Integrating PETG with Biodegradable Polymers for Enhanced Eco-Efficiency

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG-Biopolymer Integration Background

The integration of PETG (Polyethylene Terephthalate Glycol-modified) with biodegradable polymers represents a significant advancement in the field of eco-efficient materials. This innovative approach aims to combine the desirable properties of PETG, such as its clarity, toughness, and chemical resistance, with the environmental benefits of biodegradable polymers.

PETG, a thermoplastic polyester, has gained widespread use in various industries due to its excellent mechanical properties and processability. However, its non-biodegradable nature has raised concerns about its environmental impact, particularly in terms of plastic waste accumulation. On the other hand, biodegradable polymers, derived from renewable resources or engineered to degrade under specific conditions, offer a more sustainable alternative but often lack the performance characteristics required for certain applications.

The concept of integrating PETG with biodegradable polymers emerged as a response to the growing demand for materials that balance performance with environmental responsibility. This approach seeks to create composite materials or blends that retain the advantageous properties of PETG while incorporating the biodegradability of eco-friendly polymers.

Early research in this field focused on identifying compatible biodegradable polymers that could be effectively combined with PETG without significantly compromising its desirable characteristics. Polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and thermoplastic starch (TPS) were among the initial candidates explored for integration with PETG.

The development of PETG-biopolymer integration techniques has progressed through several stages. Initial efforts concentrated on simple blending methods, which often resulted in materials with suboptimal properties due to poor compatibility between the components. Subsequent research explored more sophisticated approaches, including reactive blending, compatibilization techniques, and the use of nanofillers to enhance the interaction between PETG and biodegradable polymers.

Recent advancements in polymer science and processing technologies have opened up new possibilities for achieving more effective integration. These include the development of novel compatibilizers specifically designed for PETG-biopolymer systems, the exploration of in-situ polymerization techniques, and the application of advanced surface modification methods to improve interfacial adhesion between the components.

The ongoing evolution of PETG-biopolymer integration reflects a broader trend in materials science towards creating more sustainable and environmentally friendly products. This research area aligns with global initiatives to reduce plastic waste and promote circular economy principles in the plastics industry.

PETG, a thermoplastic polyester, has gained widespread use in various industries due to its excellent mechanical properties and processability. However, its non-biodegradable nature has raised concerns about its environmental impact, particularly in terms of plastic waste accumulation. On the other hand, biodegradable polymers, derived from renewable resources or engineered to degrade under specific conditions, offer a more sustainable alternative but often lack the performance characteristics required for certain applications.

The concept of integrating PETG with biodegradable polymers emerged as a response to the growing demand for materials that balance performance with environmental responsibility. This approach seeks to create composite materials or blends that retain the advantageous properties of PETG while incorporating the biodegradability of eco-friendly polymers.

Early research in this field focused on identifying compatible biodegradable polymers that could be effectively combined with PETG without significantly compromising its desirable characteristics. Polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and thermoplastic starch (TPS) were among the initial candidates explored for integration with PETG.

The development of PETG-biopolymer integration techniques has progressed through several stages. Initial efforts concentrated on simple blending methods, which often resulted in materials with suboptimal properties due to poor compatibility between the components. Subsequent research explored more sophisticated approaches, including reactive blending, compatibilization techniques, and the use of nanofillers to enhance the interaction between PETG and biodegradable polymers.

Recent advancements in polymer science and processing technologies have opened up new possibilities for achieving more effective integration. These include the development of novel compatibilizers specifically designed for PETG-biopolymer systems, the exploration of in-situ polymerization techniques, and the application of advanced surface modification methods to improve interfacial adhesion between the components.

The ongoing evolution of PETG-biopolymer integration reflects a broader trend in materials science towards creating more sustainable and environmentally friendly products. This research area aligns with global initiatives to reduce plastic waste and promote circular economy principles in the plastics industry.

Eco-Efficient Packaging Market Analysis

The eco-efficient packaging market has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. This market segment focuses on packaging solutions that minimize environmental impact while maintaining or improving product protection and performance. The integration of PETG (Polyethylene Terephthalate Glycol) with biodegradable polymers represents a promising avenue for enhancing eco-efficiency in packaging applications.

Market demand for eco-efficient packaging solutions has been steadily rising across various industries, including food and beverage, personal care, and consumer goods. Consumers are increasingly seeking products with sustainable packaging, leading to a shift in corporate strategies towards more environmentally friendly options. This trend is particularly pronounced in developed markets such as North America and Europe, where environmental regulations are more stringent.

The global eco-efficient packaging market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is fueled by factors such as increasing consumer awareness, government initiatives promoting sustainable packaging, and corporate commitments to reduce plastic waste and carbon footprints.

PETG, known for its clarity, durability, and recyclability, has been a popular choice in the packaging industry. However, its integration with biodegradable polymers presents new opportunities for enhancing its eco-efficiency. This combination aims to address the limitations of traditional PETG while leveraging its desirable properties, potentially creating a new category of packaging materials that offer improved end-of-life options.

The market for PETG-biodegradable polymer blends is still in its nascent stages, with significant potential for growth. Early adopters in the packaging industry are exploring these materials for applications where traditional PETG is currently used, such as food containers, beverage bottles, and personal care product packaging. The ability to offer enhanced biodegradability without compromising on the performance characteristics of PETG is a key selling point for these innovative materials.

Challenges in the eco-efficient packaging market include the higher costs associated with sustainable materials and the need for infrastructure development to support proper disposal and recycling. However, as production scales up and technologies improve, these barriers are expected to diminish, further driving market growth.

In conclusion, the eco-efficient packaging market, particularly the segment focusing on integrating PETG with biodegradable polymers, presents substantial opportunities for innovation and growth. As consumer demand for sustainable packaging solutions continues to rise and regulatory pressures increase, this market is poised for significant expansion in the coming years.

Market demand for eco-efficient packaging solutions has been steadily rising across various industries, including food and beverage, personal care, and consumer goods. Consumers are increasingly seeking products with sustainable packaging, leading to a shift in corporate strategies towards more environmentally friendly options. This trend is particularly pronounced in developed markets such as North America and Europe, where environmental regulations are more stringent.

The global eco-efficient packaging market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is fueled by factors such as increasing consumer awareness, government initiatives promoting sustainable packaging, and corporate commitments to reduce plastic waste and carbon footprints.

PETG, known for its clarity, durability, and recyclability, has been a popular choice in the packaging industry. However, its integration with biodegradable polymers presents new opportunities for enhancing its eco-efficiency. This combination aims to address the limitations of traditional PETG while leveraging its desirable properties, potentially creating a new category of packaging materials that offer improved end-of-life options.

The market for PETG-biodegradable polymer blends is still in its nascent stages, with significant potential for growth. Early adopters in the packaging industry are exploring these materials for applications where traditional PETG is currently used, such as food containers, beverage bottles, and personal care product packaging. The ability to offer enhanced biodegradability without compromising on the performance characteristics of PETG is a key selling point for these innovative materials.

Challenges in the eco-efficient packaging market include the higher costs associated with sustainable materials and the need for infrastructure development to support proper disposal and recycling. However, as production scales up and technologies improve, these barriers are expected to diminish, further driving market growth.

In conclusion, the eco-efficient packaging market, particularly the segment focusing on integrating PETG with biodegradable polymers, presents substantial opportunities for innovation and growth. As consumer demand for sustainable packaging solutions continues to rise and regulatory pressures increase, this market is poised for significant expansion in the coming years.

Current Challenges in PETG-Biopolymer Blending

The integration of PETG (Polyethylene Terephthalate Glycol) with biodegradable polymers presents several significant challenges that hinder the widespread adoption of this eco-efficient solution. One of the primary obstacles is the inherent incompatibility between PETG and most biodegradable polymers at the molecular level. This incompatibility often results in poor interfacial adhesion, leading to phase separation and compromised mechanical properties in the final blended material.

Another major challenge lies in maintaining the desirable properties of PETG, such as its excellent clarity, toughness, and chemical resistance, while incorporating biodegradable components. The addition of biodegradable polymers can potentially degrade these key characteristics, making it difficult to achieve a balance between eco-efficiency and performance.

The processing of PETG-biopolymer blends also poses significant technical hurdles. The different melting temperatures and rheological properties of PETG and biodegradable polymers often lead to processing difficulties, including uneven mixing, thermal degradation, and inconsistent product quality. This challenge is particularly pronounced in large-scale industrial production settings.

Furthermore, ensuring consistent and predictable biodegradation rates in PETG-biopolymer blends remains a complex issue. The presence of PETG can significantly alter the biodegradation behavior of the blended material, potentially leading to incomplete or slower degradation than desired. This unpredictability complicates end-of-life management strategies and may limit the environmental benefits of the blended material.

Cost considerations also present a significant challenge in PETG-biopolymer integration. Biodegradable polymers are often more expensive than conventional plastics, and the additional processing steps required for effective blending can further increase production costs. This economic barrier can deter manufacturers from adopting these eco-efficient solutions, particularly in price-sensitive markets.

Regulatory compliance and standardization pose additional challenges. The lack of universally accepted standards for biodegradability and compostability of polymer blends creates uncertainty in product development and marketing. Manufacturers must navigate complex and sometimes conflicting regulations across different regions, which can slow down innovation and market adoption.

Lastly, the challenge of scalability and consistent quality control in PETG-biopolymer blending cannot be overstated. Achieving uniform properties and performance across large production batches requires sophisticated blending technologies and quality assurance processes. The variability in raw material properties, particularly of biodegradable polymers, further complicates this challenge, necessitating robust and adaptable manufacturing processes.

Another major challenge lies in maintaining the desirable properties of PETG, such as its excellent clarity, toughness, and chemical resistance, while incorporating biodegradable components. The addition of biodegradable polymers can potentially degrade these key characteristics, making it difficult to achieve a balance between eco-efficiency and performance.

The processing of PETG-biopolymer blends also poses significant technical hurdles. The different melting temperatures and rheological properties of PETG and biodegradable polymers often lead to processing difficulties, including uneven mixing, thermal degradation, and inconsistent product quality. This challenge is particularly pronounced in large-scale industrial production settings.

Furthermore, ensuring consistent and predictable biodegradation rates in PETG-biopolymer blends remains a complex issue. The presence of PETG can significantly alter the biodegradation behavior of the blended material, potentially leading to incomplete or slower degradation than desired. This unpredictability complicates end-of-life management strategies and may limit the environmental benefits of the blended material.

Cost considerations also present a significant challenge in PETG-biopolymer integration. Biodegradable polymers are often more expensive than conventional plastics, and the additional processing steps required for effective blending can further increase production costs. This economic barrier can deter manufacturers from adopting these eco-efficient solutions, particularly in price-sensitive markets.

Regulatory compliance and standardization pose additional challenges. The lack of universally accepted standards for biodegradability and compostability of polymer blends creates uncertainty in product development and marketing. Manufacturers must navigate complex and sometimes conflicting regulations across different regions, which can slow down innovation and market adoption.

Lastly, the challenge of scalability and consistent quality control in PETG-biopolymer blending cannot be overstated. Achieving uniform properties and performance across large production batches requires sophisticated blending technologies and quality assurance processes. The variability in raw material properties, particularly of biodegradable polymers, further complicates this challenge, necessitating robust and adaptable manufacturing processes.

Existing PETG-Biopolymer Blend Solutions

01 Eco-friendly PETG material composition

Development of PETG materials with improved eco-efficiency through the incorporation of biodegradable additives or renewable resources. These compositions aim to reduce environmental impact while maintaining the desirable properties of PETG.- Eco-friendly PETG production methods: Various methods are being developed to produce PETG in a more environmentally friendly manner. These include using renewable resources, optimizing production processes to reduce energy consumption, and implementing recycling techniques to minimize waste. Such approaches aim to improve the overall eco-efficiency of PETG manufacturing.

- PETG recycling and reuse strategies: Innovative recycling and reuse strategies are being implemented to enhance the eco-efficiency of PETG. These include developing advanced sorting and processing techniques, creating closed-loop recycling systems, and finding new applications for recycled PETG materials. Such efforts contribute to reducing the environmental impact of PETG throughout its lifecycle.

- PETG blends and composites for improved sustainability: Research is focused on creating PETG blends and composites that offer enhanced eco-efficiency. By combining PETG with other materials or additives, researchers aim to improve its biodegradability, reduce its carbon footprint, or enhance its recyclability. These innovations contribute to the development of more sustainable PETG-based products.

- Energy-efficient PETG processing techniques: Advancements in PETG processing techniques are being made to improve energy efficiency and reduce environmental impact. These include optimizing molding and extrusion processes, developing low-temperature processing methods, and implementing energy recovery systems. Such innovations contribute to the overall eco-efficiency of PETG product manufacturing.

- Bio-based alternatives to traditional PETG: Research is being conducted on bio-based alternatives to traditional petroleum-derived PETG. These alternatives aim to reduce reliance on fossil fuels and decrease the carbon footprint of PETG production. Bio-based PETG variants may offer similar properties to conventional PETG while providing improved eco-efficiency and sustainability.

02 PETG recycling and reuse processes

Innovative methods for recycling and reusing PETG materials, including chemical recycling, mechanical recycling, and upcycling techniques. These processes aim to reduce waste and improve the overall eco-efficiency of PETG products.Expand Specific Solutions03 Energy-efficient PETG production methods

Development of energy-efficient production methods for PETG, including optimized polymerization processes, improved catalysts, and innovative reactor designs. These methods aim to reduce energy consumption and greenhouse gas emissions during PETG manufacturing.Expand Specific Solutions04 PETG applications in sustainable packaging

Utilization of PETG in eco-friendly packaging solutions, including lightweight designs, multi-layer structures, and barrier properties enhancement. These applications aim to reduce material usage, improve recyclability, and extend product shelf life.Expand Specific Solutions05 PETG blends and composites for improved eco-efficiency

Development of PETG blends and composites with other materials to enhance overall eco-efficiency. These combinations aim to improve mechanical properties, reduce material consumption, and increase biodegradability or recyclability of the final products.Expand Specific Solutions

Key Players in Sustainable Packaging Materials

The integration of PETG with biodegradable polymers for enhanced eco-efficiency is in a nascent stage of development, with significant potential for growth. The market is characterized by a mix of academic institutions and innovative companies exploring this technology. Key players like Tianjin University, Beijing University of Chemical Technology, and Everywhere Apparel are driving research and development. The market size is expanding as sustainability concerns grow, but commercialization remains limited. Technical challenges persist in achieving optimal performance and cost-effectiveness, indicating that the technology is still evolving. Companies like revalyu Resources and Novamont are at the forefront of commercializing related technologies, suggesting a competitive landscape poised for rapid advancement in the coming years.

Bioplastics Innovations Ltd.

Technical Solution: Bioplastics Innovations Ltd. has developed a novel approach to integrating PETG with biodegradable polymers using a proprietary reactive extrusion process. Their technology focuses on creating compatibilized blends of PETG with polylactic acid (PLA) and polyhydroxyalkanoates (PHAs). The company utilizes a series of reactive compatibilizers that form covalent bonds between PETG and the biodegradable polymers, resulting in improved miscibility and enhanced mechanical properties[4]. Additionally, they have incorporated nanocellulose as a reinforcing agent to further improve the strength and barrier properties of the eco-efficient composites. Bioplastics Innovations Ltd. has also developed a controlled degradation mechanism that allows for the tuning of biodegradation rates based on specific application requirements[5].

Strengths: Innovative reactive extrusion technology, ability to create customized blends, and incorporation of nanocellulose for enhanced properties. Weaknesses: Limited commercial scale production and potential challenges in meeting diverse industry standards.

Novamont SpA

Technical Solution: Novamont has developed a proprietary technology called MATER-BI, which combines PETG with biodegradable polymers to create eco-efficient materials. Their approach involves blending PETG with starch-based biopolymers and other biodegradable additives to enhance the overall biodegradability of the resulting composite. The company has successfully implemented a multi-phase compatibilization process that improves the interfacial adhesion between PETG and biodegradable components, resulting in materials with enhanced mechanical properties and controlled degradation rates[1][3]. Novamont's technology also incorporates the use of specific enzymes and microorganisms to accelerate the biodegradation process of the PETG-biopolymer blends in various environmental conditions[2].

Strengths: Proven track record in bioplastics, established MATER-BI technology, and ability to tailor biodegradation rates. Weaknesses: Potential higher production costs compared to conventional plastics and limited scalability for certain applications.

Innovative PETG-Biopolymer Compatibilization Techniques

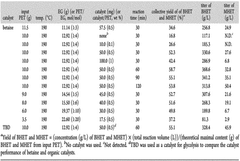

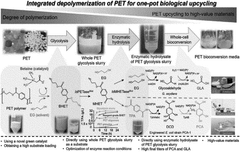

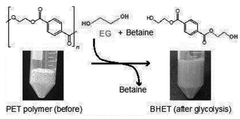

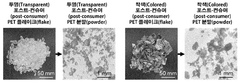

Chemical and biological integrated degradation process for polyethylene terephthalate (PET), for recycling pet

PatentWO2022182196A1

Innovation

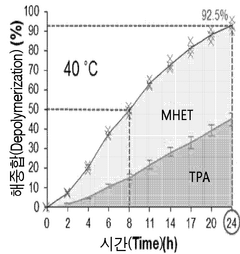

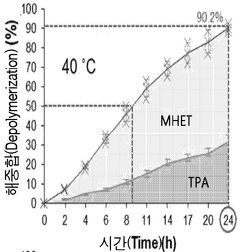

- An integrated chemical-biological process using glycolysis with ethylene glycol and betaine as a catalyst to break down PET into oligomers, followed by enzymatic hydrolysis to produce terephthalic acid and ethylene glycol, which are then converted into high-value platform chemicals like protocatechuic acid and glycolic acid using recombinant E. coli and Gluconobacter oxydans, respectively, eliminating the need for additional purification steps.

Modified polypeptide having pet degradation activity

PatentWO2024237738A1

Innovation

- Development of a variant polypeptide with PET degrading activity that enzymatically decomposes PET into recyclable components like mono(2-hydroxymethyl) terephthalate, terephthalic acid, and ethylene glycol, allowing for environmentally friendly recycling and reuse of PET materials.

Environmental Impact Assessment

The integration of PETG with biodegradable polymers for enhanced eco-efficiency presents a significant opportunity to address environmental concerns associated with plastic waste. This assessment examines the potential environmental impacts of this innovative approach, considering both positive outcomes and potential challenges.

One of the primary benefits of integrating PETG with biodegradable polymers is the potential reduction in plastic waste accumulation. By incorporating biodegradable components, the overall environmental persistence of PETG-based products can be significantly reduced. This could lead to a decrease in plastic pollution in terrestrial and aquatic ecosystems, mitigating the long-term ecological impacts associated with conventional plastics.

The biodegradation process of these integrated materials may also contribute to reduced greenhouse gas emissions compared to traditional PETG disposal methods. As biodegradable polymers break down, they typically release fewer harmful byproducts than the incineration or landfilling of conventional plastics. This could potentially lower the carbon footprint associated with the product's end-of-life stage.

However, it is crucial to consider the environmental impacts of producing biodegradable polymers and integrating them with PETG. The manufacturing process may require additional energy and resources, potentially offsetting some of the environmental benefits gained at the disposal stage. A comprehensive life cycle assessment would be necessary to quantify the net environmental impact of this integration.

The introduction of biodegradable components into PETG products may also affect recycling streams. While this integration aims to enhance eco-efficiency, it could potentially complicate existing recycling processes designed for pure PETG. Careful consideration must be given to the development of appropriate sorting and recycling technologies to maximize the environmental benefits of this approach.

Furthermore, the biodegradation of these integrated materials in various environmental conditions needs to be thoroughly evaluated. Factors such as temperature, humidity, and microbial activity can significantly influence the rate and completeness of biodegradation. Incomplete biodegradation could lead to the persistence of microplastics in the environment, which may have unforeseen ecological consequences.

The potential for these integrated materials to leach chemicals during biodegradation should also be assessed. While biodegradable polymers are generally considered environmentally friendly, the interaction between PETG and biodegradable components during breakdown could potentially release substances that impact soil or water quality.

In conclusion, the integration of PETG with biodegradable polymers shows promise in enhancing eco-efficiency, particularly in reducing plastic waste accumulation and potentially lowering greenhouse gas emissions associated with disposal. However, a thorough environmental impact assessment must consider the entire life cycle of these materials, from production to disposal, to ensure that the intended environmental benefits are realized without introducing new ecological challenges.

One of the primary benefits of integrating PETG with biodegradable polymers is the potential reduction in plastic waste accumulation. By incorporating biodegradable components, the overall environmental persistence of PETG-based products can be significantly reduced. This could lead to a decrease in plastic pollution in terrestrial and aquatic ecosystems, mitigating the long-term ecological impacts associated with conventional plastics.

The biodegradation process of these integrated materials may also contribute to reduced greenhouse gas emissions compared to traditional PETG disposal methods. As biodegradable polymers break down, they typically release fewer harmful byproducts than the incineration or landfilling of conventional plastics. This could potentially lower the carbon footprint associated with the product's end-of-life stage.

However, it is crucial to consider the environmental impacts of producing biodegradable polymers and integrating them with PETG. The manufacturing process may require additional energy and resources, potentially offsetting some of the environmental benefits gained at the disposal stage. A comprehensive life cycle assessment would be necessary to quantify the net environmental impact of this integration.

The introduction of biodegradable components into PETG products may also affect recycling streams. While this integration aims to enhance eco-efficiency, it could potentially complicate existing recycling processes designed for pure PETG. Careful consideration must be given to the development of appropriate sorting and recycling technologies to maximize the environmental benefits of this approach.

Furthermore, the biodegradation of these integrated materials in various environmental conditions needs to be thoroughly evaluated. Factors such as temperature, humidity, and microbial activity can significantly influence the rate and completeness of biodegradation. Incomplete biodegradation could lead to the persistence of microplastics in the environment, which may have unforeseen ecological consequences.

The potential for these integrated materials to leach chemicals during biodegradation should also be assessed. While biodegradable polymers are generally considered environmentally friendly, the interaction between PETG and biodegradable components during breakdown could potentially release substances that impact soil or water quality.

In conclusion, the integration of PETG with biodegradable polymers shows promise in enhancing eco-efficiency, particularly in reducing plastic waste accumulation and potentially lowering greenhouse gas emissions associated with disposal. However, a thorough environmental impact assessment must consider the entire life cycle of these materials, from production to disposal, to ensure that the intended environmental benefits are realized without introducing new ecological challenges.

Regulatory Landscape for Sustainable Packaging

The regulatory landscape for sustainable packaging is rapidly evolving, driven by increasing environmental concerns and the global push towards circular economy principles. Governments and international organizations are implementing stricter regulations to promote eco-friendly packaging solutions, including those integrating PETG with biodegradable polymers.

In the European Union, the Packaging and Packaging Waste Directive (PPWD) sets targets for recycling and recovery of packaging materials. The directive is currently under revision to align with the EU's Circular Economy Action Plan, which aims to make all packaging reusable or recyclable by 2030. This revision is likely to impact the use of PETG and biodegradable polymers in packaging applications.

The United States lacks a comprehensive federal policy on sustainable packaging, but several states have enacted their own regulations. California's SB 54, for instance, requires all packaging to be recyclable or compostable by 2032. This legislation could potentially favor the integration of PETG with biodegradable polymers as a means to achieve compliance.

In Asia, countries like Japan and South Korea have implemented extended producer responsibility (EPR) systems for packaging waste. China's recent ban on certain types of plastic waste imports has also spurred global efforts to develop more sustainable packaging solutions.

Certification schemes and standards play a crucial role in the regulatory landscape. The ISO 14021 standard for environmental labels and declarations provides guidelines for claims related to biodegradability and compostability. The European Standard EN 13432 specifies requirements for packaging recoverable through composting and biodegradation.

Regulatory bodies are increasingly focusing on the life cycle assessment (LCA) of packaging materials. The integration of PETG with biodegradable polymers must demonstrate improved environmental performance across the entire life cycle to gain regulatory approval and market acceptance.

Emerging regulations are also addressing concerns about microplastics and marine pollution. The EU's Single-Use Plastics Directive, for example, restricts certain single-use plastic products and could potentially impact the use of PETG-biodegradable polymer blends in specific applications.

As the regulatory landscape continues to evolve, companies developing integrated PETG-biodegradable polymer solutions must stay informed of regional and global policy changes. Proactive engagement with policymakers and participation in industry associations can help shape future regulations and ensure compliance with emerging standards in sustainable packaging.

In the European Union, the Packaging and Packaging Waste Directive (PPWD) sets targets for recycling and recovery of packaging materials. The directive is currently under revision to align with the EU's Circular Economy Action Plan, which aims to make all packaging reusable or recyclable by 2030. This revision is likely to impact the use of PETG and biodegradable polymers in packaging applications.

The United States lacks a comprehensive federal policy on sustainable packaging, but several states have enacted their own regulations. California's SB 54, for instance, requires all packaging to be recyclable or compostable by 2032. This legislation could potentially favor the integration of PETG with biodegradable polymers as a means to achieve compliance.

In Asia, countries like Japan and South Korea have implemented extended producer responsibility (EPR) systems for packaging waste. China's recent ban on certain types of plastic waste imports has also spurred global efforts to develop more sustainable packaging solutions.

Certification schemes and standards play a crucial role in the regulatory landscape. The ISO 14021 standard for environmental labels and declarations provides guidelines for claims related to biodegradability and compostability. The European Standard EN 13432 specifies requirements for packaging recoverable through composting and biodegradation.

Regulatory bodies are increasingly focusing on the life cycle assessment (LCA) of packaging materials. The integration of PETG with biodegradable polymers must demonstrate improved environmental performance across the entire life cycle to gain regulatory approval and market acceptance.

Emerging regulations are also addressing concerns about microplastics and marine pollution. The EU's Single-Use Plastics Directive, for example, restricts certain single-use plastic products and could potentially impact the use of PETG-biodegradable polymer blends in specific applications.

As the regulatory landscape continues to evolve, companies developing integrated PETG-biodegradable polymer solutions must stay informed of regional and global policy changes. Proactive engagement with policymakers and participation in industry associations can help shape future regulations and ensure compliance with emerging standards in sustainable packaging.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!