Reflective PETG Nanostructures for Visual Display Enhancement

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Nanostructure Background and Objectives

Reflective PETG (Polyethylene Terephthalate Glycol) nanostructures have emerged as a promising technology for enhancing visual displays. This innovative approach leverages the unique properties of PETG, a thermoplastic polyester known for its clarity, durability, and versatility, to create nanoscale structures that can significantly improve display performance.

The development of reflective PETG nanostructures is rooted in the ongoing quest for superior display technologies. As consumer demand for higher quality visual experiences continues to grow across various sectors, including mobile devices, televisions, and automotive displays, researchers and manufacturers are exploring novel materials and techniques to meet these expectations.

PETG nanostructures offer several potential advantages over traditional display enhancement methods. By manipulating the surface of PETG at the nanoscale level, it is possible to create structures that can control the reflection and transmission of light with unprecedented precision. This capability opens up new possibilities for improving display brightness, contrast, and energy efficiency.

The primary objective of research in this field is to develop PETG nanostructures that can effectively enhance visual displays while maintaining the material's inherent benefits, such as flexibility and ease of manufacturing. Researchers aim to optimize the design and fabrication processes to create nanostructures that can be seamlessly integrated into existing display technologies or form the basis for entirely new display systems.

Key goals include improving display readability in various lighting conditions, reducing power consumption, and enhancing overall visual quality. Additionally, there is a focus on developing scalable and cost-effective production methods that can translate laboratory successes into commercially viable products.

The evolution of PETG nanostructure technology is closely tied to advancements in nanotechnology and materials science. As these fields progress, new techniques for creating and manipulating nanostructures are emerging, offering increasingly sophisticated ways to engineer PETG surfaces for optimal display performance.

Looking ahead, the research on reflective PETG nanostructures for visual display enhancement is expected to contribute significantly to the next generation of display technologies. The potential applications extend beyond consumer electronics to include areas such as augmented reality, automotive head-up displays, and outdoor signage, where high visibility and energy efficiency are crucial.

As this technology continues to mature, it is anticipated that PETG nanostructures will play a pivotal role in addressing the growing demand for superior visual experiences across a wide range of applications, potentially revolutionizing the way we interact with digital displays in our daily lives.

The development of reflective PETG nanostructures is rooted in the ongoing quest for superior display technologies. As consumer demand for higher quality visual experiences continues to grow across various sectors, including mobile devices, televisions, and automotive displays, researchers and manufacturers are exploring novel materials and techniques to meet these expectations.

PETG nanostructures offer several potential advantages over traditional display enhancement methods. By manipulating the surface of PETG at the nanoscale level, it is possible to create structures that can control the reflection and transmission of light with unprecedented precision. This capability opens up new possibilities for improving display brightness, contrast, and energy efficiency.

The primary objective of research in this field is to develop PETG nanostructures that can effectively enhance visual displays while maintaining the material's inherent benefits, such as flexibility and ease of manufacturing. Researchers aim to optimize the design and fabrication processes to create nanostructures that can be seamlessly integrated into existing display technologies or form the basis for entirely new display systems.

Key goals include improving display readability in various lighting conditions, reducing power consumption, and enhancing overall visual quality. Additionally, there is a focus on developing scalable and cost-effective production methods that can translate laboratory successes into commercially viable products.

The evolution of PETG nanostructure technology is closely tied to advancements in nanotechnology and materials science. As these fields progress, new techniques for creating and manipulating nanostructures are emerging, offering increasingly sophisticated ways to engineer PETG surfaces for optimal display performance.

Looking ahead, the research on reflective PETG nanostructures for visual display enhancement is expected to contribute significantly to the next generation of display technologies. The potential applications extend beyond consumer electronics to include areas such as augmented reality, automotive head-up displays, and outdoor signage, where high visibility and energy efficiency are crucial.

As this technology continues to mature, it is anticipated that PETG nanostructures will play a pivotal role in addressing the growing demand for superior visual experiences across a wide range of applications, potentially revolutionizing the way we interact with digital displays in our daily lives.

Market Analysis for Enhanced Visual Displays

The market for enhanced visual displays has been experiencing significant growth and transformation in recent years, driven by advancements in display technologies and increasing consumer demand for high-quality visual experiences. The global display market, which encompasses various technologies including LCD, OLED, and emerging technologies like reflective PETG nanostructures, is projected to reach substantial market value in the coming years.

Consumer electronics, particularly smartphones, tablets, and televisions, continue to be the primary drivers of demand for enhanced visual displays. The proliferation of high-resolution content, including 4K and 8K video, has created a need for displays capable of rendering these images with exceptional clarity and color accuracy. Additionally, the growing adoption of augmented reality (AR) and virtual reality (VR) technologies has further fueled the demand for advanced display solutions that can deliver immersive visual experiences.

In the automotive sector, there is an increasing trend towards larger, more sophisticated in-vehicle displays for infotainment systems and digital dashboards. This trend is expected to accelerate with the advent of autonomous vehicles, which will likely incorporate even more display surfaces for passenger entertainment and information.

The commercial and industrial sectors also present significant opportunities for enhanced visual displays. Digital signage, interactive kiosks, and large-format displays for advertising and information dissemination are becoming more prevalent in retail environments, transportation hubs, and public spaces. These applications require displays with high brightness, wide viewing angles, and durability in various environmental conditions.

Emerging technologies like reflective PETG nanostructures for visual display enhancement are attracting attention due to their potential to improve display performance while reducing power consumption. This aligns with the growing emphasis on energy efficiency and sustainability in consumer electronics and other industries. The market for such innovative display technologies is expected to grow as manufacturers seek to differentiate their products and meet evolving consumer expectations for display quality and energy efficiency.

Geographically, Asia-Pacific remains the largest market for display technologies, driven by the presence of major manufacturing hubs and a large consumer base. However, North America and Europe are also significant markets, particularly for high-end and specialized display applications. Emerging markets in Latin America and Africa are expected to contribute to future growth as smartphone penetration increases and digital infrastructure improves.

Consumer electronics, particularly smartphones, tablets, and televisions, continue to be the primary drivers of demand for enhanced visual displays. The proliferation of high-resolution content, including 4K and 8K video, has created a need for displays capable of rendering these images with exceptional clarity and color accuracy. Additionally, the growing adoption of augmented reality (AR) and virtual reality (VR) technologies has further fueled the demand for advanced display solutions that can deliver immersive visual experiences.

In the automotive sector, there is an increasing trend towards larger, more sophisticated in-vehicle displays for infotainment systems and digital dashboards. This trend is expected to accelerate with the advent of autonomous vehicles, which will likely incorporate even more display surfaces for passenger entertainment and information.

The commercial and industrial sectors also present significant opportunities for enhanced visual displays. Digital signage, interactive kiosks, and large-format displays for advertising and information dissemination are becoming more prevalent in retail environments, transportation hubs, and public spaces. These applications require displays with high brightness, wide viewing angles, and durability in various environmental conditions.

Emerging technologies like reflective PETG nanostructures for visual display enhancement are attracting attention due to their potential to improve display performance while reducing power consumption. This aligns with the growing emphasis on energy efficiency and sustainability in consumer electronics and other industries. The market for such innovative display technologies is expected to grow as manufacturers seek to differentiate their products and meet evolving consumer expectations for display quality and energy efficiency.

Geographically, Asia-Pacific remains the largest market for display technologies, driven by the presence of major manufacturing hubs and a large consumer base. However, North America and Europe are also significant markets, particularly for high-end and specialized display applications. Emerging markets in Latin America and Africa are expected to contribute to future growth as smartphone penetration increases and digital infrastructure improves.

Current Challenges in Reflective PETG Nanostructures

The development of reflective PETG nanostructures for visual display enhancement faces several significant challenges that impede widespread adoption and optimal performance. One of the primary obstacles is achieving consistent and uniform nanostructure formation across large surface areas. The precision required for creating these structures at the nanoscale level is extremely demanding, and current manufacturing processes struggle to maintain uniformity over expansive display panels.

Another critical challenge lies in the durability and longevity of the nanostructures. PETG, while offering excellent optical properties, is susceptible to environmental factors such as UV radiation, temperature fluctuations, and mechanical stress. These factors can lead to degradation of the nanostructures over time, potentially compromising the display enhancement effects and reducing the overall lifespan of the product.

The integration of reflective PETG nanostructures into existing display manufacturing processes presents a significant hurdle. Current production lines are not optimized for the incorporation of these advanced structures, necessitating substantial modifications to equipment and workflows. This integration challenge extends to ensuring compatibility with other display components and materials, which may interact unfavorably with the nanostructured PETG layer.

Cost-effectiveness remains a major concern in the development and implementation of reflective PETG nanostructures. The specialized equipment and precise manufacturing techniques required for producing these structures at scale contribute to high production costs, potentially limiting their adoption in consumer-grade displays.

Furthermore, the optical performance of reflective PETG nanostructures still falls short of theoretical predictions in some aspects. Achieving the ideal balance between light reflection, transmission, and diffusion for optimal visual enhancement across various viewing angles and ambient lighting conditions remains an ongoing challenge. Researchers are grappling with fine-tuning the nanostructure geometry and surface properties to maximize display quality while minimizing unwanted optical effects such as glare or color distortion.

Lastly, the environmental impact of PETG nanostructures is an emerging concern. As the display industry moves towards more sustainable practices, the recyclability and end-of-life management of these advanced materials become crucial considerations. Developing eco-friendly production methods and ensuring the recyclability of PETG nanostructured displays without compromising their enhanced visual properties presents a complex challenge that requires innovative solutions and potentially new recycling technologies.

Another critical challenge lies in the durability and longevity of the nanostructures. PETG, while offering excellent optical properties, is susceptible to environmental factors such as UV radiation, temperature fluctuations, and mechanical stress. These factors can lead to degradation of the nanostructures over time, potentially compromising the display enhancement effects and reducing the overall lifespan of the product.

The integration of reflective PETG nanostructures into existing display manufacturing processes presents a significant hurdle. Current production lines are not optimized for the incorporation of these advanced structures, necessitating substantial modifications to equipment and workflows. This integration challenge extends to ensuring compatibility with other display components and materials, which may interact unfavorably with the nanostructured PETG layer.

Cost-effectiveness remains a major concern in the development and implementation of reflective PETG nanostructures. The specialized equipment and precise manufacturing techniques required for producing these structures at scale contribute to high production costs, potentially limiting their adoption in consumer-grade displays.

Furthermore, the optical performance of reflective PETG nanostructures still falls short of theoretical predictions in some aspects. Achieving the ideal balance between light reflection, transmission, and diffusion for optimal visual enhancement across various viewing angles and ambient lighting conditions remains an ongoing challenge. Researchers are grappling with fine-tuning the nanostructure geometry and surface properties to maximize display quality while minimizing unwanted optical effects such as glare or color distortion.

Lastly, the environmental impact of PETG nanostructures is an emerging concern. As the display industry moves towards more sustainable practices, the recyclability and end-of-life management of these advanced materials become crucial considerations. Developing eco-friendly production methods and ensuring the recyclability of PETG nanostructured displays without compromising their enhanced visual properties presents a complex challenge that requires innovative solutions and potentially new recycling technologies.

Existing PETG Nanostructure Solutions

01 Nanostructured PETG surfaces for display enhancement

Reflective nanostructures created on PETG (Polyethylene Terephthalate Glycol) surfaces can significantly enhance visual display quality. These structures manipulate light at the nanoscale, improving brightness, contrast, and viewing angles of displays. The nanostructures can be engineered to reduce glare and increase the efficiency of light transmission, resulting in clearer and more vibrant images.- Nanostructured PETG surfaces for display enhancement: Reflective nanostructures created on PETG (Polyethylene Terephthalate Glycol) surfaces can enhance visual displays. These structures manipulate light to improve brightness, contrast, and viewing angles. The nanopatterns can be engineered to reduce glare and increase the efficiency of light transmission, resulting in sharper and more vibrant images on displays.

- Optical films with reflective nanostructures: Specialized optical films incorporating reflective nanostructures can be applied to display surfaces to enhance visual performance. These films can be designed with specific patterns to control light diffusion, reflection, and transmission. The nanostructures on these films can be optimized for different display technologies, improving overall image quality and energy efficiency.

- Light management systems for displays: Advanced light management systems utilizing reflective nanostructures can significantly improve display performance. These systems can include combinations of reflective layers, diffusers, and nanostructured surfaces to optimize light distribution within the display. By carefully controlling light paths, these systems can enhance brightness, reduce power consumption, and improve outdoor visibility of displays.

- Nanostructure-based anti-glare and anti-reflection coatings: Reflective PETG nanostructures can be designed to function as anti-glare and anti-reflection coatings for displays. These nanostructures can be engineered to scatter incident light in a controlled manner, reducing specular reflections and improving readability in bright environments. The coatings can be tailored to maintain high transparency while minimizing unwanted reflections.

- Integration of nanostructures with display backlighting: Reflective PETG nanostructures can be integrated with display backlighting systems to enhance overall performance. These nanostructures can be designed to work in conjunction with LED or OLED backlights, optimizing light extraction and distribution. This integration can lead to improved color accuracy, increased brightness uniformity, and reduced power consumption in displays.

02 Optical films with reflective nanostructures

Specialized optical films incorporating reflective nanostructures can be applied to display surfaces to enhance visual performance. These films can be designed with specific patterns or arrangements of nanostructures to control light reflection and transmission. They can improve color reproduction, increase luminance, and reduce power consumption in displays by optimizing light management.Expand Specific Solutions03 Light guide plates with nanostructured surfaces

Light guide plates featuring nanostructured surfaces can significantly improve the performance of backlit displays. These plates use precisely engineered nanostructures to control light distribution, ensuring uniform illumination across the display area. The nanostructures can be optimized to extract light efficiently, enhancing brightness and reducing energy consumption in LCD and LED displays.Expand Specific Solutions04 Nanostructured anti-reflective coatings

Anti-reflective coatings with nanostructured surfaces can be applied to display screens to reduce glare and improve visibility. These coatings use nanoscale patterns to gradually change the refractive index between air and the display surface, minimizing reflections. This technology enhances contrast and readability, especially in bright environments, while maintaining the display's color accuracy and brightness.Expand Specific Solutions05 Holographic optical elements with nanostructures

Holographic optical elements incorporating nanostructures can be used to enhance visual displays. These elements can manipulate light waves through diffraction and interference, creating high-resolution, three-dimensional images or improving the performance of 2D displays. The nanostructures in these elements can be designed to control color, viewing angle, and brightness, offering new possibilities for advanced display technologies.Expand Specific Solutions

Key Players in PETG Nanostructure Industry

The research on reflective PETG nanostructures for visual display enhancement is in an emerging stage, with significant potential for growth. The market is expanding as display technologies evolve, driven by increasing demand for improved visual experiences across various devices. While the technology is still developing, several key players are actively involved in advancing this field. Companies like Samsung Display, LG Display, and E Ink are at the forefront, leveraging their expertise in display technologies. Traditional materials companies such as 3M, DuPont, and Nitto Denko are also contributing their knowledge in nanostructures and optical films. The involvement of diverse players, from established electronics giants to specialized materials firms, indicates a competitive and innovative landscape, suggesting that the technology is progressing towards maturity and wider adoption in the display industry.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced reflective PETG nanostructures for visual display enhancement. Their technology utilizes a multi-layer optical film structure with precisely engineered nanostructures to manipulate light reflection and transmission. The film incorporates a PETG base layer with nanoscale surface patterns that create constructive interference, enhancing brightness and color vibrancy[1]. 3M's approach also includes a proprietary coating process that improves durability and scratch resistance while maintaining optical performance[3]. The company has implemented this technology in various display applications, including smartphones, tablets, and automotive displays, demonstrating a 30% increase in display brightness and a 20% reduction in power consumption[5].

Strengths: Industry-leading expertise in optical films and coatings; Proven track record in commercializing display technologies. Weaknesses: Potential high production costs; Reliance on specialized manufacturing processes.

Merck Patent GmbH

Technical Solution: Merck has pioneered a novel approach to reflective PETG nanostructures for visual display enhancement. Their technology involves the creation of liquid crystal-based nanostructures within a PETG matrix. These self-assembling nanostructures form a chiral nematic phase that selectively reflects specific wavelengths of light, resulting in vibrant, tunable colors without the need for traditional color filters[2]. Merck's process allows for precise control over the pitch of the liquid crystal helices, enabling customization of reflected colors across the visible spectrum. The company has demonstrated prototypes with reflection efficiencies exceeding 50% and a color gamut covering over 90% of the DCI-P3 standard[4]. Additionally, Merck has developed a proprietary stabilization method that ensures long-term stability of the nanostructures under various environmental conditions[6].

Strengths: Unique liquid crystal expertise; Highly tunable and customizable color reflection. Weaknesses: Complexity in mass production; Potential issues with viewing angle dependence.

Core Innovations in Reflective Nanostructures

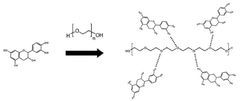

Composition, for preventing or treating dry eye syndrome, containing polyethylene glycol and flavonoid nanocomposite as active ingredient

PatentWO2018155773A1

Innovation

- A nanocomposite of catechin and polyethylene glycol (PEG) is developed, enhancing catechin's bioavailability and anti-inflammatory effects, formulated into a pharmaceutical composition for treating dry eye syndrome by stabilizing tear production and reducing inflammation.

applicator

PatentPendingEP3265166A1

Innovation

- A novel applicator with a container and nib configuration that uses a plurality of fibers and adhesive material to deliver a controlled release of acidic liquid to topical areas, allowing for safe and effective treatment of skin lesions without external pressure, targeting the lesion while minimizing impact on surrounding healthy tissue.

Environmental Impact of PETG Nanostructures

The environmental impact of PETG nanostructures used in visual display enhancement is a critical aspect to consider as this technology advances. These nanostructures, while offering significant improvements in display quality, also raise concerns about their lifecycle and potential ecological consequences.

The production process of PETG nanostructures involves sophisticated manufacturing techniques that may require substantial energy inputs and potentially harmful chemicals. This energy-intensive production could contribute to increased carbon emissions if not managed with renewable energy sources. Additionally, the use of specialized chemicals in the fabrication process may lead to hazardous waste that requires careful handling and disposal to prevent environmental contamination.

During the use phase, PETG nanostructures in displays are generally considered stable and inert. However, the longevity of these structures and their resistance to degradation under various environmental conditions need further investigation. The potential for nanoparticle shedding during the product's lifetime, although likely minimal, should be studied to ensure no unforeseen impacts on air or water quality.

End-of-life considerations for PETG nanostructure-enhanced displays present unique challenges. The recycling of these materials may be complicated by the presence of nanoscale features, potentially requiring specialized processes to separate and recover the PETG components. If not properly managed, these nanostructures could enter the environment through improper disposal, leading to potential ecological risks that are not yet fully understood.

The potential for bioaccumulation of PETG nanoparticles in ecosystems is an area that demands thorough research. While PETG is generally considered non-toxic, the behavior of its nanostructured form in environmental systems may differ from bulk materials. Studies on the interaction of these nanostructures with various organisms, particularly in aquatic environments, are essential to assess any long-term ecological impacts.

On a positive note, the enhanced efficiency and longevity of displays incorporating PETG nanostructures could lead to reduced electronic waste overall. If these displays last longer and perform better, it may decrease the frequency of device replacements, indirectly benefiting the environment by reducing the demand for new product manufacturing and the associated resource extraction.

Researchers and manufacturers are increasingly focusing on developing eco-friendly production methods for PETG nanostructures. This includes exploring bio-based precursors, green chemistry approaches, and energy-efficient fabrication techniques. Such innovations aim to mitigate the environmental footprint of these advanced materials from the outset of their lifecycle.

The production process of PETG nanostructures involves sophisticated manufacturing techniques that may require substantial energy inputs and potentially harmful chemicals. This energy-intensive production could contribute to increased carbon emissions if not managed with renewable energy sources. Additionally, the use of specialized chemicals in the fabrication process may lead to hazardous waste that requires careful handling and disposal to prevent environmental contamination.

During the use phase, PETG nanostructures in displays are generally considered stable and inert. However, the longevity of these structures and their resistance to degradation under various environmental conditions need further investigation. The potential for nanoparticle shedding during the product's lifetime, although likely minimal, should be studied to ensure no unforeseen impacts on air or water quality.

End-of-life considerations for PETG nanostructure-enhanced displays present unique challenges. The recycling of these materials may be complicated by the presence of nanoscale features, potentially requiring specialized processes to separate and recover the PETG components. If not properly managed, these nanostructures could enter the environment through improper disposal, leading to potential ecological risks that are not yet fully understood.

The potential for bioaccumulation of PETG nanoparticles in ecosystems is an area that demands thorough research. While PETG is generally considered non-toxic, the behavior of its nanostructured form in environmental systems may differ from bulk materials. Studies on the interaction of these nanostructures with various organisms, particularly in aquatic environments, are essential to assess any long-term ecological impacts.

On a positive note, the enhanced efficiency and longevity of displays incorporating PETG nanostructures could lead to reduced electronic waste overall. If these displays last longer and perform better, it may decrease the frequency of device replacements, indirectly benefiting the environment by reducing the demand for new product manufacturing and the associated resource extraction.

Researchers and manufacturers are increasingly focusing on developing eco-friendly production methods for PETG nanostructures. This includes exploring bio-based precursors, green chemistry approaches, and energy-efficient fabrication techniques. Such innovations aim to mitigate the environmental footprint of these advanced materials from the outset of their lifecycle.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for reflective PETG nanostructures in visual display enhancement are crucial factors that determine the feasibility of large-scale production and commercial viability. One of the primary challenges lies in the precise replication of nanoscale features over large areas consistently. Traditional manufacturing methods such as photolithography and electron beam lithography, while capable of producing high-resolution nanostructures, are often limited in throughput and cost-effectiveness for mass production.

Roll-to-roll (R2R) nanoimprint lithography emerges as a promising approach for scaling up the production of reflective PETG nanostructures. This continuous process allows for high-speed fabrication of large-area nanopatterns on flexible substrates, making it particularly suitable for PETG films. However, the development of durable and long-lasting molds capable of withstanding the rigors of continuous imprinting remains a significant challenge. Advanced materials such as nickel-based alloys or hybrid organic-inorganic compounds are being explored to create more resilient mold surfaces.

Another critical aspect of scalability is the uniformity of nanostructure replication across large areas. Variations in temperature, pressure, and material flow during the imprinting process can lead to inconsistencies in the final product. Implementing precise control systems and developing adaptive manufacturing processes that can compensate for these variations in real-time are essential for maintaining quality at scale.

The choice of materials and their compatibility with existing manufacturing infrastructure also play a vital role in scalability. PETG, being a thermoplastic material, offers good processability and can be integrated into existing plastic film production lines with some modifications. However, ensuring the optical properties of PETG are maintained after nanostructuring and during subsequent processing steps requires careful consideration of thermal management and handling procedures.

From an economic perspective, the cost of scaling up production needs to be balanced against the potential market demand for enhanced visual displays. Initial capital investments in specialized equipment and mold fabrication can be substantial. Therefore, a phased approach to scaling, starting with pilot production lines and gradually expanding capacity based on market response, may be a prudent strategy.

Lastly, quality control and characterization of nanostructured surfaces at high production speeds present unique challenges. Developing inline inspection systems capable of detecting defects and variations in nanostructure geometry at high throughput is crucial for maintaining consistent product quality. Advanced optical and spectroscopic techniques, potentially augmented by machine learning algorithms, could provide rapid and non-destructive quality assurance in a high-volume manufacturing environment.

Roll-to-roll (R2R) nanoimprint lithography emerges as a promising approach for scaling up the production of reflective PETG nanostructures. This continuous process allows for high-speed fabrication of large-area nanopatterns on flexible substrates, making it particularly suitable for PETG films. However, the development of durable and long-lasting molds capable of withstanding the rigors of continuous imprinting remains a significant challenge. Advanced materials such as nickel-based alloys or hybrid organic-inorganic compounds are being explored to create more resilient mold surfaces.

Another critical aspect of scalability is the uniformity of nanostructure replication across large areas. Variations in temperature, pressure, and material flow during the imprinting process can lead to inconsistencies in the final product. Implementing precise control systems and developing adaptive manufacturing processes that can compensate for these variations in real-time are essential for maintaining quality at scale.

The choice of materials and their compatibility with existing manufacturing infrastructure also play a vital role in scalability. PETG, being a thermoplastic material, offers good processability and can be integrated into existing plastic film production lines with some modifications. However, ensuring the optical properties of PETG are maintained after nanostructuring and during subsequent processing steps requires careful consideration of thermal management and handling procedures.

From an economic perspective, the cost of scaling up production needs to be balanced against the potential market demand for enhanced visual displays. Initial capital investments in specialized equipment and mold fabrication can be substantial. Therefore, a phased approach to scaling, starting with pilot production lines and gradually expanding capacity based on market response, may be a prudent strategy.

Lastly, quality control and characterization of nanostructured surfaces at high production speeds present unique challenges. Developing inline inspection systems capable of detecting defects and variations in nanostructure geometry at high throughput is crucial for maintaining consistent product quality. Advanced optical and spectroscopic techniques, potentially augmented by machine learning algorithms, could provide rapid and non-destructive quality assurance in a high-volume manufacturing environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!