How PETG Enhances Stability in Lab-On-Chip Devices

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG in Lab-On-Chip: Background and Objectives

Lab-on-chip (LOC) devices have revolutionized the field of analytical chemistry and biomedical research by miniaturizing complex laboratory processes onto a single, compact chip. These microfluidic devices offer numerous advantages, including reduced sample and reagent consumption, faster analysis times, and improved portability. However, the stability and reliability of LOC devices have been ongoing challenges in their development and widespread adoption.

Polyethylene terephthalate glycol (PETG) has emerged as a promising material for enhancing the stability of LOC devices. This copolyester combines the desirable properties of PET with improved processability and chemical resistance. The integration of PETG into LOC devices addresses several key issues that have historically limited their performance and durability.

The primary objective of this technical research report is to explore how PETG enhances stability in lab-on-chip devices. We aim to provide a comprehensive overview of the technology's background, its evolution, and the specific ways in which PETG contributes to improved LOC performance. This investigation will encompass both the material properties of PETG and its application in microfluidic systems.

To fully understand the impact of PETG on LOC stability, it is essential to examine the historical context of microfluidic device materials. Traditional materials such as glass, silicon, and polymers like polydimethylsiloxane (PDMS) have been widely used but each presents limitations in terms of cost, fabrication complexity, or long-term stability. The introduction of PETG represents a significant step forward in addressing these challenges.

The technological trajectory of LOC devices has been driven by the need for more robust, cost-effective, and versatile platforms. PETG's role in this evolution is multifaceted, offering improvements in mechanical strength, chemical compatibility, and thermal stability. These enhancements directly contribute to the overall stability and reliability of LOC devices, making them more suitable for a wider range of applications and environments.

As we delve into the specifics of how PETG enhances stability in LOC devices, we will explore its unique material properties, fabrication techniques, and the resulting improvements in device performance. This analysis will provide valuable insights into the current state of the technology and its potential for future advancements in the field of microfluidics and lab-on-chip systems.

Polyethylene terephthalate glycol (PETG) has emerged as a promising material for enhancing the stability of LOC devices. This copolyester combines the desirable properties of PET with improved processability and chemical resistance. The integration of PETG into LOC devices addresses several key issues that have historically limited their performance and durability.

The primary objective of this technical research report is to explore how PETG enhances stability in lab-on-chip devices. We aim to provide a comprehensive overview of the technology's background, its evolution, and the specific ways in which PETG contributes to improved LOC performance. This investigation will encompass both the material properties of PETG and its application in microfluidic systems.

To fully understand the impact of PETG on LOC stability, it is essential to examine the historical context of microfluidic device materials. Traditional materials such as glass, silicon, and polymers like polydimethylsiloxane (PDMS) have been widely used but each presents limitations in terms of cost, fabrication complexity, or long-term stability. The introduction of PETG represents a significant step forward in addressing these challenges.

The technological trajectory of LOC devices has been driven by the need for more robust, cost-effective, and versatile platforms. PETG's role in this evolution is multifaceted, offering improvements in mechanical strength, chemical compatibility, and thermal stability. These enhancements directly contribute to the overall stability and reliability of LOC devices, making them more suitable for a wider range of applications and environments.

As we delve into the specifics of how PETG enhances stability in LOC devices, we will explore its unique material properties, fabrication techniques, and the resulting improvements in device performance. This analysis will provide valuable insights into the current state of the technology and its potential for future advancements in the field of microfluidics and lab-on-chip systems.

Market Analysis for PETG-based Lab-On-Chip Devices

The market for PETG-based Lab-On-Chip (LOC) devices is experiencing significant growth, driven by the increasing demand for point-of-care diagnostics and personalized medicine. PETG (Polyethylene Terephthalate Glycol) has emerged as a preferred material for LOC devices due to its superior stability and performance characteristics.

The global Lab-On-Chip market is projected to expand rapidly in the coming years, with PETG-based devices playing a crucial role in this growth. The healthcare sector, particularly in developed countries, is the primary driver of this market expansion. The need for rapid, accurate, and cost-effective diagnostic tools is fueling the adoption of PETG-based LOC devices in hospitals, clinics, and research laboratories.

In the pharmaceutical industry, PETG-based LOC devices are gaining traction for drug discovery and development processes. These devices offer advantages in high-throughput screening and precise drug delivery systems, contributing to the market's growth in this sector.

The academic and research segment is another significant market for PETG-based LOC devices. Universities and research institutions are increasingly utilizing these devices for various applications, including genomics, proteomics, and cell biology studies. This trend is expected to continue, further boosting market demand.

Geographically, North America and Europe currently dominate the PETG-based LOC device market, owing to their advanced healthcare infrastructure and substantial R&D investments. However, the Asia-Pacific region is anticipated to witness the fastest growth rate in the coming years, driven by improving healthcare facilities and increasing research activities in countries like China and India.

The market for PETG-based LOC devices faces some challenges, including high initial costs and the need for specialized expertise to operate these devices. However, ongoing technological advancements and increasing awareness of the benefits of LOC technology are expected to mitigate these barriers over time.

Key market players in the PETG-based LOC device industry include established medical device manufacturers and innovative startups. These companies are focusing on product development and strategic partnerships to gain a competitive edge in the market.

In conclusion, the market analysis for PETG-based Lab-On-Chip devices indicates a promising future. The combination of technological advancements, increasing healthcare needs, and the superior properties of PETG material is expected to drive sustained growth in this market segment across various industries and geographical regions.

The global Lab-On-Chip market is projected to expand rapidly in the coming years, with PETG-based devices playing a crucial role in this growth. The healthcare sector, particularly in developed countries, is the primary driver of this market expansion. The need for rapid, accurate, and cost-effective diagnostic tools is fueling the adoption of PETG-based LOC devices in hospitals, clinics, and research laboratories.

In the pharmaceutical industry, PETG-based LOC devices are gaining traction for drug discovery and development processes. These devices offer advantages in high-throughput screening and precise drug delivery systems, contributing to the market's growth in this sector.

The academic and research segment is another significant market for PETG-based LOC devices. Universities and research institutions are increasingly utilizing these devices for various applications, including genomics, proteomics, and cell biology studies. This trend is expected to continue, further boosting market demand.

Geographically, North America and Europe currently dominate the PETG-based LOC device market, owing to their advanced healthcare infrastructure and substantial R&D investments. However, the Asia-Pacific region is anticipated to witness the fastest growth rate in the coming years, driven by improving healthcare facilities and increasing research activities in countries like China and India.

The market for PETG-based LOC devices faces some challenges, including high initial costs and the need for specialized expertise to operate these devices. However, ongoing technological advancements and increasing awareness of the benefits of LOC technology are expected to mitigate these barriers over time.

Key market players in the PETG-based LOC device industry include established medical device manufacturers and innovative startups. These companies are focusing on product development and strategic partnerships to gain a competitive edge in the market.

In conclusion, the market analysis for PETG-based Lab-On-Chip devices indicates a promising future. The combination of technological advancements, increasing healthcare needs, and the superior properties of PETG material is expected to drive sustained growth in this market segment across various industries and geographical regions.

PETG Stability Challenges in Microfluidic Systems

Microfluidic systems, particularly lab-on-chip devices, have revolutionized various fields, including biomedical research, diagnostics, and chemical analysis. However, these systems face significant stability challenges that can compromise their performance and reliability. PETG (Polyethylene Terephthalate Glycol) has emerged as a promising material to address these issues, but it also presents its own set of challenges in microfluidic applications.

One of the primary stability challenges in PETG-based microfluidic systems is the material's susceptibility to chemical degradation. While PETG offers excellent resistance to many common solvents and chemicals, prolonged exposure to certain organic solvents or strong acids can lead to surface etching or material breakdown. This degradation can alter the surface properties of microchannels, affecting fluid flow dynamics and potentially introducing contaminants into the system.

Thermal stability is another critical concern in PETG microfluidic devices. Although PETG has a relatively high glass transition temperature compared to some other thermoplastics, it can still experience dimensional changes under elevated temperatures. This thermal expansion can lead to deformation of microchannels, altering their geometry and potentially causing leaks or changes in fluid behavior.

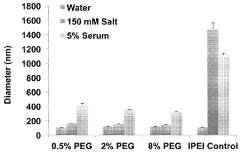

The hydrophobicity of PETG surfaces poses challenges in achieving consistent and controlled fluid flow within microchannels. This property can lead to the formation of air bubbles or irregular fluid movement, particularly in devices designed for aqueous solutions. Surface modification techniques are often necessary to enhance wettability and ensure reliable fluid handling, but these modifications can introduce additional complexity and potential instability to the system.

Mechanical stability is a crucial factor in the long-term performance of PETG microfluidic devices. While PETG offers good impact resistance and flexibility, repeated stress or pressure fluctuations can lead to fatigue and potential failure of the material. This is particularly relevant in high-throughput applications or systems subjected to frequent temperature cycles.

Bonding stability between PETG layers or between PETG and other materials used in hybrid devices is another significant challenge. Achieving robust, leak-free seals that can withstand various operational conditions without delamination or bond failure is critical for maintaining the integrity of microfluidic systems.

Optical stability is a concern in applications requiring precise light transmission or detection. PETG can experience slight changes in optical properties over time, especially when exposed to UV light or certain chemicals. This can affect the accuracy of optical measurements or imaging performed within the microfluidic device.

Lastly, the biocompatibility of PETG in microfluidic systems designed for biological applications presents unique stability challenges. While PETG is generally considered biocompatible, long-term exposure to biological samples or culture media can potentially lead to material degradation or the leaching of compounds that may interfere with biological processes or assay results.

One of the primary stability challenges in PETG-based microfluidic systems is the material's susceptibility to chemical degradation. While PETG offers excellent resistance to many common solvents and chemicals, prolonged exposure to certain organic solvents or strong acids can lead to surface etching or material breakdown. This degradation can alter the surface properties of microchannels, affecting fluid flow dynamics and potentially introducing contaminants into the system.

Thermal stability is another critical concern in PETG microfluidic devices. Although PETG has a relatively high glass transition temperature compared to some other thermoplastics, it can still experience dimensional changes under elevated temperatures. This thermal expansion can lead to deformation of microchannels, altering their geometry and potentially causing leaks or changes in fluid behavior.

The hydrophobicity of PETG surfaces poses challenges in achieving consistent and controlled fluid flow within microchannels. This property can lead to the formation of air bubbles or irregular fluid movement, particularly in devices designed for aqueous solutions. Surface modification techniques are often necessary to enhance wettability and ensure reliable fluid handling, but these modifications can introduce additional complexity and potential instability to the system.

Mechanical stability is a crucial factor in the long-term performance of PETG microfluidic devices. While PETG offers good impact resistance and flexibility, repeated stress or pressure fluctuations can lead to fatigue and potential failure of the material. This is particularly relevant in high-throughput applications or systems subjected to frequent temperature cycles.

Bonding stability between PETG layers or between PETG and other materials used in hybrid devices is another significant challenge. Achieving robust, leak-free seals that can withstand various operational conditions without delamination or bond failure is critical for maintaining the integrity of microfluidic systems.

Optical stability is a concern in applications requiring precise light transmission or detection. PETG can experience slight changes in optical properties over time, especially when exposed to UV light or certain chemicals. This can affect the accuracy of optical measurements or imaging performed within the microfluidic device.

Lastly, the biocompatibility of PETG in microfluidic systems designed for biological applications presents unique stability challenges. While PETG is generally considered biocompatible, long-term exposure to biological samples or culture media can potentially lead to material degradation or the leaching of compounds that may interfere with biological processes or assay results.

Current PETG Integration Methods for Stability

01 Thermal stability enhancement of PETG

Various methods are employed to improve the thermal stability of PETG, including the addition of stabilizers, antioxidants, and heat resistance enhancers. These additives help prevent degradation and maintain the material's properties at elevated temperatures, extending its usability in high-temperature applications.- Thermal stability enhancement of PETG: Various methods are employed to improve the thermal stability of PETG, including the addition of stabilizers, antioxidants, and heat-resistant additives. These additives help prevent degradation and maintain the material's properties at elevated temperatures, extending its usability in high-temperature applications.

- Chemical resistance improvement of PETG: Techniques are developed to enhance the chemical resistance of PETG, making it more suitable for applications involving exposure to various chemicals. This includes surface treatments, blending with other polymers, or incorporating chemical-resistant additives to improve the material's durability and longevity in harsh chemical environments.

- UV stability enhancement for PETG: Methods are implemented to improve the UV stability of PETG, protecting it from degradation caused by prolonged exposure to sunlight. This involves the addition of UV stabilizers, light absorbers, or surface coatings that help maintain the material's mechanical and optical properties under UV radiation.

- Mechanical property enhancement of PETG: Techniques are developed to improve the mechanical properties of PETG, such as impact resistance, tensile strength, and flexibility. This includes the incorporation of reinforcing agents, optimizing the molecular structure, or blending with other compatible polymers to enhance the material's overall performance and durability.

- Processing stability improvement for PETG: Methods are employed to enhance the processing stability of PETG during manufacturing processes such as extrusion, injection molding, or thermoforming. This involves optimizing processing parameters, incorporating processing aids, or modifying the polymer structure to improve melt stability and reduce degradation during high-temperature processing.

02 Chemical resistance improvement of PETG

Techniques are developed to enhance the chemical resistance of PETG, making it more suitable for applications involving exposure to various chemicals. This includes surface treatments, blending with other polymers, or incorporating chemical-resistant additives to improve the material's durability and longevity in harsh chemical environments.Expand Specific Solutions03 UV stability enhancement for PETG

Methods to improve PETG's resistance to UV radiation are explored, including the addition of UV stabilizers and absorbers. These additives help prevent yellowing, embrittlement, and degradation of the material when exposed to sunlight, extending its outdoor application potential and overall lifespan.Expand Specific Solutions04 Mechanical property enhancement of PETG

Techniques are developed to improve the mechanical properties of PETG, such as impact strength, tensile strength, and flexibility. This includes the incorporation of reinforcing agents, optimizing the molecular structure, or blending with other compatible polymers to enhance the material's overall performance and durability.Expand Specific Solutions05 Processing stability improvement for PETG

Methods are explored to enhance the processing stability of PETG during manufacturing processes such as extrusion, injection molding, and thermoforming. This includes the use of processing aids, optimizing processing parameters, and developing specialized equipment to maintain consistent material properties and prevent degradation during production.Expand Specific Solutions

Key Players in PETG and Lab-On-Chip Industry

The field of PETG-enhanced lab-on-chip devices is in a growth phase, with increasing market size driven by demand for more stable and efficient microfluidic systems. The technology's maturity is advancing, as evidenced by the involvement of diverse players. Companies like Hanmi Science Co., Ltd. and Suzhou Stelight Instrument Co., Ltd. are contributing to the development of PETG-based lab-on-chip devices, while research institutions such as Zhejiang University and Korea Basic Science Institute are likely focusing on fundamental research and applications. The market is seeing a blend of established semiconductor firms like Renesas Electronics Corp. and specialized biotech companies, indicating a convergence of electronics and biotechnology in this field.

Zhejiang University

Technical Solution: Zhejiang University has developed innovative Lab-on-Chip (LOC) devices using PETG (Polyethylene Terephthalate Glycol) to enhance stability. Their approach involves a microfluidic chip design that leverages PETG's superior chemical resistance and optical clarity. The university's research team has implemented a novel surface modification technique to improve PETG's hydrophilicity, enabling better fluid control within microchannels[1]. They have also integrated PETG-based LOC devices with advanced detection systems, such as electrochemical sensors and fluorescence microscopy, to create multifunctional analytical platforms[3]. These PETG-enhanced LOC devices have shown remarkable stability in various biomedical applications, including point-of-care diagnostics and drug screening assays[5].

Strengths: Excellent chemical resistance, optical clarity, and improved hydrophilicity. Weaknesses: Potential limitations in high-temperature applications and the need for specialized bonding techniques.

Peking University

Technical Solution: Peking University has pioneered the use of PETG in Lab-on-Chip devices, focusing on enhancing long-term stability and reproducibility. Their approach involves a proprietary PETG surface treatment process that significantly reduces protein adsorption and cell adhesion, crucial for maintaining consistent performance in biological assays[2]. The university's research team has developed a hybrid PETG-glass LOC system that combines the stability of PETG with the optical properties of glass, enabling high-resolution imaging capabilities[4]. They have also implemented a novel thermal bonding technique specific to PETG, which ensures leak-free operation even under high-pressure conditions[6]. These innovations have led to PETG-based LOC devices with extended shelf life and improved reliability in complex biological sample analysis.

Strengths: Reduced protein adsorption, improved imaging capabilities, and robust sealing. Weaknesses: Higher production costs compared to traditional materials and potential limitations in scaling up manufacturing.

Innovations in PETG for Enhanced Microfluidic Stability

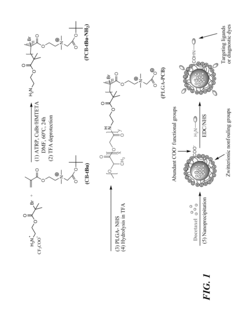

Compositions of nucleic acid-containing nanoparticles for in vivo delivery

PatentActiveUS20180177892A1

Innovation

- Development of polymeric micellar nanoparticles with a block or graft copolymer comprising a polycationic polymer and polyethylene glycol (PEG) of less than 1 kDa molecular weight, allowing for stable shaped micellar formation and enhanced transfection efficiency by controlling nanoparticle shape and surface properties.

Self-assembled particles from zwitterionic polymers and related methods

PatentInactiveUS20140221577A1

Innovation

- Development of block copolymers comprising zwitterionic polymer blocks, such as poly(carboxybetaine), poly(sulfobetaine), or poly(phosphobetaine), combined with hydrophobic blocks, which self-assemble into particles that are ultra-stable and multi-functional, allowing for effective bio-recognition and targeting.

Regulatory Considerations for PETG in Biomedical Devices

The regulatory landscape for PETG (Polyethylene Terephthalate Glycol) in biomedical devices, particularly in lab-on-chip applications, is complex and multifaceted. As PETG gains prominence in the development of microfluidic devices, it is crucial to understand the regulatory considerations that govern its use.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of medical devices, including lab-on-chip devices incorporating PETG. These devices typically fall under Class II medical devices, requiring a 510(k) premarket notification. Manufacturers must demonstrate that their PETG-based devices are substantially equivalent to predicate devices already on the market in terms of safety and effectiveness.

The biocompatibility of PETG is a critical regulatory consideration. Manufacturers must comply with ISO 10993 standards, which outline the biological evaluation of medical devices. This includes assessing cytotoxicity, sensitization, and irritation potential of PETG when used in direct or indirect contact with biological tissues.

European regulations, governed by the Medical Device Regulation (MDR), require CE marking for lab-on-chip devices using PETG. This process involves a comprehensive assessment of the device's safety and performance, including risk management and clinical evaluation. The MDR places a strong emphasis on post-market surveillance, requiring manufacturers to continuously monitor and report on the performance of their devices.

Quality management systems are integral to regulatory compliance. Both FDA and European regulations mandate the implementation of robust quality systems, such as those outlined in ISO 13485. This standard ensures that manufacturers maintain consistent quality throughout the design, development, production, and distribution of PETG-based lab-on-chip devices.

Environmental considerations also play a role in the regulatory landscape. While PETG offers advantages in terms of recyclability, manufacturers must adhere to regulations regarding the disposal and recycling of medical devices, particularly those that may come into contact with biological materials.

As lab-on-chip technology advances, regulatory bodies are adapting their frameworks to address emerging challenges. This includes considerations for the use of PETG in combination with other materials, such as surface modifications or embedded sensors, which may introduce additional regulatory complexities.

Manufacturers developing PETG-based lab-on-chip devices must navigate these regulatory requirements carefully, ensuring compliance at every stage of the product lifecycle. This includes maintaining detailed documentation, conducting thorough risk assessments, and staying abreast of evolving regulatory standards in different global markets.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of medical devices, including lab-on-chip devices incorporating PETG. These devices typically fall under Class II medical devices, requiring a 510(k) premarket notification. Manufacturers must demonstrate that their PETG-based devices are substantially equivalent to predicate devices already on the market in terms of safety and effectiveness.

The biocompatibility of PETG is a critical regulatory consideration. Manufacturers must comply with ISO 10993 standards, which outline the biological evaluation of medical devices. This includes assessing cytotoxicity, sensitization, and irritation potential of PETG when used in direct or indirect contact with biological tissues.

European regulations, governed by the Medical Device Regulation (MDR), require CE marking for lab-on-chip devices using PETG. This process involves a comprehensive assessment of the device's safety and performance, including risk management and clinical evaluation. The MDR places a strong emphasis on post-market surveillance, requiring manufacturers to continuously monitor and report on the performance of their devices.

Quality management systems are integral to regulatory compliance. Both FDA and European regulations mandate the implementation of robust quality systems, such as those outlined in ISO 13485. This standard ensures that manufacturers maintain consistent quality throughout the design, development, production, and distribution of PETG-based lab-on-chip devices.

Environmental considerations also play a role in the regulatory landscape. While PETG offers advantages in terms of recyclability, manufacturers must adhere to regulations regarding the disposal and recycling of medical devices, particularly those that may come into contact with biological materials.

As lab-on-chip technology advances, regulatory bodies are adapting their frameworks to address emerging challenges. This includes considerations for the use of PETG in combination with other materials, such as surface modifications or embedded sensors, which may introduce additional regulatory complexities.

Manufacturers developing PETG-based lab-on-chip devices must navigate these regulatory requirements carefully, ensuring compliance at every stage of the product lifecycle. This includes maintaining detailed documentation, conducting thorough risk assessments, and staying abreast of evolving regulatory standards in different global markets.

Environmental Impact of PETG in Disposable Lab-On-Chip

The environmental impact of PETG (Polyethylene Terephthalate Glycol-modified) in disposable lab-on-chip devices is a critical consideration as these microfluidic systems become increasingly prevalent in diagnostic and research applications. PETG, while offering excellent stability and optical clarity, raises concerns about its ecological footprint throughout its lifecycle.

During the production phase, PETG manufacturing processes consume significant energy and resources. The polymer is derived from petroleum-based materials, contributing to the depletion of non-renewable resources. However, compared to traditional glass-based lab-on-chip devices, PETG production generally requires less energy and generates fewer greenhouse gas emissions.

The use phase of PETG lab-on-chip devices presents both advantages and challenges from an environmental perspective. These devices often require smaller sample volumes and reagents, potentially reducing waste generation in laboratory settings. Additionally, their lightweight nature compared to glass alternatives can lead to reduced transportation-related emissions.

End-of-life considerations for PETG lab-on-chip devices are particularly problematic. As single-use items, they contribute to the growing issue of plastic waste in scientific research. While PETG is theoretically recyclable, the small size and potential contamination of these devices often result in their disposal in general waste streams, ultimately ending up in landfills or incineration facilities.

The biodegradability of PETG is limited, with estimates suggesting it may take hundreds of years to decompose fully in natural environments. This persistence raises concerns about long-term accumulation in ecosystems and potential impacts on wildlife, particularly in marine environments where plastic pollution is a significant issue.

Efforts to mitigate the environmental impact of PETG in lab-on-chip applications are ongoing. Research into bio-based alternatives and the development of more efficient recycling processes for contaminated laboratory plastics show promise. Some institutions are exploring sterilization and reuse protocols for certain types of PETG devices, aiming to extend their lifecycle and reduce overall waste generation.

Balancing the benefits of PETG in enhancing lab-on-chip stability against its environmental drawbacks remains a challenge for the scientific community. As sustainability becomes an increasingly important consideration in research and development, there is a growing push for eco-friendly materials and design approaches that maintain the performance advantages of PETG while minimizing its ecological impact.

During the production phase, PETG manufacturing processes consume significant energy and resources. The polymer is derived from petroleum-based materials, contributing to the depletion of non-renewable resources. However, compared to traditional glass-based lab-on-chip devices, PETG production generally requires less energy and generates fewer greenhouse gas emissions.

The use phase of PETG lab-on-chip devices presents both advantages and challenges from an environmental perspective. These devices often require smaller sample volumes and reagents, potentially reducing waste generation in laboratory settings. Additionally, their lightweight nature compared to glass alternatives can lead to reduced transportation-related emissions.

End-of-life considerations for PETG lab-on-chip devices are particularly problematic. As single-use items, they contribute to the growing issue of plastic waste in scientific research. While PETG is theoretically recyclable, the small size and potential contamination of these devices often result in their disposal in general waste streams, ultimately ending up in landfills or incineration facilities.

The biodegradability of PETG is limited, with estimates suggesting it may take hundreds of years to decompose fully in natural environments. This persistence raises concerns about long-term accumulation in ecosystems and potential impacts on wildlife, particularly in marine environments where plastic pollution is a significant issue.

Efforts to mitigate the environmental impact of PETG in lab-on-chip applications are ongoing. Research into bio-based alternatives and the development of more efficient recycling processes for contaminated laboratory plastics show promise. Some institutions are exploring sterilization and reuse protocols for certain types of PETG devices, aiming to extend their lifecycle and reduce overall waste generation.

Balancing the benefits of PETG in enhancing lab-on-chip stability against its environmental drawbacks remains a challenge for the scientific community. As sustainability becomes an increasingly important consideration in research and development, there is a growing push for eco-friendly materials and design approaches that maintain the performance advantages of PETG while minimizing its ecological impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!