Biodegradable PETG for Water-Resistant Packaging Applications

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Biodegradability Background and Objectives

Polyethylene terephthalate glycol-modified (PETG) has been widely used in packaging applications due to its excellent mechanical properties, transparency, and chemical resistance. However, the growing concern over plastic pollution has led to increased interest in developing biodegradable alternatives to traditional plastics. The research on biodegradable PETG for water-resistant packaging applications aims to address this environmental challenge while maintaining the desirable properties of conventional PETG.

The evolution of PETG technology can be traced back to the 1970s when it was first developed as an improvement over PET. Since then, PETG has found extensive use in various industries, particularly in packaging. The focus on biodegradability is a relatively recent trend, driven by the global push for sustainable materials and circular economy principles.

The primary objective of this research is to develop a biodegradable PETG variant that retains the water-resistant properties crucial for packaging applications. This goal presents a significant technical challenge, as biodegradability and water resistance are often conflicting properties in polymer science. The research aims to strike a balance between these characteristics, potentially through the incorporation of biodegradable additives or the modification of the PETG molecular structure.

Another key objective is to ensure that the biodegradable PETG meets industry standards for mechanical strength, clarity, and processability. This is essential for seamless integration into existing manufacturing processes and to maintain the quality expectations of end-users. The research also seeks to optimize the biodegradation rate, aiming for a material that degrades rapidly enough to address environmental concerns but remains stable during its intended use phase.

Furthermore, the study aims to investigate the environmental impact of the biodegradable PETG throughout its lifecycle. This includes assessing the sourcing of raw materials, energy consumption during production, and the end-of-life scenarios. The ultimate goal is to develop a material that not only biodegrades but also contributes to a reduction in overall carbon footprint compared to conventional PETG.

The research also explores the potential for incorporating recycled content into the biodegradable PETG formulation, aligning with the broader trend towards circular economy principles in the plastics industry. This aspect of the research seeks to address both the issues of plastic waste and the depletion of fossil resources used in traditional PETG production.

In conclusion, the background and objectives of this research reflect the growing demand for sustainable packaging solutions and the technical challenges associated with developing materials that balance performance, environmental impact, and economic viability. The success of this research could potentially revolutionize the packaging industry, offering a more sustainable alternative to conventional PETG while maintaining its desirable properties for water-resistant applications.

The evolution of PETG technology can be traced back to the 1970s when it was first developed as an improvement over PET. Since then, PETG has found extensive use in various industries, particularly in packaging. The focus on biodegradability is a relatively recent trend, driven by the global push for sustainable materials and circular economy principles.

The primary objective of this research is to develop a biodegradable PETG variant that retains the water-resistant properties crucial for packaging applications. This goal presents a significant technical challenge, as biodegradability and water resistance are often conflicting properties in polymer science. The research aims to strike a balance between these characteristics, potentially through the incorporation of biodegradable additives or the modification of the PETG molecular structure.

Another key objective is to ensure that the biodegradable PETG meets industry standards for mechanical strength, clarity, and processability. This is essential for seamless integration into existing manufacturing processes and to maintain the quality expectations of end-users. The research also seeks to optimize the biodegradation rate, aiming for a material that degrades rapidly enough to address environmental concerns but remains stable during its intended use phase.

Furthermore, the study aims to investigate the environmental impact of the biodegradable PETG throughout its lifecycle. This includes assessing the sourcing of raw materials, energy consumption during production, and the end-of-life scenarios. The ultimate goal is to develop a material that not only biodegrades but also contributes to a reduction in overall carbon footprint compared to conventional PETG.

The research also explores the potential for incorporating recycled content into the biodegradable PETG formulation, aligning with the broader trend towards circular economy principles in the plastics industry. This aspect of the research seeks to address both the issues of plastic waste and the depletion of fossil resources used in traditional PETG production.

In conclusion, the background and objectives of this research reflect the growing demand for sustainable packaging solutions and the technical challenges associated with developing materials that balance performance, environmental impact, and economic viability. The success of this research could potentially revolutionize the packaging industry, offering a more sustainable alternative to conventional PETG while maintaining its desirable properties for water-resistant applications.

Market Analysis for Eco-Friendly Packaging

The eco-friendly packaging market has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. The global market for sustainable packaging is projected to reach $413.8 billion by 2027, growing at a CAGR of 6.1% from 2020 to 2027. This growth is particularly evident in the food and beverage sector, where consumers are demanding more environmentally responsible packaging solutions.

Biodegradable PETG for water-resistant packaging applications represents a promising segment within this market. PETG, or Polyethylene Terephthalate Glycol-modified, is known for its excellent clarity, durability, and moisture resistance. The development of biodegradable variants addresses the growing concern over plastic pollution while maintaining the material's desirable properties for packaging applications.

The demand for water-resistant, biodegradable packaging is particularly strong in industries such as food and beverage, personal care, and pharmaceuticals. These sectors require packaging that can protect products from moisture while aligning with sustainability goals. The food packaging industry alone is expected to account for over 40% of the biodegradable plastics market by 2025, indicating substantial opportunities for biodegradable PETG in this sector.

Geographically, Europe leads the eco-friendly packaging market, followed closely by North America. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, changing consumer preferences, and supportive government policies promoting sustainable packaging solutions.

Key market drivers include consumer demand for sustainable products, corporate sustainability initiatives, and regulatory pressures. For instance, the European Union's Single-Use Plastics Directive has accelerated the adoption of biodegradable packaging alternatives. Similarly, several U.S. states have implemented bans on single-use plastics, creating opportunities for biodegradable PETG and other eco-friendly materials.

Challenges in the market include the higher cost of biodegradable materials compared to traditional plastics and the need for improved recycling infrastructure. However, ongoing research and development efforts are focused on reducing production costs and enhancing the performance of biodegradable PETG, which is expected to drive market growth in the coming years.

In conclusion, the market analysis for eco-friendly packaging, particularly biodegradable PETG for water-resistant applications, reveals a robust and growing demand. As technology advances and production scales up, biodegradable PETG is poised to capture a significant share of the sustainable packaging market, offering a promising solution to the dual challenges of product protection and environmental sustainability.

Biodegradable PETG for water-resistant packaging applications represents a promising segment within this market. PETG, or Polyethylene Terephthalate Glycol-modified, is known for its excellent clarity, durability, and moisture resistance. The development of biodegradable variants addresses the growing concern over plastic pollution while maintaining the material's desirable properties for packaging applications.

The demand for water-resistant, biodegradable packaging is particularly strong in industries such as food and beverage, personal care, and pharmaceuticals. These sectors require packaging that can protect products from moisture while aligning with sustainability goals. The food packaging industry alone is expected to account for over 40% of the biodegradable plastics market by 2025, indicating substantial opportunities for biodegradable PETG in this sector.

Geographically, Europe leads the eco-friendly packaging market, followed closely by North America. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, changing consumer preferences, and supportive government policies promoting sustainable packaging solutions.

Key market drivers include consumer demand for sustainable products, corporate sustainability initiatives, and regulatory pressures. For instance, the European Union's Single-Use Plastics Directive has accelerated the adoption of biodegradable packaging alternatives. Similarly, several U.S. states have implemented bans on single-use plastics, creating opportunities for biodegradable PETG and other eco-friendly materials.

Challenges in the market include the higher cost of biodegradable materials compared to traditional plastics and the need for improved recycling infrastructure. However, ongoing research and development efforts are focused on reducing production costs and enhancing the performance of biodegradable PETG, which is expected to drive market growth in the coming years.

In conclusion, the market analysis for eco-friendly packaging, particularly biodegradable PETG for water-resistant applications, reveals a robust and growing demand. As technology advances and production scales up, biodegradable PETG is poised to capture a significant share of the sustainable packaging market, offering a promising solution to the dual challenges of product protection and environmental sustainability.

Current Challenges in Biodegradable PETG Development

The development of biodegradable PETG for water-resistant packaging applications faces several significant challenges. One of the primary obstacles is achieving a balance between biodegradability and water resistance. Traditional PETG is known for its excellent moisture barrier properties, but these characteristics are often compromised when attempting to make the material biodegradable. Researchers are struggling to maintain the desired level of water resistance while ensuring the material can break down in natural environments.

Another major challenge lies in the mechanical properties of biodegradable PETG. As modifications are made to enhance biodegradability, the material often experiences a reduction in strength, flexibility, and durability. This can lead to packaging that is more prone to tearing, puncturing, or deformation during transportation and storage. Developing formulations that maintain the robust mechanical properties of conventional PETG while incorporating biodegradable elements remains a significant hurdle.

The cost-effectiveness of biodegradable PETG production is also a considerable challenge. The incorporation of biodegradable additives or the modification of the polymer structure often results in higher production costs compared to traditional PETG. This price differential can be a significant barrier to widespread adoption, particularly in industries where profit margins are slim and packaging costs are a major consideration.

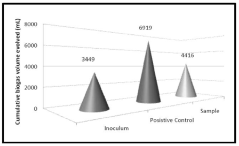

Furthermore, ensuring consistent and predictable biodegradation rates poses a complex challenge. Environmental conditions such as temperature, humidity, and microbial activity can greatly influence the breakdown of biodegradable plastics. Developing a PETG formulation that degrades reliably across various disposal scenarios while maintaining its integrity during its intended use-life is a delicate balancing act that researchers are still working to perfect.

The regulatory landscape surrounding biodegradable plastics adds another layer of complexity. Different regions and countries have varying standards and certifications for biodegradable materials. Meeting these diverse regulatory requirements while maintaining the desired performance characteristics of the packaging material is a challenge that requires ongoing research and development efforts.

Lastly, the challenge of scalability looms large in the development of biodegradable PETG. While promising results may be achieved in laboratory settings, translating these innovations into large-scale, commercially viable production processes presents its own set of obstacles. Issues such as process stability, quality control, and equipment compatibility need to be addressed to enable widespread adoption of biodegradable PETG in water-resistant packaging applications.

Another major challenge lies in the mechanical properties of biodegradable PETG. As modifications are made to enhance biodegradability, the material often experiences a reduction in strength, flexibility, and durability. This can lead to packaging that is more prone to tearing, puncturing, or deformation during transportation and storage. Developing formulations that maintain the robust mechanical properties of conventional PETG while incorporating biodegradable elements remains a significant hurdle.

The cost-effectiveness of biodegradable PETG production is also a considerable challenge. The incorporation of biodegradable additives or the modification of the polymer structure often results in higher production costs compared to traditional PETG. This price differential can be a significant barrier to widespread adoption, particularly in industries where profit margins are slim and packaging costs are a major consideration.

Furthermore, ensuring consistent and predictable biodegradation rates poses a complex challenge. Environmental conditions such as temperature, humidity, and microbial activity can greatly influence the breakdown of biodegradable plastics. Developing a PETG formulation that degrades reliably across various disposal scenarios while maintaining its integrity during its intended use-life is a delicate balancing act that researchers are still working to perfect.

The regulatory landscape surrounding biodegradable plastics adds another layer of complexity. Different regions and countries have varying standards and certifications for biodegradable materials. Meeting these diverse regulatory requirements while maintaining the desired performance characteristics of the packaging material is a challenge that requires ongoing research and development efforts.

Lastly, the challenge of scalability looms large in the development of biodegradable PETG. While promising results may be achieved in laboratory settings, translating these innovations into large-scale, commercially viable production processes presents its own set of obstacles. Issues such as process stability, quality control, and equipment compatibility need to be addressed to enable widespread adoption of biodegradable PETG in water-resistant packaging applications.

Existing Water-Resistant Biodegradable PETG Solutions

01 Biodegradable PETG compositions

Development of biodegradable PETG compositions that maintain water resistance properties. These compositions may include additives or modifications to the PETG structure to enhance biodegradability while preserving water-resistant characteristics. The focus is on creating environmentally friendly alternatives to traditional PETG without compromising its water-resistant properties.- Biodegradable PETG compositions: Development of biodegradable PETG compositions that maintain water resistance properties. These compositions may include additives or modifications to the PETG structure to enhance biodegradability while preserving water-resistant characteristics. The focus is on creating environmentally friendly alternatives to traditional PETG that can still be used in applications requiring water resistance.

- Water-resistant coatings for PETG: Application of water-resistant coatings to PETG surfaces to improve their water resistance properties. These coatings may be biodegradable themselves or designed to not interfere with the biodegradation process of the underlying PETG material. The coatings aim to enhance the material's performance in wet environments while maintaining its ability to break down over time.

- Blending PETG with other biodegradable polymers: Combining PETG with other biodegradable polymers to create blends that offer improved water resistance and biodegradability. This approach aims to leverage the beneficial properties of multiple materials to achieve a balance between water resistance and environmental friendliness. The resulting blends may exhibit enhanced performance characteristics compared to pure PETG.

- Surface treatments for biodegradable PETG: Development of surface treatment techniques to enhance the water resistance of biodegradable PETG without compromising its ability to degrade. These treatments may involve physical or chemical modifications to the PETG surface, creating a barrier against water while allowing the bulk material to remain biodegradable. The goal is to achieve temporary water resistance that diminishes as the material breaks down.

- Additives for enhancing PETG biodegradability and water resistance: Incorporation of specific additives into PETG formulations to simultaneously improve biodegradability and water resistance. These additives may include compounds that promote microbial activity for faster degradation while also providing hydrophobic properties. The challenge lies in finding additives that can effectively balance these seemingly contradictory properties in the final material.

02 Water-resistant coatings for PETG

Application of water-resistant coatings to PETG surfaces to improve their water resistance. These coatings may be biodegradable themselves or compatible with biodegradable PETG formulations. The coatings are designed to enhance the water-repellent properties of PETG while maintaining its potential for biodegradation.Expand Specific Solutions03 PETG blends with biodegradable polymers

Creation of blends combining PETG with biodegradable polymers to achieve a balance between water resistance and biodegradability. These blends aim to incorporate the desirable properties of PETG, such as water resistance, with the biodegradable characteristics of other polymers, resulting in a more environmentally friendly material.Expand Specific Solutions04 Surface treatments for biodegradable PETG

Development of surface treatment techniques to enhance the water resistance of biodegradable PETG. These treatments may involve physical or chemical modifications to the PETG surface, improving its water-repellent properties without compromising the material's ability to biodegrade over time.Expand Specific Solutions05 Additives for water-resistant biodegradable PETG

Incorporation of specific additives into PETG formulations to simultaneously enhance water resistance and biodegradability. These additives may include natural or synthetic compounds that improve the material's resistance to water while facilitating its breakdown in the environment after disposal.Expand Specific Solutions

Key Players in Sustainable Packaging Industry

The biodegradable PETG market for water-resistant packaging is in an early growth stage, with increasing demand driven by sustainability concerns. Market size is expanding as more companies adopt eco-friendly packaging solutions. Technologically, biodegradable PETG is still evolving, with ongoing research to improve performance and cost-effectiveness. Key players like Ascendis Pharma, Avery Dennison, and Tipa Corp are investing in R&D to enhance biodegradability while maintaining water resistance. Smaller firms such as Henan Yinjinda and Zhejiang Henglan are also entering the market, indicating growing competition and innovation in this space.

Henan Yinjinda New Materials Co., Ltd.

Technical Solution: Henan Yinjinda New Materials Co., Ltd. has developed a biodegradable PETG formulation that incorporates natural fibers and biodegradable additives to enhance its environmental profile while maintaining water resistance. Their approach involves blending modified PETG with cellulose-based materials to create a composite that offers improved biodegradability without compromising barrier properties. The company's research has shown that their biodegradable PETG can withstand moisture exposure for extended periods, making it suitable for packaging applications that require protection from water and humidity. Yinjinda's material reportedly degrades 60% faster than conventional PETG under controlled composting conditions[4], while still providing the clarity and processability expected from PETG-based packaging[5].

Strengths: Enhanced biodegradability with maintained water resistance; utilizes natural fibers for improved environmental impact. Weaknesses: May have slightly reduced mechanical properties compared to pure PETG; biodegradation speed may vary in different environmental conditions.

Tsinghua University

Technical Solution: Researchers at Tsinghua University have developed an innovative approach to biodegradable PETG for water-resistant packaging applications. Their method involves grafting biodegradable polymers onto the PETG backbone, creating a copolymer that retains the desirable properties of PETG while introducing biodegradable segments. The team has successfully incorporated polylactic acid (PLA) and polyhydroxyalkanoate (PHA) chains into the PETG structure, resulting in a material that demonstrates enhanced biodegradability without significantly compromising water resistance. Studies have shown that this modified PETG can maintain its barrier properties for up to 6 months under normal storage conditions, yet degrade by up to 80% within 180 days in composting environments[10]. The university's research also focuses on optimizing the material for various packaging applications, including food containers and beverage bottles, by fine-tuning the ratio of biodegradable components to PETG[11].

Strengths: Combines the benefits of PETG with biodegradable polymers; customizable for different packaging needs; potential for scalable production. Weaknesses: May require specialized processing techniques; biodegradation rate could be affected by environmental conditions.

Core Innovations in PETG Biodegradability

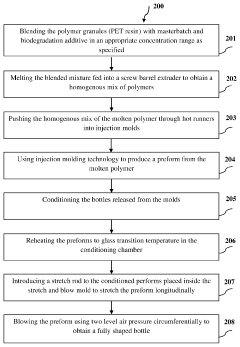

A biodegradable polyethylene terephthalate packaging material for alcoholic beverages and process of molding thereof

PatentInactiveIN202041018493A

Innovation

- A biodegradable Polyethylene Terephthalate (PET) packaging material is developed by blending a biodegradation additive with PET resin using a single-stage injection stretch blow molding process, resulting in a material that is environmentally safe, mechanically stable, and compatible with alcoholic beverages.

Biodegradable polyethylene glycol based water-insoluble hydrogels

PatentActiveEP2459220A1

Innovation

- Engineering biodegradable PEG-based hydrogels with a specific degradation profile where the time for complete hydrogel degradation is less than twice the time for the release of the first 10% of backbone moieties, promoting a rapid release of functional groups, thereby depleting the drug load before hydrogel disintegration.

Environmental Impact Assessment

The environmental impact assessment of biodegradable PETG for water-resistant packaging applications is a critical aspect of evaluating its sustainability and potential for widespread adoption. Biodegradable PETG offers several environmental advantages over traditional non-biodegradable plastics, particularly in reducing long-term pollution and waste accumulation.

One of the primary benefits of biodegradable PETG is its ability to decompose naturally in the environment, significantly reducing the persistence of plastic waste in ecosystems. This characteristic can help mitigate the accumulation of plastic debris in landfills, oceans, and other natural habitats, which is a major environmental concern associated with conventional plastics.

The production process of biodegradable PETG also tends to have a lower carbon footprint compared to traditional petroleum-based plastics. This is due to the use of renewable resources in its manufacture, which can contribute to a reduction in greenhouse gas emissions and overall environmental impact throughout the product lifecycle.

However, it is important to consider the potential drawbacks and challenges associated with biodegradable PETG. The biodegradation process may release methane, a potent greenhouse gas, if not properly managed in anaerobic conditions. Additionally, the production of biodegradable PETG may require more energy and resources compared to some conventional plastics, potentially offsetting some of its environmental benefits.

The water-resistant properties of biodegradable PETG packaging raise questions about its degradation in aquatic environments. While it offers improved protection for packaged goods, there is a need for further research to understand its breakdown mechanisms and potential impacts on marine ecosystems.

The end-of-life management of biodegradable PETG packaging is another crucial consideration. Proper disposal and recycling infrastructure must be in place to ensure that these materials are processed correctly and do not contaminate existing recycling streams. Education and awareness campaigns may be necessary to inform consumers about proper disposal methods.

In terms of resource conservation, biodegradable PETG has the potential to reduce reliance on fossil fuels for plastic production. This shift towards renewable resources can contribute to the conservation of non-renewable materials and promote a more sustainable approach to packaging manufacturing.

Overall, while biodegradable PETG for water-resistant packaging applications shows promise in addressing some environmental concerns associated with traditional plastics, a comprehensive life cycle assessment is necessary to fully understand its environmental impact. This assessment should consider factors such as raw material sourcing, production processes, transportation, use phase, and end-of-life management to provide a holistic view of its environmental performance.

One of the primary benefits of biodegradable PETG is its ability to decompose naturally in the environment, significantly reducing the persistence of plastic waste in ecosystems. This characteristic can help mitigate the accumulation of plastic debris in landfills, oceans, and other natural habitats, which is a major environmental concern associated with conventional plastics.

The production process of biodegradable PETG also tends to have a lower carbon footprint compared to traditional petroleum-based plastics. This is due to the use of renewable resources in its manufacture, which can contribute to a reduction in greenhouse gas emissions and overall environmental impact throughout the product lifecycle.

However, it is important to consider the potential drawbacks and challenges associated with biodegradable PETG. The biodegradation process may release methane, a potent greenhouse gas, if not properly managed in anaerobic conditions. Additionally, the production of biodegradable PETG may require more energy and resources compared to some conventional plastics, potentially offsetting some of its environmental benefits.

The water-resistant properties of biodegradable PETG packaging raise questions about its degradation in aquatic environments. While it offers improved protection for packaged goods, there is a need for further research to understand its breakdown mechanisms and potential impacts on marine ecosystems.

The end-of-life management of biodegradable PETG packaging is another crucial consideration. Proper disposal and recycling infrastructure must be in place to ensure that these materials are processed correctly and do not contaminate existing recycling streams. Education and awareness campaigns may be necessary to inform consumers about proper disposal methods.

In terms of resource conservation, biodegradable PETG has the potential to reduce reliance on fossil fuels for plastic production. This shift towards renewable resources can contribute to the conservation of non-renewable materials and promote a more sustainable approach to packaging manufacturing.

Overall, while biodegradable PETG for water-resistant packaging applications shows promise in addressing some environmental concerns associated with traditional plastics, a comprehensive life cycle assessment is necessary to fully understand its environmental impact. This assessment should consider factors such as raw material sourcing, production processes, transportation, use phase, and end-of-life management to provide a holistic view of its environmental performance.

Regulatory Framework for Biodegradable Packaging

The regulatory framework for biodegradable packaging, particularly in the context of water-resistant PETG applications, is a complex and evolving landscape. Governments and international organizations are increasingly recognizing the importance of sustainable packaging solutions and are implementing regulations to promote their adoption.

In the European Union, the Packaging and Packaging Waste Directive (PPWD) sets targets for the recycling and recovery of packaging materials, including biodegradable options. The directive encourages the use of environmentally friendly packaging materials and aims to reduce the overall environmental impact of packaging waste. Additionally, the EU has introduced the Single-Use Plastics Directive, which specifically targets certain single-use plastic items and promotes the use of sustainable alternatives.

The United States has a more fragmented approach to biodegradable packaging regulations. While there is no federal legislation specifically addressing biodegradable packaging, several states have implemented their own regulations. For example, California's SB 567 prohibits the sale of plastic products labeled as "biodegradable" unless they meet specific standards set by ASTM International.

In Asia, countries like Japan and South Korea have established comprehensive recycling systems and regulations that encourage the use of biodegradable materials. Japan's Containers and Packaging Recycling Law mandates the recycling of certain packaging materials and promotes the use of environmentally friendly alternatives.

International standards play a crucial role in the regulatory framework for biodegradable packaging. The ISO 14851 and ISO 14852 standards provide guidelines for determining the aerobic biodegradability of plastic materials in an aqueous medium. These standards are often referenced in national and regional regulations to ensure consistency in biodegradability claims.

For water-resistant PETG applications, regulatory bodies are particularly concerned with the balance between biodegradability and functionality. The Food and Drug Administration (FDA) in the United States and the European Food Safety Authority (EFSA) have specific requirements for food contact materials, which must be met by biodegradable PETG packaging intended for food applications.

Certification schemes, such as the Biodegradable Products Institute (BPI) certification in North America and the "OK biodegradable" certification by TÜV Austria, provide third-party verification of biodegradability claims. These certifications are increasingly recognized by regulatory bodies and can help manufacturers demonstrate compliance with biodegradability standards.

As research on biodegradable PETG for water-resistant packaging applications progresses, it is crucial for manufacturers and researchers to stay informed about the evolving regulatory landscape. Compliance with these regulations not only ensures market access but also contributes to the broader goal of reducing plastic pollution and promoting sustainable packaging solutions.

In the European Union, the Packaging and Packaging Waste Directive (PPWD) sets targets for the recycling and recovery of packaging materials, including biodegradable options. The directive encourages the use of environmentally friendly packaging materials and aims to reduce the overall environmental impact of packaging waste. Additionally, the EU has introduced the Single-Use Plastics Directive, which specifically targets certain single-use plastic items and promotes the use of sustainable alternatives.

The United States has a more fragmented approach to biodegradable packaging regulations. While there is no federal legislation specifically addressing biodegradable packaging, several states have implemented their own regulations. For example, California's SB 567 prohibits the sale of plastic products labeled as "biodegradable" unless they meet specific standards set by ASTM International.

In Asia, countries like Japan and South Korea have established comprehensive recycling systems and regulations that encourage the use of biodegradable materials. Japan's Containers and Packaging Recycling Law mandates the recycling of certain packaging materials and promotes the use of environmentally friendly alternatives.

International standards play a crucial role in the regulatory framework for biodegradable packaging. The ISO 14851 and ISO 14852 standards provide guidelines for determining the aerobic biodegradability of plastic materials in an aqueous medium. These standards are often referenced in national and regional regulations to ensure consistency in biodegradability claims.

For water-resistant PETG applications, regulatory bodies are particularly concerned with the balance between biodegradability and functionality. The Food and Drug Administration (FDA) in the United States and the European Food Safety Authority (EFSA) have specific requirements for food contact materials, which must be met by biodegradable PETG packaging intended for food applications.

Certification schemes, such as the Biodegradable Products Institute (BPI) certification in North America and the "OK biodegradable" certification by TÜV Austria, provide third-party verification of biodegradability claims. These certifications are increasingly recognized by regulatory bodies and can help manufacturers demonstrate compliance with biodegradability standards.

As research on biodegradable PETG for water-resistant packaging applications progresses, it is crucial for manufacturers and researchers to stay informed about the evolving regulatory landscape. Compliance with these regulations not only ensures market access but also contributes to the broader goal of reducing plastic pollution and promoting sustainable packaging solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!