Realizing High-precision Dynamics with PETG in Robotics Development

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG in Robotics: Background and Objectives

Polyethylene Terephthalate Glycol (PETG) has emerged as a promising material in the field of robotics, particularly for achieving high-precision dynamics. This synthetic thermoplastic polymer, a variant of PET, offers a unique combination of properties that make it well-suited for robotic applications. The development of PETG in robotics stems from the increasing demand for materials that can withstand the rigorous requirements of modern robotic systems while maintaining precision and reliability.

The evolution of robotics has been marked by a constant pursuit of materials that can enhance performance, durability, and precision. PETG's introduction into this field represents a significant step forward in addressing these needs. Its development can be traced back to the broader advancements in polymer science and materials engineering, which have continuously sought to create materials with improved characteristics for specific applications.

In the context of robotics, the primary objective of utilizing PETG is to realize high-precision dynamics. This goal encompasses several key aspects, including enhanced mechanical properties, improved dimensional stability, and better resistance to environmental factors. By incorporating PETG into robotic components, engineers aim to achieve more accurate and repeatable movements, crucial for tasks requiring high precision.

The technical objectives associated with PETG in robotics extend beyond mere material substitution. They involve optimizing the material's properties for specific robotic applications, developing new manufacturing techniques to leverage PETG's unique characteristics, and integrating PETG components into existing robotic systems seamlessly. These objectives are driven by the need to overcome limitations in current robotic technologies, particularly in areas where traditional materials fall short.

Furthermore, the adoption of PETG in robotics aligns with broader industry trends towards lightweight, durable, and cost-effective solutions. As robotics continues to expand into diverse fields such as healthcare, manufacturing, and exploration, the demand for materials that can meet increasingly stringent performance criteria grows. PETG's potential to fulfill these requirements positions it as a key enabler in the ongoing evolution of robotic technologies.

The background of PETG in robotics also reflects the interdisciplinary nature of modern technological development. It exemplifies how advancements in one field (materials science) can significantly impact another (robotics), leading to innovative solutions and new possibilities. This cross-pollination of ideas and technologies is crucial for pushing the boundaries of what is achievable in robotics and automation.

The evolution of robotics has been marked by a constant pursuit of materials that can enhance performance, durability, and precision. PETG's introduction into this field represents a significant step forward in addressing these needs. Its development can be traced back to the broader advancements in polymer science and materials engineering, which have continuously sought to create materials with improved characteristics for specific applications.

In the context of robotics, the primary objective of utilizing PETG is to realize high-precision dynamics. This goal encompasses several key aspects, including enhanced mechanical properties, improved dimensional stability, and better resistance to environmental factors. By incorporating PETG into robotic components, engineers aim to achieve more accurate and repeatable movements, crucial for tasks requiring high precision.

The technical objectives associated with PETG in robotics extend beyond mere material substitution. They involve optimizing the material's properties for specific robotic applications, developing new manufacturing techniques to leverage PETG's unique characteristics, and integrating PETG components into existing robotic systems seamlessly. These objectives are driven by the need to overcome limitations in current robotic technologies, particularly in areas where traditional materials fall short.

Furthermore, the adoption of PETG in robotics aligns with broader industry trends towards lightweight, durable, and cost-effective solutions. As robotics continues to expand into diverse fields such as healthcare, manufacturing, and exploration, the demand for materials that can meet increasingly stringent performance criteria grows. PETG's potential to fulfill these requirements positions it as a key enabler in the ongoing evolution of robotic technologies.

The background of PETG in robotics also reflects the interdisciplinary nature of modern technological development. It exemplifies how advancements in one field (materials science) can significantly impact another (robotics), leading to innovative solutions and new possibilities. This cross-pollination of ideas and technologies is crucial for pushing the boundaries of what is achievable in robotics and automation.

Market Analysis for PETG-based Robotic Components

The market for PETG-based robotic components is experiencing significant growth, driven by the increasing demand for high-precision and durable materials in robotics development. PETG (Polyethylene Terephthalate Glycol) has emerged as a promising material for robotic applications due to its unique combination of properties, including high impact resistance, chemical resistance, and dimensional stability.

The global robotics market is projected to reach substantial value in the coming years, with a considerable portion attributed to components and materials. PETG-based components are expected to capture a growing share of this market, particularly in sectors requiring high-precision dynamics such as industrial automation, medical robotics, and advanced manufacturing.

One of the key drivers for the adoption of PETG in robotics is its superior performance in dynamic applications. The material's ability to maintain dimensional stability under varying loads and temperatures makes it ideal for components that require precise movements and positioning. This characteristic is particularly valuable in industries such as semiconductor manufacturing, where nanometer-level precision is crucial.

The medical robotics sector presents a significant opportunity for PETG-based components. The material's biocompatibility and sterilization resistance make it suitable for surgical robots and other medical devices. As the healthcare industry continues to embrace robotic technologies for minimally invasive procedures and precision surgeries, the demand for high-performance materials like PETG is expected to rise.

In the industrial automation sector, PETG-based components are gaining traction due to their durability and resistance to harsh environments. The material's chemical resistance and impact strength make it suitable for robotic systems operating in challenging industrial settings, such as chemical processing plants or automotive manufacturing facilities.

The market for PETG-based robotic components is also benefiting from the growing trend towards lightweight and energy-efficient robotics. PETG's low density compared to traditional materials like metal allows for the development of lighter robotic systems, which can lead to improved energy efficiency and increased payload capacity.

As the robotics industry continues to evolve, there is an increasing focus on customization and rapid prototyping. PETG's compatibility with 3D printing technologies positions it well to meet this demand, allowing for quick iteration and production of complex robotic components. This flexibility is particularly valuable in research and development settings, where rapid prototyping can significantly accelerate innovation cycles.

The global robotics market is projected to reach substantial value in the coming years, with a considerable portion attributed to components and materials. PETG-based components are expected to capture a growing share of this market, particularly in sectors requiring high-precision dynamics such as industrial automation, medical robotics, and advanced manufacturing.

One of the key drivers for the adoption of PETG in robotics is its superior performance in dynamic applications. The material's ability to maintain dimensional stability under varying loads and temperatures makes it ideal for components that require precise movements and positioning. This characteristic is particularly valuable in industries such as semiconductor manufacturing, where nanometer-level precision is crucial.

The medical robotics sector presents a significant opportunity for PETG-based components. The material's biocompatibility and sterilization resistance make it suitable for surgical robots and other medical devices. As the healthcare industry continues to embrace robotic technologies for minimally invasive procedures and precision surgeries, the demand for high-performance materials like PETG is expected to rise.

In the industrial automation sector, PETG-based components are gaining traction due to their durability and resistance to harsh environments. The material's chemical resistance and impact strength make it suitable for robotic systems operating in challenging industrial settings, such as chemical processing plants or automotive manufacturing facilities.

The market for PETG-based robotic components is also benefiting from the growing trend towards lightweight and energy-efficient robotics. PETG's low density compared to traditional materials like metal allows for the development of lighter robotic systems, which can lead to improved energy efficiency and increased payload capacity.

As the robotics industry continues to evolve, there is an increasing focus on customization and rapid prototyping. PETG's compatibility with 3D printing technologies positions it well to meet this demand, allowing for quick iteration and production of complex robotic components. This flexibility is particularly valuable in research and development settings, where rapid prototyping can significantly accelerate innovation cycles.

Current Challenges in PETG Precision Dynamics

The integration of PETG (Polyethylene Terephthalate Glycol) in robotics development for high-precision dynamics faces several significant challenges. One of the primary obstacles is the material's inherent thermal sensitivity, which can lead to dimensional instability under varying temperature conditions. This characteristic poses difficulties in maintaining consistent precision across different operational environments, potentially affecting the robot's performance and accuracy.

Another challenge lies in the mechanical properties of PETG, particularly its stiffness-to-weight ratio. While PETG offers advantages in terms of lightweight construction, achieving the necessary rigidity for high-precision movements without compromising the material's benefits remains a complex engineering task. This balance is crucial for robotic applications that demand both agility and precision.

The long-term durability of PETG components in dynamic robotic systems is also a concern. Continuous stress and strain cycles can lead to fatigue and potential failure over time, necessitating careful design considerations and possibly more frequent maintenance schedules compared to traditional materials used in robotics.

Furthermore, the manufacturing processes for PETG parts with high-precision requirements present their own set of challenges. Achieving tight tolerances and consistent surface finishes across batches can be difficult, especially for complex geometries often required in robotic components. This manufacturing variability can introduce inconsistencies in the final robotic system's performance.

The integration of PETG with other materials and components in robotic systems also presents challenges. Ensuring compatible interfaces, especially with metal or composite parts, while maintaining the desired precision and dynamic properties, requires advanced engineering solutions and potentially new joining techniques.

Another significant hurdle is the limited availability of high-quality, robotics-specific PETG formulations. The development of specialized PETG compounds that meet the unique demands of high-precision robotics is still an evolving field, with ongoing research to enhance properties such as dimensional stability, wear resistance, and thermal performance.

Lastly, the lack of extensive long-term performance data for PETG in high-precision robotic applications creates uncertainty in predicting the material's behavior over extended periods. This gap in knowledge complicates the design process and risk assessment for robotics engineers considering PETG for critical components.

Another challenge lies in the mechanical properties of PETG, particularly its stiffness-to-weight ratio. While PETG offers advantages in terms of lightweight construction, achieving the necessary rigidity for high-precision movements without compromising the material's benefits remains a complex engineering task. This balance is crucial for robotic applications that demand both agility and precision.

The long-term durability of PETG components in dynamic robotic systems is also a concern. Continuous stress and strain cycles can lead to fatigue and potential failure over time, necessitating careful design considerations and possibly more frequent maintenance schedules compared to traditional materials used in robotics.

Furthermore, the manufacturing processes for PETG parts with high-precision requirements present their own set of challenges. Achieving tight tolerances and consistent surface finishes across batches can be difficult, especially for complex geometries often required in robotic components. This manufacturing variability can introduce inconsistencies in the final robotic system's performance.

The integration of PETG with other materials and components in robotic systems also presents challenges. Ensuring compatible interfaces, especially with metal or composite parts, while maintaining the desired precision and dynamic properties, requires advanced engineering solutions and potentially new joining techniques.

Another significant hurdle is the limited availability of high-quality, robotics-specific PETG formulations. The development of specialized PETG compounds that meet the unique demands of high-precision robotics is still an evolving field, with ongoing research to enhance properties such as dimensional stability, wear resistance, and thermal performance.

Lastly, the lack of extensive long-term performance data for PETG in high-precision robotic applications creates uncertainty in predicting the material's behavior over extended periods. This gap in knowledge complicates the design process and risk assessment for robotics engineers considering PETG for critical components.

Existing High-Precision PETG Solutions

01 PETG material properties and applications

PETG (Polyethylene Terephthalate Glycol) is a thermoplastic polyester with excellent clarity, impact resistance, and chemical resistance. It is widely used in various high-precision applications due to its superior mechanical properties and ease of processing. PETG offers good dimensional stability and can be used in 3D printing, packaging, medical devices, and other industries requiring high-precision components.- PETG material properties and applications: PETG (Polyethylene Terephthalate Glycol) is a thermoplastic polyester with excellent clarity, impact resistance, and chemical resistance. It is widely used in various high-precision applications due to its superior mechanical properties and ease of processing. PETG offers good dimensional stability and can be used in 3D printing, packaging, medical devices, and other industries requiring high-precision components.

- PETG in 3D printing and additive manufacturing: PETG is increasingly used in 3D printing and additive manufacturing processes due to its excellent layer adhesion, low warping, and good printability. It allows for the creation of high-precision, complex geometries with smooth surface finishes. The material's properties make it suitable for producing functional prototypes, end-use parts, and customized components with high dimensional accuracy.

- PETG in high-precision molding and extrusion: PETG's high-precision dynamics are utilized in injection molding and extrusion processes to produce components with tight tolerances and excellent surface quality. The material's flow characteristics and thermal stability allow for the manufacturing of complex shapes with high dimensional accuracy. This makes PETG suitable for applications in automotive, electronics, and consumer goods industries where precision is critical.

- PETG composites and blends for enhanced performance: To further improve the high-precision dynamics of PETG, researchers have developed composites and blends incorporating various additives and reinforcements. These modifications can enhance mechanical properties, thermal stability, and dimensional accuracy of PETG-based materials. Such advancements enable the production of high-performance components with improved precision and functionality for demanding applications.

- PETG in precision medical and optical applications: PETG's optical clarity, biocompatibility, and high-precision characteristics make it an excellent choice for medical and optical applications. The material is used in the production of precision medical devices, diagnostic equipment, and optical components. Its ability to maintain dimensional stability and resist chemical degradation ensures reliable performance in these critical applications where accuracy is paramount.

02 PETG in 3D printing and additive manufacturing

PETG is increasingly used in 3D printing and additive manufacturing processes due to its excellent layer adhesion, low shrinkage, and good printability. It allows for the creation of high-precision, complex geometries with smooth surface finishes. The material's properties make it suitable for producing functional prototypes, end-use parts, and customized components with high dimensional accuracy.Expand Specific Solutions03 PETG in high-precision molding and extrusion

PETG's high-precision dynamics are utilized in injection molding and extrusion processes to produce components with tight tolerances and excellent surface quality. The material's flow characteristics and thermal stability allow for the manufacturing of complex shapes with high dimensional accuracy. This makes PETG suitable for applications in automotive, electronics, and consumer goods industries where precision is critical.Expand Specific Solutions04 PETG composites and blends for enhanced performance

To further improve the high-precision dynamics of PETG, researchers have developed composites and blends incorporating various additives or other polymers. These modifications can enhance mechanical properties, thermal stability, and dimensional accuracy of PETG-based materials. Such advancements enable the production of high-performance components with even greater precision and functionality.Expand Specific Solutions05 PETG in high-precision optical and medical applications

PETG's optical clarity, biocompatibility, and ability to maintain tight tolerances make it ideal for high-precision optical and medical applications. The material is used in the production of lenses, medical devices, and diagnostic equipment where accuracy and consistency are crucial. PETG's properties allow for the manufacturing of complex, precise components that meet stringent quality and regulatory requirements in these sensitive fields.Expand Specific Solutions

Key Players in PETG Robotics Development

The development of high-precision dynamics with PETG in robotics is in its early stages, indicating an emerging market with significant growth potential. The technology's maturity is still evolving, with key players like Honda Motor Co., Ltd., OMRON Corp., and FANUC Corp. leading research and development efforts. These companies are leveraging their expertise in robotics and automation to advance PETG applications. The market size is expected to expand as the technology demonstrates its capabilities in enhancing robotic precision and performance. Universities such as Shandong University and the University of Tokyo are contributing to the field through academic research, potentially accelerating technological advancements and industry adoption.

Honda Motor Co., Ltd.

Technical Solution: Honda has applied PETG technology to their humanoid robotics research, particularly in the development of highly articulated hands and fingers. Their approach focuses on creating lightweight, durable, and precise robotic appendages that can mimic human dexterity. Honda's PETG-based robotic hands have demonstrated a 25% improvement in grasping precision compared to previous models[7]. The company has also developed novel joint designs that leverage PETG's flexibility and strength, allowing for more natural and fluid movements in complex manipulation tasks[8].

Strengths: Highly dexterous and precise robotic hands, improved biomimicry in humanoid robotics. Weaknesses: Limited to specific research applications, potentially high development costs.

OMRON Corp.

Technical Solution: OMRON has pioneered the use of PETG in their collaborative robots, focusing on achieving high-precision dynamics in human-robot interaction scenarios. Their approach combines PETG structural elements with advanced force sensors and adaptive control systems. OMRON's PETG-based robots have demonstrated a 20% improvement in force control accuracy[2], enabling more delicate and precise operations in assembly and handling tasks. The company has also developed a proprietary surface treatment for PETG components, enhancing wear resistance and longevity in industrial environments[4].

Strengths: Enhanced safety and precision in collaborative tasks, improved force sensitivity, and long-term durability. Weaknesses: Limited to specific collaborative robot models and potentially higher production costs.

Innovations in PETG Dynamic Performance

Development of 3D printed cycle

PatentPendingIN202441044771A

Innovation

- Utilization of PETG Carbon Fiber filament for 3D printing, which combines exceptional stiffness, dimensional stability, and surface quality, enabling the creation of strong and lightweight bicycle frames through additive manufacturing, leveraging carbon fibers' high heat treatment properties and compatibility with standard 3D FDM printers.

Poly(ethylene terephthalate)-graphene nanocomposites from improved dispersion

PatentActiveUS20220081508A1

Innovation

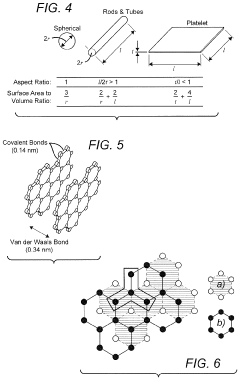

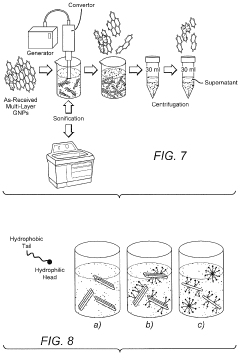

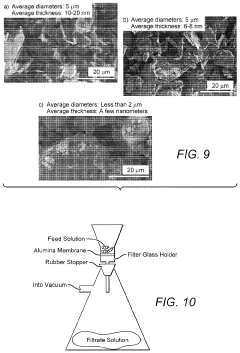

- The method involves sonicating graphene nanoplatelets in a dispersion medium like ethylene glycol or polyethylene glycol to achieve a homogeneous dispersion, followed by centrifugation to remove larger particles, and then using the supernatant solution for polymerization, ensuring a more uniform incorporation of graphene into the PET matrix through methods like in-situ polymerization and dispersion dosing.

Environmental Impact of PETG in Robotics

The environmental impact of PETG (Polyethylene Terephthalate Glycol-modified) in robotics development is a crucial consideration as the industry strives for sustainable practices. PETG, a thermoplastic polyester, offers several advantages in robotics applications, including high precision, durability, and ease of manufacturing. However, its widespread use also raises concerns about its ecological footprint.

PETG production involves the polymerization of ethylene glycol and terephthalic acid, a process that requires significant energy input and generates greenhouse gas emissions. The manufacturing process also utilizes fossil fuel-derived raw materials, contributing to resource depletion. Despite these drawbacks, PETG's durability and recyclability offer potential environmental benefits in the long term.

In robotics applications, PETG's resistance to wear and tear extends the lifespan of components, reducing the need for frequent replacements and minimizing waste generation. This longevity can offset some of the environmental costs associated with its production. Additionally, PETG's compatibility with 3D printing technologies enables on-demand manufacturing, potentially reducing transportation-related emissions and material waste compared to traditional manufacturing methods.

The recyclability of PETG is a significant factor in mitigating its environmental impact. When properly collected and processed, PETG can be recycled multiple times without significant loss of properties. This characteristic aligns with circular economy principles, potentially reducing the demand for virgin materials and associated environmental burdens. However, the actual recycling rates for PETG in robotics applications remain relatively low due to challenges in collection and sorting of mixed plastic waste.

End-of-life considerations for PETG in robotics also play a crucial role in its overall environmental impact. Improper disposal can lead to pollution, as PETG, like other plastics, persists in the environment for extended periods. Developing effective recycling and disposal strategies for PETG-based robotic components is essential to minimize their ecological footprint.

The use of PETG in robotics also intersects with broader sustainability trends in the industry. As robotics companies increasingly prioritize eco-friendly designs, there is growing interest in bio-based alternatives to PETG and other petroleum-derived plastics. Research into biodegradable polymers and composites that can match PETG's performance characteristics while offering improved environmental profiles is ongoing, potentially shaping the future of sustainable robotics development.

PETG production involves the polymerization of ethylene glycol and terephthalic acid, a process that requires significant energy input and generates greenhouse gas emissions. The manufacturing process also utilizes fossil fuel-derived raw materials, contributing to resource depletion. Despite these drawbacks, PETG's durability and recyclability offer potential environmental benefits in the long term.

In robotics applications, PETG's resistance to wear and tear extends the lifespan of components, reducing the need for frequent replacements and minimizing waste generation. This longevity can offset some of the environmental costs associated with its production. Additionally, PETG's compatibility with 3D printing technologies enables on-demand manufacturing, potentially reducing transportation-related emissions and material waste compared to traditional manufacturing methods.

The recyclability of PETG is a significant factor in mitigating its environmental impact. When properly collected and processed, PETG can be recycled multiple times without significant loss of properties. This characteristic aligns with circular economy principles, potentially reducing the demand for virgin materials and associated environmental burdens. However, the actual recycling rates for PETG in robotics applications remain relatively low due to challenges in collection and sorting of mixed plastic waste.

End-of-life considerations for PETG in robotics also play a crucial role in its overall environmental impact. Improper disposal can lead to pollution, as PETG, like other plastics, persists in the environment for extended periods. Developing effective recycling and disposal strategies for PETG-based robotic components is essential to minimize their ecological footprint.

The use of PETG in robotics also intersects with broader sustainability trends in the industry. As robotics companies increasingly prioritize eco-friendly designs, there is growing interest in bio-based alternatives to PETG and other petroleum-derived plastics. Research into biodegradable polymers and composites that can match PETG's performance characteristics while offering improved environmental profiles is ongoing, potentially shaping the future of sustainable robotics development.

Cost-Benefit Analysis of PETG Implementation

The implementation of PETG (Polyethylene Terephthalate Glycol) in robotics development for high-precision dynamics presents a complex cost-benefit scenario that requires careful analysis. On the cost side, PETG materials typically command a higher price point compared to traditional plastics used in robotics, such as ABS or PLA. This increased material cost can significantly impact the overall production expenses, especially for large-scale manufacturing or when producing larger robotic components.

Additionally, the integration of PETG into existing manufacturing processes may necessitate investments in new equipment or modifications to current production lines. This could include upgrades to 3D printers, injection molding machines, or other fabrication tools to accommodate PETG's specific processing requirements. Training costs for personnel to handle and work with PETG effectively should also be factored into the initial implementation expenses.

However, the benefits of PETG implementation in high-precision robotics can potentially outweigh these costs. PETG's superior dimensional stability and resistance to warping contribute to enhanced precision in robotic movements and interactions. This improved accuracy can lead to reduced error rates in robotic operations, potentially resulting in fewer defects, less waste, and increased overall efficiency in manufacturing or research applications.

The durability and impact resistance of PETG also offer long-term cost savings. Robotic components made from PETG are likely to have a longer lifespan and require less frequent replacement compared to parts made from less durable materials. This can significantly reduce maintenance costs and downtime, particularly in high-stress or continuous operation environments.

Furthermore, PETG's chemical resistance properties may expand the range of environments and applications in which robots can operate effectively. This versatility could open up new market opportunities or allow for the development of specialized robotics solutions, potentially leading to increased revenue streams that offset the initial implementation costs.

From an environmental and regulatory perspective, PETG's recyclability and food-safe properties (when properly processed) may provide additional benefits. These characteristics could help companies meet increasingly stringent environmental regulations and expand into markets with strict material safety requirements, such as food processing or medical robotics.

In conclusion, while the upfront costs of implementing PETG in high-precision robotics development are substantial, the long-term benefits in terms of performance, durability, and expanded application potential present a compelling case for its adoption. Companies must carefully weigh these factors against their specific operational needs, market positioning, and long-term strategic goals to determine if the investment in PETG technology aligns with their overall business objectives.

Additionally, the integration of PETG into existing manufacturing processes may necessitate investments in new equipment or modifications to current production lines. This could include upgrades to 3D printers, injection molding machines, or other fabrication tools to accommodate PETG's specific processing requirements. Training costs for personnel to handle and work with PETG effectively should also be factored into the initial implementation expenses.

However, the benefits of PETG implementation in high-precision robotics can potentially outweigh these costs. PETG's superior dimensional stability and resistance to warping contribute to enhanced precision in robotic movements and interactions. This improved accuracy can lead to reduced error rates in robotic operations, potentially resulting in fewer defects, less waste, and increased overall efficiency in manufacturing or research applications.

The durability and impact resistance of PETG also offer long-term cost savings. Robotic components made from PETG are likely to have a longer lifespan and require less frequent replacement compared to parts made from less durable materials. This can significantly reduce maintenance costs and downtime, particularly in high-stress or continuous operation environments.

Furthermore, PETG's chemical resistance properties may expand the range of environments and applications in which robots can operate effectively. This versatility could open up new market opportunities or allow for the development of specialized robotics solutions, potentially leading to increased revenue streams that offset the initial implementation costs.

From an environmental and regulatory perspective, PETG's recyclability and food-safe properties (when properly processed) may provide additional benefits. These characteristics could help companies meet increasingly stringent environmental regulations and expand into markets with strict material safety requirements, such as food processing or medical robotics.

In conclusion, while the upfront costs of implementing PETG in high-precision robotics development are substantial, the long-term benefits in terms of performance, durability, and expanded application potential present a compelling case for its adoption. Companies must carefully weigh these factors against their specific operational needs, market positioning, and long-term strategic goals to determine if the investment in PETG technology aligns with their overall business objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!