PETG’s Transformation of Environmental Sensor Device Durability

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Sensor Evolution

The evolution of PETG (Polyethylene Terephthalate Glycol-modified) in environmental sensor devices marks a significant advancement in durability and performance. This transformation began in the early 2000s when researchers first recognized the potential of PETG as a superior material for sensor enclosures. Initially, environmental sensors were primarily constructed using traditional plastics or metals, which often fell short in harsh conditions.

The first generation of PETG-based sensor housings emerged around 2005, offering improved chemical resistance and impact strength compared to conventional materials. These early iterations demonstrated PETG's ability to withstand exposure to various environmental pollutants and extreme weather conditions, extending the operational lifespan of sensors deployed in challenging environments.

By 2010, advancements in PETG formulation led to the development of sensors with enhanced UV resistance, addressing a critical weakness in outdoor applications. This breakthrough allowed for prolonged exposure to sunlight without significant degradation, expanding the use of environmental sensors in long-term monitoring projects and remote locations.

The period between 2012 and 2015 saw a focus on improving the thermal properties of PETG-based sensors. Researchers developed new composites and manufacturing techniques that increased the material's heat deflection temperature, enabling sensors to operate reliably in a wider range of climates. This evolution was particularly crucial for applications in industrial settings and extreme weather monitoring.

From 2016 onwards, the integration of nanotechnology with PETG opened new frontiers in sensor durability. Nanoparticle-enhanced PETG composites exhibited superior barrier properties, reducing gas permeation and moisture ingress. This innovation significantly extended the calibration intervals of sensors, reducing maintenance requirements and improving long-term accuracy.

The most recent developments, from 2020 to the present, have focused on sustainability and smart functionalities. Biodegradable PETG variants have been introduced, addressing end-of-life environmental concerns. Additionally, the incorporation of self-healing properties and smart coatings has further enhanced the resilience of PETG-based sensors, allowing them to recover from minor damages and adapt to changing environmental conditions.

Throughout this evolution, PETG has consistently demonstrated its versatility and adaptability, transforming from a simple housing material to an integral component of advanced sensor technologies. Its journey reflects the broader trends in materials science and environmental monitoring, showcasing how innovative materials can drive progress in critical technological applications.

The first generation of PETG-based sensor housings emerged around 2005, offering improved chemical resistance and impact strength compared to conventional materials. These early iterations demonstrated PETG's ability to withstand exposure to various environmental pollutants and extreme weather conditions, extending the operational lifespan of sensors deployed in challenging environments.

By 2010, advancements in PETG formulation led to the development of sensors with enhanced UV resistance, addressing a critical weakness in outdoor applications. This breakthrough allowed for prolonged exposure to sunlight without significant degradation, expanding the use of environmental sensors in long-term monitoring projects and remote locations.

The period between 2012 and 2015 saw a focus on improving the thermal properties of PETG-based sensors. Researchers developed new composites and manufacturing techniques that increased the material's heat deflection temperature, enabling sensors to operate reliably in a wider range of climates. This evolution was particularly crucial for applications in industrial settings and extreme weather monitoring.

From 2016 onwards, the integration of nanotechnology with PETG opened new frontiers in sensor durability. Nanoparticle-enhanced PETG composites exhibited superior barrier properties, reducing gas permeation and moisture ingress. This innovation significantly extended the calibration intervals of sensors, reducing maintenance requirements and improving long-term accuracy.

The most recent developments, from 2020 to the present, have focused on sustainability and smart functionalities. Biodegradable PETG variants have been introduced, addressing end-of-life environmental concerns. Additionally, the incorporation of self-healing properties and smart coatings has further enhanced the resilience of PETG-based sensors, allowing them to recover from minor damages and adapt to changing environmental conditions.

Throughout this evolution, PETG has consistently demonstrated its versatility and adaptability, transforming from a simple housing material to an integral component of advanced sensor technologies. Its journey reflects the broader trends in materials science and environmental monitoring, showcasing how innovative materials can drive progress in critical technological applications.

Market Demand Analysis

The market demand for environmental sensor devices with enhanced durability has been steadily increasing across various industries. This growth is primarily driven by the expanding applications of these sensors in harsh environments, where traditional materials often fail to provide long-term reliability. PETG (Polyethylene Terephthalate Glycol) has emerged as a promising material for transforming the durability of environmental sensor devices, addressing the critical need for robust and long-lasting monitoring solutions.

In the industrial sector, there is a significant demand for sensors that can withstand extreme temperatures, corrosive chemicals, and high-pressure environments. The oil and gas industry, in particular, requires sensors capable of operating in deep-sea conditions and withstanding exposure to hydrocarbons and other corrosive substances. PETG's superior chemical resistance and thermal stability make it an attractive option for these applications, potentially extending the lifespan of sensor devices and reducing maintenance costs.

The agricultural sector presents another substantial market for durable environmental sensors. Farmers increasingly rely on soil moisture sensors, weather stations, and crop monitoring devices to optimize irrigation and improve crop yields. These sensors are exposed to varying weather conditions, UV radiation, and agricultural chemicals. PETG's resistance to UV degradation and its ability to maintain structural integrity in outdoor environments position it as a valuable material for enhancing the longevity of agricultural sensing equipment.

Environmental monitoring and climate research organizations also contribute to the growing demand for durable sensor devices. Long-term data collection in remote or hostile environments, such as arctic regions, deserts, or rainforests, requires sensors that can operate reliably for extended periods without frequent maintenance or replacement. PETG's potential to improve the durability of these devices aligns well with the needs of researchers and environmental agencies seeking to gather consistent, long-term data sets.

The smart city and urban planning sectors represent an emerging market for durable environmental sensors. As cities invest in infrastructure to monitor air quality, noise levels, and other environmental parameters, there is a growing need for sensor networks that can withstand urban pollution, vibration, and varying weather conditions. PETG's durability and resistance to environmental stressors make it a suitable material for developing long-lasting urban sensing solutions.

In the automotive industry, the demand for durable environmental sensors is driven by the increasing integration of advanced driver assistance systems (ADAS) and the development of autonomous vehicles. These systems rely on a variety of sensors to monitor road conditions, weather, and air quality. PETG's potential to enhance the durability of these sensors could contribute to improved reliability and safety in automotive applications.

The market potential for PETG-enhanced environmental sensor devices is further amplified by the global focus on sustainability and reducing electronic waste. By extending the operational life of sensor devices, PETG contributes to reducing the frequency of replacements and the associated environmental impact. This aligns with the growing consumer and regulatory demand for more sustainable and durable electronic products across all industries.

In the industrial sector, there is a significant demand for sensors that can withstand extreme temperatures, corrosive chemicals, and high-pressure environments. The oil and gas industry, in particular, requires sensors capable of operating in deep-sea conditions and withstanding exposure to hydrocarbons and other corrosive substances. PETG's superior chemical resistance and thermal stability make it an attractive option for these applications, potentially extending the lifespan of sensor devices and reducing maintenance costs.

The agricultural sector presents another substantial market for durable environmental sensors. Farmers increasingly rely on soil moisture sensors, weather stations, and crop monitoring devices to optimize irrigation and improve crop yields. These sensors are exposed to varying weather conditions, UV radiation, and agricultural chemicals. PETG's resistance to UV degradation and its ability to maintain structural integrity in outdoor environments position it as a valuable material for enhancing the longevity of agricultural sensing equipment.

Environmental monitoring and climate research organizations also contribute to the growing demand for durable sensor devices. Long-term data collection in remote or hostile environments, such as arctic regions, deserts, or rainforests, requires sensors that can operate reliably for extended periods without frequent maintenance or replacement. PETG's potential to improve the durability of these devices aligns well with the needs of researchers and environmental agencies seeking to gather consistent, long-term data sets.

The smart city and urban planning sectors represent an emerging market for durable environmental sensors. As cities invest in infrastructure to monitor air quality, noise levels, and other environmental parameters, there is a growing need for sensor networks that can withstand urban pollution, vibration, and varying weather conditions. PETG's durability and resistance to environmental stressors make it a suitable material for developing long-lasting urban sensing solutions.

In the automotive industry, the demand for durable environmental sensors is driven by the increasing integration of advanced driver assistance systems (ADAS) and the development of autonomous vehicles. These systems rely on a variety of sensors to monitor road conditions, weather, and air quality. PETG's potential to enhance the durability of these sensors could contribute to improved reliability and safety in automotive applications.

The market potential for PETG-enhanced environmental sensor devices is further amplified by the global focus on sustainability and reducing electronic waste. By extending the operational life of sensor devices, PETG contributes to reducing the frequency of replacements and the associated environmental impact. This aligns with the growing consumer and regulatory demand for more sustainable and durable electronic products across all industries.

PETG Challenges

Despite the numerous advantages of PETG in environmental sensor device manufacturing, several challenges persist in its application. One of the primary concerns is the material's susceptibility to UV radiation. Prolonged exposure to sunlight can lead to degradation of PETG's mechanical properties, potentially compromising the durability of sensor devices deployed in outdoor environments. This issue necessitates the development of effective UV stabilization techniques or protective coatings to enhance PETG's resistance to photodegradation.

Another significant challenge lies in PETG's limited chemical resistance compared to some other engineering plastics. While it demonstrates good resistance to many common chemicals, it can be vulnerable to certain organic solvents and strong acids. This vulnerability may restrict its use in sensor devices exposed to harsh chemical environments, requiring careful consideration of the specific deployment conditions and potential chemical interactions.

Temperature sensitivity presents an additional hurdle for PETG in sensor applications. Although it offers improved heat resistance compared to PET, PETG still has a relatively low heat deflection temperature. This characteristic can lead to dimensional instability or warping in high-temperature environments, potentially affecting the precision and reliability of sensor measurements. Addressing this limitation may involve developing heat-stabilized PETG formulations or implementing thermal management strategies in device design.

The moisture absorption properties of PETG also pose challenges in environmental sensor applications. While PETG has lower moisture absorption rates compared to some other polymers, it is not entirely impervious to water. In high-humidity environments or during prolonged exposure to moisture, PETG can absorb small amounts of water, potentially leading to dimensional changes or affecting the performance of sensitive electronic components within the sensor device.

Furthermore, the processing and manufacturing of PETG for sensor device applications present their own set of challenges. Achieving consistent quality and dimensional stability during injection molding or extrusion processes can be demanding, especially for complex sensor device geometries. Optimizing processing parameters to minimize internal stresses and ensure uniform material properties throughout the molded parts is crucial for maintaining the long-term reliability of PETG-based sensor devices.

Lastly, while PETG offers good impact resistance, there is still room for improvement in terms of overall mechanical strength and stiffness for certain high-stress applications. Enhancing these properties without compromising other beneficial characteristics of PETG remains an ongoing challenge in materials science and engineering.

Another significant challenge lies in PETG's limited chemical resistance compared to some other engineering plastics. While it demonstrates good resistance to many common chemicals, it can be vulnerable to certain organic solvents and strong acids. This vulnerability may restrict its use in sensor devices exposed to harsh chemical environments, requiring careful consideration of the specific deployment conditions and potential chemical interactions.

Temperature sensitivity presents an additional hurdle for PETG in sensor applications. Although it offers improved heat resistance compared to PET, PETG still has a relatively low heat deflection temperature. This characteristic can lead to dimensional instability or warping in high-temperature environments, potentially affecting the precision and reliability of sensor measurements. Addressing this limitation may involve developing heat-stabilized PETG formulations or implementing thermal management strategies in device design.

The moisture absorption properties of PETG also pose challenges in environmental sensor applications. While PETG has lower moisture absorption rates compared to some other polymers, it is not entirely impervious to water. In high-humidity environments or during prolonged exposure to moisture, PETG can absorb small amounts of water, potentially leading to dimensional changes or affecting the performance of sensitive electronic components within the sensor device.

Furthermore, the processing and manufacturing of PETG for sensor device applications present their own set of challenges. Achieving consistent quality and dimensional stability during injection molding or extrusion processes can be demanding, especially for complex sensor device geometries. Optimizing processing parameters to minimize internal stresses and ensure uniform material properties throughout the molded parts is crucial for maintaining the long-term reliability of PETG-based sensor devices.

Lastly, while PETG offers good impact resistance, there is still room for improvement in terms of overall mechanical strength and stiffness for certain high-stress applications. Enhancing these properties without compromising other beneficial characteristics of PETG remains an ongoing challenge in materials science and engineering.

Current PETG Solutions

01 Enhanced durability through additives

PETG durability can be improved by incorporating various additives. These additives can enhance properties such as impact resistance, heat resistance, and overall mechanical strength. Examples include impact modifiers, UV stabilizers, and reinforcing agents like glass fibers or carbon nanotubes.- Enhanced durability through additives: PETG durability can be improved by incorporating various additives. These additives can enhance properties such as impact resistance, heat resistance, and overall mechanical strength. Examples include impact modifiers, UV stabilizers, and reinforcing agents like glass fibers or carbon nanotubes.

- Surface treatment for improved durability: Surface treatments can significantly enhance the durability of PETG. These treatments may include plasma treatment, chemical etching, or application of protective coatings. Such processes can improve scratch resistance, chemical resistance, and weatherability of PETG products.

- Blending with other polymers: Blending PETG with other compatible polymers can result in improved durability characteristics. This approach can enhance properties such as impact strength, chemical resistance, and thermal stability. Common blend partners include polycarbonate, ABS, or other engineered plastics.

- Optimized processing conditions: The durability of PETG products can be enhanced through optimized processing conditions. This includes careful control of molding temperatures, cooling rates, and post-processing treatments. Proper processing can minimize internal stresses and improve the overall structural integrity of PETG parts.

- Specialized PETG formulations: Development of specialized PETG formulations can lead to improved durability. These formulations may involve modifications to the polymer structure, such as increased glycol content or the incorporation of comonomers. Such modifications can enhance properties like impact resistance, chemical resistance, and long-term stability.

02 Surface treatment for improved durability

Surface treatments can significantly enhance the durability of PETG. These treatments may include plasma treatment, chemical etching, or application of protective coatings. Such processes can improve scratch resistance, chemical resistance, and weatherability of PETG products.Expand Specific Solutions03 Blending with other polymers

Blending PETG with other compatible polymers can result in improved durability characteristics. This approach can enhance properties such as impact strength, chemical resistance, and thermal stability. Common blend partners include polycarbonate, ABS, or other engineered plastics.Expand Specific Solutions04 Optimized processing conditions

Careful control of processing conditions during PETG manufacturing can lead to improved durability. This includes optimizing parameters such as temperature, pressure, and cooling rates during extrusion or injection molding. Proper processing can enhance crystallinity, molecular orientation, and overall mechanical properties.Expand Specific Solutions05 Specialized PETG formulations

Development of specialized PETG formulations tailored for specific applications can enhance durability. These formulations may involve modifications to the polymer structure, such as increased glycol content or the incorporation of comonomers. Such tailored formulations can offer improved resistance to specific environmental factors or mechanical stresses.Expand Specific Solutions

Key PETG Players

The PETG transformation of environmental sensor device durability is in a nascent stage of development, with the market showing promising growth potential. The technology's maturity varies among key players, with companies like Shenzhen Goodix Technology Co., Ltd. and Robert Bosch GmbH leading in sensor technology integration. Nitto Denko Corp. and IHI Inspection & Instrumentation Co. Ltd. are advancing materials science applications, while academic institutions such as Qingdao University of Technology and Shandong University contribute to fundamental research. The competitive landscape is diverse, encompassing both established electronics manufacturers and specialized materials firms, indicating a dynamic and evolving market with opportunities for innovation and collaboration across sectors.

Nitto Denko Corp.

Technical Solution: Nitto Denko Corp. has developed advanced PETG-based materials for environmental sensor devices, focusing on improving durability and performance. Their approach involves incorporating specialized additives and surface treatments to enhance PETG's resistance to environmental factors. The company has implemented a multi-layer structure in their PETG films, which includes a protective outer layer resistant to UV radiation and chemical exposure[1]. This design significantly extends the lifespan of sensors in harsh environments. Additionally, Nitto Denko has developed a proprietary coating technology that further enhances the moisture barrier properties of PETG, crucial for maintaining sensor accuracy in high-humidity conditions[3].

Strengths: Superior durability in harsh environments, excellent moisture barrier properties, and enhanced UV resistance. Weaknesses: Potentially higher production costs due to specialized additives and multi-layer structure, which may limit widespread adoption in cost-sensitive applications.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has leveraged PETG's properties to revolutionize their environmental sensor devices. They have developed a proprietary PETG compound that incorporates nanoparticles to enhance thermal stability and mechanical strength[2]. This innovation allows their sensors to operate reliably in a wider temperature range. Bosch has also implemented a unique molding process that minimizes internal stresses in PETG components, reducing the risk of cracking and deformation over time[4]. Furthermore, they have integrated PETG with other materials in a hybrid design, combining the benefits of PETG with complementary materials to create sensors with exceptional durability and performance[5].

Strengths: Wide operating temperature range, improved mechanical strength, and innovative hybrid material design. Weaknesses: Complex manufacturing process may lead to higher production costs, and the use of nanoparticles might raise concerns about long-term environmental impact.

PETG Innovations

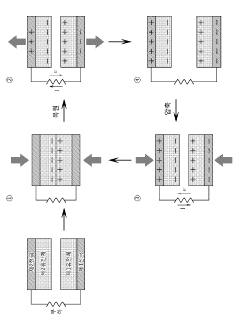

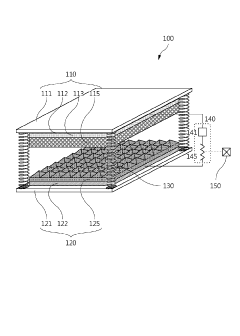

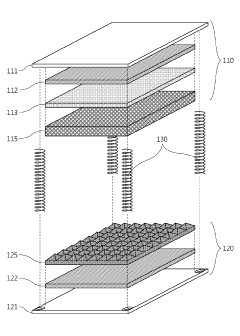

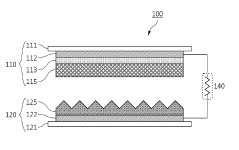

Highly-durable self-powered active environmental sensor

PatentActiveKR1020200121449A

Innovation

- A self-powered environmental sensor with a durable plate formed of a porous or transparent material, separate from the sensing material, enhances durability while allowing for high sensitivity by using triboelectric charge to generate electric energy and measure environmental changes.

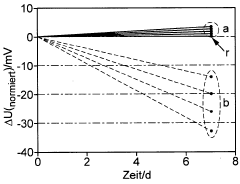

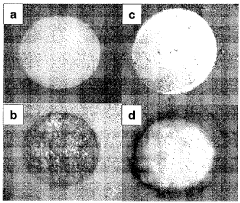

Sensor having long-term stability for bioprocesses

PatentWO2009050105A1

Innovation

- A sensor with a surface section coated using a biocidal substance like polyethylene glycol (PEG) that is immobilized on the surface, preventing protein adsorption and maintaining biocidal properties even after cleaning and sterilization, thereby reducing the need for frequent interventions.

Environmental Impact

The adoption of PETG (Polyethylene Terephthalate Glycol) in environmental sensor devices has significant implications for environmental sustainability. PETG's durability and resistance to harsh conditions contribute to extended device lifespans, reducing the frequency of replacements and, consequently, electronic waste generation. This longevity is particularly crucial in remote or challenging environments where frequent maintenance is impractical.

PETG's chemical resistance properties also play a vital role in preventing the leaching of harmful substances into the environment. Unlike some traditional materials, PETG maintains its integrity when exposed to various chemicals, reducing the risk of contamination in sensitive ecosystems where these sensors are often deployed.

The material's recyclability further enhances its environmental credentials. At the end of a device's life cycle, PETG components can be effectively recycled, supporting circular economy principles and reducing the overall environmental footprint of sensor production and disposal. This recyclability is particularly important given the increasing global focus on sustainable manufacturing practices.

PETG's lightweight nature contributes to reduced transportation-related emissions during the distribution of environmental sensor devices. This characteristic becomes especially significant when considering the large-scale deployment of sensor networks across vast geographical areas for environmental monitoring purposes.

Moreover, the improved durability of PETG-based sensors may lead to more comprehensive and consistent environmental data collection. Longer-lasting devices ensure continuous monitoring without interruptions due to equipment failure, potentially leading to more accurate environmental assessments and better-informed conservation strategies.

However, it's important to consider the energy and resources required for PETG production. While the material offers environmental benefits in use and end-of-life stages, the manufacturing process should be scrutinized to ensure it aligns with sustainable practices. Ongoing research into more eco-friendly production methods for PETG could further enhance its overall environmental impact.

In conclusion, PETG's application in environmental sensor devices presents a net positive environmental impact. Its durability, recyclability, and chemical resistance contribute to reduced waste, improved data collection, and enhanced protection of ecosystems. As environmental monitoring becomes increasingly crucial in addressing global challenges, the role of materials like PETG in creating sustainable, long-lasting sensor solutions cannot be overstated.

PETG's chemical resistance properties also play a vital role in preventing the leaching of harmful substances into the environment. Unlike some traditional materials, PETG maintains its integrity when exposed to various chemicals, reducing the risk of contamination in sensitive ecosystems where these sensors are often deployed.

The material's recyclability further enhances its environmental credentials. At the end of a device's life cycle, PETG components can be effectively recycled, supporting circular economy principles and reducing the overall environmental footprint of sensor production and disposal. This recyclability is particularly important given the increasing global focus on sustainable manufacturing practices.

PETG's lightweight nature contributes to reduced transportation-related emissions during the distribution of environmental sensor devices. This characteristic becomes especially significant when considering the large-scale deployment of sensor networks across vast geographical areas for environmental monitoring purposes.

Moreover, the improved durability of PETG-based sensors may lead to more comprehensive and consistent environmental data collection. Longer-lasting devices ensure continuous monitoring without interruptions due to equipment failure, potentially leading to more accurate environmental assessments and better-informed conservation strategies.

However, it's important to consider the energy and resources required for PETG production. While the material offers environmental benefits in use and end-of-life stages, the manufacturing process should be scrutinized to ensure it aligns with sustainable practices. Ongoing research into more eco-friendly production methods for PETG could further enhance its overall environmental impact.

In conclusion, PETG's application in environmental sensor devices presents a net positive environmental impact. Its durability, recyclability, and chemical resistance contribute to reduced waste, improved data collection, and enhanced protection of ecosystems. As environmental monitoring becomes increasingly crucial in addressing global challenges, the role of materials like PETG in creating sustainable, long-lasting sensor solutions cannot be overstated.

PETG Manufacturing

PETG (Polyethylene Terephthalate Glycol) manufacturing has emerged as a crucial process in enhancing the durability of environmental sensor devices. This innovative material offers a unique combination of properties that make it ideal for protecting sensitive electronic components from harsh environmental conditions. The manufacturing process of PETG involves a series of carefully controlled steps to ensure the production of high-quality, consistent material.

The first stage in PETG manufacturing is the polymerization process. This involves combining ethylene glycol with dimethyl terephthalate or terephthalic acid under controlled temperature and pressure conditions. The resulting polymer is then extruded into pellets, which serve as the raw material for subsequent processing steps. These pellets are carefully formulated to achieve the desired balance of properties, including transparency, impact resistance, and chemical stability.

Next, the PETG pellets undergo a drying process to remove any moisture that could affect the quality of the final product. This step is critical as moisture can lead to hydrolysis during processing, potentially compromising the material's performance. The dried pellets are then fed into an injection molding machine or extruder, depending on the desired form of the final product.

For environmental sensor device casings, injection molding is often the preferred method. This process involves melting the PETG pellets and injecting the molten material into a mold cavity under high pressure. The mold is designed to create the specific shape and features required for the sensor housing. Precise control of temperature, pressure, and cooling rates is essential to ensure the final product meets the required specifications for durability and dimensional accuracy.

In some applications, PETG sheets may be required. These are produced through an extrusion process where the molten PETG is forced through a die to create a continuous sheet. The thickness and width of the sheet can be precisely controlled to meet specific requirements. These sheets can then be thermoformed into custom shapes for sensor housings or protective covers.

Post-processing steps may include surface treatments to enhance specific properties such as scratch resistance or UV protection. These treatments can significantly extend the lifespan of the sensor devices in outdoor or harsh industrial environments. Additionally, secondary operations like machining or welding may be employed to create complex assemblies or integrate the PETG components with other materials.

Quality control is a critical aspect of PETG manufacturing for environmental sensor devices. Rigorous testing protocols are implemented throughout the production process to ensure consistency and adherence to specifications. This includes checks for optical clarity, impact strength, chemical resistance, and dimensional accuracy. Advanced techniques such as spectroscopy and thermal analysis are often employed to verify the material's composition and performance characteristics.

The first stage in PETG manufacturing is the polymerization process. This involves combining ethylene glycol with dimethyl terephthalate or terephthalic acid under controlled temperature and pressure conditions. The resulting polymer is then extruded into pellets, which serve as the raw material for subsequent processing steps. These pellets are carefully formulated to achieve the desired balance of properties, including transparency, impact resistance, and chemical stability.

Next, the PETG pellets undergo a drying process to remove any moisture that could affect the quality of the final product. This step is critical as moisture can lead to hydrolysis during processing, potentially compromising the material's performance. The dried pellets are then fed into an injection molding machine or extruder, depending on the desired form of the final product.

For environmental sensor device casings, injection molding is often the preferred method. This process involves melting the PETG pellets and injecting the molten material into a mold cavity under high pressure. The mold is designed to create the specific shape and features required for the sensor housing. Precise control of temperature, pressure, and cooling rates is essential to ensure the final product meets the required specifications for durability and dimensional accuracy.

In some applications, PETG sheets may be required. These are produced through an extrusion process where the molten PETG is forced through a die to create a continuous sheet. The thickness and width of the sheet can be precisely controlled to meet specific requirements. These sheets can then be thermoformed into custom shapes for sensor housings or protective covers.

Post-processing steps may include surface treatments to enhance specific properties such as scratch resistance or UV protection. These treatments can significantly extend the lifespan of the sensor devices in outdoor or harsh industrial environments. Additionally, secondary operations like machining or welding may be employed to create complex assemblies or integrate the PETG components with other materials.

Quality control is a critical aspect of PETG manufacturing for environmental sensor devices. Rigorous testing protocols are implemented throughout the production process to ensure consistency and adherence to specifications. This includes checks for optical clarity, impact strength, chemical resistance, and dimensional accuracy. Advanced techniques such as spectroscopy and thermal analysis are often employed to verify the material's composition and performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!