Innovations in PETG Recycling to Achieve Zero Waste

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Recycling Evolution

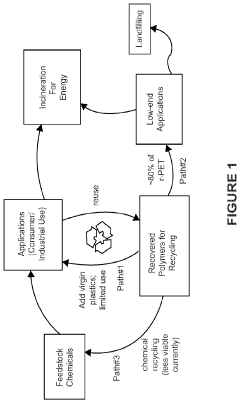

The recycling of PETG (Polyethylene Terephthalate Glycol-modified) has undergone significant evolution over the past few decades, driven by increasing environmental concerns and the push towards a circular economy. Initially, PETG was considered difficult to recycle due to its unique chemical properties, which differ from standard PET.

In the early stages of PETG recycling, the material was often downcycled into lower-grade products or incinerated for energy recovery. This approach, while better than landfilling, did not fully capitalize on the material's potential for reuse. As awareness of plastic pollution grew, researchers and industry professionals began exploring more efficient recycling methods for PETG.

The mid-2000s saw the development of improved mechanical recycling techniques for PETG. These processes involved sorting, grinding, washing, and reprocessing the material into pellets for reuse. However, the recycled PETG often suffered from degraded properties, limiting its applications.

A significant breakthrough came with the advent of chemical recycling methods in the 2010s. Depolymerization techniques, such as methanolysis and glycolysis, allowed PETG to be broken down into its constituent monomers. These could then be purified and repolymerized into virgin-quality PETG, effectively closing the loop on the material's lifecycle.

Recent years have seen the integration of advanced technologies in PETG recycling. Artificial intelligence and machine learning have been employed to improve sorting efficiency, while robotics have enhanced the automation of recycling processes. These innovations have significantly increased the purity of recycled PETG streams, leading to higher-quality recycled materials.

The latest frontier in PETG recycling involves the development of bio-based and biodegradable alternatives. Researchers are exploring ways to create PETG-like materials from renewable sources that maintain the desirable properties of traditional PETG while being more environmentally friendly at end-of-life.

As we move towards a zero-waste future, the focus has shifted to designing PETG products with recycling in mind. This "design for recycling" approach considers the entire lifecycle of the product, from production to disposal and recycling. It includes innovations such as easily separable multi-material products and the use of compatible additives that do not hinder recycling processes.

In the early stages of PETG recycling, the material was often downcycled into lower-grade products or incinerated for energy recovery. This approach, while better than landfilling, did not fully capitalize on the material's potential for reuse. As awareness of plastic pollution grew, researchers and industry professionals began exploring more efficient recycling methods for PETG.

The mid-2000s saw the development of improved mechanical recycling techniques for PETG. These processes involved sorting, grinding, washing, and reprocessing the material into pellets for reuse. However, the recycled PETG often suffered from degraded properties, limiting its applications.

A significant breakthrough came with the advent of chemical recycling methods in the 2010s. Depolymerization techniques, such as methanolysis and glycolysis, allowed PETG to be broken down into its constituent monomers. These could then be purified and repolymerized into virgin-quality PETG, effectively closing the loop on the material's lifecycle.

Recent years have seen the integration of advanced technologies in PETG recycling. Artificial intelligence and machine learning have been employed to improve sorting efficiency, while robotics have enhanced the automation of recycling processes. These innovations have significantly increased the purity of recycled PETG streams, leading to higher-quality recycled materials.

The latest frontier in PETG recycling involves the development of bio-based and biodegradable alternatives. Researchers are exploring ways to create PETG-like materials from renewable sources that maintain the desirable properties of traditional PETG while being more environmentally friendly at end-of-life.

As we move towards a zero-waste future, the focus has shifted to designing PETG products with recycling in mind. This "design for recycling" approach considers the entire lifecycle of the product, from production to disposal and recycling. It includes innovations such as easily separable multi-material products and the use of compatible additives that do not hinder recycling processes.

Circular Economy Demand

The circular economy concept has gained significant traction in recent years, driving a growing demand for innovative recycling solutions, particularly in the plastics industry. PETG (Polyethylene Terephthalate Glycol-modified), a widely used plastic in packaging and manufacturing, has become a focal point for recycling efforts due to its prevalence and potential for reuse.

Market analysis indicates a substantial increase in demand for circular economy solutions, with the global circular economy market projected to expand rapidly. This growth is fueled by increasing environmental awareness, stringent regulations on plastic waste, and corporate sustainability initiatives. The PETG recycling sector, in particular, is experiencing heightened interest from both consumers and businesses seeking to reduce their environmental footprint.

Consumer preferences are shifting towards eco-friendly products and packaging, creating a pull effect for recycled PETG materials. Major brands across various industries, including food and beverage, cosmetics, and consumer electronics, are committing to incorporating recycled plastics into their packaging, further driving demand for innovative PETG recycling technologies.

Government policies and regulations play a crucial role in shaping the circular economy landscape. Many countries have implemented or are considering legislation to promote plastic recycling and reduce single-use plastics. These regulatory pressures are compelling businesses to seek out effective PETG recycling solutions to comply with new standards and avoid potential penalties.

The economic potential of PETG recycling is substantial. As virgin plastic prices fluctuate and recycling technologies improve, recycled PETG is becoming increasingly cost-competitive. This economic incentive is encouraging investment in recycling infrastructure and technologies, creating a positive feedback loop that further drives demand for circular economy solutions.

Industry collaborations and partnerships are emerging as key drivers in the circular economy for PETG. Companies across the value chain, from plastic manufacturers to recyclers and end-users, are forming alliances to develop closed-loop systems for PETG recycling. These collaborations are not only addressing technical challenges but also creating new market opportunities and business models centered around recycled PETG.

The demand for circular economy solutions in PETG recycling extends beyond mere material recovery. There is a growing interest in technologies that can upcycle PETG waste into higher-value products, expanding the potential applications and market for recycled materials. This trend is spurring innovation in chemical recycling processes and material science to enhance the quality and versatility of recycled PETG.

Market analysis indicates a substantial increase in demand for circular economy solutions, with the global circular economy market projected to expand rapidly. This growth is fueled by increasing environmental awareness, stringent regulations on plastic waste, and corporate sustainability initiatives. The PETG recycling sector, in particular, is experiencing heightened interest from both consumers and businesses seeking to reduce their environmental footprint.

Consumer preferences are shifting towards eco-friendly products and packaging, creating a pull effect for recycled PETG materials. Major brands across various industries, including food and beverage, cosmetics, and consumer electronics, are committing to incorporating recycled plastics into their packaging, further driving demand for innovative PETG recycling technologies.

Government policies and regulations play a crucial role in shaping the circular economy landscape. Many countries have implemented or are considering legislation to promote plastic recycling and reduce single-use plastics. These regulatory pressures are compelling businesses to seek out effective PETG recycling solutions to comply with new standards and avoid potential penalties.

The economic potential of PETG recycling is substantial. As virgin plastic prices fluctuate and recycling technologies improve, recycled PETG is becoming increasingly cost-competitive. This economic incentive is encouraging investment in recycling infrastructure and technologies, creating a positive feedback loop that further drives demand for circular economy solutions.

Industry collaborations and partnerships are emerging as key drivers in the circular economy for PETG. Companies across the value chain, from plastic manufacturers to recyclers and end-users, are forming alliances to develop closed-loop systems for PETG recycling. These collaborations are not only addressing technical challenges but also creating new market opportunities and business models centered around recycled PETG.

The demand for circular economy solutions in PETG recycling extends beyond mere material recovery. There is a growing interest in technologies that can upcycle PETG waste into higher-value products, expanding the potential applications and market for recycled materials. This trend is spurring innovation in chemical recycling processes and material science to enhance the quality and versatility of recycled PETG.

PETG Recycling Challenges

PETG (Polyethylene Terephthalate Glycol-modified) recycling faces several significant challenges that hinder the achievement of zero waste in its lifecycle. One of the primary obstacles is the lack of widespread collection and sorting infrastructure specifically designed for PETG materials. Unlike more common plastics such as PET, PETG is often misclassified or mixed with other plastic waste streams, making it difficult to isolate and process effectively.

The chemical composition of PETG presents another hurdle in recycling efforts. The glycol modification that gives PETG its desirable properties also makes it more challenging to recycle compared to standard PET. The presence of glycol alters the melting behavior and chemical structure, requiring specialized recycling processes that are not widely available in most recycling facilities.

Contamination is a persistent issue in PETG recycling. The material is often used in food packaging and medical applications, which can lead to organic residues and potential biohazards. These contaminants must be thoroughly removed before recycling, adding complexity and cost to the process. Additionally, PETG products frequently incorporate additives, colorants, and multi-layer structures that further complicate recycling efforts.

The economic viability of PETG recycling poses another significant challenge. The relatively low volume of PETG waste compared to other plastics means that establishing dedicated recycling streams and facilities is often not cost-effective. This economic barrier has led to a lack of investment in PETG-specific recycling technologies and infrastructure.

Technical limitations in recycling processes also contribute to the challenges. Current mechanical recycling methods may result in degradation of PETG's properties, limiting the applications for recycled material. Chemical recycling techniques, while promising, are still in the early stages of development and face scalability issues.

Market demand for recycled PETG is another factor impeding progress towards zero waste. Many industries that use PETG require high-quality, virgin material to meet stringent performance and regulatory standards, particularly in medical and food packaging applications. This preference for virgin PETG creates a barrier to closing the recycling loop.

Lastly, the lack of standardization in PETG formulations across manufacturers complicates recycling efforts. Variations in the glycol content and other additives can lead to inconsistencies in recycled material properties, making it difficult to produce a uniform, high-quality recycled PETG product that meets industry specifications.

The chemical composition of PETG presents another hurdle in recycling efforts. The glycol modification that gives PETG its desirable properties also makes it more challenging to recycle compared to standard PET. The presence of glycol alters the melting behavior and chemical structure, requiring specialized recycling processes that are not widely available in most recycling facilities.

Contamination is a persistent issue in PETG recycling. The material is often used in food packaging and medical applications, which can lead to organic residues and potential biohazards. These contaminants must be thoroughly removed before recycling, adding complexity and cost to the process. Additionally, PETG products frequently incorporate additives, colorants, and multi-layer structures that further complicate recycling efforts.

The economic viability of PETG recycling poses another significant challenge. The relatively low volume of PETG waste compared to other plastics means that establishing dedicated recycling streams and facilities is often not cost-effective. This economic barrier has led to a lack of investment in PETG-specific recycling technologies and infrastructure.

Technical limitations in recycling processes also contribute to the challenges. Current mechanical recycling methods may result in degradation of PETG's properties, limiting the applications for recycled material. Chemical recycling techniques, while promising, are still in the early stages of development and face scalability issues.

Market demand for recycled PETG is another factor impeding progress towards zero waste. Many industries that use PETG require high-quality, virgin material to meet stringent performance and regulatory standards, particularly in medical and food packaging applications. This preference for virgin PETG creates a barrier to closing the recycling loop.

Lastly, the lack of standardization in PETG formulations across manufacturers complicates recycling efforts. Variations in the glycol content and other additives can lead to inconsistencies in recycled material properties, making it difficult to produce a uniform, high-quality recycled PETG product that meets industry specifications.

Current PETG Recycling

01 Chemical recycling of PETG waste

Chemical recycling methods are used to break down PETG waste into its constituent monomers or other valuable chemicals. This process involves depolymerization techniques such as glycolysis, methanolysis, or hydrolysis. The resulting monomers can be purified and reused to produce new PETG or other products, effectively closing the recycling loop.- PETG waste recycling methods: Various methods for recycling PETG waste have been developed, including mechanical recycling, chemical recycling, and thermal processes. These methods aim to convert PETG waste into reusable materials or chemical feedstocks, reducing environmental impact and promoting circular economy principles.

- PETG waste sorting and pretreatment: Efficient sorting and pretreatment of PETG waste are crucial steps in the recycling process. This involves separating PETG from other plastics, removing contaminants, and preparing the material for further processing. Advanced sorting technologies and cleaning methods are employed to improve the quality of recycled PETG.

- Chemical recycling of PETG: Chemical recycling processes break down PETG waste into its constituent monomers or other valuable chemical compounds. This approach allows for the production of high-quality recycled materials that can be used in various applications, including food-grade packaging.

- PETG recycling equipment and systems: Specialized equipment and systems have been developed for PETG recycling, including grinding machines, extrusion systems, and pelletizing units. These technologies are designed to efficiently process PETG waste and produce high-quality recycled materials suitable for various applications.

- Applications of recycled PETG: Recycled PETG finds applications in various industries, including packaging, textiles, and construction. Research focuses on improving the properties of recycled PETG to expand its use in high-value applications, such as food packaging and automotive parts, thereby increasing the demand for recycled PETG and promoting a circular economy.

02 Mechanical recycling of PETG waste

Mechanical recycling processes involve sorting, cleaning, shredding, and melting PETG waste to produce recycled pellets or flakes. These can be used in various applications, including the production of new PETG products or as raw materials for other plastic products. This method is often more cost-effective and energy-efficient compared to chemical recycling for certain types of PETG waste.Expand Specific Solutions03 Separation and purification of PETG from mixed plastic waste

Techniques for separating PETG from other plastic waste streams are crucial for effective recycling. This includes methods such as density separation, optical sorting, and selective dissolution. Purification processes are then applied to remove contaminants and improve the quality of the recycled PETG, making it suitable for high-value applications.Expand Specific Solutions04 Upcycling of PETG waste into high-value products

Innovative approaches to transform PETG waste into higher-value products are being developed. This includes the production of specialty chemicals, composite materials, or advanced polymers. These upcycling methods aim to create new markets for recycled PETG and improve the economic viability of recycling processes.Expand Specific Solutions05 Equipment and systems for PETG waste recycling

Specialized equipment and integrated systems are designed for efficient PETG waste recycling. This includes sorting machines, shredders, extruders, and reactors optimized for PETG processing. Automated systems and advanced control mechanisms are incorporated to improve the efficiency and quality of the recycling process.Expand Specific Solutions

Key PETG Recyclers

The recycling of PETG (Polyethylene Terephthalate Glycol-modified) is an emerging field within the broader plastic recycling industry. The market is in its early growth stage, with increasing demand for sustainable packaging solutions driving innovation. The global PETG market size is projected to expand significantly in the coming years, fueled by its versatility and recyclability. Technologically, PETG recycling is advancing, but still faces challenges in achieving full circularity. Companies like Eastman Chemical Co. are leading the way with molecular recycling technologies, while academic institutions such as the University of North Carolina at Chapel Hill and Washington State University are contributing to research and development efforts. The involvement of both industry leaders and research institutions indicates a growing focus on developing efficient PETG recycling solutions to meet sustainability goals.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has developed a revolutionary molecular recycling technology for PETG called "polyester renewal technology" (PRT). This process breaks down PETG waste into its basic molecular building blocks, which can then be used to create new, virgin-quality materials. The PRT process can handle mixed plastic waste streams, including those containing colored PETG, which are typically difficult to recycle using traditional mechanical methods[1]. Eastman's technology can recycle PETG products that are traditionally considered non-recyclable, such as textiles and carpets, effectively diverting them from landfills and incinerators[2]. The company has invested in large-scale molecular recycling facilities, with plans to recycle up to 250 million pounds of plastic waste annually by 2025[3].

Strengths: Ability to handle mixed and colored PETG waste, production of virgin-quality recycled material, and potential for closed-loop recycling. Weaknesses: High initial investment costs and energy requirements for the molecular recycling process.

East China University of Science & Technology

Technical Solution: East China University of Science & Technology has developed an advanced chemical recycling process for PETG using a novel solvolysis technique. This method employs environmentally friendly solvents and catalysts to selectively depolymerize PETG into its constituent monomers under mild conditions[13]. The researchers have optimized the process to achieve high conversion rates and selectivity, resulting in monomers suitable for direct repolymerization into virgin-quality PETG. The university has also explored the use of ionic liquids as both solvents and catalysts in the PETG recycling process, demonstrating improved efficiency and recyclability of the reaction medium[14]. Furthermore, they have investigated the integration of membrane separation technologies to purify the recovered monomers, enhancing the overall sustainability of the recycling process by reducing energy consumption and solvent usage[15].

Strengths: High monomer recovery rates, potential for closed-loop recycling, and use of environmentally friendly solvents. Weaknesses: Potential high costs of specialized solvents and catalysts, and the need for efficient separation and purification processes.

PETG Recycling Patents

Methods for chemical recycling of condensation polymers

PatentPendingUS20240182665A1

Innovation

- A method involving melt-processing a condensation polymer with an internal catalyst to increase its amorphous content, followed by depolymerization in a reactive solvent, which enhances the efficiency and rate of the depolymerization process, allowing for the production of monomers that can be reused as chemical feedstocks.

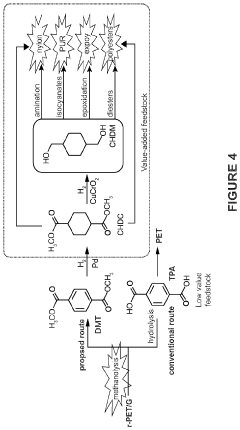

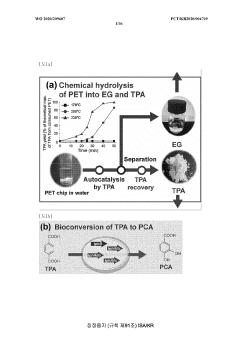

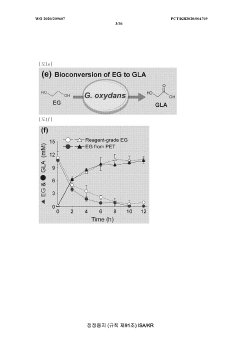

Method for producing high value-added compounds from polyethylene terephthalate

PatentWO2020209607A1

Innovation

- A method involving chemical hydrolysis of PET to produce terephthalic acid and ethylene glycol, followed by biotransformation using metabolically engineered microorganisms to convert these monomers into high-value compounds such as gallic acid, pyrogallol, catechol, muconic acid, and vanillic acid, and glycolic acid, leveraging enzymes like TPA 1,2-deoxygenase, DCD dehydrogenase, p-hydroxybenzoate hydroxylase, and O-methyltransferase.

Environmental Regulations

Environmental regulations play a crucial role in shaping the landscape of PETG recycling and the pursuit of zero waste initiatives. As governments and international organizations increasingly prioritize sustainability and circular economy principles, the regulatory framework surrounding PETG recycling has become more stringent and comprehensive.

In recent years, many countries have implemented extended producer responsibility (EPR) programs, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. These regulations have significantly impacted the PETG recycling industry by incentivizing companies to invest in more efficient recycling technologies and design products with recyclability in mind.

The European Union has been at the forefront of environmental regulations with its Circular Economy Action Plan, which sets ambitious targets for plastic recycling and waste reduction. This plan includes specific measures for PETG and other plastic materials, such as mandatory recycled content requirements and restrictions on single-use plastics. These regulations have driven innovation in PETG recycling technologies and encouraged the development of more sustainable packaging solutions.

In the United States, while federal regulations on PETG recycling are less comprehensive, individual states have taken the lead in implementing their own recycling laws. California, for instance, has enacted legislation requiring a minimum percentage of recycled content in plastic beverage containers, including those made from PETG. This has spurred investment in recycling infrastructure and technologies within the state.

Asian countries, particularly China and Japan, have also introduced stricter regulations on plastic waste and recycling. China's ban on importing plastic waste has forced many countries to develop domestic recycling capabilities, including for PETG materials. Japan's comprehensive recycling laws have led to high recycling rates and innovative approaches to plastic waste management.

International agreements, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, have been amended to include plastic waste. This has implications for the global trade of PETG waste and recycled materials, encouraging countries to develop local recycling capacities and reduce reliance on exporting waste.

As environmental regulations continue to evolve, they are likely to drive further innovations in PETG recycling technologies. Future regulatory trends may include stricter recycling targets, increased focus on chemical recycling methods, and the implementation of digital tracking systems to improve transparency in the recycling supply chain. These regulations will continue to shape the landscape of PETG recycling and push the industry towards achieving zero waste goals.

In recent years, many countries have implemented extended producer responsibility (EPR) programs, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. These regulations have significantly impacted the PETG recycling industry by incentivizing companies to invest in more efficient recycling technologies and design products with recyclability in mind.

The European Union has been at the forefront of environmental regulations with its Circular Economy Action Plan, which sets ambitious targets for plastic recycling and waste reduction. This plan includes specific measures for PETG and other plastic materials, such as mandatory recycled content requirements and restrictions on single-use plastics. These regulations have driven innovation in PETG recycling technologies and encouraged the development of more sustainable packaging solutions.

In the United States, while federal regulations on PETG recycling are less comprehensive, individual states have taken the lead in implementing their own recycling laws. California, for instance, has enacted legislation requiring a minimum percentage of recycled content in plastic beverage containers, including those made from PETG. This has spurred investment in recycling infrastructure and technologies within the state.

Asian countries, particularly China and Japan, have also introduced stricter regulations on plastic waste and recycling. China's ban on importing plastic waste has forced many countries to develop domestic recycling capabilities, including for PETG materials. Japan's comprehensive recycling laws have led to high recycling rates and innovative approaches to plastic waste management.

International agreements, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, have been amended to include plastic waste. This has implications for the global trade of PETG waste and recycled materials, encouraging countries to develop local recycling capacities and reduce reliance on exporting waste.

As environmental regulations continue to evolve, they are likely to drive further innovations in PETG recycling technologies. Future regulatory trends may include stricter recycling targets, increased focus on chemical recycling methods, and the implementation of digital tracking systems to improve transparency in the recycling supply chain. These regulations will continue to shape the landscape of PETG recycling and push the industry towards achieving zero waste goals.

Economic Feasibility

The economic feasibility of innovations in PETG recycling to achieve zero waste is a critical factor in determining the viability and potential success of such initiatives. PETG (Polyethylene Terephthalate Glycol-modified) is a widely used plastic material in various industries, and its recycling presents both challenges and opportunities from an economic perspective.

One of the primary economic drivers for PETG recycling innovations is the potential cost savings associated with reduced raw material consumption. As virgin PETG production relies heavily on petroleum-based resources, recycling can significantly decrease the dependency on these finite and often volatile-priced inputs. This reduction in material costs can lead to improved profit margins for manufacturers and potentially lower prices for consumers, creating a win-win situation for both industry and end-users.

The market demand for recycled PETG is another crucial factor in the economic equation. With increasing consumer awareness and regulatory pressure for sustainable packaging solutions, many companies are actively seeking recycled materials to incorporate into their products. This growing demand can create a stable and potentially lucrative market for recycled PETG, providing economic incentives for recycling innovations and investments in related technologies.

However, the economic feasibility of PETG recycling innovations also faces several challenges. The initial capital investment required for developing and implementing new recycling technologies can be substantial. This includes costs associated with research and development, equipment acquisition, and process optimization. The return on investment (ROI) timeline for these initiatives can be lengthy, which may deter some companies from pursuing such innovations without clear economic benefits in the short to medium term.

Operating costs are another significant consideration in the economic feasibility analysis. While recycling can reduce raw material costs, the energy consumption and labor requirements for collecting, sorting, and processing PETG waste can be substantial. Innovations that can streamline these processes and reduce associated costs are crucial for improving the overall economic viability of PETG recycling initiatives.

The quality of recycled PETG is a critical factor that impacts its economic value. Innovations that can maintain or improve the properties of recycled PETG, making it comparable to virgin material, can significantly enhance its market value and expand its potential applications. This, in turn, can improve the economic feasibility of recycling processes by increasing the revenue potential of the recycled material.

Government policies and incentives play a vital role in shaping the economic landscape for PETG recycling innovations. Tax breaks, grants, or subsidies for recycling initiatives can significantly improve the financial attractiveness of these projects. Additionally, regulations that mandate the use of recycled content in certain products can create a guaranteed market for recycled PETG, further enhancing its economic viability.

In conclusion, the economic feasibility of innovations in PETG recycling to achieve zero waste is influenced by a complex interplay of factors including material cost savings, market demand, capital investment requirements, operating costs, product quality, and regulatory environment. While challenges exist, the growing emphasis on sustainability and circular economy principles suggests that economically viable solutions in this area have significant potential for long-term success and profitability.

One of the primary economic drivers for PETG recycling innovations is the potential cost savings associated with reduced raw material consumption. As virgin PETG production relies heavily on petroleum-based resources, recycling can significantly decrease the dependency on these finite and often volatile-priced inputs. This reduction in material costs can lead to improved profit margins for manufacturers and potentially lower prices for consumers, creating a win-win situation for both industry and end-users.

The market demand for recycled PETG is another crucial factor in the economic equation. With increasing consumer awareness and regulatory pressure for sustainable packaging solutions, many companies are actively seeking recycled materials to incorporate into their products. This growing demand can create a stable and potentially lucrative market for recycled PETG, providing economic incentives for recycling innovations and investments in related technologies.

However, the economic feasibility of PETG recycling innovations also faces several challenges. The initial capital investment required for developing and implementing new recycling technologies can be substantial. This includes costs associated with research and development, equipment acquisition, and process optimization. The return on investment (ROI) timeline for these initiatives can be lengthy, which may deter some companies from pursuing such innovations without clear economic benefits in the short to medium term.

Operating costs are another significant consideration in the economic feasibility analysis. While recycling can reduce raw material costs, the energy consumption and labor requirements for collecting, sorting, and processing PETG waste can be substantial. Innovations that can streamline these processes and reduce associated costs are crucial for improving the overall economic viability of PETG recycling initiatives.

The quality of recycled PETG is a critical factor that impacts its economic value. Innovations that can maintain or improve the properties of recycled PETG, making it comparable to virgin material, can significantly enhance its market value and expand its potential applications. This, in turn, can improve the economic feasibility of recycling processes by increasing the revenue potential of the recycled material.

Government policies and incentives play a vital role in shaping the economic landscape for PETG recycling innovations. Tax breaks, grants, or subsidies for recycling initiatives can significantly improve the financial attractiveness of these projects. Additionally, regulations that mandate the use of recycled content in certain products can create a guaranteed market for recycled PETG, further enhancing its economic viability.

In conclusion, the economic feasibility of innovations in PETG recycling to achieve zero waste is influenced by a complex interplay of factors including material cost savings, market demand, capital investment requirements, operating costs, product quality, and regulatory environment. While challenges exist, the growing emphasis on sustainability and circular economy principles suggests that economically viable solutions in this area have significant potential for long-term success and profitability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!