How PETG Enables Advancement in Scalable Resource Deployment

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Technology Evolution

PETG (Polyethylene Terephthalate Glycol-modified) technology has undergone significant evolution since its inception, playing a crucial role in advancing scalable resource deployment across various industries. The journey of PETG began in the late 1970s as a modified version of PET, addressing the limitations of its predecessor in terms of clarity, toughness, and processability.

In the early stages of its development, PETG was primarily used in niche applications where its unique properties offered distinct advantages. The 1980s saw the first commercial applications of PETG in packaging and medical devices, where its clarity and chemical resistance were highly valued. This period marked the beginning of PETG's trajectory towards becoming a versatile material for scalable resource deployment.

The 1990s witnessed a significant leap in PETG technology, with improvements in manufacturing processes leading to enhanced material properties and cost-effectiveness. This decade saw the expansion of PETG into broader industrial applications, including food packaging, consumer goods, and automotive components. The material's ability to be easily thermoformed and its excellent impact resistance made it an attractive option for scalable production in these sectors.

As we entered the 2000s, PETG technology experienced another wave of innovation, particularly in the realm of 3D printing and additive manufacturing. The material's low shrinkage rate and good layer adhesion properties made it an ideal candidate for rapid prototyping and small-scale production. This development opened up new possibilities for on-demand manufacturing and customization, further enhancing its role in scalable resource deployment.

The past decade has seen PETG evolve to meet the growing demands of sustainability and circular economy principles. Researchers and manufacturers have focused on developing bio-based PETG variants and improving the material's recyclability. These advancements have positioned PETG as a more environmentally friendly alternative in industries striving for sustainable resource management.

Recent years have brought about significant improvements in PETG's thermal and mechanical properties, expanding its application in high-performance sectors such as aerospace and advanced engineering. The development of PETG composites and blends has further extended its capabilities, allowing for tailored solutions in scalable resource deployment across diverse industrial landscapes.

Looking ahead, the evolution of PETG technology is expected to continue its upward trajectory. Emerging trends include the integration of smart materials and nanotechnology with PETG, potentially leading to self-healing or adaptive properties. Additionally, ongoing research into improving PETG's barrier properties and chemical resistance promises to unlock new applications in fields such as flexible electronics and advanced packaging solutions.

In the early stages of its development, PETG was primarily used in niche applications where its unique properties offered distinct advantages. The 1980s saw the first commercial applications of PETG in packaging and medical devices, where its clarity and chemical resistance were highly valued. This period marked the beginning of PETG's trajectory towards becoming a versatile material for scalable resource deployment.

The 1990s witnessed a significant leap in PETG technology, with improvements in manufacturing processes leading to enhanced material properties and cost-effectiveness. This decade saw the expansion of PETG into broader industrial applications, including food packaging, consumer goods, and automotive components. The material's ability to be easily thermoformed and its excellent impact resistance made it an attractive option for scalable production in these sectors.

As we entered the 2000s, PETG technology experienced another wave of innovation, particularly in the realm of 3D printing and additive manufacturing. The material's low shrinkage rate and good layer adhesion properties made it an ideal candidate for rapid prototyping and small-scale production. This development opened up new possibilities for on-demand manufacturing and customization, further enhancing its role in scalable resource deployment.

The past decade has seen PETG evolve to meet the growing demands of sustainability and circular economy principles. Researchers and manufacturers have focused on developing bio-based PETG variants and improving the material's recyclability. These advancements have positioned PETG as a more environmentally friendly alternative in industries striving for sustainable resource management.

Recent years have brought about significant improvements in PETG's thermal and mechanical properties, expanding its application in high-performance sectors such as aerospace and advanced engineering. The development of PETG composites and blends has further extended its capabilities, allowing for tailored solutions in scalable resource deployment across diverse industrial landscapes.

Looking ahead, the evolution of PETG technology is expected to continue its upward trajectory. Emerging trends include the integration of smart materials and nanotechnology with PETG, potentially leading to self-healing or adaptive properties. Additionally, ongoing research into improving PETG's barrier properties and chemical resistance promises to unlock new applications in fields such as flexible electronics and advanced packaging solutions.

Market Demand Analysis

The market demand for PETG (Polyethylene Terephthalate Glycol) in scalable resource deployment has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for efficient and flexible resource management across various industries, particularly in sectors such as telecommunications, energy, and cloud computing.

PETG's unique properties, including its durability, transparency, and ease of processing, make it an ideal material for creating modular and scalable infrastructure components. These characteristics align well with the growing trend towards adaptable and rapidly deployable resource systems, which are crucial in today's fast-paced technological landscape.

In the telecommunications sector, the rollout of 5G networks has created a substantial demand for PETG-based solutions. The material's resistance to environmental factors and its ability to be molded into complex shapes make it suitable for creating protective enclosures for sensitive equipment and modular components for network infrastructure. This application is expected to drive a significant portion of the market growth in the coming years.

The energy sector, particularly in renewable energy installations, has also shown increased interest in PETG-enabled solutions. As solar and wind farms continue to expand, the need for scalable and easily deployable components has grown. PETG's lightweight nature and durability make it an excellent choice for creating modular mounting systems and protective casings for energy storage units.

In the realm of cloud computing and data centers, PETG is finding applications in creating scalable cooling systems and modular server racks. The material's thermal properties and resistance to chemicals make it suitable for developing innovative cooling solutions that can be easily scaled up or down based on demand.

The market for PETG in scalable resource deployment is also benefiting from the global push towards sustainability. As businesses and governments focus on reducing their carbon footprint, the recyclability of PETG makes it an attractive option for creating eco-friendly infrastructure components.

Industry analysts project that the market for PETG in scalable resource deployment applications will continue to grow at a compound annual growth rate (CAGR) of over 6% in the next five years. This growth is expected to be fueled by ongoing technological advancements and the increasing adoption of modular and scalable solutions across various industries.

However, challenges such as the volatility of raw material prices and competition from alternative materials may impact market growth. Despite these challenges, the overall outlook for PETG in scalable resource deployment remains positive, with innovations in material science and manufacturing processes expected to further enhance its applicability and market penetration.

PETG's unique properties, including its durability, transparency, and ease of processing, make it an ideal material for creating modular and scalable infrastructure components. These characteristics align well with the growing trend towards adaptable and rapidly deployable resource systems, which are crucial in today's fast-paced technological landscape.

In the telecommunications sector, the rollout of 5G networks has created a substantial demand for PETG-based solutions. The material's resistance to environmental factors and its ability to be molded into complex shapes make it suitable for creating protective enclosures for sensitive equipment and modular components for network infrastructure. This application is expected to drive a significant portion of the market growth in the coming years.

The energy sector, particularly in renewable energy installations, has also shown increased interest in PETG-enabled solutions. As solar and wind farms continue to expand, the need for scalable and easily deployable components has grown. PETG's lightweight nature and durability make it an excellent choice for creating modular mounting systems and protective casings for energy storage units.

In the realm of cloud computing and data centers, PETG is finding applications in creating scalable cooling systems and modular server racks. The material's thermal properties and resistance to chemicals make it suitable for developing innovative cooling solutions that can be easily scaled up or down based on demand.

The market for PETG in scalable resource deployment is also benefiting from the global push towards sustainability. As businesses and governments focus on reducing their carbon footprint, the recyclability of PETG makes it an attractive option for creating eco-friendly infrastructure components.

Industry analysts project that the market for PETG in scalable resource deployment applications will continue to grow at a compound annual growth rate (CAGR) of over 6% in the next five years. This growth is expected to be fueled by ongoing technological advancements and the increasing adoption of modular and scalable solutions across various industries.

However, challenges such as the volatility of raw material prices and competition from alternative materials may impact market growth. Despite these challenges, the overall outlook for PETG in scalable resource deployment remains positive, with innovations in material science and manufacturing processes expected to further enhance its applicability and market penetration.

PETG Technical Challenges

PETG (Polyethylene Terephthalate Glycol-modified) presents several technical challenges in its application for scalable resource deployment. One of the primary issues is the material's sensitivity to moisture absorption, which can significantly affect its mechanical properties and processing characteristics. This hygroscopic nature requires careful handling and storage to prevent degradation of the material before and during use.

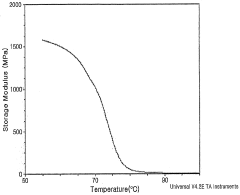

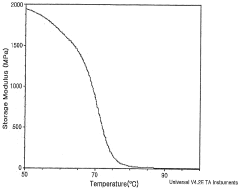

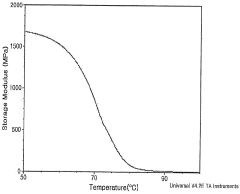

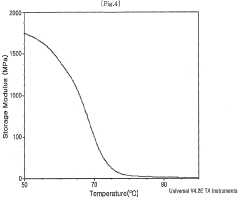

Another challenge lies in the thermal stability of PETG. While it offers improved heat resistance compared to standard PET, it still has limitations in high-temperature applications. This constraint can impact its use in certain deployment scenarios where elevated temperatures are encountered, potentially leading to deformation or loss of structural integrity.

The crystallization behavior of PETG also poses technical difficulties. Unlike PET, PETG has a slower crystallization rate, which can affect its dimensional stability and mechanical strength in some applications. This characteristic necessitates precise control of cooling rates during processing to achieve desired properties, adding complexity to manufacturing processes.

Adhesion and compatibility issues present further challenges when integrating PETG with other materials in multi-component systems. Ensuring strong and durable bonds between PETG and other substrates or components is crucial for many scalable resource deployment applications, requiring specialized surface treatments or adhesive systems.

The recyclability of PETG, while generally good, can be complicated by its modified chemical structure. Separating PETG from other plastics in the recycling stream and maintaining its properties through multiple recycling cycles remain areas of ongoing research and development, impacting the material's long-term sustainability in large-scale deployments.

Processing PETG for scalable applications also presents challenges in terms of achieving consistent quality across large production volumes. Controlling variables such as melt viscosity, die swell, and shrinkage during extrusion or injection molding processes becomes increasingly critical as production scales up.

Lastly, the cost-effectiveness of PETG in large-scale deployments can be a limiting factor. While offering advantages over some materials, PETG's production costs and performance trade-offs must be carefully balanced against alternative materials to ensure economic viability in scalable resource deployment scenarios.

Another challenge lies in the thermal stability of PETG. While it offers improved heat resistance compared to standard PET, it still has limitations in high-temperature applications. This constraint can impact its use in certain deployment scenarios where elevated temperatures are encountered, potentially leading to deformation or loss of structural integrity.

The crystallization behavior of PETG also poses technical difficulties. Unlike PET, PETG has a slower crystallization rate, which can affect its dimensional stability and mechanical strength in some applications. This characteristic necessitates precise control of cooling rates during processing to achieve desired properties, adding complexity to manufacturing processes.

Adhesion and compatibility issues present further challenges when integrating PETG with other materials in multi-component systems. Ensuring strong and durable bonds between PETG and other substrates or components is crucial for many scalable resource deployment applications, requiring specialized surface treatments or adhesive systems.

The recyclability of PETG, while generally good, can be complicated by its modified chemical structure. Separating PETG from other plastics in the recycling stream and maintaining its properties through multiple recycling cycles remain areas of ongoing research and development, impacting the material's long-term sustainability in large-scale deployments.

Processing PETG for scalable applications also presents challenges in terms of achieving consistent quality across large production volumes. Controlling variables such as melt viscosity, die swell, and shrinkage during extrusion or injection molding processes becomes increasingly critical as production scales up.

Lastly, the cost-effectiveness of PETG in large-scale deployments can be a limiting factor. While offering advantages over some materials, PETG's production costs and performance trade-offs must be carefully balanced against alternative materials to ensure economic viability in scalable resource deployment scenarios.

Current PETG Solutions

01 PETG production and processing methods

Various methods for producing and processing PETG are described, including techniques for improving scalability and efficiency. These methods involve specific processing parameters, equipment configurations, and material compositions to enhance the production of PETG on a larger scale.- PETG production and processing methods: Various methods for producing and processing PETG are described, including techniques for improving its properties and scalability. These methods involve specific processing conditions, additives, and equipment to enhance the material's performance and production efficiency.

- PETG applications in packaging and containers: PETG is widely used in packaging and container manufacturing due to its excellent properties. Innovations in this area focus on improving the material's performance for specific applications, such as food packaging, bottles, and other consumer goods containers.

- PETG blends and composites: Research on PETG blends and composites aims to enhance the material's properties and expand its applications. These developments involve combining PETG with other polymers or additives to create materials with improved characteristics, such as increased strength, flexibility, or thermal stability.

- PETG recycling and sustainability: Efforts to improve PETG recycling and sustainability focus on developing more efficient recycling processes, reducing waste, and creating eco-friendly alternatives. These innovations aim to address environmental concerns and promote the circular economy in the plastics industry.

- PETG modification for specific industries: Tailoring PETG properties for specific industries involves modifying the material to meet unique requirements in sectors such as automotive, electronics, and medical devices. These modifications may include improving heat resistance, chemical resistance, or biocompatibility.

02 PETG material properties and modifications

Techniques for modifying PETG properties to improve its scalability and performance in various applications are discussed. This includes methods for enhancing thermal stability, mechanical strength, and other physical characteristics of PETG through additives or processing techniques.Expand Specific Solutions03 PETG applications in packaging and containers

The use of PETG in scalable packaging solutions and container manufacturing is explored. Various designs and production methods for PETG-based packaging materials and containers are presented, focusing on improving efficiency and scalability in these applications.Expand Specific Solutions04 PETG recycling and sustainability

Methods for recycling PETG and improving its sustainability in large-scale applications are described. These include techniques for efficient material recovery, reprocessing of PETG waste, and development of more environmentally friendly PETG-based products.Expand Specific Solutions05 PETG blends and composites

The development of PETG blends and composites to enhance scalability and performance is discussed. Various formulations and processing techniques for creating PETG-based materials with improved properties for large-scale applications are presented.Expand Specific Solutions

Key PETG Industry Players

The advancement of PETG in scalable resource deployment is currently in an early growth stage, with the market showing promising expansion potential. The technology's maturity is evolving rapidly, driven by significant investments from key players. Companies like Huawei, ZTE, and Qualcomm are at the forefront, leveraging their expertise in telecommunications and semiconductor technologies to push PETG capabilities forward. The market size is expected to grow substantially as more industries recognize the benefits of PETG in resource management. While established tech giants like Samsung and IBM are contributing to the field, emerging players such as Jio Platforms are also making notable strides, indicating a dynamic and competitive landscape.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed a PETG (Programmable Elastic Time-Triggered Granular) scheduling framework for scalable resource deployment in 5G and beyond networks. This framework enables dynamic allocation of network resources based on real-time demand and network conditions. Huawei's PETG implementation utilizes AI-driven predictive algorithms to optimize resource distribution across network slices, ensuring efficient utilization of bandwidth, computing power, and storage[1]. The system employs a granular approach, allowing for fine-tuned control over resource allocation at various network levels, from core to edge[3]. Huawei's PETG solution also incorporates edge computing capabilities, enabling low-latency processing and reduced backhaul traffic, which is crucial for emerging applications like autonomous vehicles and industrial IoT[5].

Strengths: Advanced AI-driven predictive algorithms, fine-grained resource control, and edge computing integration. Weaknesses: Potential complexity in implementation and management, may require significant infrastructure upgrades.

QUALCOMM, Inc.

Technical Solution: Qualcomm has integrated PETG principles into its 5G NR (New Radio) technology to enhance scalable resource deployment. Their approach focuses on flexible numerology and dynamic spectrum sharing, allowing for efficient allocation of radio resources across diverse use cases. Qualcomm's implementation of PETG concepts enables seamless switching between different subcarrier spacings and frame structures, adapting to varying network demands and environmental conditions[2]. The company has also developed advanced beamforming techniques that work in conjunction with PETG scheduling to optimize spatial resource utilization[4]. Qualcomm's solution incorporates machine learning algorithms to predict traffic patterns and proactively adjust resource allocation, improving overall network efficiency and user experience[6].

Strengths: Flexible numerology adaptation, advanced beamforming integration, and ML-driven predictive resource allocation. Weaknesses: May require specialized hardware support, potential interoperability challenges with legacy systems.

PETG Innovations Review

applicator

PatentPendingEP3265166A1

Innovation

- A novel applicator with a container and nib configuration that uses a plurality of fibers and adhesive material to deliver a controlled release of acidic liquid to topical areas, allowing for safe and effective treatment of skin lesions without external pressure, targeting the lesion while minimizing impact on surrounding healthy tissue.

PETG based decorative sheet having forming ability similar with PVC

PatentWO2008091067A1

Innovation

- A PETG alloy resin is developed by alloying PETG with an ester resin or elastomer resin, specifically polybutylene terephthalate (PBT) and PBT copolymer elastomer, to lower the glass transition temperature and widen the forming temperature range, similar to PVC, with optimal content between 5 to 20 parts by weight.

PETG Sustainability Impact

PETG (Polyethylene Terephthalate Glycol-modified) has emerged as a significant player in advancing sustainable resource deployment across various industries. This innovative material offers a unique combination of properties that contribute to its growing popularity in sustainable applications. PETG's impact on sustainability is multifaceted, encompassing both environmental and economic aspects of resource management.

From an environmental perspective, PETG demonstrates several advantages over traditional plastics. Its production process requires less energy compared to other commonly used plastics, resulting in a reduced carbon footprint. Additionally, PETG is fully recyclable, allowing for the creation of closed-loop systems that minimize waste and conserve resources. The material's durability and resistance to chemical degradation also contribute to its longevity, reducing the need for frequent replacements and thereby conserving resources over time.

In terms of scalable resource deployment, PETG's versatility plays a crucial role. Its ability to be easily molded, thermoformed, and fabricated into various shapes and sizes enables efficient production processes and reduces material waste. This flexibility allows manufacturers to optimize resource utilization and streamline production lines, leading to more sustainable manufacturing practices.

PETG's impact extends beyond manufacturing to end-use applications. In the packaging industry, for instance, PETG's clarity, strength, and barrier properties make it an excellent alternative to less sustainable materials. Its use in food packaging can extend shelf life, reducing food waste and the associated environmental impact. In the construction sector, PETG's durability and weather resistance contribute to longer-lasting building materials, reducing the need for frequent replacements and conserving resources in the long term.

The material's contribution to sustainable resource deployment is further exemplified in its application in renewable energy technologies. PETG's properties make it suitable for use in solar panel components and wind turbine blades, supporting the growth of clean energy infrastructure. Its resistance to UV radiation and weathering ensures longevity in these outdoor applications, maximizing the efficiency of renewable energy systems over time.

Moreover, PETG's role in advancing sustainable resource deployment is evident in its potential for upcycling and repurposing. Unlike some plastics that degrade in quality upon recycling, PETG can maintain its properties through multiple recycling cycles. This characteristic opens up possibilities for innovative circular economy models, where PETG products can be continuously reprocessed and repurposed, significantly extending the lifecycle of the material and reducing the demand for virgin resources.

In conclusion, PETG's impact on sustainability is substantial and far-reaching. Its unique properties enable advancements in scalable resource deployment across various sectors, contributing to more efficient production processes, longer-lasting products, and improved recyclability. As industries continue to prioritize sustainability, PETG stands out as a material that aligns with these goals, offering solutions that balance performance with environmental responsibility.

From an environmental perspective, PETG demonstrates several advantages over traditional plastics. Its production process requires less energy compared to other commonly used plastics, resulting in a reduced carbon footprint. Additionally, PETG is fully recyclable, allowing for the creation of closed-loop systems that minimize waste and conserve resources. The material's durability and resistance to chemical degradation also contribute to its longevity, reducing the need for frequent replacements and thereby conserving resources over time.

In terms of scalable resource deployment, PETG's versatility plays a crucial role. Its ability to be easily molded, thermoformed, and fabricated into various shapes and sizes enables efficient production processes and reduces material waste. This flexibility allows manufacturers to optimize resource utilization and streamline production lines, leading to more sustainable manufacturing practices.

PETG's impact extends beyond manufacturing to end-use applications. In the packaging industry, for instance, PETG's clarity, strength, and barrier properties make it an excellent alternative to less sustainable materials. Its use in food packaging can extend shelf life, reducing food waste and the associated environmental impact. In the construction sector, PETG's durability and weather resistance contribute to longer-lasting building materials, reducing the need for frequent replacements and conserving resources in the long term.

The material's contribution to sustainable resource deployment is further exemplified in its application in renewable energy technologies. PETG's properties make it suitable for use in solar panel components and wind turbine blades, supporting the growth of clean energy infrastructure. Its resistance to UV radiation and weathering ensures longevity in these outdoor applications, maximizing the efficiency of renewable energy systems over time.

Moreover, PETG's role in advancing sustainable resource deployment is evident in its potential for upcycling and repurposing. Unlike some plastics that degrade in quality upon recycling, PETG can maintain its properties through multiple recycling cycles. This characteristic opens up possibilities for innovative circular economy models, where PETG products can be continuously reprocessed and repurposed, significantly extending the lifecycle of the material and reducing the demand for virgin resources.

In conclusion, PETG's impact on sustainability is substantial and far-reaching. Its unique properties enable advancements in scalable resource deployment across various sectors, contributing to more efficient production processes, longer-lasting products, and improved recyclability. As industries continue to prioritize sustainability, PETG stands out as a material that aligns with these goals, offering solutions that balance performance with environmental responsibility.

PETG Manufacturing Process

The manufacturing process of PETG (Polyethylene Terephthalate Glycol-modified) plays a crucial role in enabling advancements in scalable resource deployment. This process involves several key stages, each contributing to the production of high-quality PETG materials suitable for various applications.

The first stage of PETG manufacturing begins with the polymerization of ethylene glycol and dimethyl terephthalate or terephthalic acid. This reaction takes place under controlled conditions, typically involving high temperatures and the presence of catalysts. The resulting polymer undergoes a series of modifications, including the addition of cyclohexanedimethanol (CHDM), which imparts enhanced properties to the final product.

Following polymerization, the PETG resin undergoes a drying process to remove any residual moisture. This step is critical in ensuring the quality and consistency of the final product. The dried resin is then fed into an extruder, where it is melted and homogenized under high temperature and pressure. The molten PETG is forced through a die, shaping it into the desired form, such as sheets, films, or pellets.

The extrusion process allows for precise control over the thickness and width of the PETG material. Cooling systems are employed to rapidly solidify the extruded PETG, preserving its desired properties and dimensions. For sheet production, the cooled material passes through a series of rollers that further refine its thickness and surface quality.

Quality control measures are implemented throughout the manufacturing process to ensure consistency and adherence to specifications. These may include in-line monitoring of thickness, optical properties, and mechanical characteristics. Post-production testing is also conducted to verify the material's performance in various applications.

The versatility of the PETG manufacturing process enables the production of materials with tailored properties. By adjusting parameters such as the ratio of components, processing temperatures, and cooling rates, manufacturers can fine-tune the PETG's characteristics to meet specific requirements for different industries and applications.

Advanced manufacturing techniques, such as co-extrusion and multi-layer extrusion, allow for the creation of PETG products with enhanced functionalities. These methods enable the combination of PETG with other materials or the production of PETG sheets with varying properties across their thickness, expanding the range of potential applications in scalable resource deployment scenarios.

The first stage of PETG manufacturing begins with the polymerization of ethylene glycol and dimethyl terephthalate or terephthalic acid. This reaction takes place under controlled conditions, typically involving high temperatures and the presence of catalysts. The resulting polymer undergoes a series of modifications, including the addition of cyclohexanedimethanol (CHDM), which imparts enhanced properties to the final product.

Following polymerization, the PETG resin undergoes a drying process to remove any residual moisture. This step is critical in ensuring the quality and consistency of the final product. The dried resin is then fed into an extruder, where it is melted and homogenized under high temperature and pressure. The molten PETG is forced through a die, shaping it into the desired form, such as sheets, films, or pellets.

The extrusion process allows for precise control over the thickness and width of the PETG material. Cooling systems are employed to rapidly solidify the extruded PETG, preserving its desired properties and dimensions. For sheet production, the cooled material passes through a series of rollers that further refine its thickness and surface quality.

Quality control measures are implemented throughout the manufacturing process to ensure consistency and adherence to specifications. These may include in-line monitoring of thickness, optical properties, and mechanical characteristics. Post-production testing is also conducted to verify the material's performance in various applications.

The versatility of the PETG manufacturing process enables the production of materials with tailored properties. By adjusting parameters such as the ratio of components, processing temperatures, and cooling rates, manufacturers can fine-tune the PETG's characteristics to meet specific requirements for different industries and applications.

Advanced manufacturing techniques, such as co-extrusion and multi-layer extrusion, allow for the creation of PETG products with enhanced functionalities. These methods enable the combination of PETG with other materials or the production of PETG sheets with varying properties across their thickness, expanding the range of potential applications in scalable resource deployment scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!