Military Device Applications: How PETG Enhances Functionality

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG in Military Tech: Background and Objectives

Polyethylene terephthalate glycol (PETG) has emerged as a revolutionary material in military technology, offering enhanced functionality and durability for various device applications. The evolution of PETG in military contexts can be traced back to the early 2000s when the need for lightweight, robust, and versatile materials became increasingly apparent in modern warfare and defense systems.

The primary objective of incorporating PETG into military devices is to improve their overall performance, reliability, and longevity in challenging operational environments. This copolyester combines the strength and clarity of PET with the flexibility and ease of processing of glycol, resulting in a material that is well-suited for a wide range of military applications.

PETG's development in military technology has been driven by several key factors. First, the material's exceptional impact resistance and durability make it ideal for protective equipment, such as helmet visors and body armor components. Second, its chemical resistance and stability under varying temperatures enable its use in sensitive electronic enclosures and communication devices deployed in extreme conditions.

The trend towards miniaturization and portability in military equipment has further accelerated the adoption of PETG. Its low weight-to-strength ratio allows for the creation of lighter, more mobile devices without compromising on structural integrity. This characteristic is particularly valuable in the development of unmanned aerial vehicles (UAVs) and portable communication systems.

Another significant aspect of PETG's technological evolution in military applications is its compatibility with advanced manufacturing techniques, such as 3D printing. This has opened up new possibilities for rapid prototyping and on-demand production of custom parts in the field, potentially revolutionizing military logistics and maintenance operations.

As military technology continues to advance, the objectives for PETG applications are expanding. Current research focuses on enhancing the material's properties to withstand even more extreme conditions, such as higher temperatures and increased radiation exposure. Additionally, efforts are being made to improve PETG's recyclability and environmental impact, aligning with broader sustainability goals in military procurement.

The future trajectory of PETG in military device applications aims to push the boundaries of material science, exploring hybrid composites and smart materials that can adapt to changing environmental conditions. These developments are expected to lead to the next generation of military equipment, characterized by unprecedented levels of functionality, durability, and adaptability in the face of evolving global security challenges.

The primary objective of incorporating PETG into military devices is to improve their overall performance, reliability, and longevity in challenging operational environments. This copolyester combines the strength and clarity of PET with the flexibility and ease of processing of glycol, resulting in a material that is well-suited for a wide range of military applications.

PETG's development in military technology has been driven by several key factors. First, the material's exceptional impact resistance and durability make it ideal for protective equipment, such as helmet visors and body armor components. Second, its chemical resistance and stability under varying temperatures enable its use in sensitive electronic enclosures and communication devices deployed in extreme conditions.

The trend towards miniaturization and portability in military equipment has further accelerated the adoption of PETG. Its low weight-to-strength ratio allows for the creation of lighter, more mobile devices without compromising on structural integrity. This characteristic is particularly valuable in the development of unmanned aerial vehicles (UAVs) and portable communication systems.

Another significant aspect of PETG's technological evolution in military applications is its compatibility with advanced manufacturing techniques, such as 3D printing. This has opened up new possibilities for rapid prototyping and on-demand production of custom parts in the field, potentially revolutionizing military logistics and maintenance operations.

As military technology continues to advance, the objectives for PETG applications are expanding. Current research focuses on enhancing the material's properties to withstand even more extreme conditions, such as higher temperatures and increased radiation exposure. Additionally, efforts are being made to improve PETG's recyclability and environmental impact, aligning with broader sustainability goals in military procurement.

The future trajectory of PETG in military device applications aims to push the boundaries of material science, exploring hybrid composites and smart materials that can adapt to changing environmental conditions. These developments are expected to lead to the next generation of military equipment, characterized by unprecedented levels of functionality, durability, and adaptability in the face of evolving global security challenges.

Market Analysis for PETG in Defense Sector

The defense sector has shown a growing interest in PETG (Polyethylene Terephthalate Glycol-modified) due to its unique properties and versatile applications in military devices. The market for PETG in defense applications is experiencing significant growth, driven by the material's exceptional durability, chemical resistance, and adaptability to various manufacturing processes.

In recent years, the global defense industry has been increasingly adopting advanced materials to enhance the functionality and performance of military equipment. PETG has emerged as a preferred choice for numerous applications, including protective gear, optical components, and lightweight structural elements in military vehicles and aircraft.

The market size for PETG in the defense sector is projected to expand substantially over the next five years. This growth is attributed to the increasing demand for lightweight, high-performance materials that can withstand extreme conditions while offering superior optical clarity and impact resistance. PETG's ability to meet these requirements positions it as a valuable material in the development of next-generation military technologies.

Key market drivers include the ongoing modernization of military equipment, the need for enhanced soldier protection, and the growing emphasis on reducing the overall weight of military vehicles and aircraft to improve fuel efficiency and operational range. Additionally, the increasing focus on developing advanced communication and surveillance systems has created new opportunities for PETG in optical and electronic components.

Regional analysis indicates that North America currently holds the largest market share for PETG in defense applications, followed by Europe and Asia-Pacific. The United States, in particular, is a major consumer of PETG in military applications, driven by its substantial defense budget and ongoing military modernization programs.

Market trends suggest a shift towards the integration of PETG in multi-functional composite materials, combining its properties with other advanced materials to create hybrid solutions that offer enhanced performance characteristics. This trend is expected to open up new avenues for PETG applications in the defense sector, particularly in areas such as ballistic protection and stealth technology.

The competitive landscape of the PETG market in the defense sector is characterized by the presence of several key players, including major chemical companies and specialized material manufacturers. These companies are investing heavily in research and development to improve the properties of PETG and develop tailored solutions for specific military applications.

In recent years, the global defense industry has been increasingly adopting advanced materials to enhance the functionality and performance of military equipment. PETG has emerged as a preferred choice for numerous applications, including protective gear, optical components, and lightweight structural elements in military vehicles and aircraft.

The market size for PETG in the defense sector is projected to expand substantially over the next five years. This growth is attributed to the increasing demand for lightweight, high-performance materials that can withstand extreme conditions while offering superior optical clarity and impact resistance. PETG's ability to meet these requirements positions it as a valuable material in the development of next-generation military technologies.

Key market drivers include the ongoing modernization of military equipment, the need for enhanced soldier protection, and the growing emphasis on reducing the overall weight of military vehicles and aircraft to improve fuel efficiency and operational range. Additionally, the increasing focus on developing advanced communication and surveillance systems has created new opportunities for PETG in optical and electronic components.

Regional analysis indicates that North America currently holds the largest market share for PETG in defense applications, followed by Europe and Asia-Pacific. The United States, in particular, is a major consumer of PETG in military applications, driven by its substantial defense budget and ongoing military modernization programs.

Market trends suggest a shift towards the integration of PETG in multi-functional composite materials, combining its properties with other advanced materials to create hybrid solutions that offer enhanced performance characteristics. This trend is expected to open up new avenues for PETG applications in the defense sector, particularly in areas such as ballistic protection and stealth technology.

The competitive landscape of the PETG market in the defense sector is characterized by the presence of several key players, including major chemical companies and specialized material manufacturers. These companies are investing heavily in research and development to improve the properties of PETG and develop tailored solutions for specific military applications.

PETG Challenges in Military Applications

While PETG (Polyethylene Terephthalate Glycol) offers numerous advantages in military device applications, it also presents several challenges that need to be addressed for optimal performance. One of the primary concerns is the material's susceptibility to environmental factors, particularly extreme temperatures and UV radiation. In harsh military environments, PETG components may experience degradation or loss of mechanical properties, potentially compromising the functionality and reliability of critical equipment.

Another significant challenge lies in the chemical resistance of PETG. Although it demonstrates good resistance to many common chemicals, certain solvents and aggressive substances encountered in military operations can cause material breakdown or stress cracking. This limitation necessitates careful consideration of the specific chemical exposures a device may face during its lifecycle.

The impact resistance of PETG, while generally good, may not always meet the stringent requirements of some military applications. High-impact scenarios or ballistic threats may require additional reinforcement or alternative materials in certain areas of a device to ensure adequate protection and durability.

Manufacturing challenges also arise when working with PETG for military devices. The material's tendency to absorb moisture can lead to processing difficulties and potential quality issues if not properly managed during production. Additionally, achieving consistent part quality across large production runs can be challenging, especially for complex geometries or when tight tolerances are required.

Long-term stability and aging characteristics of PETG in military applications remain areas of concern. The material may exhibit changes in physical properties over time, particularly when exposed to harsh environmental conditions or prolonged stress. This potential for degradation necessitates rigorous testing and monitoring protocols to ensure the longevity and reliability of PETG-based components in military devices.

Joining and bonding PETG components with other materials commonly used in military equipment can present technical difficulties. Achieving strong, durable bonds that withstand the rigors of military use often requires specialized adhesives or bonding techniques, adding complexity to the manufacturing and assembly processes.

Lastly, the recyclability and end-of-life management of PETG in military applications pose environmental and logistical challenges. While PETG is theoretically recyclable, the presence of additives, coatings, or contamination from military use may complicate recycling efforts. Developing effective strategies for the responsible disposal or recycling of PETG-based military devices is crucial for minimizing environmental impact and adhering to sustainability goals.

Another significant challenge lies in the chemical resistance of PETG. Although it demonstrates good resistance to many common chemicals, certain solvents and aggressive substances encountered in military operations can cause material breakdown or stress cracking. This limitation necessitates careful consideration of the specific chemical exposures a device may face during its lifecycle.

The impact resistance of PETG, while generally good, may not always meet the stringent requirements of some military applications. High-impact scenarios or ballistic threats may require additional reinforcement or alternative materials in certain areas of a device to ensure adequate protection and durability.

Manufacturing challenges also arise when working with PETG for military devices. The material's tendency to absorb moisture can lead to processing difficulties and potential quality issues if not properly managed during production. Additionally, achieving consistent part quality across large production runs can be challenging, especially for complex geometries or when tight tolerances are required.

Long-term stability and aging characteristics of PETG in military applications remain areas of concern. The material may exhibit changes in physical properties over time, particularly when exposed to harsh environmental conditions or prolonged stress. This potential for degradation necessitates rigorous testing and monitoring protocols to ensure the longevity and reliability of PETG-based components in military devices.

Joining and bonding PETG components with other materials commonly used in military equipment can present technical difficulties. Achieving strong, durable bonds that withstand the rigors of military use often requires specialized adhesives or bonding techniques, adding complexity to the manufacturing and assembly processes.

Lastly, the recyclability and end-of-life management of PETG in military applications pose environmental and logistical challenges. While PETG is theoretically recyclable, the presence of additives, coatings, or contamination from military use may complicate recycling efforts. Developing effective strategies for the responsible disposal or recycling of PETG-based military devices is crucial for minimizing environmental impact and adhering to sustainability goals.

Current PETG Solutions in Military Devices

01 Enhanced mechanical properties

PETG exhibits improved mechanical properties compared to traditional PET, including higher impact strength, better flexibility, and enhanced durability. These characteristics make it suitable for applications requiring toughness and resistance to breakage.- Enhanced mechanical properties: PETG exhibits improved mechanical properties compared to traditional PET, including higher impact strength, better flexibility, and increased toughness. These characteristics make it suitable for applications requiring durability and resistance to breakage.

- Thermal stability and processing advantages: PETG demonstrates excellent thermal stability and can be processed at lower temperatures than PET. This allows for easier molding, extrusion, and thermoforming, making it ideal for various manufacturing processes and applications in packaging and consumer goods.

- Optical clarity and transparency: PETG offers superior optical clarity and transparency compared to many other polymers. This property makes it suitable for applications in packaging, displays, and medical devices where visual appeal and product visibility are important.

- Chemical resistance and barrier properties: PETG exhibits good chemical resistance to various substances and provides effective barrier properties against moisture, gases, and odors. These characteristics make it suitable for packaging applications in food, beverage, and pharmaceutical industries.

- Recyclability and sustainability: PETG can be recycled and reprocessed, contributing to sustainability efforts. It can be blended with other recycled materials or used in the production of new products, making it an environmentally friendly option for various applications.

02 Improved thermal stability

PETG demonstrates better thermal stability than standard PET, allowing for a wider processing temperature range and improved resistance to heat-induced deformation. This property makes it valuable in applications where temperature resistance is crucial.Expand Specific Solutions03 Enhanced clarity and transparency

PETG offers superior optical properties, including high clarity and transparency. This makes it an excellent choice for applications where visual appeal and product visibility are important, such as packaging and display materials.Expand Specific Solutions04 Chemical resistance and barrier properties

PETG exhibits good chemical resistance and barrier properties, making it suitable for packaging applications that require protection against moisture, gases, and certain chemicals. These properties contribute to extended shelf life for packaged products.Expand Specific Solutions05 Ease of processing and fabrication

PETG is known for its ease of processing and fabrication, including thermoforming, injection molding, and extrusion. It offers good melt strength and can be easily bonded or welded, making it versatile for various manufacturing processes and product designs.Expand Specific Solutions

Key PETG Suppliers for Defense Industry

The military device applications of PETG are in an emerging stage, with the market showing significant growth potential due to increasing demand for lightweight, durable materials in defense equipment. The global market size for military-grade polymers is expanding, driven by technological advancements and the need for enhanced functionality in military devices. While PETG technology is relatively mature in commercial applications, its adaptation for military use is still evolving. Companies like Siemens Medical Solutions USA, Koninklijke Philips NV, and Huawei Technologies are leveraging their expertise in materials science and engineering to develop PETG-based solutions for military applications, focusing on improving durability, thermal resistance, and overall performance in harsh environments.

Koninklijke Philips NV

Technical Solution: Philips has applied its healthcare and consumer electronics expertise to develop PETG solutions for military medical devices. Their PETG formulations meet stringent biocompatibility standards, making them suitable for wearable military health monitoring systems[15]. Philips has engineered PETG materials with enhanced optical clarity and scratch resistance, ideal for military display covers and protective eyewear[16]. The company's PETG compounds feature improved sterilization resistance, crucial for field medical equipment in military settings[17]. Additionally, Philips has developed PETG grades with controlled drug release properties, potentially useful for advanced military first-aid kits and drug delivery systems[18].

Strengths: Extensive experience in medical-grade materials, strong focus on user-centric design, and global presence. Weaknesses: Primary focus on healthcare may limit applications in other military sectors.

Dragon Special Resin Xiamen Co. Ltd.

Technical Solution: Dragon Special Resin Xiamen Co. Ltd. has developed advanced PETG formulations specifically tailored for military device applications. Their proprietary PETG compounds offer enhanced impact resistance and chemical stability, crucial for harsh military environments. The company's PETG materials undergo rigorous testing to meet military specifications, including MIL-STD-810 for environmental performance[1]. Their PETG solutions feature improved flame retardancy and reduced smoke generation, addressing critical safety concerns in military equipment[2]. Additionally, Dragon Special Resin has implemented nano-additives to enhance the PETG's barrier properties, extending the shelf life of sensitive military components[3].

Strengths: Tailored formulations for military needs, high impact resistance, and improved safety features. Weaknesses: Potentially higher cost compared to standard PETG, limited global presence may affect supply chain reliability.

PETG Innovations for Military Use

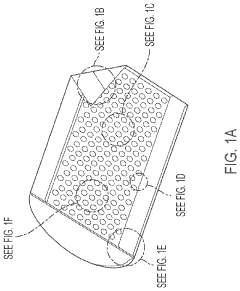

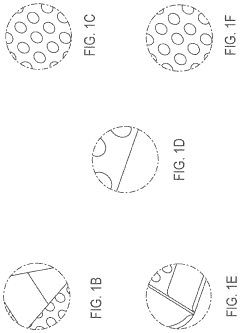

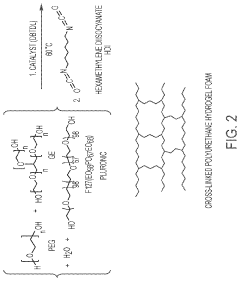

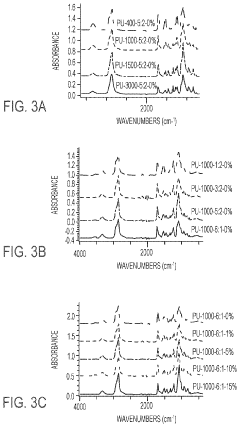

Acute care cover for severe injuries

PatentActiveUS20200002456A1

Innovation

- Development of a multifunctional bandage using block-copolymer hydrogels and polyurethane hydrogel foams with stimuli-responsive poly(N-isopropylacrylamide) and polyethylene glycol diacrylate, which provide thermal stability, hemostatic properties, and controlled drug release, along with antimicrobial activity, through copolymerization and high internal phase emulsion polymerization techniques.

Military Standards and PETG Compliance

In the realm of military device applications, adherence to stringent standards is paramount. PETG (Polyethylene Terephthalate Glycol-modified) has emerged as a material of choice due to its ability to meet and exceed military specifications. The U.S. Department of Defense (DoD) has established comprehensive standards for materials used in military equipment, and PETG has proven its compliance across various criteria.

MIL-STD-810G, a crucial standard for environmental engineering considerations and laboratory tests, outlines rigorous requirements for materials used in military applications. PETG demonstrates exceptional performance in areas such as temperature resistance, humidity tolerance, and impact resistance, aligning with the standard's specifications for durability and reliability in extreme conditions.

The material's chemical resistance properties align with MIL-STD-1250, which governs corrosion prevention and deterioration control in military equipment. PETG's resistance to a wide range of chemicals and solvents ensures longevity and maintains functionality in diverse operational environments, from arid deserts to humid jungles.

PETG's optical clarity and impact resistance make it suitable for applications governed by MIL-PRF-25690, the standard for aircraft windshield materials. Its ability to maintain visibility and structural integrity under stress contributes to enhanced safety and operational effectiveness in military aircraft.

The material's low outgassing characteristics comply with NASA's ASTM E595 standard, which is often referenced in military space applications. This property ensures that PETG-based components do not release harmful gases in vacuum environments, critical for space-based military systems and sensitive electronic equipment.

MIL-DTL-32383, which specifies requirements for transparent armor, finds PETG as a potential candidate for certain applications due to its impact resistance and optical clarity. While not suitable for all armor applications, PETG can be utilized in conjunction with other materials to create lightweight, yet effective protective solutions.

PETG's recyclability and potential for sustainable manufacturing align with the DoD's Sustainable Procurement Program, which emphasizes the use of environmentally preferable materials. This compliance positions PETG favorably in the context of long-term military procurement strategies focused on sustainability and reduced environmental impact.

The material's compatibility with various fabrication methods, including 3D printing, aligns with the military's increasing focus on additive manufacturing, as outlined in the DoD's Manufacturing Technology Program. This versatility enables rapid prototyping and on-demand production of components, enhancing logistical efficiency and reducing lead times for critical equipment.

MIL-STD-810G, a crucial standard for environmental engineering considerations and laboratory tests, outlines rigorous requirements for materials used in military applications. PETG demonstrates exceptional performance in areas such as temperature resistance, humidity tolerance, and impact resistance, aligning with the standard's specifications for durability and reliability in extreme conditions.

The material's chemical resistance properties align with MIL-STD-1250, which governs corrosion prevention and deterioration control in military equipment. PETG's resistance to a wide range of chemicals and solvents ensures longevity and maintains functionality in diverse operational environments, from arid deserts to humid jungles.

PETG's optical clarity and impact resistance make it suitable for applications governed by MIL-PRF-25690, the standard for aircraft windshield materials. Its ability to maintain visibility and structural integrity under stress contributes to enhanced safety and operational effectiveness in military aircraft.

The material's low outgassing characteristics comply with NASA's ASTM E595 standard, which is often referenced in military space applications. This property ensures that PETG-based components do not release harmful gases in vacuum environments, critical for space-based military systems and sensitive electronic equipment.

MIL-DTL-32383, which specifies requirements for transparent armor, finds PETG as a potential candidate for certain applications due to its impact resistance and optical clarity. While not suitable for all armor applications, PETG can be utilized in conjunction with other materials to create lightweight, yet effective protective solutions.

PETG's recyclability and potential for sustainable manufacturing align with the DoD's Sustainable Procurement Program, which emphasizes the use of environmentally preferable materials. This compliance positions PETG favorably in the context of long-term military procurement strategies focused on sustainability and reduced environmental impact.

The material's compatibility with various fabrication methods, including 3D printing, aligns with the military's increasing focus on additive manufacturing, as outlined in the DoD's Manufacturing Technology Program. This versatility enables rapid prototyping and on-demand production of components, enhancing logistical efficiency and reducing lead times for critical equipment.

Environmental Impact of PETG in Defense

The environmental impact of PETG (Polyethylene Terephthalate Glycol-modified) in defense applications is a critical consideration as military organizations strive to balance operational effectiveness with sustainability. PETG, known for its durability and versatility, has found increasing use in military devices, but its environmental footprint warrants careful examination.

PETG's production process involves the use of fossil fuel-derived materials, contributing to greenhouse gas emissions and resource depletion. However, compared to some traditional materials used in military applications, PETG often requires less energy to manufacture, potentially offsetting some of its environmental impact. The material's lightweight nature also contributes to fuel efficiency in transportation and deployment scenarios, indirectly reducing the carbon footprint of military operations.

One of the primary environmental concerns surrounding PETG is its end-of-life management. While PETG is technically recyclable, the specialized nature of military applications often means that these products are not easily integrated into conventional recycling streams. This can lead to increased waste in landfills or incineration facilities, contributing to pollution and habitat degradation.

The durability of PETG, while advantageous for military applications, presents a double-edged sword from an environmental perspective. Its resistance to degradation ensures longevity in use, reducing the need for frequent replacements and thereby conserving resources. However, this same property means that PETG products, if improperly disposed of, can persist in the environment for extended periods, potentially harming ecosystems and wildlife.

In response to these challenges, research is ongoing to develop more environmentally friendly alternatives or modifications to PETG. Efforts include incorporating biodegradable additives, improving recycling processes specific to military-grade PETG, and exploring bio-based sources for PETG production. Some defense organizations are also implementing lifecycle assessment protocols to better understand and mitigate the environmental impact of PETG-based military devices.

The use of PETG in defense applications also intersects with broader environmental considerations in military operations. For instance, PETG's chemical resistance and durability can help prevent leaks or spills of hazardous materials, indirectly contributing to environmental protection in operational settings. Additionally, the material's clarity and impact resistance make it suitable for protective equipment, potentially reducing the need for more environmentally harmful alternatives.

As defense sectors globally face increasing pressure to adopt sustainable practices, the environmental impact of materials like PETG is likely to receive greater scrutiny. This may drive innovation in material science, leading to the development of next-generation polymers that maintain the performance characteristics of PETG while offering improved environmental profiles. Such advancements could significantly influence the future trajectory of military device design and manufacturing.

PETG's production process involves the use of fossil fuel-derived materials, contributing to greenhouse gas emissions and resource depletion. However, compared to some traditional materials used in military applications, PETG often requires less energy to manufacture, potentially offsetting some of its environmental impact. The material's lightweight nature also contributes to fuel efficiency in transportation and deployment scenarios, indirectly reducing the carbon footprint of military operations.

One of the primary environmental concerns surrounding PETG is its end-of-life management. While PETG is technically recyclable, the specialized nature of military applications often means that these products are not easily integrated into conventional recycling streams. This can lead to increased waste in landfills or incineration facilities, contributing to pollution and habitat degradation.

The durability of PETG, while advantageous for military applications, presents a double-edged sword from an environmental perspective. Its resistance to degradation ensures longevity in use, reducing the need for frequent replacements and thereby conserving resources. However, this same property means that PETG products, if improperly disposed of, can persist in the environment for extended periods, potentially harming ecosystems and wildlife.

In response to these challenges, research is ongoing to develop more environmentally friendly alternatives or modifications to PETG. Efforts include incorporating biodegradable additives, improving recycling processes specific to military-grade PETG, and exploring bio-based sources for PETG production. Some defense organizations are also implementing lifecycle assessment protocols to better understand and mitigate the environmental impact of PETG-based military devices.

The use of PETG in defense applications also intersects with broader environmental considerations in military operations. For instance, PETG's chemical resistance and durability can help prevent leaks or spills of hazardous materials, indirectly contributing to environmental protection in operational settings. Additionally, the material's clarity and impact resistance make it suitable for protective equipment, potentially reducing the need for more environmentally harmful alternatives.

As defense sectors globally face increasing pressure to adopt sustainable practices, the environmental impact of materials like PETG is likely to receive greater scrutiny. This may drive innovation in material science, leading to the development of next-generation polymers that maintain the performance characteristics of PETG while offering improved environmental profiles. Such advancements could significantly influence the future trajectory of military device design and manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!