How PETG Forms the Backbone of Intelligent Packaging Solutions

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG in Packaging: Evolution and Objectives

Polyethylene terephthalate glycol (PETG) has emerged as a revolutionary material in the packaging industry, particularly in the realm of intelligent packaging solutions. The evolution of PETG in packaging can be traced back to the mid-20th century when PET was first developed. However, it was the introduction of glycol-modified PET (PETG) in the 1970s that marked a significant milestone in packaging technology.

PETG's journey in packaging has been characterized by continuous innovation and adaptation to meet evolving market demands. Initially used primarily for rigid containers, PETG has expanded its applications to include flexible packaging, thermoformed trays, and intelligent packaging systems. The material's unique properties, such as clarity, durability, and chemical resistance, have made it an ideal choice for a wide range of packaging applications.

The objectives of PETG in intelligent packaging solutions are multifaceted. Firstly, PETG aims to enhance product protection by providing a robust barrier against external factors such as moisture, oxygen, and UV radiation. This is crucial for extending shelf life and maintaining product quality, especially for sensitive goods like pharmaceuticals and perishable foods.

Secondly, PETG seeks to improve consumer engagement through innovative packaging designs. Its excellent formability allows for the creation of unique shapes and structures that can incorporate smart features like QR codes, NFC tags, or color-changing indicators. These elements not only attract consumer attention but also facilitate interactive experiences and provide valuable product information.

Another key objective is sustainability. As environmental concerns gain prominence, PETG is being developed to be more recyclable and eco-friendly. Research is ongoing to improve its biodegradability and to incorporate recycled content without compromising performance. This aligns with the growing demand for sustainable packaging solutions in various industries.

Furthermore, PETG aims to enable advanced functionalities in intelligent packaging. This includes the integration of sensors for real-time monitoring of product conditions, such as temperature and freshness. The material's compatibility with various printing technologies also allows for the incorporation of smart labels and anti-counterfeiting features, enhancing product authenticity and traceability.

In the context of Industry 4.0, PETG is positioned to play a crucial role in the development of smart supply chains. Its ability to interface with IoT technologies opens up possibilities for end-to-end tracking and data-driven inventory management. This not only optimizes logistics but also provides valuable insights for manufacturers and retailers.

PETG's journey in packaging has been characterized by continuous innovation and adaptation to meet evolving market demands. Initially used primarily for rigid containers, PETG has expanded its applications to include flexible packaging, thermoformed trays, and intelligent packaging systems. The material's unique properties, such as clarity, durability, and chemical resistance, have made it an ideal choice for a wide range of packaging applications.

The objectives of PETG in intelligent packaging solutions are multifaceted. Firstly, PETG aims to enhance product protection by providing a robust barrier against external factors such as moisture, oxygen, and UV radiation. This is crucial for extending shelf life and maintaining product quality, especially for sensitive goods like pharmaceuticals and perishable foods.

Secondly, PETG seeks to improve consumer engagement through innovative packaging designs. Its excellent formability allows for the creation of unique shapes and structures that can incorporate smart features like QR codes, NFC tags, or color-changing indicators. These elements not only attract consumer attention but also facilitate interactive experiences and provide valuable product information.

Another key objective is sustainability. As environmental concerns gain prominence, PETG is being developed to be more recyclable and eco-friendly. Research is ongoing to improve its biodegradability and to incorporate recycled content without compromising performance. This aligns with the growing demand for sustainable packaging solutions in various industries.

Furthermore, PETG aims to enable advanced functionalities in intelligent packaging. This includes the integration of sensors for real-time monitoring of product conditions, such as temperature and freshness. The material's compatibility with various printing technologies also allows for the incorporation of smart labels and anti-counterfeiting features, enhancing product authenticity and traceability.

In the context of Industry 4.0, PETG is positioned to play a crucial role in the development of smart supply chains. Its ability to interface with IoT technologies opens up possibilities for end-to-end tracking and data-driven inventory management. This not only optimizes logistics but also provides valuable insights for manufacturers and retailers.

Market Demand for Smart Packaging Solutions

The market demand for smart packaging solutions has been experiencing significant growth in recent years, driven by various factors across multiple industries. The food and beverage sector has emerged as a primary driver, with consumers increasingly seeking products that offer enhanced freshness, extended shelf life, and improved safety. Smart packaging technologies, such as those incorporating PETG (Polyethylene Terephthalate Glycol), have proven instrumental in meeting these demands by providing real-time monitoring of product conditions and quality.

In the pharmaceutical industry, there is a growing need for intelligent packaging solutions to ensure medication safety, compliance, and authenticity. PETG-based smart packaging can incorporate features like temperature sensors and tamper-evident seals, addressing concerns related to drug efficacy and counterfeiting. This has become particularly crucial in the context of global supply chains and the rise of e-commerce in pharmaceutical distribution.

The retail sector has also shown increasing interest in smart packaging solutions, driven by the need for improved inventory management, reduced waste, and enhanced customer engagement. PETG-based intelligent packaging can facilitate better tracking of products throughout the supply chain, provide valuable data on consumer behavior, and enable interactive experiences through technologies like NFC (Near Field Communication) and QR codes.

Environmental concerns and sustainability initiatives have further fueled the demand for smart packaging solutions. PETG's recyclability and potential for integration with biodegradable materials align well with the growing consumer preference for eco-friendly packaging options. This has led to increased adoption of PETG-based smart packaging in industries ranging from cosmetics to electronics, where brands seek to differentiate themselves through sustainable and technologically advanced packaging solutions.

The e-commerce boom has also contributed significantly to the market demand for intelligent packaging. As online shopping continues to grow, there is an increasing need for packaging that can withstand the rigors of shipping while providing real-time tracking and condition monitoring. PETG-based smart packaging solutions offer the durability and flexibility required for e-commerce applications, while also enabling features like anti-theft protection and authenticity verification.

Market research indicates that the global smart packaging market is poised for substantial growth in the coming years. Factors such as increasing urbanization, rising disposable incomes, and growing awareness of food safety and sustainability are expected to drive this expansion. The versatility of PETG as a material for intelligent packaging solutions positions it well to capitalize on these market trends across various industries and applications.

In the pharmaceutical industry, there is a growing need for intelligent packaging solutions to ensure medication safety, compliance, and authenticity. PETG-based smart packaging can incorporate features like temperature sensors and tamper-evident seals, addressing concerns related to drug efficacy and counterfeiting. This has become particularly crucial in the context of global supply chains and the rise of e-commerce in pharmaceutical distribution.

The retail sector has also shown increasing interest in smart packaging solutions, driven by the need for improved inventory management, reduced waste, and enhanced customer engagement. PETG-based intelligent packaging can facilitate better tracking of products throughout the supply chain, provide valuable data on consumer behavior, and enable interactive experiences through technologies like NFC (Near Field Communication) and QR codes.

Environmental concerns and sustainability initiatives have further fueled the demand for smart packaging solutions. PETG's recyclability and potential for integration with biodegradable materials align well with the growing consumer preference for eco-friendly packaging options. This has led to increased adoption of PETG-based smart packaging in industries ranging from cosmetics to electronics, where brands seek to differentiate themselves through sustainable and technologically advanced packaging solutions.

The e-commerce boom has also contributed significantly to the market demand for intelligent packaging. As online shopping continues to grow, there is an increasing need for packaging that can withstand the rigors of shipping while providing real-time tracking and condition monitoring. PETG-based smart packaging solutions offer the durability and flexibility required for e-commerce applications, while also enabling features like anti-theft protection and authenticity verification.

Market research indicates that the global smart packaging market is poised for substantial growth in the coming years. Factors such as increasing urbanization, rising disposable incomes, and growing awareness of food safety and sustainability are expected to drive this expansion. The versatility of PETG as a material for intelligent packaging solutions positions it well to capitalize on these market trends across various industries and applications.

PETG Technology: Current State and Challenges

PETG (Polyethylene Terephthalate Glycol-modified) has emerged as a key material in the development of intelligent packaging solutions. However, its current state and challenges in this application warrant careful examination.

The current state of PETG technology in intelligent packaging is characterized by its versatility and adaptability. PETG offers excellent clarity, durability, and chemical resistance, making it an ideal choice for various packaging applications. Its ability to be easily thermoformed and its compatibility with different printing techniques have positioned PETG as a preferred material for creating smart packaging solutions.

One of the primary advantages of PETG in intelligent packaging is its ability to incorporate various smart features. These include QR codes, NFC tags, and RFID chips, which can be seamlessly integrated into PETG packaging without compromising its structural integrity or aesthetic appeal. This integration allows for enhanced traceability, authentication, and consumer engagement.

Despite its advantages, PETG technology faces several challenges in the intelligent packaging domain. One significant hurdle is the need for improved recyclability. While PETG is recyclable, the presence of additives and smart components can complicate the recycling process, potentially limiting its sustainability credentials.

Another challenge lies in the cost-effectiveness of PETG-based intelligent packaging solutions. The integration of smart technologies often increases production costs, which can be a barrier to widespread adoption, particularly for smaller businesses or in price-sensitive markets.

The durability of smart features in PETG packaging also presents a challenge. Ensuring that embedded technologies remain functional throughout the product's lifecycle, including during transportation and storage, requires ongoing research and development.

Furthermore, there is a growing demand for PETG packaging solutions that offer enhanced barrier properties, particularly for food and pharmaceutical applications. Meeting these requirements while maintaining the material's compatibility with smart technologies is an area of active research.

The scalability of PETG-based intelligent packaging solutions is another challenge. As demand for smart packaging grows, manufacturers must develop efficient production processes that can maintain quality and functionality at larger scales.

Lastly, regulatory compliance remains a complex issue. As intelligent packaging evolves, regulations surrounding the use of smart technologies in packaging, especially for food and medical products, continue to develop. Ensuring that PETG-based intelligent packaging meets these evolving standards is an ongoing challenge for the industry.

The current state of PETG technology in intelligent packaging is characterized by its versatility and adaptability. PETG offers excellent clarity, durability, and chemical resistance, making it an ideal choice for various packaging applications. Its ability to be easily thermoformed and its compatibility with different printing techniques have positioned PETG as a preferred material for creating smart packaging solutions.

One of the primary advantages of PETG in intelligent packaging is its ability to incorporate various smart features. These include QR codes, NFC tags, and RFID chips, which can be seamlessly integrated into PETG packaging without compromising its structural integrity or aesthetic appeal. This integration allows for enhanced traceability, authentication, and consumer engagement.

Despite its advantages, PETG technology faces several challenges in the intelligent packaging domain. One significant hurdle is the need for improved recyclability. While PETG is recyclable, the presence of additives and smart components can complicate the recycling process, potentially limiting its sustainability credentials.

Another challenge lies in the cost-effectiveness of PETG-based intelligent packaging solutions. The integration of smart technologies often increases production costs, which can be a barrier to widespread adoption, particularly for smaller businesses or in price-sensitive markets.

The durability of smart features in PETG packaging also presents a challenge. Ensuring that embedded technologies remain functional throughout the product's lifecycle, including during transportation and storage, requires ongoing research and development.

Furthermore, there is a growing demand for PETG packaging solutions that offer enhanced barrier properties, particularly for food and pharmaceutical applications. Meeting these requirements while maintaining the material's compatibility with smart technologies is an area of active research.

The scalability of PETG-based intelligent packaging solutions is another challenge. As demand for smart packaging grows, manufacturers must develop efficient production processes that can maintain quality and functionality at larger scales.

Lastly, regulatory compliance remains a complex issue. As intelligent packaging evolves, regulations surrounding the use of smart technologies in packaging, especially for food and medical products, continue to develop. Ensuring that PETG-based intelligent packaging meets these evolving standards is an ongoing challenge for the industry.

Existing PETG-based Intelligent Packaging Solutions

01 Composition and properties of PETG

PETG is a copolyester derived from polyethylene terephthalate (PET) with added glycol. It offers improved clarity, toughness, and processability compared to standard PET. PETG is known for its excellent impact resistance, chemical resistance, and dimensional stability, making it suitable for various applications in packaging, medical devices, and consumer goods.- Composition and properties of PETG: PETG is a copolyester derived from polyethylene terephthalate (PET) with added glycol. It offers improved clarity, toughness, and processability compared to standard PET. PETG is known for its excellent impact resistance, chemical resistance, and ease of thermoforming.

- Applications of PETG in packaging: PETG is widely used in packaging applications due to its transparency, durability, and food-safe properties. It is commonly employed in the production of bottles, containers, and trays for food, beverages, cosmetics, and pharmaceuticals. PETG packaging offers good barrier properties and can be easily recycled.

- PETG in 3D printing and additive manufacturing: PETG has gained popularity as a filament material for 3D printing due to its ease of use, dimensional stability, and good layer adhesion. It is suitable for both hobbyist and industrial applications, offering a balance between strength and flexibility in printed parts.

- PETG blends and composites: Researchers have explored blending PETG with other polymers or incorporating additives to enhance its properties. These blends and composites can improve characteristics such as heat resistance, mechanical strength, or specific functionalities for targeted applications.

- PETG in medical and healthcare products: PETG's biocompatibility, sterilizability, and clarity make it suitable for various medical and healthcare applications. It is used in the production of medical devices, laboratory equipment, prosthetics, and pharmaceutical packaging, where safety and performance are critical.

02 PETG in 3D printing and additive manufacturing

PETG has gained popularity in 3D printing due to its ease of use, good layer adhesion, and minimal warping. It is often used as a filament material for fused deposition modeling (FDM) printers. PETG's properties make it suitable for producing functional prototypes, end-use parts, and various consumer products through additive manufacturing techniques.Expand Specific Solutions03 PETG in packaging and container applications

PETG is widely used in packaging applications, particularly for food and beverage containers, due to its clarity, durability, and food-safe properties. It is also used in cosmetic packaging, pharmaceutical bottles, and other consumer product containers. PETG's ability to be thermoformed and its resistance to cracking make it ideal for these applications.Expand Specific Solutions04 PETG in medical and healthcare applications

PETG's biocompatibility and sterilizability make it suitable for various medical and healthcare applications. It is used in medical device components, laboratory equipment, prosthetics, and pharmaceutical packaging. PETG's clarity and impact resistance are particularly valuable in these fields, where visibility and durability are crucial.Expand Specific Solutions05 PETG blends and modifications

Researchers and manufacturers have developed various PETG blends and modifications to enhance its properties for specific applications. These include blending PETG with other polymers, adding reinforcing agents, or incorporating additives to improve characteristics such as flame retardancy, UV resistance, or antimicrobial properties. These modifications expand the range of applications for PETG-based materials.Expand Specific Solutions

Key Players in PETG and Smart Packaging Sector

The intelligent packaging solutions market, driven by PETG technology, is in a growth phase characterized by increasing adoption across various industries. The global market size for smart packaging is projected to reach significant figures in the coming years, with PETG playing a crucial role. Technologically, PETG-based solutions are maturing rapidly, with companies like Henan Yinjinda New Materials, Zhejiang Henglan Science & Technology, and Jiangsu Huaxin High-tech Materials leading innovation. These firms are developing advanced PETG formulations for enhanced durability, flexibility, and sustainability in packaging applications. The competitive landscape is intensifying as more players enter the market, driving further technological advancements and market expansion.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced PETG formulations for intelligent packaging solutions. Their PETG materials incorporate nanotechnology to enhance barrier properties, extending shelf life of packaged goods[1]. Sinopec's PETG also features smart indicators that change color based on temperature or pH levels, allowing real-time monitoring of product freshness and safety[2]. Additionally, they've integrated RFID technology into PETG packaging, enabling track-and-trace capabilities throughout the supply chain[3]. Sinopec's PETG solutions also include antimicrobial properties, inhibiting bacterial growth on package surfaces[4].

Strengths: Comprehensive R&D capabilities, large-scale production capacity, and integration of multiple smart technologies. Weaknesses: Potentially higher costs due to advanced features, may require specialized equipment for full utilization.

Nan Ya Plastics Corp.

Technical Solution: Nan Ya Plastics Corp. has developed PETG-based intelligent packaging solutions focusing on sustainability and functionality. Their PETG formulations incorporate oxygen-scavenging additives, significantly extending the shelf life of oxygen-sensitive products[1]. Nan Ya has also introduced PETG with embedded time-temperature indicators, allowing consumers to visually assess product freshness[2]. Their research has yielded PETG materials with enhanced recyclability, addressing environmental concerns while maintaining the material's desirable properties for packaging[3]. Furthermore, Nan Ya has developed PETG films with tunable gas permeability, enabling controlled atmosphere packaging for fresh produce[4].

Strengths: Strong focus on sustainability, innovative functional additives, and wide range of applications. Weaknesses: May face challenges in cost-competitiveness against traditional packaging materials.

Innovations in PETG for Smart Packaging Applications

Packaging container

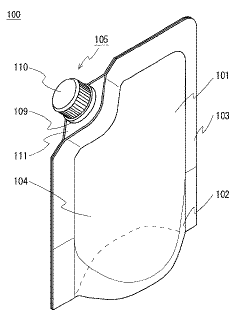

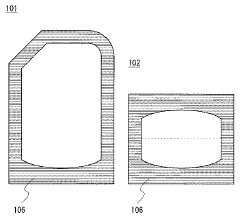

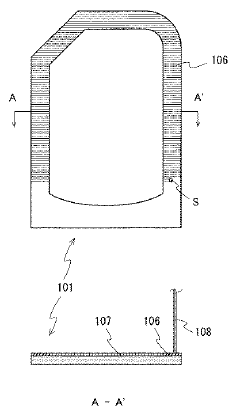

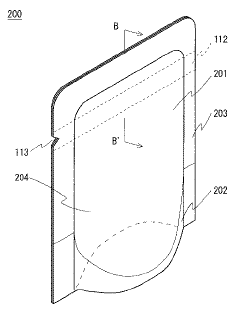

PatentActiveJP2018002295A

Innovation

- A packaging container with a biaxially stretched polyester layer having heat-sealing properties, where members like PETG or A-PET are heat-sealed on at least a part of the surface, eliminating the need for hot melt adhesives.

Environmental Impact and Sustainability of PETG Packaging

The environmental impact and sustainability of PETG packaging are critical considerations in the intelligent packaging industry. PETG (Polyethylene Terephthalate Glycol-modified) has gained popularity due to its versatility and performance characteristics. However, its widespread use raises concerns about its ecological footprint and long-term sustainability.

PETG packaging offers several environmental advantages compared to traditional materials. Its durability and resistance to breakage reduce the need for frequent replacements, potentially lowering overall material consumption. Additionally, PETG's lightweight nature contributes to reduced transportation emissions, as it requires less fuel to ship compared to heavier packaging alternatives.

Despite these benefits, PETG faces challenges in terms of recyclability. While technically recyclable, PETG is often not accepted in standard recycling streams due to its different melting point compared to PET. This limitation can lead to contamination issues in recycling facilities, potentially resulting in more PETG ending up in landfills or incineration plants.

The production of PETG also raises environmental concerns. The manufacturing process involves the use of fossil fuel-derived raw materials and energy-intensive procedures, contributing to greenhouse gas emissions and resource depletion. However, ongoing research and development efforts are focused on improving production efficiency and exploring bio-based alternatives to reduce the carbon footprint of PETG manufacturing.

In response to sustainability challenges, the packaging industry is exploring various strategies to enhance the environmental profile of PETG. One approach involves increasing the use of recycled PETG content in new packaging products, creating a more circular economy for this material. Some companies are also investing in specialized recycling infrastructure to handle PETG more effectively, addressing the current limitations in recycling capabilities.

Another promising avenue is the development of biodegradable or compostable variants of PETG. These innovations aim to maintain the desirable properties of PETG while ensuring that the material can break down more readily in natural environments or industrial composting facilities. However, these alternatives are still in the early stages of development and face challenges in terms of performance, cost, and scalability.

The intelligent packaging sector is also leveraging PETG's properties to create more sustainable solutions. For instance, PETG's clarity and printability enable the integration of smart technologies that can extend product shelf life, reduce food waste, and optimize supply chain efficiency. These advancements contribute to overall sustainability by minimizing resource waste and improving product utilization.

As environmental regulations become more stringent and consumer awareness grows, the packaging industry is under increasing pressure to improve the sustainability of PETG and similar materials. This has led to accelerated research into eco-friendly additives, improved recycling technologies, and alternative materials that could potentially replace PETG in certain applications while maintaining its intelligent packaging capabilities.

PETG packaging offers several environmental advantages compared to traditional materials. Its durability and resistance to breakage reduce the need for frequent replacements, potentially lowering overall material consumption. Additionally, PETG's lightweight nature contributes to reduced transportation emissions, as it requires less fuel to ship compared to heavier packaging alternatives.

Despite these benefits, PETG faces challenges in terms of recyclability. While technically recyclable, PETG is often not accepted in standard recycling streams due to its different melting point compared to PET. This limitation can lead to contamination issues in recycling facilities, potentially resulting in more PETG ending up in landfills or incineration plants.

The production of PETG also raises environmental concerns. The manufacturing process involves the use of fossil fuel-derived raw materials and energy-intensive procedures, contributing to greenhouse gas emissions and resource depletion. However, ongoing research and development efforts are focused on improving production efficiency and exploring bio-based alternatives to reduce the carbon footprint of PETG manufacturing.

In response to sustainability challenges, the packaging industry is exploring various strategies to enhance the environmental profile of PETG. One approach involves increasing the use of recycled PETG content in new packaging products, creating a more circular economy for this material. Some companies are also investing in specialized recycling infrastructure to handle PETG more effectively, addressing the current limitations in recycling capabilities.

Another promising avenue is the development of biodegradable or compostable variants of PETG. These innovations aim to maintain the desirable properties of PETG while ensuring that the material can break down more readily in natural environments or industrial composting facilities. However, these alternatives are still in the early stages of development and face challenges in terms of performance, cost, and scalability.

The intelligent packaging sector is also leveraging PETG's properties to create more sustainable solutions. For instance, PETG's clarity and printability enable the integration of smart technologies that can extend product shelf life, reduce food waste, and optimize supply chain efficiency. These advancements contribute to overall sustainability by minimizing resource waste and improving product utilization.

As environmental regulations become more stringent and consumer awareness grows, the packaging industry is under increasing pressure to improve the sustainability of PETG and similar materials. This has led to accelerated research into eco-friendly additives, improved recycling technologies, and alternative materials that could potentially replace PETG in certain applications while maintaining its intelligent packaging capabilities.

Regulatory Framework for Intelligent Packaging Materials

The regulatory framework for intelligent packaging materials incorporating PETG (Polyethylene Terephthalate Glycol) is a complex and evolving landscape. As intelligent packaging solutions gain traction in various industries, regulatory bodies worldwide are adapting their guidelines to ensure consumer safety, environmental protection, and product integrity.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating intelligent packaging materials. The FDA's Food Contact Substance Notification Program requires manufacturers to submit detailed information about the composition and intended use of packaging materials, including PETG-based intelligent packaging solutions. This process ensures that these materials meet safety standards for food contact applications.

The European Union has implemented comprehensive regulations through the European Food Safety Authority (EFSA). The EU Regulation No. 1935/2004 sets out general principles for all food contact materials, while specific measures for plastic materials are outlined in Regulation (EU) No. 10/2011. These regulations establish migration limits for substances used in packaging materials and require extensive testing to demonstrate compliance.

In Asia, countries like Japan and China have their own regulatory frameworks. Japan's Food Sanitation Law governs the use of packaging materials in contact with food, while China's GB 4806 series of national standards provides specific requirements for food contact materials, including intelligent packaging solutions.

Environmental considerations are increasingly shaping the regulatory landscape for intelligent packaging materials. The EU's Packaging and Packaging Waste Directive (94/62/EC) sets targets for recycling and recovery of packaging waste, impacting the design and disposal of PETG-based intelligent packaging. Similarly, many countries are implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their packaging materials.

Emerging technologies in intelligent packaging, such as active and smart packaging systems, are prompting regulatory bodies to develop new guidelines. The EU's Regulation (EC) No. 450/2009 specifically addresses active and intelligent materials and articles intended to come into contact with food, providing a framework for the safety assessment of these innovative packaging solutions.

As the field of intelligent packaging continues to advance, regulatory frameworks are likely to evolve. Manufacturers and developers of PETG-based intelligent packaging solutions must stay abreast of these changes and engage in ongoing dialogue with regulatory authorities to ensure compliance and foster innovation in this rapidly growing sector.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating intelligent packaging materials. The FDA's Food Contact Substance Notification Program requires manufacturers to submit detailed information about the composition and intended use of packaging materials, including PETG-based intelligent packaging solutions. This process ensures that these materials meet safety standards for food contact applications.

The European Union has implemented comprehensive regulations through the European Food Safety Authority (EFSA). The EU Regulation No. 1935/2004 sets out general principles for all food contact materials, while specific measures for plastic materials are outlined in Regulation (EU) No. 10/2011. These regulations establish migration limits for substances used in packaging materials and require extensive testing to demonstrate compliance.

In Asia, countries like Japan and China have their own regulatory frameworks. Japan's Food Sanitation Law governs the use of packaging materials in contact with food, while China's GB 4806 series of national standards provides specific requirements for food contact materials, including intelligent packaging solutions.

Environmental considerations are increasingly shaping the regulatory landscape for intelligent packaging materials. The EU's Packaging and Packaging Waste Directive (94/62/EC) sets targets for recycling and recovery of packaging waste, impacting the design and disposal of PETG-based intelligent packaging. Similarly, many countries are implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their packaging materials.

Emerging technologies in intelligent packaging, such as active and smart packaging systems, are prompting regulatory bodies to develop new guidelines. The EU's Regulation (EC) No. 450/2009 specifically addresses active and intelligent materials and articles intended to come into contact with food, providing a framework for the safety assessment of these innovative packaging solutions.

As the field of intelligent packaging continues to advance, regulatory frameworks are likely to evolve. Manufacturers and developers of PETG-based intelligent packaging solutions must stay abreast of these changes and engage in ongoing dialogue with regulatory authorities to ensure compliance and foster innovation in this rapidly growing sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!