies and standards organizations are adopting agile approaches to keep pace with technological advancements. This includes establishing mechanisms for regular review and updates of PETG-related standards and regulations, ensuring they remain relevant and effective in addressing emerging challenges and opportunities in autonomous system development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!