Intelligent Supply Chain Frameworks Accelerating PETG Distributions

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Supply Chain Evolution

The evolution of the PETG supply chain has undergone significant transformations in recent years, driven by technological advancements and changing market demands. Initially, the supply chain for PETG (Polyethylene Terephthalate Glycol-modified) was characterized by traditional linear models, with limited visibility and coordination between different stages of production and distribution.

As global demand for PETG increased, particularly in packaging and manufacturing industries, the need for more efficient and responsive supply chain systems became apparent. This led to the gradual adoption of digital technologies and data-driven approaches in supply chain management. Early implementations focused on improving inventory management and demand forecasting, utilizing basic analytics tools to optimize stock levels and reduce waste.

The introduction of cloud-based platforms marked a significant milestone in PETG supply chain evolution. These platforms enabled real-time data sharing and collaboration among various stakeholders, including suppliers, manufacturers, distributors, and retailers. This enhanced visibility across the entire supply chain, allowing for better coordination and faster response to market fluctuations.

The integration of Internet of Things (IoT) devices further revolutionized the PETG supply chain. Sensors and tracking devices were deployed throughout the supply chain, providing continuous monitoring of product quality, location, and environmental conditions. This real-time data collection enabled proactive quality control measures and more accurate tracking of PETG products from production to end-user delivery.

Advanced analytics and machine learning algorithms began to play a crucial role in supply chain optimization. These technologies enabled more accurate demand forecasting, predictive maintenance of manufacturing equipment, and dynamic route optimization for distribution. As a result, PETG supply chains became more agile and responsive to market changes, reducing lead times and improving overall efficiency.

The concept of circular economy principles started to influence PETG supply chain design, with increased focus on recyclability and sustainable practices. This led to the development of closed-loop supply chains, where post-consumer PETG products are collected, processed, and reintegrated into the production cycle, reducing waste and environmental impact.

Most recently, the emergence of blockchain technology has begun to address issues of traceability and transparency in the PETG supply chain. Blockchain-based solutions offer immutable records of transactions and product movements, enhancing trust among stakeholders and facilitating easier compliance with regulatory requirements.

As we look towards the future, the PETG supply chain continues to evolve with the integration of artificial intelligence and autonomous systems. These technologies promise to further optimize decision-making processes, automate routine tasks, and create self-adjusting supply chain networks capable of responding to disruptions and market changes with minimal human intervention.

As global demand for PETG increased, particularly in packaging and manufacturing industries, the need for more efficient and responsive supply chain systems became apparent. This led to the gradual adoption of digital technologies and data-driven approaches in supply chain management. Early implementations focused on improving inventory management and demand forecasting, utilizing basic analytics tools to optimize stock levels and reduce waste.

The introduction of cloud-based platforms marked a significant milestone in PETG supply chain evolution. These platforms enabled real-time data sharing and collaboration among various stakeholders, including suppliers, manufacturers, distributors, and retailers. This enhanced visibility across the entire supply chain, allowing for better coordination and faster response to market fluctuations.

The integration of Internet of Things (IoT) devices further revolutionized the PETG supply chain. Sensors and tracking devices were deployed throughout the supply chain, providing continuous monitoring of product quality, location, and environmental conditions. This real-time data collection enabled proactive quality control measures and more accurate tracking of PETG products from production to end-user delivery.

Advanced analytics and machine learning algorithms began to play a crucial role in supply chain optimization. These technologies enabled more accurate demand forecasting, predictive maintenance of manufacturing equipment, and dynamic route optimization for distribution. As a result, PETG supply chains became more agile and responsive to market changes, reducing lead times and improving overall efficiency.

The concept of circular economy principles started to influence PETG supply chain design, with increased focus on recyclability and sustainable practices. This led to the development of closed-loop supply chains, where post-consumer PETG products are collected, processed, and reintegrated into the production cycle, reducing waste and environmental impact.

Most recently, the emergence of blockchain technology has begun to address issues of traceability and transparency in the PETG supply chain. Blockchain-based solutions offer immutable records of transactions and product movements, enhancing trust among stakeholders and facilitating easier compliance with regulatory requirements.

As we look towards the future, the PETG supply chain continues to evolve with the integration of artificial intelligence and autonomous systems. These technologies promise to further optimize decision-making processes, automate routine tasks, and create self-adjusting supply chain networks capable of responding to disruptions and market changes with minimal human intervention.

PETG Market Demand Analysis

The market demand for PETG (Polyethylene Terephthalate Glycol-modified) has been experiencing significant growth in recent years, driven by its versatile properties and wide range of applications. PETG's unique combination of clarity, durability, and chemical resistance has made it a preferred material in various industries, including packaging, medical devices, and consumer goods.

In the packaging sector, PETG has gained traction due to its excellent barrier properties and recyclability. The increasing consumer awareness of sustainable packaging solutions has further boosted the demand for PETG, as it can be easily recycled and reprocessed. The food and beverage industry, in particular, has shown a strong inclination towards PETG packaging for its ability to preserve product freshness and extend shelf life.

The medical device industry has also contributed to the rising demand for PETG. Its biocompatibility, sterilization resistance, and clarity make it an ideal material for medical packaging, diagnostic equipment, and laboratory consumables. The ongoing global health concerns have further accelerated the adoption of PETG in medical applications, driving market growth.

Consumer goods manufacturers have increasingly turned to PETG for its aesthetic appeal and durability. The material's ability to mimic glass while being shatter-resistant has made it popular in cosmetics packaging, household products, and electronic device casings. The growing e-commerce sector has also fueled the demand for PETG packaging solutions that can withstand the rigors of shipping and handling.

The automotive industry has emerged as a promising market for PETG, particularly in interior components and lightweight structural parts. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, PETG's low density and high impact strength make it an attractive alternative to traditional materials.

Market analysts project the global PETG market to grow at a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is attributed to the material's expanding applications and the increasing adoption of sustainable packaging solutions across industries. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization, urbanization, and changing consumer preferences.

However, the PETG market faces challenges from fluctuating raw material prices and competition from alternative materials. The volatility in crude oil prices, a key component in PETG production, can impact manufacturing costs and market dynamics. Additionally, the development of bio-based and biodegradable plastics poses a potential threat to PETG's market share in certain applications.

To address these challenges and capitalize on market opportunities, industry players are focusing on innovation and sustainability. Research and development efforts are directed towards improving PETG's properties, enhancing its recyclability, and exploring new applications. Collaborations between material suppliers, manufacturers, and end-users are becoming increasingly common to develop tailored PETG solutions that meet specific industry requirements.

In the packaging sector, PETG has gained traction due to its excellent barrier properties and recyclability. The increasing consumer awareness of sustainable packaging solutions has further boosted the demand for PETG, as it can be easily recycled and reprocessed. The food and beverage industry, in particular, has shown a strong inclination towards PETG packaging for its ability to preserve product freshness and extend shelf life.

The medical device industry has also contributed to the rising demand for PETG. Its biocompatibility, sterilization resistance, and clarity make it an ideal material for medical packaging, diagnostic equipment, and laboratory consumables. The ongoing global health concerns have further accelerated the adoption of PETG in medical applications, driving market growth.

Consumer goods manufacturers have increasingly turned to PETG for its aesthetic appeal and durability. The material's ability to mimic glass while being shatter-resistant has made it popular in cosmetics packaging, household products, and electronic device casings. The growing e-commerce sector has also fueled the demand for PETG packaging solutions that can withstand the rigors of shipping and handling.

The automotive industry has emerged as a promising market for PETG, particularly in interior components and lightweight structural parts. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, PETG's low density and high impact strength make it an attractive alternative to traditional materials.

Market analysts project the global PETG market to grow at a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is attributed to the material's expanding applications and the increasing adoption of sustainable packaging solutions across industries. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization, urbanization, and changing consumer preferences.

However, the PETG market faces challenges from fluctuating raw material prices and competition from alternative materials. The volatility in crude oil prices, a key component in PETG production, can impact manufacturing costs and market dynamics. Additionally, the development of bio-based and biodegradable plastics poses a potential threat to PETG's market share in certain applications.

To address these challenges and capitalize on market opportunities, industry players are focusing on innovation and sustainability. Research and development efforts are directed towards improving PETG's properties, enhancing its recyclability, and exploring new applications. Collaborations between material suppliers, manufacturers, and end-users are becoming increasingly common to develop tailored PETG solutions that meet specific industry requirements.

Intelligent SCM Challenges

The implementation of intelligent supply chain management (SCM) frameworks for accelerating PETG distributions faces several significant challenges. One of the primary obstacles is the complexity of integrating diverse data sources across the supply chain. PETG (Polyethylene Terephthalate Glycol-modified) distribution involves multiple stakeholders, each with their own systems and data formats. Harmonizing this data to create a cohesive, real-time view of the supply chain requires sophisticated data integration and standardization techniques.

Another challenge lies in the accurate forecasting of PETG demand. The material's usage spans various industries, including packaging, electronics, and automotive, each with its own market dynamics. Intelligent SCM systems must be capable of processing vast amounts of historical data, market trends, and external factors to generate reliable demand forecasts. This requires advanced machine learning algorithms and predictive analytics capabilities, which can be complex to develop and maintain.

The volatility of raw material prices and availability poses a significant challenge for intelligent SCM in PETG distribution. Fluctuations in oil prices, which affect the cost of PETG production, can rapidly impact the entire supply chain. Intelligent systems need to be agile enough to adapt to these changes in real-time, adjusting procurement strategies and pricing models accordingly. This demands sophisticated risk assessment and mitigation algorithms integrated into the SCM framework.

Inventory optimization presents another hurdle for intelligent SCM in PETG distribution. Balancing the need for sufficient stock to meet demand with the desire to minimize carrying costs requires precise control. Intelligent systems must consider factors such as lead times, storage capacities, and transportation constraints across multiple nodes in the supply chain. Implementing dynamic inventory management that can respond to sudden changes in demand or supply disruptions is a complex task that requires advanced optimization algorithms.

Lastly, the challenge of end-to-end visibility and traceability in PETG distribution cannot be overstated. Intelligent SCM frameworks must provide real-time tracking of materials from production to end-user, ensuring quality control and enabling rapid response to any issues. This requires the implementation of IoT devices, blockchain technology, or other advanced tracking systems throughout the supply chain. The integration of these technologies with existing systems and processes can be technically challenging and resource-intensive.

Another challenge lies in the accurate forecasting of PETG demand. The material's usage spans various industries, including packaging, electronics, and automotive, each with its own market dynamics. Intelligent SCM systems must be capable of processing vast amounts of historical data, market trends, and external factors to generate reliable demand forecasts. This requires advanced machine learning algorithms and predictive analytics capabilities, which can be complex to develop and maintain.

The volatility of raw material prices and availability poses a significant challenge for intelligent SCM in PETG distribution. Fluctuations in oil prices, which affect the cost of PETG production, can rapidly impact the entire supply chain. Intelligent systems need to be agile enough to adapt to these changes in real-time, adjusting procurement strategies and pricing models accordingly. This demands sophisticated risk assessment and mitigation algorithms integrated into the SCM framework.

Inventory optimization presents another hurdle for intelligent SCM in PETG distribution. Balancing the need for sufficient stock to meet demand with the desire to minimize carrying costs requires precise control. Intelligent systems must consider factors such as lead times, storage capacities, and transportation constraints across multiple nodes in the supply chain. Implementing dynamic inventory management that can respond to sudden changes in demand or supply disruptions is a complex task that requires advanced optimization algorithms.

Lastly, the challenge of end-to-end visibility and traceability in PETG distribution cannot be overstated. Intelligent SCM frameworks must provide real-time tracking of materials from production to end-user, ensuring quality control and enabling rapid response to any issues. This requires the implementation of IoT devices, blockchain technology, or other advanced tracking systems throughout the supply chain. The integration of these technologies with existing systems and processes can be technically challenging and resource-intensive.

Current PETG SCM Solutions

01 AI-driven supply chain optimization

Intelligent frameworks leverage artificial intelligence to optimize supply chain processes, enhancing efficiency and decision-making. These systems analyze vast amounts of data to predict demand, manage inventory, and streamline logistics operations, resulting in faster and more accurate supply chain management.- AI-driven supply chain optimization: Intelligent frameworks leverage artificial intelligence to optimize supply chain processes, enhancing efficiency and decision-making. These systems analyze vast amounts of data to predict demand, optimize inventory levels, and streamline logistics operations, resulting in faster and more responsive supply chains.

- Blockchain integration for transparency and traceability: Incorporating blockchain technology into supply chain frameworks enhances transparency, traceability, and security. This integration allows for real-time tracking of goods, verification of authenticity, and improved collaboration among supply chain partners, accelerating overall operations and reducing fraud risks.

- IoT-enabled real-time monitoring and control: Internet of Things (IoT) devices and sensors are integrated into supply chain frameworks to provide real-time monitoring and control of assets, inventory, and transportation. This enables proactive decision-making, reduces delays, and improves overall supply chain visibility and responsiveness.

- Cloud-based supply chain management platforms: Cloud-based platforms facilitate seamless collaboration, data sharing, and integration across the entire supply chain ecosystem. These solutions offer scalability, accessibility, and real-time analytics capabilities, enabling faster decision-making and improved agility in responding to market changes.

- Predictive analytics for demand forecasting and risk management: Advanced predictive analytics techniques are employed to forecast demand patterns, identify potential disruptions, and manage risks in the supply chain. These intelligent frameworks use historical data, market trends, and external factors to provide accurate predictions, enabling proactive planning and mitigation strategies.

02 Blockchain integration for transparency and traceability

Incorporating blockchain technology into supply chain frameworks enhances transparency and traceability. This integration allows for secure, real-time tracking of goods and transactions, reducing fraud and improving overall supply chain visibility and accountability.Expand Specific Solutions03 IoT-enabled real-time monitoring and control

Internet of Things (IoT) devices are integrated into supply chain frameworks to enable real-time monitoring and control of assets, inventory, and transportation. This connectivity allows for immediate response to changes or disruptions, improving overall supply chain agility and responsiveness.Expand Specific Solutions04 Machine learning for predictive analytics

Advanced machine learning algorithms are employed to analyze historical and real-time data, providing predictive analytics for supply chain management. These intelligent systems can forecast demand, identify potential disruptions, and suggest proactive measures to optimize supply chain performance.Expand Specific Solutions05 Cloud-based supply chain collaboration platforms

Cloud-based platforms facilitate seamless collaboration and data sharing among supply chain partners. These intelligent frameworks enable real-time communication, synchronized planning, and coordinated execution across the entire supply chain network, accelerating decision-making and improving overall efficiency.Expand Specific Solutions

Key PETG Industry Players

The intelligent supply chain frameworks accelerating PETG distributions market is in its growth stage, with increasing adoption across industries. The global market size is projected to expand significantly in the coming years, driven by the need for efficient and automated supply chain solutions. Technologically, the field is rapidly evolving, with companies like Ingram Micro, Cisco Technology, and BASF Corp leading innovations in IoT, AI, and advanced analytics for supply chain optimization. While established players dominate, startups and research institutions like The University of North Carolina at Chapel Hill are also contributing to technological advancements. The integration of blockchain and cloud computing is further enhancing the capabilities of these frameworks, indicating a trend towards more sophisticated and interconnected supply chain ecosystems.

Ingram Micro, Inc.

Technical Solution: Ingram Micro has implemented an Intelligent Supply Chain Framework that focuses on accelerating PETG distribution through advanced automation and data analytics. Their solution incorporates robotic process automation (RPA) to streamline order processing and fulfillment[5]. The framework also utilizes machine learning algorithms to optimize inventory allocation across multiple distribution centers, reducing lead times and improving order accuracy[6]. Ingram Micro's platform integrates with various e-commerce platforms, enabling seamless omnichannel distribution for PETG products.

Strengths: Extensive distribution network, strong focus on automation, and seamless e-commerce integration. Weaknesses: May have limitations in handling specialized PETG products or custom packaging requirements.

Cisco Technology, Inc.

Technical Solution: Cisco has developed an Intelligent Supply Chain Framework that leverages AI and IoT technologies to optimize PETG distribution. Their solution incorporates real-time tracking and predictive analytics to forecast demand and manage inventory levels efficiently. The framework utilizes blockchain technology for enhanced transparency and traceability throughout the supply chain[1]. Cisco's system integrates with existing ERP and warehouse management systems, providing a seamless end-to-end solution for PETG manufacturers and distributors[3].

Strengths: Robust network infrastructure, advanced analytics capabilities, and seamless integration with existing systems. Weaknesses: Potential high implementation costs and complexity for smaller organizations.

Innovative PETG Logistics

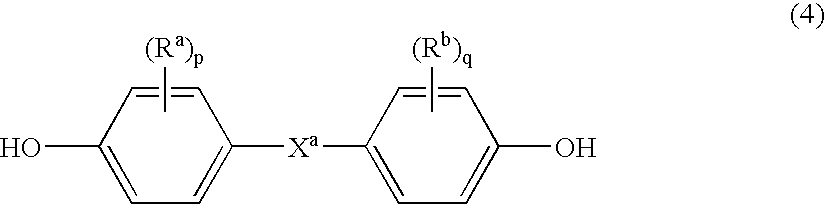

PETG based decorative sheet having forming ability similar with PVC

PatentWO2008091067A1

Innovation

- A PETG alloy resin is developed by alloying PETG with an ester resin or elastomer resin, specifically polybutylene terephthalate (PBT) and PBT copolymer elastomer, to lower the glass transition temperature and widen the forming temperature range, similar to PVC, with optimal content between 5 to 20 parts by weight.

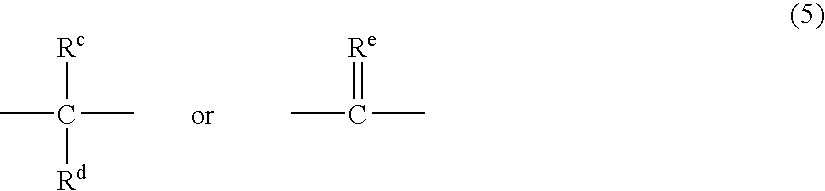

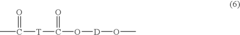

Molding compositions containing polycarbonate and modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

PatentActiveUS20070276069A1

Innovation

- Development of modified polybutylene terephthalate random copolymers derived from PET, incorporating residues such as ethylene glycol and isophthalic acid groups, combined with polycarbonate and impact modifiers, to create molding compositions with improved flow properties and performance comparable to those made from virgin PBT.

Sustainability in PETG SCM

Sustainability has become a critical focus in the PETG (Polyethylene Terephthalate Glycol-modified) supply chain management (SCM) as industries strive to reduce their environmental impact while maintaining operational efficiency. The integration of intelligent supply chain frameworks in PETG distribution not only accelerates the process but also contributes significantly to sustainability efforts.

One of the key aspects of sustainability in PETG SCM is the optimization of transportation routes. Intelligent systems utilize advanced algorithms to determine the most fuel-efficient paths, reducing carbon emissions and minimizing the overall environmental footprint of distribution operations. These systems take into account various factors such as traffic patterns, weather conditions, and vehicle capacity to ensure optimal resource utilization.

Another crucial element is the implementation of real-time inventory management systems. These systems enable precise tracking of PETG stocks, reducing overproduction and waste. By accurately predicting demand and adjusting production accordingly, companies can minimize excess inventory, which not only reduces storage costs but also decreases the likelihood of material expiration and disposal.

The adoption of blockchain technology in PETG SCM has also contributed to enhanced sustainability. Blockchain provides transparent and immutable records of the entire supply chain process, from raw material sourcing to end-product delivery. This transparency allows for better traceability of materials, ensuring that sustainable and ethically sourced PETG is used throughout the production and distribution process.

Energy efficiency in PETG production and distribution facilities is another area where intelligent frameworks have made significant strides. Smart energy management systems optimize power consumption by adjusting lighting, heating, and cooling based on real-time needs. Additionally, the integration of renewable energy sources, such as solar panels on warehouse roofs, further reduces the carbon footprint of PETG SCM operations.

Waste reduction and recycling initiatives have also been bolstered by intelligent supply chain frameworks. Advanced sorting systems use machine learning algorithms to identify and separate different types of plastic waste, including PETG, improving recycling efficiency. These systems also help in tracking the lifecycle of PETG products, facilitating closed-loop recycling processes and promoting a circular economy approach.

Lastly, the use of data analytics and artificial intelligence in PETG SCM has enabled more accurate demand forecasting and production planning. This precision reduces overproduction and minimizes waste throughout the supply chain. By analyzing historical data and market trends, companies can make informed decisions about production volumes, leading to more sustainable resource utilization and reduced environmental impact.

One of the key aspects of sustainability in PETG SCM is the optimization of transportation routes. Intelligent systems utilize advanced algorithms to determine the most fuel-efficient paths, reducing carbon emissions and minimizing the overall environmental footprint of distribution operations. These systems take into account various factors such as traffic patterns, weather conditions, and vehicle capacity to ensure optimal resource utilization.

Another crucial element is the implementation of real-time inventory management systems. These systems enable precise tracking of PETG stocks, reducing overproduction and waste. By accurately predicting demand and adjusting production accordingly, companies can minimize excess inventory, which not only reduces storage costs but also decreases the likelihood of material expiration and disposal.

The adoption of blockchain technology in PETG SCM has also contributed to enhanced sustainability. Blockchain provides transparent and immutable records of the entire supply chain process, from raw material sourcing to end-product delivery. This transparency allows for better traceability of materials, ensuring that sustainable and ethically sourced PETG is used throughout the production and distribution process.

Energy efficiency in PETG production and distribution facilities is another area where intelligent frameworks have made significant strides. Smart energy management systems optimize power consumption by adjusting lighting, heating, and cooling based on real-time needs. Additionally, the integration of renewable energy sources, such as solar panels on warehouse roofs, further reduces the carbon footprint of PETG SCM operations.

Waste reduction and recycling initiatives have also been bolstered by intelligent supply chain frameworks. Advanced sorting systems use machine learning algorithms to identify and separate different types of plastic waste, including PETG, improving recycling efficiency. These systems also help in tracking the lifecycle of PETG products, facilitating closed-loop recycling processes and promoting a circular economy approach.

Lastly, the use of data analytics and artificial intelligence in PETG SCM has enabled more accurate demand forecasting and production planning. This precision reduces overproduction and minimizes waste throughout the supply chain. By analyzing historical data and market trends, companies can make informed decisions about production volumes, leading to more sustainable resource utilization and reduced environmental impact.

PETG SCM Data Analytics

Data analytics plays a crucial role in optimizing PETG (Polyethylene Terephthalate Glycol-modified) supply chain management. By leveraging advanced analytics techniques, companies can gain valuable insights into their PETG distribution processes, leading to improved efficiency, reduced costs, and enhanced customer satisfaction.

One of the key applications of data analytics in PETG supply chain management is demand forecasting. By analyzing historical sales data, market trends, and external factors such as economic indicators, companies can more accurately predict future demand for PETG products. This enables better inventory management, reducing the risk of stockouts or excess inventory, which can be particularly costly for PETG materials due to their specific storage requirements.

Predictive maintenance is another area where data analytics can significantly impact PETG distribution. By collecting and analyzing data from sensors on manufacturing equipment and transportation vehicles, companies can predict potential failures before they occur. This proactive approach minimizes downtime, reduces maintenance costs, and ensures a more reliable supply chain for PETG products.

Route optimization is a critical aspect of PETG distribution that can be greatly enhanced through data analytics. By analyzing real-time traffic data, weather conditions, and delivery schedules, companies can determine the most efficient routes for their PETG shipments. This not only reduces transportation costs but also improves delivery times and customer satisfaction.

Supply chain visibility is significantly improved through the use of data analytics. By integrating data from various sources across the supply chain, companies can gain a real-time view of their PETG inventory levels, production status, and shipment locations. This enhanced visibility allows for better decision-making and faster response times to potential disruptions in the supply chain.

Quality control is another area where data analytics can make a substantial impact on PETG distribution. By analyzing production data and customer feedback, companies can identify patterns that may indicate quality issues. This allows for early detection and resolution of problems, ensuring that only high-quality PETG products reach customers.

Supplier performance analysis is greatly enhanced through the use of data analytics. By analyzing metrics such as delivery times, quality levels, and pricing, companies can make more informed decisions about their PETG suppliers. This can lead to improved supplier relationships, better negotiation positions, and ultimately, a more reliable and cost-effective supply chain.

In conclusion, data analytics is transforming PETG supply chain management by providing actionable insights across various aspects of the distribution process. As companies continue to invest in advanced analytics capabilities, we can expect to see further improvements in efficiency, cost-effectiveness, and customer satisfaction in PETG distribution.

One of the key applications of data analytics in PETG supply chain management is demand forecasting. By analyzing historical sales data, market trends, and external factors such as economic indicators, companies can more accurately predict future demand for PETG products. This enables better inventory management, reducing the risk of stockouts or excess inventory, which can be particularly costly for PETG materials due to their specific storage requirements.

Predictive maintenance is another area where data analytics can significantly impact PETG distribution. By collecting and analyzing data from sensors on manufacturing equipment and transportation vehicles, companies can predict potential failures before they occur. This proactive approach minimizes downtime, reduces maintenance costs, and ensures a more reliable supply chain for PETG products.

Route optimization is a critical aspect of PETG distribution that can be greatly enhanced through data analytics. By analyzing real-time traffic data, weather conditions, and delivery schedules, companies can determine the most efficient routes for their PETG shipments. This not only reduces transportation costs but also improves delivery times and customer satisfaction.

Supply chain visibility is significantly improved through the use of data analytics. By integrating data from various sources across the supply chain, companies can gain a real-time view of their PETG inventory levels, production status, and shipment locations. This enhanced visibility allows for better decision-making and faster response times to potential disruptions in the supply chain.

Quality control is another area where data analytics can make a substantial impact on PETG distribution. By analyzing production data and customer feedback, companies can identify patterns that may indicate quality issues. This allows for early detection and resolution of problems, ensuring that only high-quality PETG products reach customers.

Supplier performance analysis is greatly enhanced through the use of data analytics. By analyzing metrics such as delivery times, quality levels, and pricing, companies can make more informed decisions about their PETG suppliers. This can lead to improved supplier relationships, better negotiation positions, and ultimately, a more reliable and cost-effective supply chain.

In conclusion, data analytics is transforming PETG supply chain management by providing actionable insights across various aspects of the distribution process. As companies continue to invest in advanced analytics capabilities, we can expect to see further improvements in efficiency, cost-effectiveness, and customer satisfaction in PETG distribution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!