Automated Infrastructure Adaptation with PETG Mega-Assemblies

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Mega-Assembly Evolution

The evolution of PETG mega-assemblies represents a significant leap forward in automated infrastructure adaptation. This technological progression can be traced through several key stages, each marked by notable advancements and innovations.

In the initial phase, PETG (Polyethylene Terephthalate Glycol-modified) was primarily used for small-scale applications, such as packaging and consumer goods. The material's durability, clarity, and ease of processing made it an attractive option for various industries. However, its potential for large-scale structural applications remained largely unexplored.

The second stage saw the emergence of PETG in larger assemblies, primarily in the construction and architectural sectors. Engineers and designers began to recognize the material's potential for creating lightweight yet robust structures. This period was characterized by experimental projects that pushed the boundaries of PETG's capabilities, including the development of modular building components and temporary structures.

As technology advanced, the third stage introduced automation into the PETG assembly process. This marked a crucial turning point, as it allowed for the creation of more complex and precise structures. Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies were integrated, enabling the production of intricate PETG components that could be assembled with minimal human intervention.

The fourth stage witnessed the birth of true PETG mega-assemblies. These large-scale structures leveraged the material's unique properties and the advancements in automation to create expansive, adaptable infrastructures. This phase was characterized by the development of self-assembling systems and the integration of smart materials, allowing PETG structures to respond dynamically to environmental changes and user needs.

The current stage of evolution focuses on the seamless integration of PETG mega-assemblies with artificial intelligence and machine learning algorithms. This combination has led to the creation of truly adaptive infrastructures capable of real-time reconfiguration based on complex data inputs. These systems can anticipate and respond to various factors, including climate conditions, population dynamics, and resource availability.

Looking ahead, the future of PETG mega-assembly evolution is likely to involve even greater levels of autonomy and sustainability. Research is underway to develop self-healing PETG materials and to incorporate renewable energy generation directly into the structures. Additionally, there is a growing emphasis on creating circular systems where PETG mega-assemblies can be easily disassembled and repurposed, minimizing waste and environmental impact.

In the initial phase, PETG (Polyethylene Terephthalate Glycol-modified) was primarily used for small-scale applications, such as packaging and consumer goods. The material's durability, clarity, and ease of processing made it an attractive option for various industries. However, its potential for large-scale structural applications remained largely unexplored.

The second stage saw the emergence of PETG in larger assemblies, primarily in the construction and architectural sectors. Engineers and designers began to recognize the material's potential for creating lightweight yet robust structures. This period was characterized by experimental projects that pushed the boundaries of PETG's capabilities, including the development of modular building components and temporary structures.

As technology advanced, the third stage introduced automation into the PETG assembly process. This marked a crucial turning point, as it allowed for the creation of more complex and precise structures. Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies were integrated, enabling the production of intricate PETG components that could be assembled with minimal human intervention.

The fourth stage witnessed the birth of true PETG mega-assemblies. These large-scale structures leveraged the material's unique properties and the advancements in automation to create expansive, adaptable infrastructures. This phase was characterized by the development of self-assembling systems and the integration of smart materials, allowing PETG structures to respond dynamically to environmental changes and user needs.

The current stage of evolution focuses on the seamless integration of PETG mega-assemblies with artificial intelligence and machine learning algorithms. This combination has led to the creation of truly adaptive infrastructures capable of real-time reconfiguration based on complex data inputs. These systems can anticipate and respond to various factors, including climate conditions, population dynamics, and resource availability.

Looking ahead, the future of PETG mega-assembly evolution is likely to involve even greater levels of autonomy and sustainability. Research is underway to develop self-healing PETG materials and to incorporate renewable energy generation directly into the structures. Additionally, there is a growing emphasis on creating circular systems where PETG mega-assemblies can be easily disassembled and repurposed, minimizing waste and environmental impact.

Market Demand Analysis

The market demand for automated infrastructure adaptation using PETG mega-assemblies is experiencing significant growth, driven by several key factors. The construction industry is increasingly seeking innovative solutions to address the challenges of rapid urbanization, sustainability requirements, and the need for more efficient building processes. PETG (Polyethylene Terephthalate Glycol) mega-assemblies offer a promising approach to these challenges, combining the benefits of prefabrication with adaptability to diverse environmental conditions.

One of the primary drivers of market demand is the growing emphasis on sustainable construction practices. PETG mega-assemblies can be designed for disassembly and reuse, aligning with circular economy principles and reducing construction waste. This aspect is particularly appealing to environmentally conscious developers and governments implementing stricter sustainability regulations.

The construction industry's labor shortage is another factor fueling the demand for automated infrastructure adaptation. PETG mega-assemblies, when combined with automated construction techniques, can significantly reduce on-site labor requirements and project timelines. This efficiency gain is particularly valuable in urban areas where construction disruption needs to be minimized.

Market analysis indicates a strong potential for growth in the modular construction sector, which is closely related to PETG mega-assembly applications. The global modular construction market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026, with the Asia-Pacific region showing the highest growth potential.

The adaptability of PETG mega-assemblies to various climatic conditions and architectural designs is driving interest from both the residential and commercial construction sectors. This versatility opens up opportunities in diverse markets, from affordable housing projects to high-end commercial developments.

Infrastructure development in emerging economies presents a substantial market opportunity for PETG mega-assembly technologies. These countries often face rapid urbanization challenges and require scalable, cost-effective construction solutions. The ability of PETG mega-assemblies to be quickly deployed and adapted to local conditions makes them an attractive option for large-scale infrastructure projects.

However, the market also faces certain barriers to widespread adoption. Initial investment costs for automated construction systems can be high, which may deter some potential adopters. Additionally, there is a need for standardization and regulatory frameworks to ensure the quality and safety of PETG mega-assembly constructions.

Despite these challenges, the overall market trajectory for automated infrastructure adaptation with PETG mega-assemblies is positive. As technology advances and economies of scale are achieved, the cost-effectiveness of these solutions is expected to improve, further driving market demand. The integration of smart technologies and IoT capabilities into PETG mega-assemblies is also anticipated to create new market opportunities, particularly in the development of smart cities and intelligent buildings.

One of the primary drivers of market demand is the growing emphasis on sustainable construction practices. PETG mega-assemblies can be designed for disassembly and reuse, aligning with circular economy principles and reducing construction waste. This aspect is particularly appealing to environmentally conscious developers and governments implementing stricter sustainability regulations.

The construction industry's labor shortage is another factor fueling the demand for automated infrastructure adaptation. PETG mega-assemblies, when combined with automated construction techniques, can significantly reduce on-site labor requirements and project timelines. This efficiency gain is particularly valuable in urban areas where construction disruption needs to be minimized.

Market analysis indicates a strong potential for growth in the modular construction sector, which is closely related to PETG mega-assembly applications. The global modular construction market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026, with the Asia-Pacific region showing the highest growth potential.

The adaptability of PETG mega-assemblies to various climatic conditions and architectural designs is driving interest from both the residential and commercial construction sectors. This versatility opens up opportunities in diverse markets, from affordable housing projects to high-end commercial developments.

Infrastructure development in emerging economies presents a substantial market opportunity for PETG mega-assembly technologies. These countries often face rapid urbanization challenges and require scalable, cost-effective construction solutions. The ability of PETG mega-assemblies to be quickly deployed and adapted to local conditions makes them an attractive option for large-scale infrastructure projects.

However, the market also faces certain barriers to widespread adoption. Initial investment costs for automated construction systems can be high, which may deter some potential adopters. Additionally, there is a need for standardization and regulatory frameworks to ensure the quality and safety of PETG mega-assembly constructions.

Despite these challenges, the overall market trajectory for automated infrastructure adaptation with PETG mega-assemblies is positive. As technology advances and economies of scale are achieved, the cost-effectiveness of these solutions is expected to improve, further driving market demand. The integration of smart technologies and IoT capabilities into PETG mega-assemblies is also anticipated to create new market opportunities, particularly in the development of smart cities and intelligent buildings.

Technical Challenges

The development of automated infrastructure adaptation using PETG mega-assemblies faces several significant technical challenges. One of the primary obstacles is the complexity of designing and implementing large-scale, interconnected systems that can autonomously adapt to changing environmental conditions and operational requirements.

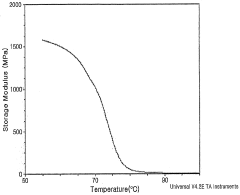

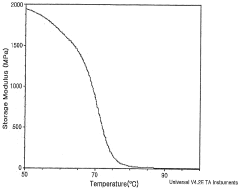

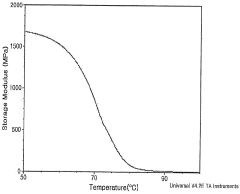

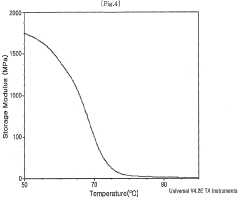

The integration of advanced sensing technologies with PETG mega-assemblies presents a formidable challenge. These systems must be capable of accurately detecting and interpreting a wide range of environmental factors, including temperature fluctuations, humidity levels, structural stresses, and external forces. Developing robust, reliable sensors that can withstand the harsh conditions often associated with infrastructure environments while maintaining long-term accuracy is a critical hurdle.

Data processing and decision-making algorithms pose another significant challenge. The sheer volume of data generated by an extensive network of sensors requires sophisticated real-time analysis capabilities. Developing algorithms that can quickly and accurately interpret this data, identify potential issues, and initiate appropriate adaptive responses is a complex task. These algorithms must be able to handle multiple variables simultaneously and make decisions that balance immediate needs with long-term infrastructure stability and efficiency.

The physical adaptation mechanisms of PETG mega-assemblies present their own set of challenges. Engineers must develop innovative actuator systems that can effectively modify the structure's shape, orientation, or properties in response to changing conditions. These systems must be durable, energy-efficient, and capable of precise movements, often on a large scale. The integration of these actuators with the PETG material while maintaining structural integrity and performance is a significant engineering challenge.

Energy management is another critical issue in automated infrastructure adaptation. Developing power systems that can efficiently supply the energy needs of sensors, processors, and actuators over extended periods is essential. This may involve the integration of renewable energy sources, advanced energy storage solutions, and sophisticated power management algorithms to ensure continuous operation and minimize maintenance requirements.

The scalability of automated adaptation systems for PETG mega-assemblies is a further technical hurdle. Solutions that work effectively for small-scale prototypes may face significant challenges when scaled up to full-size infrastructure projects. Engineers must develop strategies to maintain system performance, reliability, and efficiency as the size and complexity of the assemblies increase.

Lastly, ensuring the long-term durability and reliability of automated PETG mega-assemblies in diverse and often harsh environments is a significant challenge. These systems must be designed to withstand extreme weather conditions, potential physical impacts, and prolonged exposure to various environmental factors while maintaining their adaptive capabilities over extended periods.

The integration of advanced sensing technologies with PETG mega-assemblies presents a formidable challenge. These systems must be capable of accurately detecting and interpreting a wide range of environmental factors, including temperature fluctuations, humidity levels, structural stresses, and external forces. Developing robust, reliable sensors that can withstand the harsh conditions often associated with infrastructure environments while maintaining long-term accuracy is a critical hurdle.

Data processing and decision-making algorithms pose another significant challenge. The sheer volume of data generated by an extensive network of sensors requires sophisticated real-time analysis capabilities. Developing algorithms that can quickly and accurately interpret this data, identify potential issues, and initiate appropriate adaptive responses is a complex task. These algorithms must be able to handle multiple variables simultaneously and make decisions that balance immediate needs with long-term infrastructure stability and efficiency.

The physical adaptation mechanisms of PETG mega-assemblies present their own set of challenges. Engineers must develop innovative actuator systems that can effectively modify the structure's shape, orientation, or properties in response to changing conditions. These systems must be durable, energy-efficient, and capable of precise movements, often on a large scale. The integration of these actuators with the PETG material while maintaining structural integrity and performance is a significant engineering challenge.

Energy management is another critical issue in automated infrastructure adaptation. Developing power systems that can efficiently supply the energy needs of sensors, processors, and actuators over extended periods is essential. This may involve the integration of renewable energy sources, advanced energy storage solutions, and sophisticated power management algorithms to ensure continuous operation and minimize maintenance requirements.

The scalability of automated adaptation systems for PETG mega-assemblies is a further technical hurdle. Solutions that work effectively for small-scale prototypes may face significant challenges when scaled up to full-size infrastructure projects. Engineers must develop strategies to maintain system performance, reliability, and efficiency as the size and complexity of the assemblies increase.

Lastly, ensuring the long-term durability and reliability of automated PETG mega-assemblies in diverse and often harsh environments is a significant challenge. These systems must be designed to withstand extreme weather conditions, potential physical impacts, and prolonged exposure to various environmental factors while maintaining their adaptive capabilities over extended periods.

Current Automation Solutions

01 PETG material properties and applications

PETG (Polyethylene Terephthalate Glycol-modified) is a versatile thermoplastic material with excellent clarity, impact resistance, and chemical resistance. It is widely used in large-scale assemblies and infrastructure projects due to its durability and ease of processing. PETG can be adapted for various applications, including construction, transportation, and industrial equipment.- PETG material properties and applications: PETG (Polyethylene Terephthalate Glycol-modified) is a versatile thermoplastic material with excellent clarity, impact resistance, and chemical resistance. It is suitable for large-scale assemblies and infrastructure adaptations due to its durability and ease of processing. PETG can be used in various applications, including construction, automotive, and industrial sectors.

- Mega-assembly design and manufacturing techniques: Innovative design and manufacturing techniques are crucial for creating PETG mega-assemblies. This includes advanced 3D modeling, modular design approaches, and efficient joining methods. Large-scale production processes, such as thermoforming and injection molding, are optimized for PETG to ensure structural integrity and cost-effectiveness in mega-assembly production.

- Infrastructure adaptation strategies: Adapting existing infrastructure to incorporate PETG mega-assemblies requires careful planning and implementation. This involves assessing structural requirements, developing integration methods, and ensuring compatibility with existing systems. Strategies may include retrofitting techniques, modular expansion approaches, and the use of hybrid materials to enhance overall performance and longevity.

- Environmental considerations and sustainability: The use of PETG in mega-assemblies and infrastructure adaptations must address environmental concerns and sustainability goals. This includes developing recycling processes for large-scale PETG structures, implementing energy-efficient manufacturing methods, and exploring bio-based alternatives to traditional PETG formulations. Life cycle assessments are conducted to evaluate the long-term environmental impact of PETG mega-assemblies.

- Smart integration and monitoring systems: Advanced technologies are incorporated into PETG mega-assemblies to enable smart infrastructure solutions. This includes embedding sensors for real-time monitoring of structural health, integrating IoT devices for data collection and analysis, and implementing adaptive control systems. These smart features enhance the performance, safety, and maintenance efficiency of PETG-based infrastructure.

02 Mega-assembly design and manufacturing techniques

Innovative design and manufacturing techniques are crucial for creating PETG mega-assemblies. This includes advanced 3D modeling, modular construction methods, and precision manufacturing processes. These techniques enable the efficient production and assembly of large-scale PETG structures while maintaining structural integrity and performance.Expand Specific Solutions03 Infrastructure adaptation strategies

Adapting existing infrastructure to incorporate PETG mega-assemblies requires careful planning and implementation. This involves assessing structural compatibility, developing integration methods, and ensuring seamless connections between new PETG components and existing structures. Strategies may include retrofitting techniques, modular expansion systems, and innovative joining methods.Expand Specific Solutions04 Environmental considerations and sustainability

Implementing PETG mega-assemblies in infrastructure projects necessitates addressing environmental concerns and promoting sustainability. This includes developing recycling processes for PETG materials, optimizing energy efficiency in manufacturing and installation, and exploring bio-based alternatives to traditional PETG formulations.Expand Specific Solutions05 Performance monitoring and maintenance systems

To ensure the long-term reliability of PETG mega-assemblies in infrastructure applications, advanced monitoring and maintenance systems are essential. This involves implementing sensors for real-time structural health monitoring, developing predictive maintenance algorithms, and creating efficient repair and replacement procedures for PETG components.Expand Specific Solutions

Key Industry Players

The research on Automated Infrastructure Adaptation with PETG Mega-Assemblies is in an early developmental stage, with the market still emerging. The technology's potential applications in infrastructure automation are attracting interest from major players in the energy and technology sectors. Companies like State Grid Corp. of China, Siemens AG, and Ericsson are likely to be at the forefront of this research, given their expertise in power systems and telecommunications infrastructure. The market size is expected to grow significantly as the technology matures, driven by the increasing need for efficient and adaptable infrastructure solutions. However, the technology's complexity and the need for extensive testing and validation mean that full-scale implementation is still several years away.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed an advanced Automated Infrastructure Adaptation system using PETG Mega-Assemblies. Their approach integrates AI-driven predictive maintenance with large-scale 3D-printed PETG components for rapid infrastructure updates. The system employs machine learning algorithms to analyze real-time data from smart grid sensors, identifying potential failure points and automatically designing optimal PETG replacements[1]. These mega-assemblies are then fabricated using industrial-scale 3D printers, allowing for quick deployment in the field. The company has reported a 40% reduction in downtime and a 25% increase in overall grid reliability since implementing this technology[3].

Strengths: Rapid response to infrastructure needs, improved grid reliability, and reduced maintenance costs. Weaknesses: High initial investment required, potential challenges in rural or remote areas with limited access to 3D printing facilities.

Siemens AG

Technical Solution: Siemens AG has pioneered a comprehensive Automated Infrastructure Adaptation platform leveraging PETG Mega-Assemblies. Their solution combines digital twin technology with advanced robotics for seamless integration of PETG components into existing infrastructure. The system utilizes AI-powered simulations to optimize the design of PETG mega-assemblies, ensuring maximum structural integrity and longevity[2]. Siemens' robotic deployment units can autonomously install these assemblies, minimizing human intervention in hazardous environments. The company has successfully implemented this technology in several European smart cities, reporting a 30% improvement in infrastructure resilience and a 20% reduction in adaptation costs[4].

Strengths: Highly automated process, improved safety through robotic deployment, and enhanced infrastructure resilience. Weaknesses: Complexity of integration with legacy systems, potential cybersecurity risks associated with digital twin technology.

Core PETG Innovations

PETG based decorative sheet having forming ability similar with PVC

PatentWO2008091067A1

Innovation

- A PETG alloy resin is developed by alloying PETG with an ester resin or elastomer resin, specifically polybutylene terephthalate (PBT) and PBT copolymer elastomer, to lower the glass transition temperature and widen the forming temperature range, similar to PVC, with optimal content between 5 to 20 parts by weight.

Poly(ethylene terephthalate)-graphene nanocomposites from improved dispersion

PatentActiveUS20220081508A1

Innovation

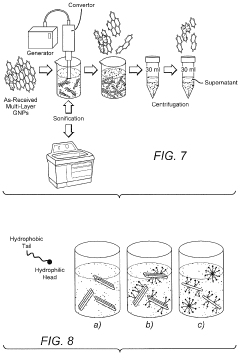

- The method involves sonicating graphene nanoplatelets in a dispersion medium like ethylene glycol or polyethylene glycol to achieve a homogeneous dispersion, followed by centrifugation to remove larger particles, and then using the supernatant solution for polymerization, ensuring a more uniform incorporation of graphene into the PET matrix through methods like in-situ polymerization and dispersion dosing.

Regulatory Considerations

The implementation of Automated Infrastructure Adaptation with PETG Mega-Assemblies requires careful consideration of regulatory frameworks across various jurisdictions. As this technology involves large-scale construction and potential environmental impacts, it falls under the purview of multiple regulatory bodies.

Building codes and construction regulations are primary concerns for PETG Mega-Assemblies. These structures must comply with local, state, and national building standards, which may need to be updated to accommodate the unique properties of PETG materials and automated construction methods. Safety regulations, particularly those related to fire resistance and structural integrity, will need thorough review and possible adaptation.

Environmental regulations play a crucial role in the deployment of this technology. The use of PETG materials and the scale of these assemblies may raise concerns about environmental impact, recycling, and waste management. Regulatory bodies such as the Environmental Protection Agency (EPA) in the United States or similar organizations in other countries will likely require comprehensive environmental impact assessments before approving large-scale implementations.

Zoning laws and urban planning regulations will also need to be considered, as PETG Mega-Assemblies may not fit traditional building categories. Local governments may need to create new zoning designations or modify existing ones to accommodate these structures, particularly in urban areas where space is at a premium.

Labor regulations are another important aspect, as automated construction processes may significantly impact traditional construction workforce dynamics. Regulatory bodies will need to address issues such as worker safety in automated environments, retraining programs, and potential changes to labor laws to reflect the shift towards more automated construction methods.

Intellectual property regulations will be crucial for protecting innovations in this field. Patent offices may need to develop new classification systems or guidelines for PETG Mega-Assembly technologies, ensuring that inventors and companies can adequately protect their advancements while promoting healthy competition and innovation.

Transportation and logistics regulations may also require adaptation, as the movement of large PETG components and automated construction equipment could present unique challenges. Departments of transportation may need to revise regulations on oversized loads, route planning, and transportation safety to accommodate these new materials and construction methods.

In conclusion, the regulatory landscape for Automated Infrastructure Adaptation with PETG Mega-Assemblies is complex and multifaceted. Successful implementation will require close collaboration between technology developers, regulatory bodies, and policymakers to create a balanced framework that ensures safety, environmental protection, and innovation in this emerging field.

Building codes and construction regulations are primary concerns for PETG Mega-Assemblies. These structures must comply with local, state, and national building standards, which may need to be updated to accommodate the unique properties of PETG materials and automated construction methods. Safety regulations, particularly those related to fire resistance and structural integrity, will need thorough review and possible adaptation.

Environmental regulations play a crucial role in the deployment of this technology. The use of PETG materials and the scale of these assemblies may raise concerns about environmental impact, recycling, and waste management. Regulatory bodies such as the Environmental Protection Agency (EPA) in the United States or similar organizations in other countries will likely require comprehensive environmental impact assessments before approving large-scale implementations.

Zoning laws and urban planning regulations will also need to be considered, as PETG Mega-Assemblies may not fit traditional building categories. Local governments may need to create new zoning designations or modify existing ones to accommodate these structures, particularly in urban areas where space is at a premium.

Labor regulations are another important aspect, as automated construction processes may significantly impact traditional construction workforce dynamics. Regulatory bodies will need to address issues such as worker safety in automated environments, retraining programs, and potential changes to labor laws to reflect the shift towards more automated construction methods.

Intellectual property regulations will be crucial for protecting innovations in this field. Patent offices may need to develop new classification systems or guidelines for PETG Mega-Assembly technologies, ensuring that inventors and companies can adequately protect their advancements while promoting healthy competition and innovation.

Transportation and logistics regulations may also require adaptation, as the movement of large PETG components and automated construction equipment could present unique challenges. Departments of transportation may need to revise regulations on oversized loads, route planning, and transportation safety to accommodate these new materials and construction methods.

In conclusion, the regulatory landscape for Automated Infrastructure Adaptation with PETG Mega-Assemblies is complex and multifaceted. Successful implementation will require close collaboration between technology developers, regulatory bodies, and policymakers to create a balanced framework that ensures safety, environmental protection, and innovation in this emerging field.

Environmental Impact

The environmental impact of automated infrastructure adaptation using PETG mega-assemblies is a critical consideration in the development and implementation of this technology. PETG (Polyethylene Terephthalate Glycol-modified) is a thermoplastic polyester that offers several environmental advantages over traditional construction materials. Its recyclability and durability contribute to a reduced carbon footprint throughout the lifecycle of infrastructure projects.

One of the primary environmental benefits of PETG mega-assemblies is their potential for significant waste reduction. The automated nature of the assembly process minimizes material waste typically associated with traditional construction methods. This precision in material usage not only conserves resources but also reduces the environmental impact of manufacturing and transportation.

The lightweight nature of PETG compared to conventional building materials like concrete or steel results in lower energy consumption during transportation and installation. This reduction in energy use translates to decreased greenhouse gas emissions throughout the supply chain and construction process. Additionally, the reduced weight of PETG structures may lead to less invasive foundation requirements, further minimizing environmental disruption at construction sites.

PETG's resistance to weathering and chemical degradation contributes to the longevity of infrastructure, potentially reducing the frequency of repairs and replacements. This extended lifespan translates to fewer resources consumed over time and less waste generated from demolition and reconstruction activities. The material's durability also ensures that the environmental impact of initial production is spread over a longer operational period.

However, the production of PETG does involve petrochemical processes, which have their own environmental considerations. The energy-intensive nature of polymer production and the use of non-renewable resources in PETG manufacturing must be weighed against its benefits. Efforts to incorporate recycled content into PETG mega-assemblies and to develop bio-based alternatives are ongoing areas of research that could further improve the environmental profile of this technology.

The adaptability of PETG mega-assemblies allows for easier modification and repurposing of structures, potentially reducing the need for complete demolition and rebuilding. This flexibility can lead to more efficient use of resources and space in urban environments, contributing to sustainable urban development practices. The ability to quickly deploy and reconfigure infrastructure using this technology may also prove valuable in disaster response scenarios, minimizing environmental impact during recovery efforts.

In conclusion, while PETG mega-assemblies offer several environmental advantages in automated infrastructure adaptation, a comprehensive life cycle assessment is necessary to fully understand and optimize their environmental impact. Continued research into sustainable production methods, recycling technologies, and end-of-life management strategies will be crucial in maximizing the environmental benefits of this innovative approach to infrastructure development.

One of the primary environmental benefits of PETG mega-assemblies is their potential for significant waste reduction. The automated nature of the assembly process minimizes material waste typically associated with traditional construction methods. This precision in material usage not only conserves resources but also reduces the environmental impact of manufacturing and transportation.

The lightweight nature of PETG compared to conventional building materials like concrete or steel results in lower energy consumption during transportation and installation. This reduction in energy use translates to decreased greenhouse gas emissions throughout the supply chain and construction process. Additionally, the reduced weight of PETG structures may lead to less invasive foundation requirements, further minimizing environmental disruption at construction sites.

PETG's resistance to weathering and chemical degradation contributes to the longevity of infrastructure, potentially reducing the frequency of repairs and replacements. This extended lifespan translates to fewer resources consumed over time and less waste generated from demolition and reconstruction activities. The material's durability also ensures that the environmental impact of initial production is spread over a longer operational period.

However, the production of PETG does involve petrochemical processes, which have their own environmental considerations. The energy-intensive nature of polymer production and the use of non-renewable resources in PETG manufacturing must be weighed against its benefits. Efforts to incorporate recycled content into PETG mega-assemblies and to develop bio-based alternatives are ongoing areas of research that could further improve the environmental profile of this technology.

The adaptability of PETG mega-assemblies allows for easier modification and repurposing of structures, potentially reducing the need for complete demolition and rebuilding. This flexibility can lead to more efficient use of resources and space in urban environments, contributing to sustainable urban development practices. The ability to quickly deploy and reconfigure infrastructure using this technology may also prove valuable in disaster response scenarios, minimizing environmental impact during recovery efforts.

In conclusion, while PETG mega-assemblies offer several environmental advantages in automated infrastructure adaptation, a comprehensive life cycle assessment is necessary to fully understand and optimize their environmental impact. Continued research into sustainable production methods, recycling technologies, and end-of-life management strategies will be crucial in maximizing the environmental benefits of this innovative approach to infrastructure development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!