How Advanced PETG Applications Support Renewable Resource Management

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Evolution and Objectives

Polyethylene terephthalate glycol (PETG) has emerged as a significant player in the field of renewable resource management, evolving from its initial applications in packaging to become a versatile material with advanced capabilities. The journey of PETG began in the 1970s as a modified version of PET, offering improved clarity, durability, and processability. Over the decades, its potential in supporting sustainable practices has become increasingly apparent.

The evolution of PETG has been marked by continuous improvements in its chemical composition and manufacturing processes. Early iterations focused on enhancing its physical properties, such as impact resistance and thermal stability. As environmental concerns gained prominence, research shifted towards developing PETG variants with improved recyclability and biodegradability. This progression aligns with the growing global emphasis on circular economy principles and sustainable material use.

In recent years, the objectives for PETG development have expanded significantly, driven by the urgent need for renewable resource management solutions. One primary goal is to optimize PETG's role in reducing plastic waste through enhanced recyclability and the integration of bio-based components. Researchers are exploring ways to incorporate renewable feedstocks into PETG production, aiming to decrease reliance on fossil fuel-derived materials.

Another critical objective is to leverage PETG's unique properties in creating advanced applications that directly support renewable resource management. This includes developing PETG-based materials for water filtration systems, enhancing the efficiency of solar panels, and improving the performance of wind turbine components. The material's clarity, strength, and chemical resistance make it an ideal candidate for these environmentally crucial applications.

The current technological landscape surrounding PETG is focused on pushing the boundaries of its capabilities. Objectives include developing PETG composites that combine the material's inherent benefits with those of other sustainable materials, such as natural fibers or recycled content. These efforts aim to create high-performance, eco-friendly materials suitable for a wide range of applications in renewable energy infrastructure and resource conservation technologies.

Furthermore, there is a growing emphasis on optimizing the end-of-life management of PETG products. This involves improving collection and sorting systems, enhancing recycling technologies, and exploring innovative methods for PETG decomposition that minimize environmental impact. The ultimate goal is to establish a closed-loop system where PETG materials can be efficiently recycled or safely biodegraded, supporting a more sustainable approach to resource management.

As we look to the future, the evolution of PETG in the context of renewable resource management is poised to accelerate. Objectives are likely to include the development of "smart" PETG materials that can adapt to environmental conditions, further improving their efficiency in resource conservation applications. Additionally, integrating PETG into advanced manufacturing techniques, such as 3D printing, opens up new possibilities for creating customized, sustainable solutions for complex environmental challenges.

The evolution of PETG has been marked by continuous improvements in its chemical composition and manufacturing processes. Early iterations focused on enhancing its physical properties, such as impact resistance and thermal stability. As environmental concerns gained prominence, research shifted towards developing PETG variants with improved recyclability and biodegradability. This progression aligns with the growing global emphasis on circular economy principles and sustainable material use.

In recent years, the objectives for PETG development have expanded significantly, driven by the urgent need for renewable resource management solutions. One primary goal is to optimize PETG's role in reducing plastic waste through enhanced recyclability and the integration of bio-based components. Researchers are exploring ways to incorporate renewable feedstocks into PETG production, aiming to decrease reliance on fossil fuel-derived materials.

Another critical objective is to leverage PETG's unique properties in creating advanced applications that directly support renewable resource management. This includes developing PETG-based materials for water filtration systems, enhancing the efficiency of solar panels, and improving the performance of wind turbine components. The material's clarity, strength, and chemical resistance make it an ideal candidate for these environmentally crucial applications.

The current technological landscape surrounding PETG is focused on pushing the boundaries of its capabilities. Objectives include developing PETG composites that combine the material's inherent benefits with those of other sustainable materials, such as natural fibers or recycled content. These efforts aim to create high-performance, eco-friendly materials suitable for a wide range of applications in renewable energy infrastructure and resource conservation technologies.

Furthermore, there is a growing emphasis on optimizing the end-of-life management of PETG products. This involves improving collection and sorting systems, enhancing recycling technologies, and exploring innovative methods for PETG decomposition that minimize environmental impact. The ultimate goal is to establish a closed-loop system where PETG materials can be efficiently recycled or safely biodegraded, supporting a more sustainable approach to resource management.

As we look to the future, the evolution of PETG in the context of renewable resource management is poised to accelerate. Objectives are likely to include the development of "smart" PETG materials that can adapt to environmental conditions, further improving their efficiency in resource conservation applications. Additionally, integrating PETG into advanced manufacturing techniques, such as 3D printing, opens up new possibilities for creating customized, sustainable solutions for complex environmental challenges.

Renewable Resource Market Analysis

The renewable resource market has experienced significant growth in recent years, driven by increasing environmental awareness, government policies, and technological advancements. This market encompasses various sectors, including renewable energy, sustainable materials, and eco-friendly products. The global renewable resource market was valued at approximately $928 billion in 2020 and is projected to reach $1,512 billion by 2025, growing at a CAGR of 10.3% during the forecast period.

Within this market, advanced PETG (Polyethylene Terephthalate Glycol) applications are gaining traction due to their potential to support sustainable resource management. PETG, a modified version of PET, offers improved durability, clarity, and recyclability, making it an attractive option for various industries seeking to reduce their environmental impact.

The demand for PETG in renewable resource management is primarily driven by its applications in packaging, construction, and consumer goods. In the packaging sector, PETG is increasingly used for food containers, beverage bottles, and personal care product packaging, offering a more sustainable alternative to traditional plastics. The construction industry is adopting PETG for energy-efficient windows, skylights, and architectural panels, contributing to improved building sustainability.

Consumer awareness of environmental issues has led to a growing preference for eco-friendly products, further boosting the demand for PETG-based solutions. This trend is particularly evident in the consumer goods sector, where PETG is used in reusable water bottles, household items, and electronics casings.

The renewable resource market faces several challenges, including high initial costs, technological limitations, and regulatory hurdles. However, ongoing research and development in PETG applications are addressing these issues, leading to more cost-effective and efficient solutions. Innovations in PETG formulations and processing techniques are expanding its potential applications in renewable resource management.

Geographically, North America and Europe lead the market for advanced PETG applications in renewable resource management, driven by stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, urbanization, and increasing government initiatives to promote sustainable development.

Key market players in the PETG sector are investing heavily in research and development to enhance the material's properties and expand its applications in renewable resource management. Collaborations between material manufacturers, end-users, and research institutions are accelerating innovation in this field, leading to the development of more sustainable and efficient PETG-based solutions.

As the renewable resource market continues to evolve, advanced PETG applications are poised to play a crucial role in supporting sustainable resource management across various industries. The material's versatility, recyclability, and improving cost-effectiveness position it as a key enabler in the transition towards a more circular and sustainable economy.

Within this market, advanced PETG (Polyethylene Terephthalate Glycol) applications are gaining traction due to their potential to support sustainable resource management. PETG, a modified version of PET, offers improved durability, clarity, and recyclability, making it an attractive option for various industries seeking to reduce their environmental impact.

The demand for PETG in renewable resource management is primarily driven by its applications in packaging, construction, and consumer goods. In the packaging sector, PETG is increasingly used for food containers, beverage bottles, and personal care product packaging, offering a more sustainable alternative to traditional plastics. The construction industry is adopting PETG for energy-efficient windows, skylights, and architectural panels, contributing to improved building sustainability.

Consumer awareness of environmental issues has led to a growing preference for eco-friendly products, further boosting the demand for PETG-based solutions. This trend is particularly evident in the consumer goods sector, where PETG is used in reusable water bottles, household items, and electronics casings.

The renewable resource market faces several challenges, including high initial costs, technological limitations, and regulatory hurdles. However, ongoing research and development in PETG applications are addressing these issues, leading to more cost-effective and efficient solutions. Innovations in PETG formulations and processing techniques are expanding its potential applications in renewable resource management.

Geographically, North America and Europe lead the market for advanced PETG applications in renewable resource management, driven by stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, urbanization, and increasing government initiatives to promote sustainable development.

Key market players in the PETG sector are investing heavily in research and development to enhance the material's properties and expand its applications in renewable resource management. Collaborations between material manufacturers, end-users, and research institutions are accelerating innovation in this field, leading to the development of more sustainable and efficient PETG-based solutions.

As the renewable resource market continues to evolve, advanced PETG applications are poised to play a crucial role in supporting sustainable resource management across various industries. The material's versatility, recyclability, and improving cost-effectiveness position it as a key enabler in the transition towards a more circular and sustainable economy.

PETG Challenges in Sustainability

PETG (Polyethylene Terephthalate Glycol-modified) has gained significant attention in the field of sustainable materials due to its potential to support renewable resource management. However, several challenges persist in fully realizing its sustainability potential.

One of the primary challenges is the energy-intensive production process of PETG. While it offers improved properties compared to traditional PET, the additional glycol modification step increases energy consumption and carbon emissions during manufacturing. This raises concerns about the overall environmental impact of PETG production, particularly in regions where energy grids are heavily reliant on fossil fuels.

Recycling PETG presents another significant challenge. Although PETG is technically recyclable, its chemical structure differs slightly from PET, which can complicate existing recycling streams. Many recycling facilities are not equipped to properly sort and process PETG, leading to potential contamination of PET recycling streams or PETG being diverted to landfills. This issue undermines the material's circular economy potential and its ability to contribute effectively to renewable resource management.

The durability of PETG, while beneficial for many applications, poses a challenge in terms of biodegradability. In environments where proper recycling infrastructure is lacking, PETG products may persist for extended periods, contributing to plastic pollution. This longevity conflicts with the principles of sustainable resource management, especially in scenarios where single-use or short-term applications are prevalent.

Another challenge lies in the sourcing of raw materials for PETG production. While efforts are being made to incorporate bio-based components, the majority of PETG is still derived from petroleum-based sources. This dependence on non-renewable resources contradicts the goal of sustainable resource management and highlights the need for more renewable feedstock alternatives.

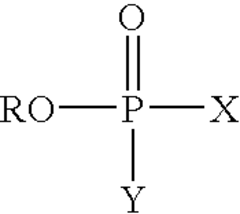

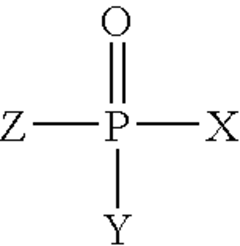

The additives used in PETG formulations to enhance its properties can also pose sustainability challenges. Some of these additives may hinder recycling processes or introduce potentially harmful substances into the environment upon degradation. Balancing the performance requirements of PETG with environmentally friendly additives remains an ongoing challenge for manufacturers and researchers.

Lastly, the lack of standardized sustainability metrics and life cycle assessment methodologies specific to PETG makes it difficult to accurately compare its environmental impact with alternative materials. This absence of clear benchmarks complicates decision-making processes for businesses and policymakers when considering PETG as a sustainable material option in various applications.

One of the primary challenges is the energy-intensive production process of PETG. While it offers improved properties compared to traditional PET, the additional glycol modification step increases energy consumption and carbon emissions during manufacturing. This raises concerns about the overall environmental impact of PETG production, particularly in regions where energy grids are heavily reliant on fossil fuels.

Recycling PETG presents another significant challenge. Although PETG is technically recyclable, its chemical structure differs slightly from PET, which can complicate existing recycling streams. Many recycling facilities are not equipped to properly sort and process PETG, leading to potential contamination of PET recycling streams or PETG being diverted to landfills. This issue undermines the material's circular economy potential and its ability to contribute effectively to renewable resource management.

The durability of PETG, while beneficial for many applications, poses a challenge in terms of biodegradability. In environments where proper recycling infrastructure is lacking, PETG products may persist for extended periods, contributing to plastic pollution. This longevity conflicts with the principles of sustainable resource management, especially in scenarios where single-use or short-term applications are prevalent.

Another challenge lies in the sourcing of raw materials for PETG production. While efforts are being made to incorporate bio-based components, the majority of PETG is still derived from petroleum-based sources. This dependence on non-renewable resources contradicts the goal of sustainable resource management and highlights the need for more renewable feedstock alternatives.

The additives used in PETG formulations to enhance its properties can also pose sustainability challenges. Some of these additives may hinder recycling processes or introduce potentially harmful substances into the environment upon degradation. Balancing the performance requirements of PETG with environmentally friendly additives remains an ongoing challenge for manufacturers and researchers.

Lastly, the lack of standardized sustainability metrics and life cycle assessment methodologies specific to PETG makes it difficult to accurately compare its environmental impact with alternative materials. This absence of clear benchmarks complicates decision-making processes for businesses and policymakers when considering PETG as a sustainable material option in various applications.

Current PETG Sustainability Solutions

01 Composition and properties of PETG

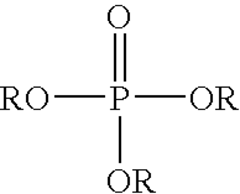

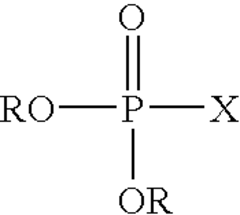

PETG is a copolyester derived from polyethylene terephthalate (PET) with added glycol. It offers improved clarity, toughness, and processability compared to standard PET. PETG is known for its excellent chemical resistance, impact strength, and dimensional stability, making it suitable for various applications.- Composition and properties of PETG: PETG is a copolyester derived from polyethylene terephthalate (PET) with added glycol. It offers improved clarity, toughness, and chemical resistance compared to standard PET. PETG is known for its ease of processing, good impact strength, and ability to be thermoformed.

- Applications of PETG in packaging: PETG is widely used in packaging applications due to its excellent transparency, barrier properties, and formability. It is commonly used for food containers, beverage bottles, cosmetic packaging, and pharmaceutical blister packs. PETG's ability to maintain clarity and strength makes it suitable for various packaging designs.

- PETG in 3D printing and additive manufacturing: PETG has gained popularity in 3D printing due to its ease of use, good layer adhesion, and minimal warping. It offers a balance between the ease of printing found in PLA and the strength and durability of ABS. PETG filaments are used in various 3D printing applications, including prototyping and functional parts.

- PETG blends and composites: PETG can be blended with other polymers or reinforced with additives to enhance its properties. These blends and composites can improve characteristics such as heat resistance, mechanical strength, or specific functionalities. Research in this area focuses on developing new materials with tailored properties for various applications.

- PETG in medical and healthcare applications: PETG's biocompatibility, sterilizability, and clarity make it suitable for medical and healthcare applications. It is used in medical device components, laboratory equipment, and diagnostic tools. PETG's resistance to chemicals and ability to maintain its properties after sterilization contribute to its popularity in this sector.

02 Applications of PETG in packaging

PETG is widely used in packaging applications due to its transparency, durability, and food-safe properties. It is commonly employed in the production of bottles, containers, and films for food, beverages, cosmetics, and pharmaceuticals. PETG packaging offers good barrier properties and can be easily molded or thermoformed into various shapes.Expand Specific Solutions03 PETG in 3D printing and additive manufacturing

PETG has gained popularity as a filament material for 3D printing due to its ease of use, good layer adhesion, and minimal warping. It offers a balance between strength and flexibility, making it suitable for prototyping and functional parts. PETG filaments are available in various colors and can be used in a wide range of 3D printing applications.Expand Specific Solutions04 PETG blends and composites

PETG can be blended with other polymers or reinforced with additives to enhance its properties for specific applications. These blends and composites can improve characteristics such as heat resistance, mechanical strength, or flame retardancy. Researchers are exploring various PETG-based materials to expand its potential uses in different industries.Expand Specific Solutions05 Recycling and sustainability of PETG

As environmental concerns grow, efforts are being made to improve the recyclability and sustainability of PETG. Research is focused on developing efficient recycling processes, exploring bio-based alternatives, and creating closed-loop systems for PETG products. The goal is to reduce the environmental impact of PETG while maintaining its desirable properties for various applications.Expand Specific Solutions

Key PETG Industry Players

The advanced PETG applications market for renewable resource management is in a growth phase, driven by increasing demand for sustainable materials. The market size is expanding as more industries adopt PETG solutions for eco-friendly packaging and products. Technologically, PETG applications are maturing, with companies like State Grid Corp. of China, Henan Yuanhong Polymer, and Eastman Chemical leading innovations. These firms are developing advanced PETG formulations with enhanced properties for renewable resource applications. The competitive landscape is characterized by a mix of established chemical companies and emerging materials technology firms, each striving to differentiate through proprietary PETG technologies and sustainable solutions.

Henan Yuanhong Polymer New Material Co Ltd.

Technical Solution: Henan Yuanhong Polymer New Material Co Ltd. specializes in the production of PETG materials with applications in renewable resource management. The company has developed a range of PETG products with enhanced biodegradability and recyclability. Their PETG formulations incorporate additives that accelerate the breakdown of the polymer in specific environmental conditions, reducing the long-term impact on ecosystems[4]. Additionally, Yuanhong has invested in research to improve the compatibility of their PETG materials with existing recycling streams, ensuring easier integration into circular economy models. The company has also explored the use of bio-based feedstocks in PETG production, aiming to reduce reliance on fossil fuel-derived raw materials[5].

Strengths: Focus on biodegradability and recyclability, research into bio-based alternatives. Weaknesses: Limited global market presence, potential trade-offs between biodegradability and material performance.

Technical Institute of Physics & Chemistry CAS

Technical Solution: The Technical Institute of Physics & Chemistry CAS has conducted extensive research on advanced PETG applications for renewable resource management. Their work focuses on developing novel PETG composites with enhanced properties for environmental applications. The institute has created PETG-based materials with improved barrier properties for packaging, reducing food waste and extending shelf life[6]. They have also explored the incorporation of nanoparticles into PETG matrices to enhance mechanical properties and UV resistance, making the materials more durable and suitable for long-term outdoor applications in renewable energy systems[7]. Additionally, the institute has investigated the use of PETG in advanced membrane technologies for water purification and resource recovery, contributing to more efficient water management practices[8].

Strengths: Cutting-edge research in PETG composites, focus on practical environmental applications. Weaknesses: Potential gap between laboratory research and industrial-scale implementation, limited commercial partnerships.

Innovative PETG Recycling Techniques

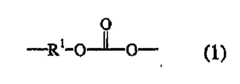

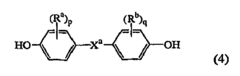

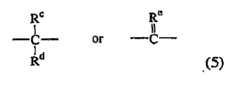

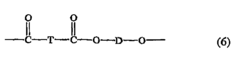

Molding compositions containing polycarbonate and modified polybutylene terephthalate(PBT) random copolymers derived from polyethylene terephthalate (PET)

PatentActiveEP2145919A1

Innovation

- Development of a molding composition comprising a modified polybutylene terephthalate random copolymer derived from PET, combined with polycarbonate and impact modifiers, which includes residues such as ethylene glycol and isophthalic acid groups, allowing for the creation of thermoplastic compositions with improved flow properties and reduced CO2 emissions.

Molding compositions containing polyalkylene terephthalates and modified polybutylene terephthalate (PBT) random copolymers derived from PET

PatentActiveUS7855238B2

Innovation

- Development of molding compositions comprising modified polybutylene terephthalate random copolymers derived from PET, incorporating residues like ethylene glycol and isophthalic acid, and combining with polyalkylene terephthalate and additives to create materials with performance comparable to virgin PBT, while reducing CO2 emissions.

Environmental Regulations Impact

Environmental regulations play a crucial role in shaping the adoption and implementation of advanced PETG applications in renewable resource management. These regulations, which vary across different regions and countries, set the framework for sustainable practices and drive innovation in the field of recyclable plastics.

In recent years, there has been a global push towards more stringent environmental policies, particularly concerning plastic waste management. Many countries have introduced legislation aimed at reducing single-use plastics and promoting recycling initiatives. These regulations have significantly impacted the PETG industry, encouraging manufacturers to develop more sustainable and recyclable PETG products.

The European Union, for instance, has implemented the Circular Economy Action Plan, which includes specific targets for plastic recycling and reuse. This has led to increased investment in advanced PETG applications that support closed-loop recycling systems. Similarly, in the United States, various states have enacted laws mandating the use of recycled content in plastic packaging, driving demand for high-quality recycled PETG materials.

Environmental regulations have also influenced the development of innovative PETG formulations that are more easily recyclable and biodegradable. Manufacturers are now focusing on creating PETG products that can be efficiently sorted and processed in existing recycling facilities, aligning with the requirements set forth by regulatory bodies.

Furthermore, extended producer responsibility (EPR) schemes have been introduced in many countries, holding manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. This has incentivized companies to invest in advanced PETG applications that facilitate easier collection, sorting, and recycling of plastic waste.

The impact of these regulations extends beyond the manufacturing process to encompass the entire supply chain. Companies are now required to provide detailed information about the environmental impact of their PETG products, including carbon footprint and recyclability. This has led to the development of more transparent and traceable supply chains, as well as improved lifecycle assessment methodologies for PETG materials.

As environmental regulations continue to evolve, they are expected to drive further advancements in PETG applications for renewable resource management. This includes the development of new recycling technologies, the creation of more efficient collection and sorting systems, and the exploration of alternative feedstocks for PETG production.

In recent years, there has been a global push towards more stringent environmental policies, particularly concerning plastic waste management. Many countries have introduced legislation aimed at reducing single-use plastics and promoting recycling initiatives. These regulations have significantly impacted the PETG industry, encouraging manufacturers to develop more sustainable and recyclable PETG products.

The European Union, for instance, has implemented the Circular Economy Action Plan, which includes specific targets for plastic recycling and reuse. This has led to increased investment in advanced PETG applications that support closed-loop recycling systems. Similarly, in the United States, various states have enacted laws mandating the use of recycled content in plastic packaging, driving demand for high-quality recycled PETG materials.

Environmental regulations have also influenced the development of innovative PETG formulations that are more easily recyclable and biodegradable. Manufacturers are now focusing on creating PETG products that can be efficiently sorted and processed in existing recycling facilities, aligning with the requirements set forth by regulatory bodies.

Furthermore, extended producer responsibility (EPR) schemes have been introduced in many countries, holding manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. This has incentivized companies to invest in advanced PETG applications that facilitate easier collection, sorting, and recycling of plastic waste.

The impact of these regulations extends beyond the manufacturing process to encompass the entire supply chain. Companies are now required to provide detailed information about the environmental impact of their PETG products, including carbon footprint and recyclability. This has led to the development of more transparent and traceable supply chains, as well as improved lifecycle assessment methodologies for PETG materials.

As environmental regulations continue to evolve, they are expected to drive further advancements in PETG applications for renewable resource management. This includes the development of new recycling technologies, the creation of more efficient collection and sorting systems, and the exploration of alternative feedstocks for PETG production.

Life Cycle Assessment of PETG

Life Cycle Assessment (LCA) of PETG plays a crucial role in understanding the environmental impact of this material throughout its entire lifecycle. PETG, or Polyethylene Terephthalate Glycol-modified, is a thermoplastic polyester widely used in various applications due to its durability, clarity, and recyclability. The LCA of PETG typically encompasses four main stages: raw material extraction, manufacturing, use phase, and end-of-life management.

The raw material extraction stage involves the acquisition of petroleum-based feedstocks and the production of ethylene glycol and terephthalic acid. This phase contributes significantly to the overall environmental impact of PETG, primarily due to the energy-intensive processes and the depletion of non-renewable resources. However, advancements in bio-based alternatives and more efficient extraction methods are gradually reducing this impact.

During the manufacturing stage, PETG undergoes polymerization, extrusion, and molding processes to create the final product. This phase is characterized by high energy consumption and potential emissions of volatile organic compounds (VOCs). Innovations in manufacturing technologies, such as improved process control and energy recovery systems, are helping to minimize these environmental burdens.

The use phase of PETG products varies widely depending on the application. In packaging, for instance, PETG's durability and barrier properties contribute to extended shelf life and reduced food waste. In renewable energy applications, such as solar panel components, PETG's long lifespan and resistance to weathering support sustainable energy production. These positive impacts during the use phase often offset some of the environmental costs associated with production.

End-of-life management is a critical aspect of PETG's lifecycle assessment. Unlike traditional PET, PETG is more challenging to recycle due to its different chemical structure. However, recent advancements in recycling technologies, including chemical recycling and improved sorting methods, are enhancing the recyclability of PETG. This progress is crucial for closing the loop in PETG's lifecycle and supporting circular economy principles.

Comparative LCAs have shown that PETG often performs favorably against alternative materials in terms of energy consumption and greenhouse gas emissions over its entire lifecycle. This is particularly true in applications where PETG's unique properties lead to resource efficiency or extended product lifespans. However, the material's end-of-life management remains an area for improvement to fully realize its potential in supporting renewable resource management.

As the demand for sustainable materials grows, ongoing research focuses on further optimizing PETG's lifecycle performance. This includes developing bio-based PETG variants, improving manufacturing efficiencies, and enhancing recycling capabilities. These efforts aim to position PETG as a key player in the transition towards more sustainable and renewable resource management practices across various industries.

The raw material extraction stage involves the acquisition of petroleum-based feedstocks and the production of ethylene glycol and terephthalic acid. This phase contributes significantly to the overall environmental impact of PETG, primarily due to the energy-intensive processes and the depletion of non-renewable resources. However, advancements in bio-based alternatives and more efficient extraction methods are gradually reducing this impact.

During the manufacturing stage, PETG undergoes polymerization, extrusion, and molding processes to create the final product. This phase is characterized by high energy consumption and potential emissions of volatile organic compounds (VOCs). Innovations in manufacturing technologies, such as improved process control and energy recovery systems, are helping to minimize these environmental burdens.

The use phase of PETG products varies widely depending on the application. In packaging, for instance, PETG's durability and barrier properties contribute to extended shelf life and reduced food waste. In renewable energy applications, such as solar panel components, PETG's long lifespan and resistance to weathering support sustainable energy production. These positive impacts during the use phase often offset some of the environmental costs associated with production.

End-of-life management is a critical aspect of PETG's lifecycle assessment. Unlike traditional PET, PETG is more challenging to recycle due to its different chemical structure. However, recent advancements in recycling technologies, including chemical recycling and improved sorting methods, are enhancing the recyclability of PETG. This progress is crucial for closing the loop in PETG's lifecycle and supporting circular economy principles.

Comparative LCAs have shown that PETG often performs favorably against alternative materials in terms of energy consumption and greenhouse gas emissions over its entire lifecycle. This is particularly true in applications where PETG's unique properties lead to resource efficiency or extended product lifespans. However, the material's end-of-life management remains an area for improvement to fully realize its potential in supporting renewable resource management.

As the demand for sustainable materials grows, ongoing research focuses on further optimizing PETG's lifecycle performance. This includes developing bio-based PETG variants, improving manufacturing efficiencies, and enhancing recycling capabilities. These efforts aim to position PETG as a key player in the transition towards more sustainable and renewable resource management practices across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!