Developing PETG Smart Weldless Creation Processes

JUL 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Smart Welding Evolution and Objectives

Polyethylene terephthalate glycol (PETG) has emerged as a versatile and widely used thermoplastic in various industries, including packaging, automotive, and consumer goods. The evolution of PETG smart welding processes has been driven by the increasing demand for efficient, cost-effective, and environmentally friendly manufacturing techniques. This technological progression aims to address the challenges associated with traditional welding methods while enhancing the overall quality and performance of PETG products.

The development of PETG smart welding processes can be traced back to the early 2000s when researchers began exploring alternative joining techniques for thermoplastics. Initially, the focus was on improving existing methods such as ultrasonic welding and hot plate welding. However, these techniques often resulted in inconsistent weld quality and limited design flexibility. As a result, the industry recognized the need for more advanced and intelligent welding solutions.

In recent years, the advent of Industry 4.0 and the integration of smart technologies have revolutionized manufacturing processes, including PETG welding. The concept of smart welding for PETG involves the use of advanced sensors, real-time monitoring systems, and data analytics to optimize the welding process. This approach aims to achieve precise control over welding parameters, such as temperature, pressure, and time, resulting in higher-quality welds and reduced material waste.

The primary objectives of developing PETG smart weldless creation processes are multifaceted. Firstly, there is a strong emphasis on improving weld strength and durability, ensuring that the joined PETG components can withstand various environmental conditions and mechanical stresses. Secondly, the industry seeks to enhance process efficiency by reducing cycle times and minimizing energy consumption during welding operations. This not only improves productivity but also contributes to sustainability goals.

Another crucial objective is to expand the design possibilities for PETG products. Smart welding technologies aim to enable the creation of complex geometries and intricate designs that were previously challenging or impossible to achieve with traditional welding methods. This opens up new opportunities for product innovation and customization across various industries.

Furthermore, the development of PETG smart welding processes focuses on improving process consistency and repeatability. By leveraging advanced control systems and real-time monitoring, manufacturers can ensure that each weld meets the required quality standards, reducing defects and improving overall product reliability. This is particularly important in industries with stringent quality requirements, such as automotive and medical device manufacturing.

As the technology continues to evolve, researchers and industry professionals are exploring novel approaches to PETG smart welding. These include the integration of artificial intelligence and machine learning algorithms to optimize welding parameters based on material properties and environmental conditions. Additionally, there is growing interest in developing hybrid welding techniques that combine multiple energy sources or joining methods to achieve superior weld quality and efficiency.

The development of PETG smart welding processes can be traced back to the early 2000s when researchers began exploring alternative joining techniques for thermoplastics. Initially, the focus was on improving existing methods such as ultrasonic welding and hot plate welding. However, these techniques often resulted in inconsistent weld quality and limited design flexibility. As a result, the industry recognized the need for more advanced and intelligent welding solutions.

In recent years, the advent of Industry 4.0 and the integration of smart technologies have revolutionized manufacturing processes, including PETG welding. The concept of smart welding for PETG involves the use of advanced sensors, real-time monitoring systems, and data analytics to optimize the welding process. This approach aims to achieve precise control over welding parameters, such as temperature, pressure, and time, resulting in higher-quality welds and reduced material waste.

The primary objectives of developing PETG smart weldless creation processes are multifaceted. Firstly, there is a strong emphasis on improving weld strength and durability, ensuring that the joined PETG components can withstand various environmental conditions and mechanical stresses. Secondly, the industry seeks to enhance process efficiency by reducing cycle times and minimizing energy consumption during welding operations. This not only improves productivity but also contributes to sustainability goals.

Another crucial objective is to expand the design possibilities for PETG products. Smart welding technologies aim to enable the creation of complex geometries and intricate designs that were previously challenging or impossible to achieve with traditional welding methods. This opens up new opportunities for product innovation and customization across various industries.

Furthermore, the development of PETG smart welding processes focuses on improving process consistency and repeatability. By leveraging advanced control systems and real-time monitoring, manufacturers can ensure that each weld meets the required quality standards, reducing defects and improving overall product reliability. This is particularly important in industries with stringent quality requirements, such as automotive and medical device manufacturing.

As the technology continues to evolve, researchers and industry professionals are exploring novel approaches to PETG smart welding. These include the integration of artificial intelligence and machine learning algorithms to optimize welding parameters based on material properties and environmental conditions. Additionally, there is growing interest in developing hybrid welding techniques that combine multiple energy sources or joining methods to achieve superior weld quality and efficiency.

Market Analysis for PETG Smart Welding Solutions

The market for PETG smart welding solutions is experiencing significant growth, driven by the increasing demand for efficient and cost-effective manufacturing processes across various industries. PETG (Polyethylene Terephthalate Glycol-modified) has gained popularity as a versatile thermoplastic material due to its excellent clarity, impact resistance, and chemical resistance properties. The development of smart weldless creation processes for PETG has opened up new opportunities in sectors such as packaging, automotive, electronics, and medical devices.

The global PETG market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026, with the smart welding segment expected to outpace this growth rate. This surge is attributed to the rising adoption of automation and Industry 4.0 technologies in manufacturing processes, which align well with the principles of smart welding solutions.

In the packaging industry, which accounts for the largest share of PETG consumption, smart welding technologies are revolutionizing production lines by enabling faster, more precise, and energy-efficient joining of PETG components. This is particularly crucial in the food and beverage sector, where stringent hygiene standards and the need for tamper-evident packaging drive the demand for advanced welding solutions.

The automotive sector represents another significant market for PETG smart welding solutions. As vehicle manufacturers increasingly incorporate lightweight materials to improve fuel efficiency and reduce emissions, PETG components are becoming more prevalent. Smart welding processes offer the potential to create strong, durable bonds in complex automotive assemblies while minimizing material waste and production time.

In the medical device industry, the demand for PETG smart welding solutions is growing due to the material's biocompatibility and the need for precise, contamination-free joining methods. The ability to create seamless, weldless connections in medical devices enhances product quality and patient safety, driving adoption in this highly regulated sector.

The electronics industry is also a key market for PETG smart welding solutions, particularly in the production of consumer electronics and appliances. The trend towards miniaturization and increased functionality in electronic devices requires advanced joining techniques that can handle delicate components and maintain the integrity of sensitive electronic systems.

Geographically, Asia-Pacific is expected to be the fastest-growing market for PETG smart welding solutions, driven by rapid industrialization, increasing manufacturing activities, and the adoption of advanced technologies in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with a focus on high-value applications in aerospace, medical devices, and automotive industries.

As environmental concerns and sustainability initiatives gain prominence, the market for PETG smart welding solutions is likely to benefit from the material's recyclability and the potential for these processes to reduce waste and energy consumption in manufacturing. This aligns with the growing trend of circular economy practices and may further drive market growth in the coming years.

The global PETG market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026, with the smart welding segment expected to outpace this growth rate. This surge is attributed to the rising adoption of automation and Industry 4.0 technologies in manufacturing processes, which align well with the principles of smart welding solutions.

In the packaging industry, which accounts for the largest share of PETG consumption, smart welding technologies are revolutionizing production lines by enabling faster, more precise, and energy-efficient joining of PETG components. This is particularly crucial in the food and beverage sector, where stringent hygiene standards and the need for tamper-evident packaging drive the demand for advanced welding solutions.

The automotive sector represents another significant market for PETG smart welding solutions. As vehicle manufacturers increasingly incorporate lightweight materials to improve fuel efficiency and reduce emissions, PETG components are becoming more prevalent. Smart welding processes offer the potential to create strong, durable bonds in complex automotive assemblies while minimizing material waste and production time.

In the medical device industry, the demand for PETG smart welding solutions is growing due to the material's biocompatibility and the need for precise, contamination-free joining methods. The ability to create seamless, weldless connections in medical devices enhances product quality and patient safety, driving adoption in this highly regulated sector.

The electronics industry is also a key market for PETG smart welding solutions, particularly in the production of consumer electronics and appliances. The trend towards miniaturization and increased functionality in electronic devices requires advanced joining techniques that can handle delicate components and maintain the integrity of sensitive electronic systems.

Geographically, Asia-Pacific is expected to be the fastest-growing market for PETG smart welding solutions, driven by rapid industrialization, increasing manufacturing activities, and the adoption of advanced technologies in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with a focus on high-value applications in aerospace, medical devices, and automotive industries.

As environmental concerns and sustainability initiatives gain prominence, the market for PETG smart welding solutions is likely to benefit from the material's recyclability and the potential for these processes to reduce waste and energy consumption in manufacturing. This aligns with the growing trend of circular economy practices and may further drive market growth in the coming years.

PETG Weldless Techniques: Current State and Challenges

The development of PETG smart weldless creation processes represents a significant advancement in manufacturing technology. Currently, the industry faces several challenges in implementing these techniques effectively. One of the primary obstacles is achieving consistent bond strength across different PETG materials and thicknesses. Variations in material composition and surface properties can lead to inconsistent results, affecting the overall quality and reliability of the final product.

Another challenge lies in optimizing the process parameters for different applications. Factors such as temperature, pressure, and dwell time need to be carefully controlled to ensure proper bonding without compromising the material's integrity. This requires sophisticated process control systems and a deep understanding of PETG's behavior under various conditions.

The industry is also grappling with the need for increased automation in weldless creation processes. While manual techniques can produce high-quality results, they are often time-consuming and labor-intensive. Developing automated systems that can maintain the same level of precision and quality as manual processes remains a significant challenge.

Energy efficiency is another area of concern. Current weldless techniques often require substantial energy input, which can increase production costs and environmental impact. Researchers are exploring ways to reduce energy consumption while maintaining or improving bond strength and overall product quality.

Scalability presents another hurdle for widespread adoption of PETG weldless techniques. Many existing processes work well for small-scale production but face difficulties when scaled up to meet industrial demands. Developing solutions that can maintain consistency and quality across large production volumes is crucial for the technology's broader implementation.

Material compatibility is also a key challenge, particularly when joining PETG with other polymers or materials. Creating strong, durable bonds between dissimilar materials often requires specialized techniques and additives, which can complicate the manufacturing process and increase costs.

Despite these challenges, significant progress has been made in recent years. Advanced bonding technologies, such as ultrasonic welding and laser welding, have shown promise in overcoming some of these obstacles. These techniques offer improved precision, faster processing times, and the potential for greater automation.

Researchers are also exploring novel surface treatment methods to enhance bond strength and consistency. Plasma treatment and chemical etching techniques have demonstrated the ability to modify PETG surfaces at the molecular level, improving adhesion properties and expanding the range of compatible materials.

Another challenge lies in optimizing the process parameters for different applications. Factors such as temperature, pressure, and dwell time need to be carefully controlled to ensure proper bonding without compromising the material's integrity. This requires sophisticated process control systems and a deep understanding of PETG's behavior under various conditions.

The industry is also grappling with the need for increased automation in weldless creation processes. While manual techniques can produce high-quality results, they are often time-consuming and labor-intensive. Developing automated systems that can maintain the same level of precision and quality as manual processes remains a significant challenge.

Energy efficiency is another area of concern. Current weldless techniques often require substantial energy input, which can increase production costs and environmental impact. Researchers are exploring ways to reduce energy consumption while maintaining or improving bond strength and overall product quality.

Scalability presents another hurdle for widespread adoption of PETG weldless techniques. Many existing processes work well for small-scale production but face difficulties when scaled up to meet industrial demands. Developing solutions that can maintain consistency and quality across large production volumes is crucial for the technology's broader implementation.

Material compatibility is also a key challenge, particularly when joining PETG with other polymers or materials. Creating strong, durable bonds between dissimilar materials often requires specialized techniques and additives, which can complicate the manufacturing process and increase costs.

Despite these challenges, significant progress has been made in recent years. Advanced bonding technologies, such as ultrasonic welding and laser welding, have shown promise in overcoming some of these obstacles. These techniques offer improved precision, faster processing times, and the potential for greater automation.

Researchers are also exploring novel surface treatment methods to enhance bond strength and consistency. Plasma treatment and chemical etching techniques have demonstrated the ability to modify PETG surfaces at the molecular level, improving adhesion properties and expanding the range of compatible materials.

Existing PETG Smart Weldless Creation Methods

01 PETG composition and manufacturing process

PETG is a modified form of PET with improved properties. The manufacturing process involves copolymerization of ethylene glycol with terephthalic acid and cyclohexanedimethanol. This composition results in a material with enhanced clarity, toughness, and chemical resistance, making it suitable for weldless applications.- PETG composition and manufacturing process: PETG is a modified form of PET with improved properties. The manufacturing process involves copolymerization of ethylene glycol with terephthalic acid and cyclohexanedimethanol. This composition results in a material with enhanced clarity, toughness, and chemical resistance, making it suitable for weldless applications.

- PETG-based composite materials: Composite materials incorporating PETG as a matrix or component can enhance its properties for weldless applications. These composites may include reinforcing fibers, nanoparticles, or other polymers to improve strength, thermal stability, and barrier properties while maintaining the ability to create seamless structures.

- Extrusion and molding techniques for PETG: Specialized extrusion and molding techniques are developed for PETG to create weldless structures. These methods may include co-extrusion, injection molding, or blow molding processes that allow for the formation of complex shapes without the need for welding or joining separate pieces.

- Surface treatment and coating of PETG: Surface treatments and coatings can be applied to PETG to enhance its properties for weldless applications. These treatments may improve adhesion, chemical resistance, or provide additional functionality such as antimicrobial properties, while maintaining the integrity of the weldless structure.

- PETG in packaging and container applications: PETG is utilized in packaging and container applications where weldless creation is crucial. This includes the development of seamless bottles, jars, and other containers that require high clarity, impact resistance, and the ability to maintain their shape without welded joints.

02 Extrusion and molding techniques for PETG

Various extrusion and molding techniques are employed to create weldless PETG products. These include injection molding, blow molding, and extrusion blow molding. The processes are optimized to maintain the material's properties while achieving the desired shape and structure without the need for welding.Expand Specific Solutions03 Surface treatment and coating for PETG

Surface treatments and coatings are applied to PETG to enhance its properties and eliminate the need for welding. These treatments can improve adhesion, scratch resistance, and durability. Techniques such as plasma treatment, UV curing, and application of specialized coatings are used to achieve desired surface characteristics.Expand Specific Solutions04 PETG blending and additives

Blending PETG with other polymers or incorporating additives can improve its properties for weldless applications. This includes the use of impact modifiers, UV stabilizers, and other functional additives to enhance performance and eliminate the need for welding in certain applications.Expand Specific Solutions05 Design considerations for weldless PETG products

Specific design considerations are implemented to create weldless PETG products. This includes optimizing part geometry, incorporating snap-fit or interlocking features, and utilizing advanced CAD/CAM techniques to design products that can be assembled without welding while maintaining structural integrity and functionality.Expand Specific Solutions

Key Industry Players in PETG Smart Welding

The development of PETG Smart Weldless Creation Processes is in its early stages, with the market still emerging and technology maturity relatively low. Key players like China Resources Chemical Innovative Materials and Suqian Jinghong Color Printing & Packing are leading research efforts, while companies such as Zhuhai Huarun Packing Material and Jiangsu Huaxin High-tech Materials are also contributing to advancements. The competitive landscape is characterized by a mix of established chemical companies and newer specialized materials firms, all vying to develop and commercialize this innovative technology. As the market grows, we can expect increased competition and rapid technological progress in this field.

China Resources Chemical Innovative Materials Co., Ltd.

Technical Solution: China Resources Chemical has developed a PETG smart weldless creation process that focuses on high-volume manufacturing efficiency. Their approach utilizes a modified injection molding technique combined with in-mold assembly technology[13]. The process involves injecting specially formulated PETG with smart additives into a mold that contains pre-positioned components or inserts. As the PETG cools and solidifies, it forms strong molecular bonds with the inserts, eliminating the need for traditional welding[15]. The company has also incorporated real-time monitoring systems using embedded sensors to ensure consistent bond quality and optimize process parameters during production[17].

Strengths: High production efficiency, reduced assembly steps, and consistent bond quality. Weaknesses: Limited to certain product designs that are compatible with in-mold assembly and potential higher tooling costs.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a PETG smart weldless creation process that leverages their expertise in adhesive technologies and material science. Their approach combines a specially developed PETG formulation with a proprietary adhesive system that creates strong, durable bonds without traditional welding[8]. The process involves applying a thin layer of the smart adhesive to the PETG surfaces, which is then activated by a controlled application of heat or UV light[10]. This triggers a chemical reaction that forms covalent bonds between the adhesive and the PETG substrate, resulting in a seamless and robust connection[12]. 3M's method also incorporates self-healing properties into the adhesive, allowing for improved long-term durability and resistance to environmental factors.

Strengths: Versatile application across various PETG product types, excellent bond strength, and enhanced durability. Weaknesses: Additional material cost for the adhesive system and potential limitations in high-temperature applications.

Innovative PETG Joining Techniques Analysis

Process for the production of glycol-modified polyethylene terephthalate from recycled raw materials

PatentActiveCA3025206C

Innovation

- A process involving the depolymerization of recycled PET in the presence of monoethylene glycol and neopentyl glycol, followed by polymerization under specific temperature and pressure conditions, to produce polyethylene terephthalate glycol-modified (r-PETG) without separating monomers, enabling the creation of a food-grade material suitable for various applications.

Process for the production of glycol-modified polyethylene therephthalate from recycled raw materials

PatentActiveEP3320017A1

Innovation

- A process involving the depolymerization of recycled PET in the presence of monoethylene glycol and neopentyl glycol, followed by polymerization without monomer separation, to produce polyethylene terephthalate glycol-modified (r-PETG) with improved physical and mechanical properties, making it suitable for food-grade applications.

Environmental Impact of PETG Smart Welding Processes

The environmental impact of PETG smart welding processes is a critical consideration in the development of sustainable manufacturing techniques. PETG (Polyethylene Terephthalate Glycol-modified) is a widely used thermoplastic polymer known for its durability and versatility. However, traditional welding methods for PETG often involve high energy consumption and the release of potentially harmful emissions.

Smart welding processes for PETG aim to address these environmental concerns by optimizing energy usage and minimizing waste. These advanced techniques utilize precise control systems and real-time monitoring to ensure efficient heat distribution and material fusion. By reducing the overall energy input required for welding, smart processes contribute to lower greenhouse gas emissions associated with manufacturing operations.

One of the key environmental benefits of PETG smart welding is the reduction in material waste. Traditional welding methods often result in excess material being trimmed or discarded, leading to increased resource consumption and waste generation. Smart welding processes, on the other hand, employ advanced algorithms and sensors to optimize material usage, resulting in minimal scrap and improved resource efficiency.

Furthermore, smart welding techniques for PETG often incorporate closed-loop systems that capture and recycle any volatile organic compounds (VOCs) released during the welding process. This not only reduces air pollution but also helps manufacturers comply with increasingly stringent environmental regulations. The implementation of such systems can significantly decrease the overall environmental footprint of PETG manufacturing operations.

Water consumption is another important environmental factor addressed by smart welding processes. Traditional welding methods may require substantial amounts of water for cooling or cleaning purposes. Smart welding techniques often incorporate dry or low-water alternatives, reducing the strain on local water resources and minimizing wastewater generation.

The longevity and durability of PETG products created through smart welding processes also contribute to their environmental benefits. By ensuring high-quality, consistent welds, these techniques produce products with extended lifespans, reducing the need for frequent replacements and ultimately decreasing the overall environmental impact associated with product lifecycle.

As the manufacturing industry continues to prioritize sustainability, the development of PETG smart welding processes represents a significant step towards more environmentally friendly production methods. These innovative techniques not only improve the efficiency and quality of PETG welding but also align with global efforts to reduce industrial environmental impacts and promote circular economy principles.

Smart welding processes for PETG aim to address these environmental concerns by optimizing energy usage and minimizing waste. These advanced techniques utilize precise control systems and real-time monitoring to ensure efficient heat distribution and material fusion. By reducing the overall energy input required for welding, smart processes contribute to lower greenhouse gas emissions associated with manufacturing operations.

One of the key environmental benefits of PETG smart welding is the reduction in material waste. Traditional welding methods often result in excess material being trimmed or discarded, leading to increased resource consumption and waste generation. Smart welding processes, on the other hand, employ advanced algorithms and sensors to optimize material usage, resulting in minimal scrap and improved resource efficiency.

Furthermore, smart welding techniques for PETG often incorporate closed-loop systems that capture and recycle any volatile organic compounds (VOCs) released during the welding process. This not only reduces air pollution but also helps manufacturers comply with increasingly stringent environmental regulations. The implementation of such systems can significantly decrease the overall environmental footprint of PETG manufacturing operations.

Water consumption is another important environmental factor addressed by smart welding processes. Traditional welding methods may require substantial amounts of water for cooling or cleaning purposes. Smart welding techniques often incorporate dry or low-water alternatives, reducing the strain on local water resources and minimizing wastewater generation.

The longevity and durability of PETG products created through smart welding processes also contribute to their environmental benefits. By ensuring high-quality, consistent welds, these techniques produce products with extended lifespans, reducing the need for frequent replacements and ultimately decreasing the overall environmental impact associated with product lifecycle.

As the manufacturing industry continues to prioritize sustainability, the development of PETG smart welding processes represents a significant step towards more environmentally friendly production methods. These innovative techniques not only improve the efficiency and quality of PETG welding but also align with global efforts to reduce industrial environmental impacts and promote circular economy principles.

Quality Control in PETG Smart Weldless Manufacturing

Quality control plays a crucial role in the development of PETG smart weldless creation processes. As manufacturers strive to produce high-quality, durable products using this innovative technique, implementing robust quality control measures becomes paramount. The quality control process for PETG smart weldless manufacturing encompasses several key aspects that ensure consistent and reliable output.

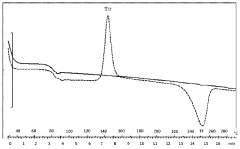

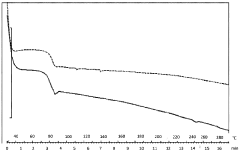

One of the primary focus areas in quality control is material inspection. PETG (Polyethylene Terephthalate Glycol-modified) must meet specific standards in terms of composition, purity, and physical properties. Rigorous testing of raw materials before production helps prevent defects and ensures optimal performance of the final product. This includes checks for molecular weight distribution, intrinsic viscosity, and thermal stability.

Process monitoring is another critical component of quality control in PETG smart weldless manufacturing. Advanced sensors and real-time data analytics are employed to track various parameters throughout the production process. These may include temperature profiles, pressure levels, and cycle times. By continuously monitoring these factors, manufacturers can detect and address deviations promptly, maintaining consistent quality across production runs.

Dimensional accuracy is a key quality metric in weldless creation processes. Sophisticated measurement tools, such as 3D scanners and coordinate measuring machines (CMMs), are utilized to verify that produced parts meet specified tolerances. This is particularly important for complex geometries or components that require precise fitting with other parts in an assembly.

Non-destructive testing (NDT) techniques play a vital role in assessing the integrity of PETG smart weldless products. Methods such as ultrasonic testing, X-ray inspection, and thermal imaging can reveal internal defects or structural weaknesses that may not be visible to the naked eye. These techniques help ensure that the final products meet stringent quality and safety standards.

Surface finish and appearance are also important quality control considerations. Visual inspection, both manual and automated, is conducted to identify surface imperfections, color inconsistencies, or other cosmetic defects. Advanced imaging systems and machine vision technology can be employed to detect even minor flaws that might affect the product's aesthetics or functionality.

Mechanical testing forms an integral part of the quality control process. This includes strength tests, impact resistance evaluations, and fatigue testing to verify that the PETG smart weldless products meet specified performance criteria. Such tests help validate the durability and reliability of the manufactured items under various conditions.

Traceability is a key aspect of modern quality control systems. Implementing a robust tracking system allows manufacturers to trace each product back to its raw materials, production batch, and specific process parameters. This not only aids in quality assurance but also facilitates efficient problem-solving and continuous improvement efforts.

In conclusion, quality control in PETG smart weldless manufacturing is a multifaceted process that combines material science, advanced technology, and rigorous testing methodologies. By implementing comprehensive quality control measures, manufacturers can ensure the production of high-quality, reliable PETG smart weldless products that meet or exceed industry standards and customer expectations.

One of the primary focus areas in quality control is material inspection. PETG (Polyethylene Terephthalate Glycol-modified) must meet specific standards in terms of composition, purity, and physical properties. Rigorous testing of raw materials before production helps prevent defects and ensures optimal performance of the final product. This includes checks for molecular weight distribution, intrinsic viscosity, and thermal stability.

Process monitoring is another critical component of quality control in PETG smart weldless manufacturing. Advanced sensors and real-time data analytics are employed to track various parameters throughout the production process. These may include temperature profiles, pressure levels, and cycle times. By continuously monitoring these factors, manufacturers can detect and address deviations promptly, maintaining consistent quality across production runs.

Dimensional accuracy is a key quality metric in weldless creation processes. Sophisticated measurement tools, such as 3D scanners and coordinate measuring machines (CMMs), are utilized to verify that produced parts meet specified tolerances. This is particularly important for complex geometries or components that require precise fitting with other parts in an assembly.

Non-destructive testing (NDT) techniques play a vital role in assessing the integrity of PETG smart weldless products. Methods such as ultrasonic testing, X-ray inspection, and thermal imaging can reveal internal defects or structural weaknesses that may not be visible to the naked eye. These techniques help ensure that the final products meet stringent quality and safety standards.

Surface finish and appearance are also important quality control considerations. Visual inspection, both manual and automated, is conducted to identify surface imperfections, color inconsistencies, or other cosmetic defects. Advanced imaging systems and machine vision technology can be employed to detect even minor flaws that might affect the product's aesthetics or functionality.

Mechanical testing forms an integral part of the quality control process. This includes strength tests, impact resistance evaluations, and fatigue testing to verify that the PETG smart weldless products meet specified performance criteria. Such tests help validate the durability and reliability of the manufactured items under various conditions.

Traceability is a key aspect of modern quality control systems. Implementing a robust tracking system allows manufacturers to trace each product back to its raw materials, production batch, and specific process parameters. This not only aids in quality assurance but also facilitates efficient problem-solving and continuous improvement efforts.

In conclusion, quality control in PETG smart weldless manufacturing is a multifaceted process that combines material science, advanced technology, and rigorous testing methodologies. By implementing comprehensive quality control measures, manufacturers can ensure the production of high-quality, reliable PETG smart weldless products that meet or exceed industry standards and customer expectations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!