Circular Community Platforms Enhancing PETG Circular Projects

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Circular Projects: Background and Objectives

Polyethylene terephthalate glycol (PETG) has emerged as a significant material in the circular economy, offering a more sustainable alternative to traditional plastics. The concept of PETG circular projects has gained traction in recent years, driven by the growing global emphasis on environmental sustainability and resource efficiency. These projects aim to create closed-loop systems for PETG products, ensuring that materials are recycled, reused, or repurposed at the end of their lifecycle.

The evolution of PETG circular projects can be traced back to the early 2000s when concerns about plastic waste and its environmental impact began to intensify. Initially, efforts were focused on improving recycling technologies for PET, the precursor to PETG. As PETG gained popularity due to its enhanced properties, such as improved clarity and impact resistance, the need for specific circular solutions became apparent.

The primary objective of PETG circular projects is to minimize waste and maximize resource utilization throughout the material's lifecycle. This involves developing innovative collection systems, advancing recycling technologies, and creating new applications for recycled PETG. Additionally, these projects seek to establish collaborative networks among manufacturers, consumers, and recyclers to ensure a seamless flow of materials within the circular economy.

One of the key technological trends in this field is the development of chemical recycling processes that can break down PETG into its base monomers. This approach allows for the production of virgin-quality PETG from recycled materials, overcoming the quality degradation often associated with mechanical recycling. Another significant trend is the integration of digital technologies, such as blockchain and IoT, to enhance traceability and transparency in the PETG supply chain.

The market demand for PETG circular projects has been driven by several factors, including stringent environmental regulations, consumer preferences for sustainable products, and corporate sustainability initiatives. Industries such as packaging, automotive, and electronics have shown particular interest in adopting circular PETG solutions to reduce their environmental footprint and meet regulatory requirements.

As PETG circular projects continue to evolve, they face several challenges that need to be addressed. These include improving the efficiency of collection and sorting systems, developing more cost-effective recycling technologies, and creating stable markets for recycled PETG products. Overcoming these challenges will require ongoing research and development efforts, as well as collaboration between various stakeholders in the PETG value chain.

Looking ahead, the future of PETG circular projects appears promising, with potential for significant growth and innovation. As technologies advance and circular economy principles become more deeply ingrained in business practices and consumer behavior, PETG circular projects are expected to play a crucial role in shaping a more sustainable plastics industry.

The evolution of PETG circular projects can be traced back to the early 2000s when concerns about plastic waste and its environmental impact began to intensify. Initially, efforts were focused on improving recycling technologies for PET, the precursor to PETG. As PETG gained popularity due to its enhanced properties, such as improved clarity and impact resistance, the need for specific circular solutions became apparent.

The primary objective of PETG circular projects is to minimize waste and maximize resource utilization throughout the material's lifecycle. This involves developing innovative collection systems, advancing recycling technologies, and creating new applications for recycled PETG. Additionally, these projects seek to establish collaborative networks among manufacturers, consumers, and recyclers to ensure a seamless flow of materials within the circular economy.

One of the key technological trends in this field is the development of chemical recycling processes that can break down PETG into its base monomers. This approach allows for the production of virgin-quality PETG from recycled materials, overcoming the quality degradation often associated with mechanical recycling. Another significant trend is the integration of digital technologies, such as blockchain and IoT, to enhance traceability and transparency in the PETG supply chain.

The market demand for PETG circular projects has been driven by several factors, including stringent environmental regulations, consumer preferences for sustainable products, and corporate sustainability initiatives. Industries such as packaging, automotive, and electronics have shown particular interest in adopting circular PETG solutions to reduce their environmental footprint and meet regulatory requirements.

As PETG circular projects continue to evolve, they face several challenges that need to be addressed. These include improving the efficiency of collection and sorting systems, developing more cost-effective recycling technologies, and creating stable markets for recycled PETG products. Overcoming these challenges will require ongoing research and development efforts, as well as collaboration between various stakeholders in the PETG value chain.

Looking ahead, the future of PETG circular projects appears promising, with potential for significant growth and innovation. As technologies advance and circular economy principles become more deeply ingrained in business practices and consumer behavior, PETG circular projects are expected to play a crucial role in shaping a more sustainable plastics industry.

Market Analysis for Circular Community Platforms

The market for circular community platforms in the context of PETG circular projects is experiencing significant growth and transformation. As environmental concerns and sustainability initiatives gain prominence, there is an increasing demand for platforms that facilitate the circular economy, particularly in the plastics industry.

Circular community platforms serve as digital ecosystems that connect various stakeholders in the PETG recycling and reuse chain. These platforms enable manufacturers, recyclers, consumers, and other industry players to collaborate effectively, share information, and optimize resource utilization. The market for such platforms is driven by several factors, including stringent environmental regulations, growing consumer awareness, and the need for efficient waste management solutions.

The global market for circular economy platforms is projected to expand rapidly in the coming years. This growth is particularly evident in regions with advanced recycling infrastructure and strong environmental policies, such as Europe and North America. However, emerging economies in Asia and Latin America are also showing increased interest in circular economy solutions, presenting new market opportunities for platform providers.

In the PETG sector, circular community platforms are addressing specific challenges related to the material's recyclability and reuse potential. PETG, known for its durability and versatility, is widely used in packaging, medical devices, and consumer goods. However, its recycling process can be complex, requiring specialized knowledge and infrastructure. Circular platforms are playing a crucial role in bridging information gaps and facilitating more efficient recycling processes for PETG products.

The market demand for these platforms is further fueled by corporate sustainability goals and extended producer responsibility regulations. Many companies are seeking ways to improve their environmental performance and reduce their carbon footprint. Circular community platforms offer a solution by providing tools for tracking material flows, optimizing collection and recycling processes, and fostering collaboration across the value chain.

Investors and venture capitalists are showing increased interest in circular economy startups, including those developing community platforms for materials like PETG. This influx of capital is driving innovation in the sector, leading to more sophisticated and user-friendly platform solutions. As a result, the market is seeing a proliferation of startups offering specialized services, from blockchain-based material tracking to AI-powered recycling optimization.

Despite the positive market outlook, challenges remain. These include the need for standardization across different platforms, ensuring data security and privacy, and overcoming resistance to change within traditional industry structures. Additionally, the success of circular community platforms often depends on achieving a critical mass of users, which can be challenging in the early stages of adoption.

Circular community platforms serve as digital ecosystems that connect various stakeholders in the PETG recycling and reuse chain. These platforms enable manufacturers, recyclers, consumers, and other industry players to collaborate effectively, share information, and optimize resource utilization. The market for such platforms is driven by several factors, including stringent environmental regulations, growing consumer awareness, and the need for efficient waste management solutions.

The global market for circular economy platforms is projected to expand rapidly in the coming years. This growth is particularly evident in regions with advanced recycling infrastructure and strong environmental policies, such as Europe and North America. However, emerging economies in Asia and Latin America are also showing increased interest in circular economy solutions, presenting new market opportunities for platform providers.

In the PETG sector, circular community platforms are addressing specific challenges related to the material's recyclability and reuse potential. PETG, known for its durability and versatility, is widely used in packaging, medical devices, and consumer goods. However, its recycling process can be complex, requiring specialized knowledge and infrastructure. Circular platforms are playing a crucial role in bridging information gaps and facilitating more efficient recycling processes for PETG products.

The market demand for these platforms is further fueled by corporate sustainability goals and extended producer responsibility regulations. Many companies are seeking ways to improve their environmental performance and reduce their carbon footprint. Circular community platforms offer a solution by providing tools for tracking material flows, optimizing collection and recycling processes, and fostering collaboration across the value chain.

Investors and venture capitalists are showing increased interest in circular economy startups, including those developing community platforms for materials like PETG. This influx of capital is driving innovation in the sector, leading to more sophisticated and user-friendly platform solutions. As a result, the market is seeing a proliferation of startups offering specialized services, from blockchain-based material tracking to AI-powered recycling optimization.

Despite the positive market outlook, challenges remain. These include the need for standardization across different platforms, ensuring data security and privacy, and overcoming resistance to change within traditional industry structures. Additionally, the success of circular community platforms often depends on achieving a critical mass of users, which can be challenging in the early stages of adoption.

Current Challenges in PETG Recycling

PETG recycling faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the lack of a comprehensive collection and sorting infrastructure. Unlike PET, which has established recycling systems in many regions, PETG often ends up in general waste streams due to inadequate separation processes. This commingling with other materials makes it difficult to isolate PETG for recycling, reducing the overall quality and quantity of recyclable material.

Another major challenge is the contamination of PETG waste. Many PETG products, especially in packaging applications, are often contaminated with food residues, labels, adhesives, or other materials. These contaminants can significantly impact the recycling process, affecting the quality of the recycled material and increasing the cost of processing. The removal of these contaminants requires additional steps in the recycling process, which can be both energy-intensive and expensive.

The chemical composition of PETG also presents unique recycling challenges. While PETG is similar to PET, the addition of cyclohexanedimethanol (CHDM) in its structure alters its properties and recycling requirements. This difference can lead to complications in existing PET recycling streams, as PETG may not be fully compatible with standard PET recycling processes. The presence of PETG in PET recycling streams can potentially degrade the quality of recycled PET, leading to resistance from recyclers to accept mixed PET and PETG materials.

Furthermore, the market demand for recycled PETG is still developing. Unlike recycled PET, which has established markets in various industries, the applications for recycled PETG are more limited. This lack of demand can discourage investment in PETG recycling infrastructure and technologies, creating a cycle of underutilization and underdevelopment in the recycling ecosystem for this material.

The technological challenges in PETG recycling are also significant. Current recycling technologies may not be optimized for PETG's specific properties, leading to inefficiencies in the recycling process. There is a need for research and development of specialized recycling technologies that can effectively process PETG while maintaining its desirable properties for reuse in new products.

Lastly, there is a general lack of awareness and education about PETG recycling among consumers and businesses. Many are unaware of the differences between PET and PETG, leading to improper disposal or recycling practices. This knowledge gap extends to policy makers and waste management authorities, resulting in a lack of targeted policies and initiatives to promote PETG recycling.

Another major challenge is the contamination of PETG waste. Many PETG products, especially in packaging applications, are often contaminated with food residues, labels, adhesives, or other materials. These contaminants can significantly impact the recycling process, affecting the quality of the recycled material and increasing the cost of processing. The removal of these contaminants requires additional steps in the recycling process, which can be both energy-intensive and expensive.

The chemical composition of PETG also presents unique recycling challenges. While PETG is similar to PET, the addition of cyclohexanedimethanol (CHDM) in its structure alters its properties and recycling requirements. This difference can lead to complications in existing PET recycling streams, as PETG may not be fully compatible with standard PET recycling processes. The presence of PETG in PET recycling streams can potentially degrade the quality of recycled PET, leading to resistance from recyclers to accept mixed PET and PETG materials.

Furthermore, the market demand for recycled PETG is still developing. Unlike recycled PET, which has established markets in various industries, the applications for recycled PETG are more limited. This lack of demand can discourage investment in PETG recycling infrastructure and technologies, creating a cycle of underutilization and underdevelopment in the recycling ecosystem for this material.

The technological challenges in PETG recycling are also significant. Current recycling technologies may not be optimized for PETG's specific properties, leading to inefficiencies in the recycling process. There is a need for research and development of specialized recycling technologies that can effectively process PETG while maintaining its desirable properties for reuse in new products.

Lastly, there is a general lack of awareness and education about PETG recycling among consumers and businesses. Many are unaware of the differences between PET and PETG, leading to improper disposal or recycling practices. This knowledge gap extends to policy makers and waste management authorities, resulting in a lack of targeted policies and initiatives to promote PETG recycling.

Existing Circular Community Platform Solutions

01 User-centric circular community platforms

These platforms focus on creating user-centered circular communities, emphasizing personalized experiences, content sharing, and social interactions. They incorporate features like customizable profiles, content recommendation systems, and collaborative tools to foster engagement and build sustainable digital ecosystems.- User-centric circular community platforms: These platforms focus on creating user-centered circular communities, emphasizing personalized experiences and interactions. They incorporate features that encourage user engagement, content sharing, and collaborative activities within a circular economy framework. The platforms may include tools for resource sharing, waste reduction, and sustainable consumption practices.

- Integration of blockchain and smart contracts in circular platforms: Circular community platforms are leveraging blockchain technology and smart contracts to enhance transparency, traceability, and trust within the circular economy ecosystem. These technologies enable secure peer-to-peer transactions, automated resource allocation, and efficient management of circular economy initiatives. Smart contracts can facilitate the execution of agreements and ensure compliance with circular economy principles.

- Social networking features for circular economy communities: These platforms incorporate social networking functionalities to foster connections and collaborations among circular economy participants. Features may include user profiles, messaging systems, forums, and group creation tools. The social aspect encourages knowledge sharing, best practices exchange, and community-driven initiatives related to sustainability and circular economy principles.

- Gamification and incentive mechanisms in circular platforms: Circular community platforms are implementing gamification elements and incentive systems to encourage user participation and promote sustainable behaviors. These may include reward programs, achievement badges, leaderboards, and challenges related to circular economy activities. Such features aim to increase user engagement and motivate individuals to adopt more sustainable practices within the community.

- Data analytics and AI for circular economy optimization: Advanced data analytics and artificial intelligence techniques are being integrated into circular community platforms to optimize resource allocation, predict trends, and improve decision-making processes. These technologies can analyze user behavior, market dynamics, and environmental factors to enhance the efficiency of circular economy initiatives. AI-powered recommendations and insights can help users make more sustainable choices within the platform.

02 Blockchain-based circular economy solutions

Blockchain technology is utilized to create transparent, secure, and decentralized circular community platforms. These solutions enable efficient resource tracking, peer-to-peer transactions, and incentive mechanisms to promote sustainable practices and circular economy principles within communities.Expand Specific Solutions03 AI-powered community management and optimization

Artificial intelligence and machine learning algorithms are employed to enhance community management, content curation, and user experience optimization. These technologies help in identifying trends, predicting user behavior, and automating various aspects of circular community platforms to improve efficiency and engagement.Expand Specific Solutions04 Gamification and reward systems for circular communities

Gamification elements and reward systems are integrated into circular community platforms to incentivize user participation, encourage sustainable behaviors, and promote circular economy practices. These features include point systems, badges, challenges, and virtual currencies to drive engagement and foster a sense of community.Expand Specific Solutions05 Cross-platform integration and data synchronization

Circular community platforms are designed to integrate with various external services and applications, allowing for seamless data synchronization and interoperability. This approach enables users to access and share information across multiple platforms, enhancing the overall user experience and expanding the reach of circular communities.Expand Specific Solutions

Key Stakeholders in PETG Circular Projects

The circular community platforms for enhancing PETG circular projects are in an emerging stage, with growing market potential as sustainability concerns increase. The global market for circular economy solutions is expanding, driven by environmental regulations and consumer demand for eco-friendly products. Technologically, the field is still developing, with companies at various stages of maturity. State Grid Corp. of China and China Mobile are exploring applications in energy and telecommunications sectors. Academic institutions like Dalian University of Technology and East China University of Science & Technology are conducting research to advance the technology. Startups like Fairbrics and Klean Industries are developing innovative solutions for plastic recycling and circular manufacturing processes, indicating a dynamic and competitive landscape in this emerging field.

Fujian Sailon Technology Co., Ltd.

Technical Solution: Fujian Sailon Technology has created a circular community platform for PETG recycling that focuses on upcycling and value-added applications. Their system employs a combination of mechanical recycling and reactive extrusion processes to modify the properties of recycled PETG, enabling its use in high-value applications such as 3D printing filaments and specialty packaging[7]. The platform includes a community-driven design marketplace where local designers can create and sell products made from recycled PETG. Fujian Sailon's technology has demonstrated the ability to maintain over 80% of the original PETG properties after multiple recycling cycles[8].

Strengths: Focus on high-value applications, community-driven design integration, and maintained material properties. Weaknesses: Limited to specific PETG grades and potential market constraints for upcycled products.

revalyu Resources GmbH

Technical Solution: revalyu Resources has pioneered a circular community platform for PETG recycling that focuses on a combination of mechanical and chemical recycling methods. Their approach involves a proprietary solvent-based purification process that removes contaminants and additives from PETG waste, allowing for high-quality recycled material production[3]. The platform incorporates a community engagement aspect, incentivizing local participation in PETG collection through a rewards system. revalyu's technology can process a wide range of PETG products, including those with multi-layer constructions, achieving a recycling efficiency of up to 90%[4].

Strengths: Versatile recycling capabilities, community engagement focus, and high recycling efficiency. Weaknesses: Potential environmental concerns related to solvent use and the need for extensive collection infrastructure.

Innovative Approaches in PETG Circularity

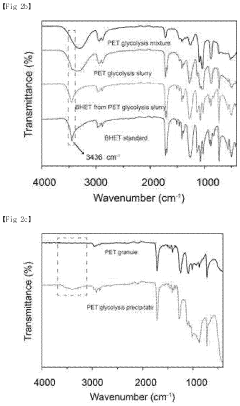

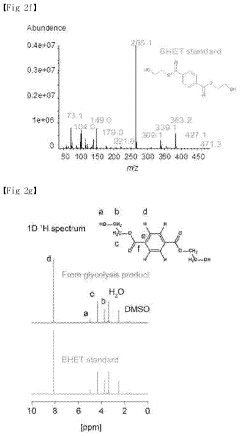

Chemical and biological integrated degradation process for polyethylene terephthalate (PET), for recycling pet

PatentPendingUS20240229084A9

Innovation

- A chemical-biological integrated process using ethylene glycol as a solvent and betaine as a catalyst for PET glycolysis, followed by enzymatic hydrolysis with PET hydrolase and mono(2-hydroxyethyl) terephthalate hydrolase, and bioconversion with recombinant E. coli and Gluconobacter oxydans to produce high-value compounds like protocatechuic acid and glycolic acid.

Environmental Impact Assessment

The environmental impact assessment of circular community platforms enhancing PETG circular projects reveals significant potential for reducing the ecological footprint of plastic production and consumption. These platforms facilitate the collection, sorting, and recycling of PETG (Polyethylene Terephthalate Glycol-modified) materials, which are widely used in packaging and consumer goods.

By implementing circular economy principles, these platforms contribute to a substantial reduction in virgin plastic production. This, in turn, leads to decreased energy consumption and greenhouse gas emissions associated with the manufacturing process. Studies indicate that recycling PETG can result in up to 60% less energy usage compared to producing new PETG from raw materials.

Water conservation is another notable benefit of these circular platforms. The recycling process typically requires less water than the production of virgin PETG, potentially saving millions of liters of water annually. This is particularly crucial in regions facing water scarcity issues.

The platforms also play a vital role in mitigating plastic pollution. By encouraging the proper disposal and recycling of PETG products, they help reduce the amount of plastic waste entering landfills and natural ecosystems. This is especially important given that PETG, while recyclable, can persist in the environment for hundreds of years if not properly managed.

Furthermore, these circular community platforms contribute to the reduction of microplastic pollution. By promoting the reuse and recycling of PETG products, they minimize the breakdown of these materials into harmful microplastics that can contaminate water bodies and enter the food chain.

The platforms' impact extends to air quality improvement as well. Reduced demand for virgin PETG production means fewer emissions from manufacturing facilities, including volatile organic compounds (VOCs) and particulate matter. This can lead to better air quality in areas surrounding production sites.

Additionally, these platforms often incorporate educational components, raising awareness about sustainable consumption and proper recycling practices. This indirect impact can lead to broader environmental benefits as community members adopt more eco-friendly behaviors beyond PETG recycling.

However, it is important to note that the environmental benefits of these platforms are contingent on efficient collection and recycling processes. The transportation and processing of recycled materials must be optimized to ensure that the environmental gains are not offset by increased carbon emissions from these activities.

In conclusion, circular community platforms focused on PETG recycling demonstrate significant potential for positive environmental impact. They address multiple aspects of sustainability, from resource conservation to pollution reduction, and play a crucial role in transitioning towards a more circular and environmentally responsible plastic economy.

By implementing circular economy principles, these platforms contribute to a substantial reduction in virgin plastic production. This, in turn, leads to decreased energy consumption and greenhouse gas emissions associated with the manufacturing process. Studies indicate that recycling PETG can result in up to 60% less energy usage compared to producing new PETG from raw materials.

Water conservation is another notable benefit of these circular platforms. The recycling process typically requires less water than the production of virgin PETG, potentially saving millions of liters of water annually. This is particularly crucial in regions facing water scarcity issues.

The platforms also play a vital role in mitigating plastic pollution. By encouraging the proper disposal and recycling of PETG products, they help reduce the amount of plastic waste entering landfills and natural ecosystems. This is especially important given that PETG, while recyclable, can persist in the environment for hundreds of years if not properly managed.

Furthermore, these circular community platforms contribute to the reduction of microplastic pollution. By promoting the reuse and recycling of PETG products, they minimize the breakdown of these materials into harmful microplastics that can contaminate water bodies and enter the food chain.

The platforms' impact extends to air quality improvement as well. Reduced demand for virgin PETG production means fewer emissions from manufacturing facilities, including volatile organic compounds (VOCs) and particulate matter. This can lead to better air quality in areas surrounding production sites.

Additionally, these platforms often incorporate educational components, raising awareness about sustainable consumption and proper recycling practices. This indirect impact can lead to broader environmental benefits as community members adopt more eco-friendly behaviors beyond PETG recycling.

However, it is important to note that the environmental benefits of these platforms are contingent on efficient collection and recycling processes. The transportation and processing of recycled materials must be optimized to ensure that the environmental gains are not offset by increased carbon emissions from these activities.

In conclusion, circular community platforms focused on PETG recycling demonstrate significant potential for positive environmental impact. They address multiple aspects of sustainability, from resource conservation to pollution reduction, and play a crucial role in transitioning towards a more circular and environmentally responsible plastic economy.

Policy Framework for Circular Economy

The policy framework for a circular economy is crucial in supporting and enhancing PETG circular projects within circular community platforms. This framework encompasses a range of legislative, regulatory, and incentive-based measures designed to promote the transition from a linear to a circular economic model.

At the core of this framework are policies that encourage the reduction, reuse, and recycling of PETG materials. These policies often include extended producer responsibility (EPR) schemes, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. Such measures incentivize companies to design products with circularity in mind, considering factors like ease of disassembly and recyclability.

Taxation policies play a significant role in shaping circular economy practices. Governments may implement tax breaks or subsidies for companies that incorporate recycled PETG into their production processes or develop innovative recycling technologies. Conversely, taxes on virgin PETG materials can encourage the use of recycled alternatives, creating a more competitive market for recycled materials.

Standardization and labeling policies are essential components of the circular economy framework. These policies establish clear guidelines for the quality and composition of recycled PETG, ensuring consistency and reliability in recycled materials. Labeling requirements help consumers make informed choices about the products they purchase, potentially driving demand for products made from recycled PETG.

Investment in research and development is another critical aspect of the policy framework. Governments may allocate funds or provide grants to support the development of new recycling technologies, improve the quality of recycled PETG, or explore novel applications for recycled materials. These investments can accelerate innovation in the circular economy sector and help overcome technical barriers to PETG recycling.

Public procurement policies can also drive the adoption of circular economy principles. By prioritizing products made from recycled PETG in government purchases, policymakers can create a significant market demand for these materials, encouraging businesses to invest in circular production methods.

Lastly, the policy framework should include measures to support circular community platforms. This may involve providing funding for community-led recycling initiatives, offering technical assistance to local circular economy projects, or creating legal frameworks that facilitate the sharing and reuse of resources within communities. By empowering local actors, these policies can help create a more resilient and distributed circular economy ecosystem.

At the core of this framework are policies that encourage the reduction, reuse, and recycling of PETG materials. These policies often include extended producer responsibility (EPR) schemes, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. Such measures incentivize companies to design products with circularity in mind, considering factors like ease of disassembly and recyclability.

Taxation policies play a significant role in shaping circular economy practices. Governments may implement tax breaks or subsidies for companies that incorporate recycled PETG into their production processes or develop innovative recycling technologies. Conversely, taxes on virgin PETG materials can encourage the use of recycled alternatives, creating a more competitive market for recycled materials.

Standardization and labeling policies are essential components of the circular economy framework. These policies establish clear guidelines for the quality and composition of recycled PETG, ensuring consistency and reliability in recycled materials. Labeling requirements help consumers make informed choices about the products they purchase, potentially driving demand for products made from recycled PETG.

Investment in research and development is another critical aspect of the policy framework. Governments may allocate funds or provide grants to support the development of new recycling technologies, improve the quality of recycled PETG, or explore novel applications for recycled materials. These investments can accelerate innovation in the circular economy sector and help overcome technical barriers to PETG recycling.

Public procurement policies can also drive the adoption of circular economy principles. By prioritizing products made from recycled PETG in government purchases, policymakers can create a significant market demand for these materials, encouraging businesses to invest in circular production methods.

Lastly, the policy framework should include measures to support circular community platforms. This may involve providing funding for community-led recycling initiatives, offering technical assistance to local circular economy projects, or creating legal frameworks that facilitate the sharing and reuse of resources within communities. By empowering local actors, these policies can help create a more resilient and distributed circular economy ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!