Eco-Efficiency Analysis of PETG in Smart Grid Equipment

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG in Smart Grids: Background and Objectives

Polyethylene terephthalate glycol (PETG) has emerged as a promising material in the development of smart grid equipment, offering a unique combination of properties that align with the evolving needs of modern power distribution systems. The integration of PETG in smart grids represents a significant technological advancement, driven by the increasing demand for more efficient, reliable, and environmentally friendly energy infrastructure.

The smart grid concept has gained momentum over the past decade as a response to the challenges faced by traditional power grids. These challenges include the integration of renewable energy sources, improving energy efficiency, and enhancing grid resilience. As the power sector undergoes this transformation, there is a growing need for materials that can meet the stringent requirements of smart grid components while also addressing sustainability concerns.

PETG, a thermoplastic polyester, has attracted attention in the smart grid industry due to its exceptional mechanical properties, electrical insulation capabilities, and recyclability. Its application in smart grid equipment spans various components, including enclosures for smart meters, protective housings for sensors and communication devices, and insulation for power distribution units. The material's durability, weather resistance, and transparency make it particularly suitable for outdoor applications, where smart grid equipment is often deployed.

The evolution of PETG usage in smart grids can be traced back to the early 2000s when the concept of smart grids began to take shape. Initially, the focus was primarily on the material's physical properties and its ability to withstand harsh environmental conditions. However, as sustainability became a more pressing concern in the energy sector, the eco-efficiency of materials used in grid infrastructure gained prominence.

The current technological landscape sees PETG competing with traditional materials such as polycarbonate and PVC in smart grid applications. The drive towards more sustainable practices in the energy sector has led to increased scrutiny of the environmental impact of materials used in grid infrastructure. This shift has positioned PETG favorably, given its potential for recycling and lower carbon footprint compared to some alternatives.

As we look towards the future, the objectives for PETG in smart grids are multifaceted. There is a push to further enhance the material's properties to meet the evolving demands of smart grid technology. This includes improving its resistance to extreme temperatures, enhancing its fire-retardant properties, and exploring ways to incorporate smart functionalities into the material itself, such as self-healing capabilities or embedded sensors.

Moreover, there is a growing emphasis on conducting comprehensive eco-efficiency analyses of PETG in smart grid equipment. These analyses aim to quantify the environmental benefits of using PETG throughout its lifecycle, from production to end-of-life management. The goal is to provide a clear understanding of the material's overall sustainability profile, taking into account factors such as energy consumption, greenhouse gas emissions, and resource utilization.

The smart grid concept has gained momentum over the past decade as a response to the challenges faced by traditional power grids. These challenges include the integration of renewable energy sources, improving energy efficiency, and enhancing grid resilience. As the power sector undergoes this transformation, there is a growing need for materials that can meet the stringent requirements of smart grid components while also addressing sustainability concerns.

PETG, a thermoplastic polyester, has attracted attention in the smart grid industry due to its exceptional mechanical properties, electrical insulation capabilities, and recyclability. Its application in smart grid equipment spans various components, including enclosures for smart meters, protective housings for sensors and communication devices, and insulation for power distribution units. The material's durability, weather resistance, and transparency make it particularly suitable for outdoor applications, where smart grid equipment is often deployed.

The evolution of PETG usage in smart grids can be traced back to the early 2000s when the concept of smart grids began to take shape. Initially, the focus was primarily on the material's physical properties and its ability to withstand harsh environmental conditions. However, as sustainability became a more pressing concern in the energy sector, the eco-efficiency of materials used in grid infrastructure gained prominence.

The current technological landscape sees PETG competing with traditional materials such as polycarbonate and PVC in smart grid applications. The drive towards more sustainable practices in the energy sector has led to increased scrutiny of the environmental impact of materials used in grid infrastructure. This shift has positioned PETG favorably, given its potential for recycling and lower carbon footprint compared to some alternatives.

As we look towards the future, the objectives for PETG in smart grids are multifaceted. There is a push to further enhance the material's properties to meet the evolving demands of smart grid technology. This includes improving its resistance to extreme temperatures, enhancing its fire-retardant properties, and exploring ways to incorporate smart functionalities into the material itself, such as self-healing capabilities or embedded sensors.

Moreover, there is a growing emphasis on conducting comprehensive eco-efficiency analyses of PETG in smart grid equipment. These analyses aim to quantify the environmental benefits of using PETG throughout its lifecycle, from production to end-of-life management. The goal is to provide a clear understanding of the material's overall sustainability profile, taking into account factors such as energy consumption, greenhouse gas emissions, and resource utilization.

Market Demand for Eco-Efficient Grid Equipment

The market demand for eco-efficient smart grid equipment has been steadily increasing in recent years, driven by several key factors. Firstly, the global push towards sustainable energy solutions and the reduction of carbon emissions has created a strong incentive for utilities and energy companies to invest in more environmentally friendly technologies. Smart grid equipment that incorporates eco-efficient materials like PETG (Polyethylene Terephthalate Glycol) aligns well with these sustainability goals.

The growing awareness of the environmental impact of traditional grid infrastructure has led to a shift in consumer preferences. End-users are increasingly demanding greener energy solutions, which in turn puts pressure on utility companies to adopt more eco-friendly equipment. This consumer-driven demand is further reinforced by regulatory frameworks and government initiatives that promote the use of sustainable materials and energy-efficient technologies in grid infrastructure.

In the smart grid sector, there is a particular focus on equipment that can enhance overall system efficiency while minimizing environmental impact. PETG, with its potential for improved eco-efficiency, is well-positioned to meet this demand. The material's properties, such as durability, recyclability, and lower energy consumption in production, make it an attractive option for various smart grid components.

The market for eco-efficient grid equipment is also being propelled by the rapid expansion of renewable energy sources. As more solar, wind, and other renewable energy systems are integrated into the grid, there is a growing need for smart grid equipment that can efficiently manage and distribute this variable energy supply. Eco-efficient materials like PETG can play a crucial role in developing such equipment, further driving market demand.

Additionally, the increasing focus on grid modernization and the implementation of smart city initiatives worldwide are creating new opportunities for eco-efficient grid equipment. These projects often prioritize sustainability and energy efficiency, making eco-friendly materials and technologies a key requirement in their specifications.

The economic benefits of eco-efficient grid equipment are also contributing to market demand. While initial costs may be higher, the long-term savings in energy consumption, maintenance, and replacement costs are attracting utilities and grid operators. This total cost of ownership perspective is shifting procurement strategies towards more sustainable options.

Furthermore, the growing emphasis on circular economy principles is influencing the smart grid equipment market. Materials that can be easily recycled or repurposed at the end of their lifecycle are gaining preference. PETG's recyclability aligns well with these circular economy goals, potentially increasing its market appeal in the smart grid sector.

The growing awareness of the environmental impact of traditional grid infrastructure has led to a shift in consumer preferences. End-users are increasingly demanding greener energy solutions, which in turn puts pressure on utility companies to adopt more eco-friendly equipment. This consumer-driven demand is further reinforced by regulatory frameworks and government initiatives that promote the use of sustainable materials and energy-efficient technologies in grid infrastructure.

In the smart grid sector, there is a particular focus on equipment that can enhance overall system efficiency while minimizing environmental impact. PETG, with its potential for improved eco-efficiency, is well-positioned to meet this demand. The material's properties, such as durability, recyclability, and lower energy consumption in production, make it an attractive option for various smart grid components.

The market for eco-efficient grid equipment is also being propelled by the rapid expansion of renewable energy sources. As more solar, wind, and other renewable energy systems are integrated into the grid, there is a growing need for smart grid equipment that can efficiently manage and distribute this variable energy supply. Eco-efficient materials like PETG can play a crucial role in developing such equipment, further driving market demand.

Additionally, the increasing focus on grid modernization and the implementation of smart city initiatives worldwide are creating new opportunities for eco-efficient grid equipment. These projects often prioritize sustainability and energy efficiency, making eco-friendly materials and technologies a key requirement in their specifications.

The economic benefits of eco-efficient grid equipment are also contributing to market demand. While initial costs may be higher, the long-term savings in energy consumption, maintenance, and replacement costs are attracting utilities and grid operators. This total cost of ownership perspective is shifting procurement strategies towards more sustainable options.

Furthermore, the growing emphasis on circular economy principles is influencing the smart grid equipment market. Materials that can be easily recycled or repurposed at the end of their lifecycle are gaining preference. PETG's recyclability aligns well with these circular economy goals, potentially increasing its market appeal in the smart grid sector.

PETG Eco-Efficiency: Current Status and Challenges

The eco-efficiency analysis of PETG (Polyethylene Terephthalate Glycol-modified) in smart grid equipment is currently facing several challenges and limitations. While PETG offers numerous advantages in terms of durability, transparency, and chemical resistance, its environmental impact and overall efficiency in smart grid applications require careful consideration.

One of the primary challenges is the energy-intensive production process of PETG. The manufacturing of this thermoplastic polymer involves high temperatures and pressures, resulting in significant energy consumption and associated carbon emissions. This aspect raises concerns about the material's overall environmental footprint, particularly when considering its application in smart grid equipment designed to enhance energy efficiency.

Additionally, the recyclability of PETG in smart grid components presents another hurdle. Although PETG is theoretically recyclable, the presence of additives and other materials in smart grid equipment can complicate the recycling process. The current recycling infrastructure may not be adequately equipped to handle PETG from these specialized applications, potentially leading to increased waste and reduced eco-efficiency.

The durability of PETG, while generally an advantage, poses a double-edged sword in terms of eco-efficiency. On one hand, its long lifespan can reduce the need for frequent replacements, thereby conserving resources. On the other hand, this durability can lead to prolonged environmental presence if not properly managed at the end of its life cycle.

Furthermore, the production of PETG relies heavily on fossil fuel-derived raw materials. This dependence on non-renewable resources raises questions about the long-term sustainability of PETG use in smart grid equipment, especially as the world moves towards more sustainable and bio-based alternatives.

The integration of PETG into smart grid systems also faces challenges in terms of optimizing its properties for specific applications. While PETG offers excellent clarity and impact resistance, fine-tuning these properties for the diverse requirements of smart grid components without compromising its eco-efficiency remains a complex task.

Lastly, the current status of PETG eco-efficiency in smart grid equipment is hampered by a lack of comprehensive life cycle assessments. There is a need for more detailed studies that consider the entire lifecycle of PETG in this specific application, from raw material extraction to end-of-life disposal or recycling. Such assessments would provide valuable insights into the true environmental impact and help identify areas for improvement in eco-efficiency.

In conclusion, while PETG offers several advantages for use in smart grid equipment, its current eco-efficiency status faces significant challenges. Addressing these issues will require innovative approaches to production, recycling, and material optimization, as well as a more comprehensive understanding of its lifecycle impact in smart grid applications.

One of the primary challenges is the energy-intensive production process of PETG. The manufacturing of this thermoplastic polymer involves high temperatures and pressures, resulting in significant energy consumption and associated carbon emissions. This aspect raises concerns about the material's overall environmental footprint, particularly when considering its application in smart grid equipment designed to enhance energy efficiency.

Additionally, the recyclability of PETG in smart grid components presents another hurdle. Although PETG is theoretically recyclable, the presence of additives and other materials in smart grid equipment can complicate the recycling process. The current recycling infrastructure may not be adequately equipped to handle PETG from these specialized applications, potentially leading to increased waste and reduced eco-efficiency.

The durability of PETG, while generally an advantage, poses a double-edged sword in terms of eco-efficiency. On one hand, its long lifespan can reduce the need for frequent replacements, thereby conserving resources. On the other hand, this durability can lead to prolonged environmental presence if not properly managed at the end of its life cycle.

Furthermore, the production of PETG relies heavily on fossil fuel-derived raw materials. This dependence on non-renewable resources raises questions about the long-term sustainability of PETG use in smart grid equipment, especially as the world moves towards more sustainable and bio-based alternatives.

The integration of PETG into smart grid systems also faces challenges in terms of optimizing its properties for specific applications. While PETG offers excellent clarity and impact resistance, fine-tuning these properties for the diverse requirements of smart grid components without compromising its eco-efficiency remains a complex task.

Lastly, the current status of PETG eco-efficiency in smart grid equipment is hampered by a lack of comprehensive life cycle assessments. There is a need for more detailed studies that consider the entire lifecycle of PETG in this specific application, from raw material extraction to end-of-life disposal or recycling. Such assessments would provide valuable insights into the true environmental impact and help identify areas for improvement in eco-efficiency.

In conclusion, while PETG offers several advantages for use in smart grid equipment, its current eco-efficiency status faces significant challenges. Addressing these issues will require innovative approaches to production, recycling, and material optimization, as well as a more comprehensive understanding of its lifecycle impact in smart grid applications.

Existing Eco-Efficiency Solutions for PETG

01 PETG recycling and eco-friendly production

PETG (Polyethylene Terephthalate Glycol-modified) can be recycled and produced in an eco-friendly manner. This involves developing efficient recycling processes, using renewable energy sources in production, and implementing closed-loop systems to minimize waste. These methods contribute to reducing the environmental impact of PETG manufacturing and usage.- Eco-efficient PETG production methods: Improved manufacturing processes for PETG that reduce energy consumption, minimize waste, and utilize more sustainable raw materials. These methods aim to enhance the overall eco-efficiency of PETG production while maintaining or improving the material's desirable properties.

- Recycling and biodegradability of PETG: Development of techniques to enhance the recyclability and biodegradability of PETG products. This includes modifications to the polymer structure or additives that facilitate easier breakdown and reprocessing, reducing the environmental impact of PETG waste.

- PETG blends and composites for improved sustainability: Creation of PETG blends or composites with other eco-friendly materials to enhance overall sustainability. These formulations aim to reduce the environmental footprint while maintaining or improving the performance characteristics of the final product.

- Energy-efficient processing of PETG: Development of energy-efficient processing techniques for PETG, including improved molding, extrusion, and forming methods. These advancements reduce energy consumption during manufacturing, contributing to the overall eco-efficiency of PETG-based products.

- Life cycle assessment and optimization for PETG products: Implementation of comprehensive life cycle assessments for PETG products to identify areas for environmental improvement. This includes optimizing product design, material usage, and end-of-life scenarios to enhance the overall eco-efficiency of PETG applications.

02 PETG material optimization for sustainability

Researchers are focusing on optimizing PETG material properties to enhance its eco-efficiency. This includes improving its durability, reducing material thickness without compromising performance, and developing additives that enhance biodegradability. These advancements aim to decrease resource consumption and extend the material's lifecycle.Expand Specific Solutions03 Energy-efficient PETG processing techniques

Innovative processing techniques are being developed to reduce energy consumption in PETG production and molding. These include optimized extrusion and injection molding processes, as well as the use of advanced temperature control systems. Such improvements contribute to lowering the overall carbon footprint of PETG products.Expand Specific Solutions04 PETG alternatives and blends for improved eco-efficiency

Research is being conducted on developing PETG alternatives and blends that offer similar properties with enhanced eco-efficiency. This includes exploring bio-based materials, creating PETG composites with natural fibers, and formulating blends that combine the benefits of PETG with more environmentally friendly polymers.Expand Specific Solutions05 Life cycle assessment and eco-design of PETG products

Implementing comprehensive life cycle assessments and eco-design principles for PETG products is crucial for improving their overall eco-efficiency. This involves analyzing the environmental impact from raw material extraction to end-of-life disposal, and using these insights to redesign products for better sustainability performance.Expand Specific Solutions

Key Players in PETG and Smart Grid Industries

The eco-efficiency analysis of PETG in smart grid equipment is in its early development stage, with the market still emerging. The global smart grid market is projected to reach $103 billion by 2026, indicating significant growth potential. However, the specific application of PETG in this sector is not yet widespread. Technologically, the maturity level varies among key players. State Grid Corporation of China and its research institutes are at the forefront, leveraging their extensive power grid infrastructure. Companies like LG Electronics and Intel are contributing advanced materials and computing technologies. Universities such as Tsinghua and Shanghai Jiao Tong are conducting foundational research, while specialized firms like GridBridge are developing innovative power delivery systems incorporating eco-efficient materials.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed an innovative Eco-Efficiency Analysis framework for PETG in smart grid equipment. Their approach integrates Life Cycle Assessment (LCA) and Life Cycle Costing (LCC) methodologies to evaluate the environmental and economic impacts of PETG usage[1]. The company has implemented advanced data analytics and machine learning algorithms to process vast amounts of operational data from their smart grid infrastructure, enabling real-time optimization of PETG-based equipment performance[3]. They have also pioneered the use of nano-enhanced PETG composites, which demonstrate improved thermal stability and electrical insulation properties, crucial for smart grid applications[5].

Strengths: Comprehensive eco-efficiency analysis framework, vast operational data for optimization, innovative nano-enhanced PETG composites. Weaknesses: High initial investment costs, potential scalability challenges in diverse geographical regions.

China Electric Power Research Institute Ltd.

Technical Solution: China Electric Power Research Institute Ltd. has developed a multi-criteria decision-making model for evaluating the eco-efficiency of PETG in smart grid equipment. Their approach incorporates environmental impact indicators, economic factors, and technical performance metrics[2]. The institute has conducted extensive field trials of PETG-based smart grid components, collecting data on durability, weathering resistance, and electrical performance under various environmental conditions[4]. They have also developed a proprietary PETG recycling process specifically designed for end-of-life smart grid equipment, significantly reducing the environmental footprint of these systems[6].

Strengths: Comprehensive evaluation model, extensive field testing data, innovative PETG recycling process. Weaknesses: Limited focus on global market applications, potential challenges in adapting the model to different regulatory environments.

Core Innovations in PETG Eco-Efficiency

applicator

PatentPendingEP3265166A1

Innovation

- A novel applicator with a container and nib configuration that uses a plurality of fibers and adhesive material to deliver a controlled release of acidic liquid to topical areas, allowing for safe and effective treatment of skin lesions without external pressure, targeting the lesion while minimizing impact on surrounding healthy tissue.

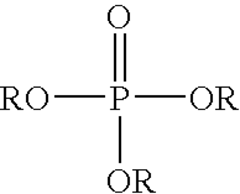

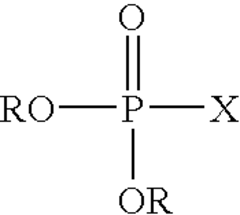

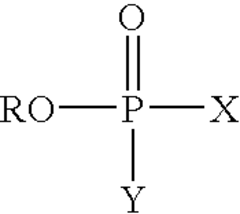

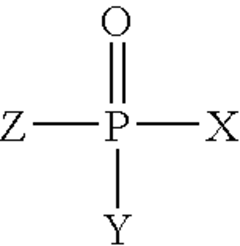

Molding compositions containing polyalkylene terephthalates and modified polybutylene terephthalate (PBT) random copolymers derived from PET

PatentActiveUS7855238B2

Innovation

- Development of molding compositions comprising modified polybutylene terephthalate random copolymers derived from PET, incorporating residues like ethylene glycol and isophthalic acid, and combining with polyalkylene terephthalate and additives to create materials with performance comparable to virgin PBT, while reducing CO2 emissions.

Environmental Regulations Impact on PETG Use

Environmental regulations have a significant impact on the use of PETG (Polyethylene Terephthalate Glycol-modified) in smart grid equipment. These regulations are designed to promote sustainability, reduce environmental impact, and ensure the safe disposal of materials used in electrical infrastructure.

One of the primary regulatory concerns is the end-of-life management of PETG components in smart grid equipment. Many countries have implemented strict regulations on the disposal and recycling of electronic waste, including the materials used in smart grid systems. These regulations often require manufacturers to establish take-back programs or participate in collective recycling schemes to ensure proper handling of discarded equipment.

The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive is a prime example of such regulations. It mandates that manufacturers of electrical and electronic equipment, including smart grid components, are responsible for the collection and recycling of their products at the end of their lifecycle. This has led to increased focus on the recyclability of PETG and its potential for reuse in new applications.

Additionally, regulations such as the Restriction of Hazardous Substances (RoHS) Directive have implications for the use of PETG in smart grid equipment. While PETG itself is not typically considered a hazardous substance, the additives and colorants used in its production may fall under regulatory scrutiny. Manufacturers must ensure that their PETG formulations comply with these regulations to avoid potential restrictions on their use in electrical equipment.

Energy efficiency standards also play a role in shaping the use of PETG in smart grid applications. Regulations like the EU's Ecodesign Directive set minimum energy efficiency requirements for various products, including some smart grid components. The thermal and electrical properties of PETG can impact the overall energy efficiency of equipment, making it necessary for manufacturers to carefully consider material selection to meet these standards.

Furthermore, emerging regulations on carbon footprint and lifecycle assessments are influencing material choices in smart grid equipment. As governments and organizations push for more sustainable practices, there is growing pressure to use materials with lower environmental impacts throughout their lifecycle. This has led to increased scrutiny of the production processes, energy consumption, and emissions associated with PETG manufacturing.

In response to these regulatory pressures, many manufacturers are exploring alternative materials or modified PETG formulations that offer improved environmental performance. This includes the development of bio-based PET variants and the incorporation of recycled content into PETG products. Such innovations aim to align with evolving environmental regulations while maintaining the desirable properties of PETG for smart grid applications.

One of the primary regulatory concerns is the end-of-life management of PETG components in smart grid equipment. Many countries have implemented strict regulations on the disposal and recycling of electronic waste, including the materials used in smart grid systems. These regulations often require manufacturers to establish take-back programs or participate in collective recycling schemes to ensure proper handling of discarded equipment.

The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive is a prime example of such regulations. It mandates that manufacturers of electrical and electronic equipment, including smart grid components, are responsible for the collection and recycling of their products at the end of their lifecycle. This has led to increased focus on the recyclability of PETG and its potential for reuse in new applications.

Additionally, regulations such as the Restriction of Hazardous Substances (RoHS) Directive have implications for the use of PETG in smart grid equipment. While PETG itself is not typically considered a hazardous substance, the additives and colorants used in its production may fall under regulatory scrutiny. Manufacturers must ensure that their PETG formulations comply with these regulations to avoid potential restrictions on their use in electrical equipment.

Energy efficiency standards also play a role in shaping the use of PETG in smart grid applications. Regulations like the EU's Ecodesign Directive set minimum energy efficiency requirements for various products, including some smart grid components. The thermal and electrical properties of PETG can impact the overall energy efficiency of equipment, making it necessary for manufacturers to carefully consider material selection to meet these standards.

Furthermore, emerging regulations on carbon footprint and lifecycle assessments are influencing material choices in smart grid equipment. As governments and organizations push for more sustainable practices, there is growing pressure to use materials with lower environmental impacts throughout their lifecycle. This has led to increased scrutiny of the production processes, energy consumption, and emissions associated with PETG manufacturing.

In response to these regulatory pressures, many manufacturers are exploring alternative materials or modified PETG formulations that offer improved environmental performance. This includes the development of bio-based PET variants and the incorporation of recycled content into PETG products. Such innovations aim to align with evolving environmental regulations while maintaining the desirable properties of PETG for smart grid applications.

Life Cycle Assessment of PETG in Smart Grids

Life Cycle Assessment (LCA) of PETG in smart grids is a crucial component in evaluating the eco-efficiency of this material in smart grid equipment. This assessment encompasses the entire lifecycle of PETG, from raw material extraction to end-of-life disposal, providing valuable insights into its environmental impact and sustainability within the context of smart grid applications.

The LCA process for PETG in smart grids typically begins with the extraction and processing of raw materials. This includes the production of ethylene glycol and terephthalic acid, the primary components of PETG. The energy consumption and emissions associated with these processes are carefully quantified and analyzed to establish a baseline for the material's environmental footprint.

Manufacturing of PETG components for smart grid equipment represents the next significant phase in the lifecycle. This stage involves the polymerization process, forming, and shaping of PETG into various components such as insulators, housings, and protective covers. The LCA examines the energy requirements, water usage, and potential emissions during manufacturing, as well as any waste generated in the process.

The transportation and distribution of PETG components to smart grid installation sites are also considered in the assessment. This includes evaluating the fuel consumption and associated emissions from various modes of transport, as well as any packaging materials used to protect the components during transit.

The use phase of PETG in smart grids is particularly important in the LCA. This stage focuses on the durability, performance, and maintenance requirements of PETG components over their operational lifespan. Factors such as resistance to weathering, electrical insulation properties, and potential energy savings due to improved grid efficiency are analyzed to determine the long-term environmental impact of using PETG in smart grid applications.

End-of-life considerations form the final stage of the LCA for PETG in smart grids. This involves assessing the recyclability of PETG components, the energy required for recycling processes, and the potential for material recovery. Additionally, the environmental impact of disposal methods for non-recyclable PETG waste is evaluated, including landfilling or incineration options.

Throughout the LCA, key environmental indicators are measured and analyzed. These typically include greenhouse gas emissions, energy consumption, water usage, and the potential for various forms of pollution. The assessment also considers the depletion of non-renewable resources and the overall carbon footprint associated with PETG use in smart grids.

By conducting a comprehensive LCA, stakeholders in the smart grid industry can make informed decisions about the use of PETG in equipment design and deployment. This analysis not only highlights the environmental pros and cons of PETG but also identifies opportunities for improving its eco-efficiency throughout its lifecycle in smart grid applications.

The LCA process for PETG in smart grids typically begins with the extraction and processing of raw materials. This includes the production of ethylene glycol and terephthalic acid, the primary components of PETG. The energy consumption and emissions associated with these processes are carefully quantified and analyzed to establish a baseline for the material's environmental footprint.

Manufacturing of PETG components for smart grid equipment represents the next significant phase in the lifecycle. This stage involves the polymerization process, forming, and shaping of PETG into various components such as insulators, housings, and protective covers. The LCA examines the energy requirements, water usage, and potential emissions during manufacturing, as well as any waste generated in the process.

The transportation and distribution of PETG components to smart grid installation sites are also considered in the assessment. This includes evaluating the fuel consumption and associated emissions from various modes of transport, as well as any packaging materials used to protect the components during transit.

The use phase of PETG in smart grids is particularly important in the LCA. This stage focuses on the durability, performance, and maintenance requirements of PETG components over their operational lifespan. Factors such as resistance to weathering, electrical insulation properties, and potential energy savings due to improved grid efficiency are analyzed to determine the long-term environmental impact of using PETG in smart grid applications.

End-of-life considerations form the final stage of the LCA for PETG in smart grids. This involves assessing the recyclability of PETG components, the energy required for recycling processes, and the potential for material recovery. Additionally, the environmental impact of disposal methods for non-recyclable PETG waste is evaluated, including landfilling or incineration options.

Throughout the LCA, key environmental indicators are measured and analyzed. These typically include greenhouse gas emissions, energy consumption, water usage, and the potential for various forms of pollution. The assessment also considers the depletion of non-renewable resources and the overall carbon footprint associated with PETG use in smart grids.

By conducting a comprehensive LCA, stakeholders in the smart grid industry can make informed decisions about the use of PETG in equipment design and deployment. This analysis not only highlights the environmental pros and cons of PETG but also identifies opportunities for improving its eco-efficiency throughout its lifecycle in smart grid applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!