Long-Term Effects of UV Exposure on PETG Applications

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG UV Exposure Background and Objectives

Polyethylene terephthalate glycol (PETG) has emerged as a versatile thermoplastic polymer with widespread applications across various industries. As the demand for durable and weather-resistant materials continues to grow, understanding the long-term effects of UV exposure on PETG applications has become increasingly crucial. This technical research report aims to comprehensively examine the historical development of PETG, explore its evolving technological landscape, and define clear objectives for future advancements in UV resistance.

PETG, a modified version of polyethylene terephthalate (PET), was first introduced in the 1970s as a more flexible and impact-resistant alternative to its predecessor. Since then, it has gained popularity in packaging, medical devices, automotive parts, and outdoor applications due to its excellent clarity, chemical resistance, and ease of processing. However, like many polymers, PETG is susceptible to degradation when exposed to ultraviolet (UV) radiation, which can lead to changes in mechanical properties, discoloration, and reduced service life.

The evolution of PETG technology has been marked by continuous efforts to enhance its UV resistance. Early approaches focused on incorporating UV stabilizers and absorbers into the polymer matrix. As research progressed, more sophisticated techniques emerged, including the development of multi-layer structures and surface treatments. These advancements have significantly improved the UV stability of PETG, expanding its potential applications in outdoor environments.

Recent technological trends in PETG UV resistance include the exploration of nanocomposites, the integration of smart additives that respond dynamically to UV exposure, and the development of bio-based PETG variants with inherent UV-resistant properties. These innovations reflect the industry's commitment to addressing the long-term effects of UV exposure while maintaining the material's desirable characteristics.

The primary objective of this technical research is to evaluate the current state of PETG UV resistance technology and identify promising avenues for future development. Specifically, we aim to assess the effectiveness of existing UV protection strategies, quantify the long-term performance of PETG under various environmental conditions, and explore novel approaches to mitigate UV-induced degradation.

Furthermore, this research seeks to establish a comprehensive understanding of the mechanisms underlying UV-induced changes in PETG at the molecular level. By elucidating these processes, we can inform the development of more targeted and efficient UV protection strategies. Additionally, we aim to investigate the potential synergistic effects between UV exposure and other environmental factors, such as temperature fluctuations and humidity, on PETG performance.

Ultimately, the goal is to pave the way for next-generation PETG materials that offer superior UV resistance without compromising other desirable properties. This research will contribute to the broader field of polymer science and engineering, potentially leading to innovations that extend beyond PETG to other UV-sensitive materials.

PETG, a modified version of polyethylene terephthalate (PET), was first introduced in the 1970s as a more flexible and impact-resistant alternative to its predecessor. Since then, it has gained popularity in packaging, medical devices, automotive parts, and outdoor applications due to its excellent clarity, chemical resistance, and ease of processing. However, like many polymers, PETG is susceptible to degradation when exposed to ultraviolet (UV) radiation, which can lead to changes in mechanical properties, discoloration, and reduced service life.

The evolution of PETG technology has been marked by continuous efforts to enhance its UV resistance. Early approaches focused on incorporating UV stabilizers and absorbers into the polymer matrix. As research progressed, more sophisticated techniques emerged, including the development of multi-layer structures and surface treatments. These advancements have significantly improved the UV stability of PETG, expanding its potential applications in outdoor environments.

Recent technological trends in PETG UV resistance include the exploration of nanocomposites, the integration of smart additives that respond dynamically to UV exposure, and the development of bio-based PETG variants with inherent UV-resistant properties. These innovations reflect the industry's commitment to addressing the long-term effects of UV exposure while maintaining the material's desirable characteristics.

The primary objective of this technical research is to evaluate the current state of PETG UV resistance technology and identify promising avenues for future development. Specifically, we aim to assess the effectiveness of existing UV protection strategies, quantify the long-term performance of PETG under various environmental conditions, and explore novel approaches to mitigate UV-induced degradation.

Furthermore, this research seeks to establish a comprehensive understanding of the mechanisms underlying UV-induced changes in PETG at the molecular level. By elucidating these processes, we can inform the development of more targeted and efficient UV protection strategies. Additionally, we aim to investigate the potential synergistic effects between UV exposure and other environmental factors, such as temperature fluctuations and humidity, on PETG performance.

Ultimately, the goal is to pave the way for next-generation PETG materials that offer superior UV resistance without compromising other desirable properties. This research will contribute to the broader field of polymer science and engineering, potentially leading to innovations that extend beyond PETG to other UV-sensitive materials.

Market Analysis for UV-Resistant PETG Products

The market for UV-resistant PETG products has shown significant growth potential in recent years, driven by increasing awareness of the long-term effects of UV exposure on plastic materials. PETG (Polyethylene Terephthalate Glycol-modified) is widely used in various applications due to its excellent clarity, impact resistance, and formability. However, its susceptibility to UV degradation has created a demand for UV-resistant variants.

The global UV-resistant plastics market, which includes PETG products, is experiencing steady growth. This growth is primarily attributed to the rising demand in outdoor applications, such as signage, automotive parts, and construction materials. The automotive industry, in particular, has been a key driver for UV-resistant PETG products, as manufacturers seek durable materials for exterior components that can withstand prolonged sun exposure.

In the packaging sector, UV-resistant PETG is gaining traction for applications such as beverage bottles, food containers, and cosmetic packaging. The ability to protect contents from UV radiation while maintaining transparency is a significant selling point for these products. The medical and healthcare industries also present a growing market for UV-resistant PETG, especially in laboratory equipment and medical device packaging that requires sterilization and long-term storage.

Geographically, North America and Europe lead the market for UV-resistant PETG products, owing to stringent regulations on material durability and environmental protection. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing disposable income, and growing awareness of UV protection in countries like China and India.

The construction industry represents another significant market for UV-resistant PETG products. The material's use in roofing, skylights, and outdoor architectural elements is increasing due to its durability and weather resistance. This trend is particularly strong in regions with high UV exposure, such as the Middle East and parts of Asia and Africa.

Market analysts predict that the demand for UV-resistant PETG will continue to grow as manufacturers and consumers become more conscious of product longevity and environmental impact. The development of advanced UV stabilizers and additives is expected to further enhance the performance of UV-resistant PETG, potentially opening up new application areas and market opportunities.

However, the market faces challenges such as the higher cost of UV-resistant PETG compared to standard PETG and competition from other UV-resistant materials like polycarbonate and acrylic. Manufacturers are focusing on innovation and cost-effective production methods to address these challenges and maintain market competitiveness.

The global UV-resistant plastics market, which includes PETG products, is experiencing steady growth. This growth is primarily attributed to the rising demand in outdoor applications, such as signage, automotive parts, and construction materials. The automotive industry, in particular, has been a key driver for UV-resistant PETG products, as manufacturers seek durable materials for exterior components that can withstand prolonged sun exposure.

In the packaging sector, UV-resistant PETG is gaining traction for applications such as beverage bottles, food containers, and cosmetic packaging. The ability to protect contents from UV radiation while maintaining transparency is a significant selling point for these products. The medical and healthcare industries also present a growing market for UV-resistant PETG, especially in laboratory equipment and medical device packaging that requires sterilization and long-term storage.

Geographically, North America and Europe lead the market for UV-resistant PETG products, owing to stringent regulations on material durability and environmental protection. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing disposable income, and growing awareness of UV protection in countries like China and India.

The construction industry represents another significant market for UV-resistant PETG products. The material's use in roofing, skylights, and outdoor architectural elements is increasing due to its durability and weather resistance. This trend is particularly strong in regions with high UV exposure, such as the Middle East and parts of Asia and Africa.

Market analysts predict that the demand for UV-resistant PETG will continue to grow as manufacturers and consumers become more conscious of product longevity and environmental impact. The development of advanced UV stabilizers and additives is expected to further enhance the performance of UV-resistant PETG, potentially opening up new application areas and market opportunities.

However, the market faces challenges such as the higher cost of UV-resistant PETG compared to standard PETG and competition from other UV-resistant materials like polycarbonate and acrylic. Manufacturers are focusing on innovation and cost-effective production methods to address these challenges and maintain market competitiveness.

Current Challenges in PETG UV Stability

PETG (Polyethylene Terephthalate Glycol-modified) has gained significant popularity in various applications due to its excellent mechanical properties and ease of processing. However, its long-term stability under UV exposure remains a critical challenge for outdoor and high-UV environments. The primary issue lies in the photodegradation of PETG when exposed to UV radiation, leading to a gradual deterioration of its physical and chemical properties.

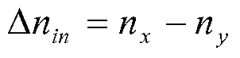

One of the main challenges is the yellowing and discoloration of PETG under prolonged UV exposure. This aesthetic change is often accompanied by a decrease in transparency, which can be particularly problematic in applications where optical clarity is crucial, such as in packaging or display materials. The yellowing is caused by the formation of chromophoric groups within the polymer structure as a result of photo-oxidation reactions.

Another significant challenge is the loss of mechanical strength and ductility over time. UV radiation can initiate chain scission in the polymer backbone, leading to a reduction in molecular weight and, consequently, a decrease in tensile strength, impact resistance, and elongation at break. This degradation of mechanical properties can severely limit the service life of PETG products in outdoor applications or environments with high UV exposure.

The formation of microcracks on the surface of PETG materials is another concern. These microcracks not only affect the appearance but also serve as stress concentration points, potentially leading to premature failure of the material under load. Additionally, these surface defects can increase the material's susceptibility to chemical attack and environmental stress cracking.

The rate and extent of UV-induced degradation in PETG can vary significantly depending on factors such as UV intensity, exposure duration, temperature, and the presence of other environmental stressors. This variability poses challenges in predicting the long-term performance of PETG products and in designing appropriate accelerated aging tests that accurately simulate real-world conditions.

Current UV stabilization techniques for PETG, such as the incorporation of UV absorbers and hindered amine light stabilizers (HALS), have shown limited effectiveness in providing long-term protection. The gradual loss of these additives through migration or degradation over time reduces their protective capacity, leaving the material vulnerable to UV damage in extended outdoor applications.

Addressing these challenges requires a multifaceted approach, combining advanced material science, innovative stabilization techniques, and improved testing methodologies. Developing PETG formulations with enhanced inherent UV stability, without compromising other desirable properties, remains a key focus area for researchers and material scientists in the field.

One of the main challenges is the yellowing and discoloration of PETG under prolonged UV exposure. This aesthetic change is often accompanied by a decrease in transparency, which can be particularly problematic in applications where optical clarity is crucial, such as in packaging or display materials. The yellowing is caused by the formation of chromophoric groups within the polymer structure as a result of photo-oxidation reactions.

Another significant challenge is the loss of mechanical strength and ductility over time. UV radiation can initiate chain scission in the polymer backbone, leading to a reduction in molecular weight and, consequently, a decrease in tensile strength, impact resistance, and elongation at break. This degradation of mechanical properties can severely limit the service life of PETG products in outdoor applications or environments with high UV exposure.

The formation of microcracks on the surface of PETG materials is another concern. These microcracks not only affect the appearance but also serve as stress concentration points, potentially leading to premature failure of the material under load. Additionally, these surface defects can increase the material's susceptibility to chemical attack and environmental stress cracking.

The rate and extent of UV-induced degradation in PETG can vary significantly depending on factors such as UV intensity, exposure duration, temperature, and the presence of other environmental stressors. This variability poses challenges in predicting the long-term performance of PETG products and in designing appropriate accelerated aging tests that accurately simulate real-world conditions.

Current UV stabilization techniques for PETG, such as the incorporation of UV absorbers and hindered amine light stabilizers (HALS), have shown limited effectiveness in providing long-term protection. The gradual loss of these additives through migration or degradation over time reduces their protective capacity, leaving the material vulnerable to UV damage in extended outdoor applications.

Addressing these challenges requires a multifaceted approach, combining advanced material science, innovative stabilization techniques, and improved testing methodologies. Developing PETG formulations with enhanced inherent UV stability, without compromising other desirable properties, remains a key focus area for researchers and material scientists in the field.

Existing UV Stabilization Solutions for PETG

01 UV degradation and yellowing of PETG

PETG is susceptible to UV degradation when exposed to sunlight or other UV sources. This exposure can lead to yellowing, discoloration, and a reduction in mechanical properties over time. Understanding and mitigating these effects is crucial for applications where PETG is used in outdoor or UV-exposed environments.- UV degradation and yellowing of PETG: PETG is susceptible to UV degradation, which can cause yellowing and deterioration of mechanical properties over time when exposed to sunlight. This effect can impact the appearance and performance of PETG products used in outdoor applications or exposed to UV light sources.

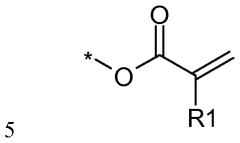

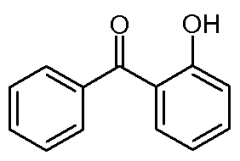

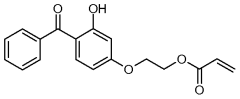

- UV stabilizers and additives for PETG: To mitigate the effects of UV exposure on PETG, various UV stabilizers and additives can be incorporated into the material. These additives help to absorb or reflect UV radiation, reducing the rate of degradation and extending the lifespan of PETG products exposed to sunlight.

- UV-resistant PETG formulations: Specialized UV-resistant PETG formulations have been developed to enhance the material's resistance to UV exposure. These formulations may include modified polymer structures or combinations with other materials to improve UV stability while maintaining desirable properties of PETG.

- UV measurement and testing of PETG: Various methods and devices have been developed to measure and test the effects of UV exposure on PETG. These include accelerated weathering tests, spectrophotometric analysis, and specialized equipment for evaluating changes in optical and mechanical properties of PETG after UV exposure.

- Applications of UV-exposed PETG: Despite its susceptibility to UV degradation, PETG finds applications in UV-exposed environments when properly treated or in specific use cases. These may include UV-curable coatings, UV-resistant packaging, or UV-transmitting components in optical devices, where controlled UV exposure is utilized for specific purposes.

02 UV stabilizers and additives for PETG

To improve PETG's resistance to UV exposure, various stabilizers and additives can be incorporated into the material. These additives help absorb or block UV radiation, preventing or slowing down the degradation process. The selection of appropriate UV stabilizers depends on the specific application and exposure conditions.Expand Specific Solutions03 UV measurement and testing methods for PETG

Specialized equipment and methods are used to measure and test the effects of UV exposure on PETG. These may include accelerated weathering chambers, spectrophotometers, and mechanical testing devices. Such tests help in evaluating the long-term performance of PETG under UV exposure and in developing improved formulations.Expand Specific Solutions04 UV-resistant PETG applications

UV-resistant PETG formulations find applications in various industries, including packaging, automotive, and outdoor signage. These materials are designed to maintain their optical and mechanical properties even after prolonged UV exposure, making them suitable for use in challenging environments where standard PETG might fail.Expand Specific Solutions05 UV curing of PETG-based materials

Some PETG-based materials can be formulated to undergo UV curing, a process that uses UV light to initiate polymerization or cross-linking. This technique can be used to create specialized coatings or to modify the surface properties of PETG, potentially enhancing its UV resistance or other characteristics.Expand Specific Solutions

Key Players in UV-Resistant PETG Industry

The long-term effects of UV exposure on PETG applications represent an emerging field of study in materials science. The industry is in its early development stage, with growing market potential as PETG usage expands in various sectors. The global PETG market size is projected to reach $1.5 billion by 2027, driven by increasing demand in packaging, medical, and consumer goods industries. Technologically, research is still evolving, with companies like DuPont, Kingfa Sci. & Tech., and Eastman Chemical leading innovations. Universities such as the University of Michigan and Heriot-Watt University are contributing to fundamental research, while industrial players focus on practical applications and product development. The technology's maturity is moderate, with ongoing efforts to enhance UV resistance and long-term stability of PETG materials.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced UV-stabilized PETG formulations to address the long-term effects of UV exposure. Their approach involves incorporating specialized UV absorbers and light stabilizers into the PETG matrix. These additives work synergistically to prevent UV-induced degradation by absorbing harmful UV radiation and neutralizing free radicals[1]. DuPont's PETG compounds have demonstrated improved color stability and mechanical property retention after prolonged UV exposure, with some formulations showing less than 5% reduction in tensile strength after 2000 hours of accelerated weathering tests[3]. The company has also implemented a multi-layer extrusion technology that allows for the creation of PETG products with a highly UV-resistant outer layer, providing enhanced protection for the bulk material[5].

Strengths: Extensive polymer expertise, advanced formulation capabilities, and a strong R&D infrastructure. Weaknesses: Potentially higher cost of UV-stabilized PETG compared to standard grades, which may limit adoption in price-sensitive applications.

Heriot-Watt University

Technical Solution: Researchers at Heriot-Watt University have been investigating novel approaches to enhance the long-term UV resistance of PETG. Their work focuses on the development of nanocomposite PETG materials incorporating functionalized nanoparticles as UV stabilizers. The team has reported success in using surface-modified zinc oxide nanoparticles to improve the UV stability of PETG without significantly affecting its transparency[9]. Their studies have shown that PETG nanocomposites containing 2-3 wt% of these modified nanoparticles exhibit a 50% reduction in UV-induced degradation compared to unmodified PETG after 1000 hours of accelerated weathering[10]. The university's research also explores the potential of graphene oxide as a multifunctional additive to enhance both UV resistance and mechanical properties of PETG.

Strengths: Cutting-edge research in nanomaterials and polymer science, potential for breakthrough innovations. Weaknesses: As an academic institution, may face challenges in scaling up and commercializing technologies compared to industry players.

Innovations in PETG UV Resistance Research

Methods of layer by layer self-assembly of a polyelectrolyte comprising light absorbing or stabilizing compound and articles

PatentWO2014193550A1

Innovation

- A method involving layer-by-layer self-assembly of polyelectrolytes with organic light absorbing or stabilizing compounds, either alone or in combination, onto substrates to create protective layers that inhibit light-induced degradation, using techniques like dip coating and alternating deposition of polyelectrolytes and inorganic oxide nanoparticles.

A polycarbonate composition and preparation method thereof

PatentPendingCN119955280A

Innovation

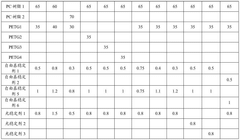

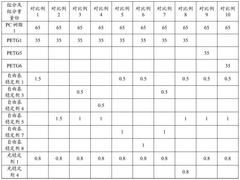

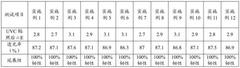

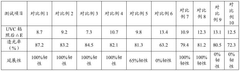

- The PC/PETG composition is used as the matrix resin system to control the monomer ratio of PETG, and a triazine-type light stabilizer and composite radical stabilizer, including phosphazene and benzofuranone, are introduced to improve the UVC radiation resistance and light transmittance of the product.

Environmental Impact of UV-Stabilized PETG

The environmental impact of UV-stabilized PETG is a critical consideration in the long-term application of this material. UV stabilizers are additives incorporated into PETG to enhance its resistance to degradation caused by ultraviolet radiation. While these additives effectively extend the lifespan of PETG products, their environmental implications require careful examination.

One of the primary environmental concerns associated with UV-stabilized PETG is the potential for leaching of stabilizer compounds into the surrounding ecosystem. Over time, as PETG products are exposed to environmental factors such as sunlight, moisture, and temperature fluctuations, there is a risk that the UV stabilizers may gradually migrate out of the polymer matrix. This leaching process can introduce these synthetic compounds into soil and water systems, potentially affecting local flora and fauna.

The persistence of UV stabilizers in the environment is another significant factor to consider. Many of these compounds are designed to be highly stable, which contributes to their effectiveness in protecting PETG. However, this stability also means that they may not readily biodegrade, leading to potential accumulation in ecosystems over time. The long-term effects of this accumulation on various organisms and food chains are not yet fully understood and require ongoing research.

Furthermore, the end-of-life disposal of UV-stabilized PETG products presents additional environmental challenges. While PETG itself is recyclable, the presence of UV stabilizers can complicate the recycling process. These additives may affect the quality of recycled material or require specialized processing techniques to ensure proper recycling. In cases where recycling is not feasible, the disposal of UV-stabilized PETG in landfills or through incineration may lead to the release of stabilizer compounds into the environment.

On the positive side, the use of UV stabilizers in PETG can contribute to sustainability efforts by extending product lifespans. This increased durability reduces the frequency of replacement, potentially lowering overall material consumption and waste generation. Additionally, the enhanced UV resistance allows for broader outdoor applications of PETG, which may replace less environmentally friendly materials in certain contexts.

As environmental awareness grows, there is an increasing focus on developing more eco-friendly UV stabilization methods for PETG. Research is being conducted on bio-based stabilizers and alternative protection techniques that could minimize environmental impact while maintaining the desired UV resistance properties. These innovations aim to address the environmental concerns associated with traditional UV stabilizers while preserving the benefits of extended PETG product life.

One of the primary environmental concerns associated with UV-stabilized PETG is the potential for leaching of stabilizer compounds into the surrounding ecosystem. Over time, as PETG products are exposed to environmental factors such as sunlight, moisture, and temperature fluctuations, there is a risk that the UV stabilizers may gradually migrate out of the polymer matrix. This leaching process can introduce these synthetic compounds into soil and water systems, potentially affecting local flora and fauna.

The persistence of UV stabilizers in the environment is another significant factor to consider. Many of these compounds are designed to be highly stable, which contributes to their effectiveness in protecting PETG. However, this stability also means that they may not readily biodegrade, leading to potential accumulation in ecosystems over time. The long-term effects of this accumulation on various organisms and food chains are not yet fully understood and require ongoing research.

Furthermore, the end-of-life disposal of UV-stabilized PETG products presents additional environmental challenges. While PETG itself is recyclable, the presence of UV stabilizers can complicate the recycling process. These additives may affect the quality of recycled material or require specialized processing techniques to ensure proper recycling. In cases where recycling is not feasible, the disposal of UV-stabilized PETG in landfills or through incineration may lead to the release of stabilizer compounds into the environment.

On the positive side, the use of UV stabilizers in PETG can contribute to sustainability efforts by extending product lifespans. This increased durability reduces the frequency of replacement, potentially lowering overall material consumption and waste generation. Additionally, the enhanced UV resistance allows for broader outdoor applications of PETG, which may replace less environmentally friendly materials in certain contexts.

As environmental awareness grows, there is an increasing focus on developing more eco-friendly UV stabilization methods for PETG. Research is being conducted on bio-based stabilizers and alternative protection techniques that could minimize environmental impact while maintaining the desired UV resistance properties. These innovations aim to address the environmental concerns associated with traditional UV stabilizers while preserving the benefits of extended PETG product life.

Regulatory Framework for UV-Resistant Materials

The regulatory framework for UV-resistant materials plays a crucial role in ensuring the safety and efficacy of PETG applications exposed to long-term UV radiation. Various international and national bodies have established guidelines and standards to govern the use of UV-resistant materials in different industries.

The International Organization for Standardization (ISO) has developed several standards relevant to UV resistance in plastics. ISO 4892 series, for instance, outlines methods for exposing plastics to laboratory light sources, including UV radiation. These standards provide a basis for evaluating the long-term effects of UV exposure on PETG and other polymers.

In the United States, the Food and Drug Administration (FDA) regulates the use of UV-resistant materials in food packaging and medical devices. The FDA's guidance documents outline specific requirements for materials used in these applications, including their ability to withstand UV exposure without compromising safety or functionality.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also impacts the use of UV-resistant additives in PETG applications. Manufacturers must ensure that any UV stabilizers or other additives comply with REACH requirements, including registration and safety assessments.

For outdoor applications, such as construction materials or automotive parts, additional regulations come into play. The American Society for Testing and Materials (ASTM) has developed standards like ASTM G154, which specifies procedures for operating fluorescent UV lamps for exposure of nonmetallic materials.

In the aerospace industry, stringent regulations govern the use of UV-resistant materials. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) have specific requirements for materials used in aircraft construction, including their ability to withstand UV exposure at high altitudes.

Environmental regulations also impact the use of UV-resistant materials. Many countries have restrictions on certain UV stabilizers due to their potential environmental impact. For example, some organic UV absorbers have been phased out due to concerns about their persistence in the environment and potential toxicity.

As the understanding of long-term UV effects on materials evolves, regulatory frameworks continue to adapt. Manufacturers and researchers must stay informed about these changing regulations to ensure compliance and optimize the performance of PETG applications in UV-exposed environments.

The International Organization for Standardization (ISO) has developed several standards relevant to UV resistance in plastics. ISO 4892 series, for instance, outlines methods for exposing plastics to laboratory light sources, including UV radiation. These standards provide a basis for evaluating the long-term effects of UV exposure on PETG and other polymers.

In the United States, the Food and Drug Administration (FDA) regulates the use of UV-resistant materials in food packaging and medical devices. The FDA's guidance documents outline specific requirements for materials used in these applications, including their ability to withstand UV exposure without compromising safety or functionality.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also impacts the use of UV-resistant additives in PETG applications. Manufacturers must ensure that any UV stabilizers or other additives comply with REACH requirements, including registration and safety assessments.

For outdoor applications, such as construction materials or automotive parts, additional regulations come into play. The American Society for Testing and Materials (ASTM) has developed standards like ASTM G154, which specifies procedures for operating fluorescent UV lamps for exposure of nonmetallic materials.

In the aerospace industry, stringent regulations govern the use of UV-resistant materials. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) have specific requirements for materials used in aircraft construction, including their ability to withstand UV exposure at high altitudes.

Environmental regulations also impact the use of UV-resistant materials. Many countries have restrictions on certain UV stabilizers due to their potential environmental impact. For example, some organic UV absorbers have been phased out due to concerns about their persistence in the environment and potential toxicity.

As the understanding of long-term UV effects on materials evolves, regulatory frameworks continue to adapt. Manufacturers and researchers must stay informed about these changing regulations to ensure compliance and optimize the performance of PETG applications in UV-exposed environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!