Pioneering Research in 3D Printed PETG-Based Structures

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Printing PETG Evolution

The evolution of 3D printing with PETG (Polyethylene Terephthalate Glycol) has been a significant advancement in additive manufacturing technology. Initially developed as a modification of PET, PETG emerged as a superior material for 3D printing due to its enhanced properties and ease of use.

In the early stages of PETG adoption for 3D printing, the material was primarily used for prototyping and small-scale production. Its clarity, durability, and food-safe properties made it an attractive option for various applications. As printing technologies improved, so did the quality and consistency of PETG prints, leading to its increased use in more demanding applications.

The mid-2010s saw a surge in PETG's popularity among 3D printing enthusiasts and professionals alike. This period was marked by significant improvements in PETG filament formulations, resulting in better print quality, reduced warping, and enhanced layer adhesion. These advancements made PETG a viable alternative to ABS and PLA for many applications, particularly those requiring greater strength and temperature resistance.

As the technology matured, PETG began to find its way into industrial applications. The material's chemical resistance and impact strength made it suitable for manufacturing functional parts and components. This shift from prototyping to end-use parts represented a crucial milestone in the evolution of PETG 3D printing.

Recent years have seen further refinements in PETG printing techniques and material compositions. The development of specialized PETG blends with additives for improved strength, flexibility, or specific properties has expanded the material's application range. Additionally, advancements in printer hardware, such as all-metal hotends and enclosed printing chambers, have allowed for better control over the printing process, resulting in higher quality PETG prints.

The integration of PETG into large-scale additive manufacturing has been another significant development. Industrial-grade 3D printers capable of processing PETG at high volumes have opened up new possibilities for mass customization and on-demand manufacturing. This has been particularly impactful in industries such as automotive, aerospace, and medical device manufacturing.

Looking towards the future, the evolution of PETG in 3D printing is likely to continue along several paths. Research into bio-based and recyclable PETG formulations is gaining traction, addressing growing environmental concerns. Furthermore, the development of multi-material printing techniques incorporating PETG with other materials promises to create complex, functional parts with tailored properties.

In the early stages of PETG adoption for 3D printing, the material was primarily used for prototyping and small-scale production. Its clarity, durability, and food-safe properties made it an attractive option for various applications. As printing technologies improved, so did the quality and consistency of PETG prints, leading to its increased use in more demanding applications.

The mid-2010s saw a surge in PETG's popularity among 3D printing enthusiasts and professionals alike. This period was marked by significant improvements in PETG filament formulations, resulting in better print quality, reduced warping, and enhanced layer adhesion. These advancements made PETG a viable alternative to ABS and PLA for many applications, particularly those requiring greater strength and temperature resistance.

As the technology matured, PETG began to find its way into industrial applications. The material's chemical resistance and impact strength made it suitable for manufacturing functional parts and components. This shift from prototyping to end-use parts represented a crucial milestone in the evolution of PETG 3D printing.

Recent years have seen further refinements in PETG printing techniques and material compositions. The development of specialized PETG blends with additives for improved strength, flexibility, or specific properties has expanded the material's application range. Additionally, advancements in printer hardware, such as all-metal hotends and enclosed printing chambers, have allowed for better control over the printing process, resulting in higher quality PETG prints.

The integration of PETG into large-scale additive manufacturing has been another significant development. Industrial-grade 3D printers capable of processing PETG at high volumes have opened up new possibilities for mass customization and on-demand manufacturing. This has been particularly impactful in industries such as automotive, aerospace, and medical device manufacturing.

Looking towards the future, the evolution of PETG in 3D printing is likely to continue along several paths. Research into bio-based and recyclable PETG formulations is gaining traction, addressing growing environmental concerns. Furthermore, the development of multi-material printing techniques incorporating PETG with other materials promises to create complex, functional parts with tailored properties.

Market Demand Analysis

The market demand for 3D printed PETG-based structures has been steadily growing, driven by the unique properties of PETG and the increasing adoption of additive manufacturing technologies across various industries. PETG (Polyethylene Terephthalate Glycol) has emerged as a popular material for 3D printing due to its excellent strength, durability, and chemical resistance, making it suitable for a wide range of applications.

In the automotive sector, there is a rising demand for lightweight, customizable parts that can withstand harsh environments. 3D printed PETG structures offer the potential to create complex geometries and reduce overall vehicle weight, contributing to improved fuel efficiency and performance. This has led to increased interest from major automotive manufacturers in incorporating PETG-based 3D printed components into their production processes.

The aerospace industry has also shown significant interest in PETG-based 3D printed structures. The material's high strength-to-weight ratio and resistance to extreme temperatures make it ideal for creating interior components, ducting systems, and even structural elements for aircraft and spacecraft. As the aerospace sector continues to push for more efficient and lightweight designs, the demand for PETG-based 3D printed solutions is expected to grow substantially.

In the medical field, PETG's biocompatibility and sterilization capabilities have opened up new possibilities for patient-specific implants, prosthetics, and medical devices. The ability to create custom-fit, lightweight structures using 3D printing technology has the potential to revolutionize personalized healthcare, driving demand for PETG-based solutions in this sector.

The consumer goods industry has also embraced 3D printed PETG structures, particularly in the production of durable, customizable products such as phone cases, household items, and sporting goods. The material's clarity and food-safe properties have made it popular for creating food containers and kitchenware, further expanding its market potential.

Industrial applications for 3D printed PETG structures are on the rise, with manufacturers exploring its use in tooling, jigs, and fixtures. The material's chemical resistance and durability make it suitable for creating components that can withstand harsh industrial environments, leading to increased adoption in manufacturing processes.

As sustainability becomes a key focus across industries, the recyclability of PETG has become a significant driver of market demand. Companies are increasingly looking for materials that can be easily recycled and reused, aligning with circular economy principles and reducing environmental impact.

The global market for 3D printed PETG structures is expected to experience substantial growth in the coming years, with some industry analysts projecting a compound annual growth rate (CAGR) of over 20% through 2025. This growth is attributed to the expanding applications across various sectors and the continuous improvement in 3D printing technologies, which are making PETG-based structures more accessible and cost-effective for a wider range of businesses.

In the automotive sector, there is a rising demand for lightweight, customizable parts that can withstand harsh environments. 3D printed PETG structures offer the potential to create complex geometries and reduce overall vehicle weight, contributing to improved fuel efficiency and performance. This has led to increased interest from major automotive manufacturers in incorporating PETG-based 3D printed components into their production processes.

The aerospace industry has also shown significant interest in PETG-based 3D printed structures. The material's high strength-to-weight ratio and resistance to extreme temperatures make it ideal for creating interior components, ducting systems, and even structural elements for aircraft and spacecraft. As the aerospace sector continues to push for more efficient and lightweight designs, the demand for PETG-based 3D printed solutions is expected to grow substantially.

In the medical field, PETG's biocompatibility and sterilization capabilities have opened up new possibilities for patient-specific implants, prosthetics, and medical devices. The ability to create custom-fit, lightweight structures using 3D printing technology has the potential to revolutionize personalized healthcare, driving demand for PETG-based solutions in this sector.

The consumer goods industry has also embraced 3D printed PETG structures, particularly in the production of durable, customizable products such as phone cases, household items, and sporting goods. The material's clarity and food-safe properties have made it popular for creating food containers and kitchenware, further expanding its market potential.

Industrial applications for 3D printed PETG structures are on the rise, with manufacturers exploring its use in tooling, jigs, and fixtures. The material's chemical resistance and durability make it suitable for creating components that can withstand harsh industrial environments, leading to increased adoption in manufacturing processes.

As sustainability becomes a key focus across industries, the recyclability of PETG has become a significant driver of market demand. Companies are increasingly looking for materials that can be easily recycled and reused, aligning with circular economy principles and reducing environmental impact.

The global market for 3D printed PETG structures is expected to experience substantial growth in the coming years, with some industry analysts projecting a compound annual growth rate (CAGR) of over 20% through 2025. This growth is attributed to the expanding applications across various sectors and the continuous improvement in 3D printing technologies, which are making PETG-based structures more accessible and cost-effective for a wider range of businesses.

PETG 3D Printing Challenges

PETG (Polyethylene Terephthalate Glycol) has emerged as a popular material for 3D printing due to its unique combination of properties. However, the use of PETG in 3D printing presents several challenges that researchers and manufacturers must address to fully harness its potential.

One of the primary challenges in PETG 3D printing is achieving optimal print bed adhesion. PETG has a tendency to warp and lift from the print bed during cooling, which can lead to failed prints or poor quality finished products. This issue is particularly pronounced for large or complex structures, where the differential cooling rates across the object can exacerbate warping.

Temperature control is another critical challenge in PETG 3D printing. PETG requires higher printing temperatures compared to other common filaments like PLA, typically ranging from 230°C to 250°C. Maintaining consistent temperature throughout the printing process is crucial for achieving good layer adhesion and preventing issues such as stringing or oozing.

Moisture sensitivity poses a significant challenge in PETG 3D printing. PETG filaments are hygroscopic, meaning they readily absorb moisture from the air. This can lead to poor print quality, with issues such as bubbling, stringing, and reduced mechanical properties in the finished product. Proper storage and drying of PETG filaments are essential to mitigate these problems.

The mechanical properties of 3D printed PETG structures present both opportunities and challenges. While PETG offers good impact resistance and flexibility, achieving consistent and predictable mechanical properties across different print orientations and infill patterns remains a challenge. This is particularly important for functional parts that need to withstand specific loads or stresses.

Post-processing of PETG printed parts can also be challenging. Unlike some other materials, PETG is resistant to many common solvents used for smoothing 3D printed surfaces. This makes it more difficult to achieve a smooth, glossy finish on PETG parts without resorting to mechanical methods like sanding, which can be time-consuming and may alter the part's dimensions.

Recycling and sustainability present another set of challenges for PETG 3D printing. While PETG is theoretically recyclable, the process of grinding and reusing PETG filament can lead to degradation of material properties. Developing effective recycling methods that maintain the quality of PETG for repeated use in 3D printing is an ongoing challenge in the field.

One of the primary challenges in PETG 3D printing is achieving optimal print bed adhesion. PETG has a tendency to warp and lift from the print bed during cooling, which can lead to failed prints or poor quality finished products. This issue is particularly pronounced for large or complex structures, where the differential cooling rates across the object can exacerbate warping.

Temperature control is another critical challenge in PETG 3D printing. PETG requires higher printing temperatures compared to other common filaments like PLA, typically ranging from 230°C to 250°C. Maintaining consistent temperature throughout the printing process is crucial for achieving good layer adhesion and preventing issues such as stringing or oozing.

Moisture sensitivity poses a significant challenge in PETG 3D printing. PETG filaments are hygroscopic, meaning they readily absorb moisture from the air. This can lead to poor print quality, with issues such as bubbling, stringing, and reduced mechanical properties in the finished product. Proper storage and drying of PETG filaments are essential to mitigate these problems.

The mechanical properties of 3D printed PETG structures present both opportunities and challenges. While PETG offers good impact resistance and flexibility, achieving consistent and predictable mechanical properties across different print orientations and infill patterns remains a challenge. This is particularly important for functional parts that need to withstand specific loads or stresses.

Post-processing of PETG printed parts can also be challenging. Unlike some other materials, PETG is resistant to many common solvents used for smoothing 3D printed surfaces. This makes it more difficult to achieve a smooth, glossy finish on PETG parts without resorting to mechanical methods like sanding, which can be time-consuming and may alter the part's dimensions.

Recycling and sustainability present another set of challenges for PETG 3D printing. While PETG is theoretically recyclable, the process of grinding and reusing PETG filament can lead to degradation of material properties. Developing effective recycling methods that maintain the quality of PETG for repeated use in 3D printing is an ongoing challenge in the field.

Current PETG Solutions

01 3D printing techniques for PETG structures

Various 3D printing methods are employed to create PETG-based structures, including fused deposition modeling (FDM) and selective laser sintering (SLS). These techniques allow for the fabrication of complex geometries and customized designs using PETG material, offering advantages such as improved strength, durability, and flexibility in manufacturing processes.- 3D printing techniques for PETG structures: Various 3D printing methods are employed to create PETG-based structures, including fused deposition modeling (FDM) and selective laser sintering (SLS). These techniques allow for the fabrication of complex geometries and customized designs using PETG material, offering advantages such as improved strength, durability, and flexibility in manufacturing processes.

- PETG material composition and modifications: PETG-based structures can be enhanced through the incorporation of additives, fillers, or reinforcing materials. These modifications can improve mechanical properties, thermal stability, or introduce specific functionalities such as conductivity or flame retardancy. The composition of PETG materials can be tailored to meet specific application requirements in various industries.

- Applications of 3D printed PETG structures: 3D printed PETG-based structures find applications in diverse fields, including medical devices, automotive parts, consumer products, and industrial components. The versatility of PETG material, combined with 3D printing capabilities, enables the creation of customized solutions for specific industry needs, such as lightweight parts, biocompatible implants, or durable prototypes.

- Post-processing and surface treatments: Various post-processing techniques and surface treatments can be applied to 3D printed PETG structures to enhance their properties or appearance. These may include heat treatments, chemical treatments, or mechanical finishing processes to improve surface quality, dimensional accuracy, or mechanical strength of the printed parts.

- Optimization of 3D printing parameters for PETG: Research focuses on optimizing 3D printing parameters specific to PETG materials, such as extrusion temperature, print speed, layer height, and cooling strategies. These optimizations aim to improve print quality, mechanical properties, and overall performance of the 3D printed PETG structures, while also addressing challenges like warping or layer adhesion.

02 PETG material composition and modifications

PETG-based structures can be enhanced through material modifications and additives. This includes the incorporation of reinforcing agents, such as fibers or nanoparticles, to improve mechanical properties. Additionally, blending PETG with other polymers or introducing specific additives can tailor the material's characteristics for specific applications, such as increased heat resistance or improved surface finish.Expand Specific Solutions03 Applications of 3D printed PETG structures

3D printed PETG-based structures find applications in various industries, including medical devices, automotive parts, consumer products, and packaging. The versatility of PETG allows for the creation of functional prototypes, end-use parts, and customized components with specific mechanical and thermal properties suited for different applications.Expand Specific Solutions04 Post-processing and surface treatment of PETG structures

Post-processing techniques are employed to enhance the properties and appearance of 3D printed PETG structures. This includes surface treatments such as smoothing, polishing, and coating to improve aesthetics and functionality. Additionally, heat treatment or annealing processes can be applied to optimize mechanical properties and reduce internal stresses in the printed parts.Expand Specific Solutions05 Optimization of 3D printing parameters for PETG

The optimization of 3D printing parameters is crucial for achieving high-quality PETG-based structures. This involves fine-tuning factors such as extrusion temperature, print speed, layer height, and cooling rates. Advanced slicing software and machine learning algorithms are utilized to determine optimal printing conditions, resulting in improved dimensional accuracy, surface finish, and mechanical properties of the printed PETG parts.Expand Specific Solutions

Key 3D Printing Players

The field of 3D printed PETG-based structures is in its early stages of development, with significant potential for growth. The market size is expanding as industries recognize the benefits of PETG in 3D printing applications. While the technology is still evolving, several key players are driving innovation. Companies like KIST Corp., South China University of Technology, and Carnegie Mellon University are conducting pioneering research, while industry leaders such as DePuy Synthes and IBM are exploring practical applications. The involvement of diverse organizations, from academic institutions to major corporations, indicates a growing interest in this technology and suggests a competitive landscape poised for rapid advancement and commercialization.

KIST Corp. (South Korea)

Technical Solution: KIST Corp. has developed advanced 3D printing techniques for PETG-based structures, focusing on improving the material's mechanical properties and printability. They have implemented a novel thermal treatment process that enhances the crystallinity of PETG, resulting in improved strength and durability of the printed structures[1]. Their research also includes the development of PETG-based composites, incorporating nanomaterials to enhance specific properties such as conductivity or flame retardancy[2]. KIST's approach involves optimizing printing parameters, including nozzle temperature, bed temperature, and print speed, to achieve high-quality PETG prints with minimal warping and excellent layer adhesion[3].

Strengths: Advanced material science expertise, innovative thermal treatment processes, and composite material development. Weaknesses: Potential scalability issues for mass production and limited focus on sustainability aspects of PETG printing.

South China University of Technology

Technical Solution: South China University of Technology has made significant strides in 3D printed PETG-based structures, particularly in the field of biomedical applications. Their research focuses on developing PETG-based biocompatible scaffolds for tissue engineering[1]. They have successfully created porous PETG structures with controlled architecture using fused deposition modeling (FDM) techniques[2]. The university's team has also explored surface modification of PETG prints to enhance cell adhesion and proliferation, making them suitable for regenerative medicine applications[3]. Additionally, they have investigated the incorporation of bioactive compounds into PETG filaments to create drug-eluting 3D printed structures for personalized medicine[4].

Strengths: Strong focus on biomedical applications, expertise in scaffold design, and surface modification techniques. Weaknesses: Limited research on large-scale industrial applications of PETG printing beyond the biomedical field.

PETG Innovations Analysis

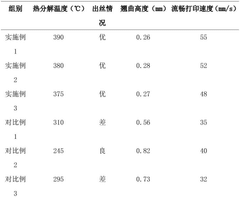

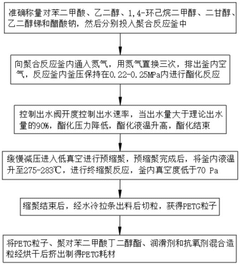

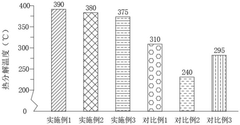

PETG (polyethylene terephthalate glycol) consumable for 3D (three-dimensional) printing and processing method of PETG consumable

PatentInactiveCN118772597A

Innovation

- By adding diethylene glycol and polybutylene terephthalate, combined with a specific polymerization reaction and granulation process, the fluidity and thermal stability of the consumables are improved, ensuring that the material maintains stable performance at high temperatures and avoids deformation and warping. Improve printing speed and quality.

Development of 3D printed cycle

PatentPendingIN202441044771A

Innovation

- Utilization of PETG Carbon Fiber filament for 3D printing, which combines exceptional stiffness, dimensional stability, and surface quality, enabling the creation of strong and lightweight bicycle frames through additive manufacturing, leveraging carbon fibers' high heat treatment properties and compatibility with standard 3D FDM printers.

Sustainability Aspects

The sustainability aspects of 3D printed PETG-based structures are of paramount importance in the context of environmental conservation and resource efficiency. PETG (Polyethylene Terephthalate Glycol-modified) is a thermoplastic polyester that offers several advantages in terms of sustainability compared to traditional materials used in construction and manufacturing.

One of the key sustainability benefits of PETG-based 3D printed structures is their potential for recyclability. PETG can be recycled multiple times without significant degradation of its mechanical properties, which contributes to a circular economy model. This characteristic allows for the reduction of waste and the conservation of raw materials, as used PETG structures can be reprocessed into new products.

Energy efficiency is another crucial aspect of sustainability in 3D printed PETG structures. The additive manufacturing process used in 3D printing typically consumes less energy compared to traditional manufacturing methods, especially for small to medium-scale production. This reduced energy consumption translates to lower carbon emissions and a smaller environmental footprint.

The durability and longevity of PETG-based structures also contribute to their sustainability profile. PETG exhibits excellent resistance to impact, chemicals, and weathering, which means that structures made from this material can have extended lifespans. This durability reduces the need for frequent replacements, thereby conserving resources and minimizing waste generation over time.

Furthermore, the precision of 3D printing technology allows for optimized material usage. Complex geometries can be created with minimal material waste, as the additive process only uses the exact amount of PETG required for the structure. This efficiency in material utilization stands in stark contrast to subtractive manufacturing methods, which often generate significant waste.

The lightweight nature of PETG-based structures offers additional sustainability benefits, particularly in transportation applications. Lighter structures require less energy to move, which can lead to fuel savings and reduced emissions in vehicles or other mobile applications where these structures are employed.

In the context of building and construction, 3D printed PETG structures have the potential to reduce on-site waste and improve construction efficiency. The ability to prefabricate components off-site and assemble them quickly on location can lead to shorter construction times and reduced environmental disturbance at building sites.

However, it is important to note that the sustainability of PETG-based structures is not without challenges. The production of PETG itself relies on petrochemical resources, which are non-renewable. Additionally, while PETG is recyclable, the infrastructure and processes for large-scale recycling of 3D printed PETG structures are still developing.

One of the key sustainability benefits of PETG-based 3D printed structures is their potential for recyclability. PETG can be recycled multiple times without significant degradation of its mechanical properties, which contributes to a circular economy model. This characteristic allows for the reduction of waste and the conservation of raw materials, as used PETG structures can be reprocessed into new products.

Energy efficiency is another crucial aspect of sustainability in 3D printed PETG structures. The additive manufacturing process used in 3D printing typically consumes less energy compared to traditional manufacturing methods, especially for small to medium-scale production. This reduced energy consumption translates to lower carbon emissions and a smaller environmental footprint.

The durability and longevity of PETG-based structures also contribute to their sustainability profile. PETG exhibits excellent resistance to impact, chemicals, and weathering, which means that structures made from this material can have extended lifespans. This durability reduces the need for frequent replacements, thereby conserving resources and minimizing waste generation over time.

Furthermore, the precision of 3D printing technology allows for optimized material usage. Complex geometries can be created with minimal material waste, as the additive process only uses the exact amount of PETG required for the structure. This efficiency in material utilization stands in stark contrast to subtractive manufacturing methods, which often generate significant waste.

The lightweight nature of PETG-based structures offers additional sustainability benefits, particularly in transportation applications. Lighter structures require less energy to move, which can lead to fuel savings and reduced emissions in vehicles or other mobile applications where these structures are employed.

In the context of building and construction, 3D printed PETG structures have the potential to reduce on-site waste and improve construction efficiency. The ability to prefabricate components off-site and assemble them quickly on location can lead to shorter construction times and reduced environmental disturbance at building sites.

However, it is important to note that the sustainability of PETG-based structures is not without challenges. The production of PETG itself relies on petrochemical resources, which are non-renewable. Additionally, while PETG is recyclable, the infrastructure and processes for large-scale recycling of 3D printed PETG structures are still developing.

Regulatory Considerations

The regulatory landscape for 3D printed PETG-based structures is complex and evolving, requiring careful consideration of various aspects to ensure compliance and safety. As this innovative technology gains traction, regulatory bodies are working to develop appropriate frameworks to address the unique challenges posed by 3D printing in general and PETG-based structures in particular.

One of the primary regulatory concerns is the safety and quality of the materials used in 3D printing. PETG (Polyethylene Terephthalate Glycol) is generally considered safe for many applications, but its use in 3D printing may introduce new considerations. Regulatory agencies, such as the FDA in the United States, are likely to scrutinize the composition, purity, and potential leaching of chemicals from PETG-based structures, especially for applications in food contact or medical devices.

Environmental regulations also play a crucial role in the development and adoption of 3D printed PETG-based structures. As sustainability becomes increasingly important, regulators may focus on the recyclability and biodegradability of these structures. Manufacturers may need to demonstrate compliance with waste management and recycling regulations, potentially influencing the design and production processes of PETG-based products.

In the context of consumer products, regulatory bodies may impose standards for mechanical properties, durability, and fire resistance of 3D printed PETG structures. This could involve rigorous testing protocols to ensure that these structures meet or exceed the performance criteria of traditionally manufactured counterparts. Additionally, labeling requirements may be implemented to inform consumers about the nature of the 3D printed product and any specific care instructions.

For medical applications, regulatory hurdles are particularly stringent. 3D printed PETG-based medical devices or implants would likely require extensive clinical trials and safety evaluations before gaining approval from agencies like the FDA or EMA. Manufacturers would need to demonstrate biocompatibility, sterility, and long-term stability of these structures in physiological environments.

Intellectual property considerations also intersect with regulatory frameworks. As 3D printing enables easier replication of designs, regulators may need to address issues of copyright infringement and establish guidelines for the protection of patented designs in the context of 3D printed PETG structures.

Standardization efforts are likely to emerge as the technology matures. Organizations such as ISO and ASTM may develop specific standards for 3D printed PETG structures, covering aspects like material specifications, printing processes, and quality control measures. Compliance with these standards could become a regulatory requirement in various jurisdictions.

As the field of 3D printed PETG-based structures continues to advance, it is crucial for researchers and manufacturers to stay abreast of evolving regulations and actively engage with regulatory bodies to shape appropriate guidelines. This proactive approach will be essential in navigating the complex regulatory landscape and ensuring the successful development and commercialization of innovative PETG-based 3D printed products.

One of the primary regulatory concerns is the safety and quality of the materials used in 3D printing. PETG (Polyethylene Terephthalate Glycol) is generally considered safe for many applications, but its use in 3D printing may introduce new considerations. Regulatory agencies, such as the FDA in the United States, are likely to scrutinize the composition, purity, and potential leaching of chemicals from PETG-based structures, especially for applications in food contact or medical devices.

Environmental regulations also play a crucial role in the development and adoption of 3D printed PETG-based structures. As sustainability becomes increasingly important, regulators may focus on the recyclability and biodegradability of these structures. Manufacturers may need to demonstrate compliance with waste management and recycling regulations, potentially influencing the design and production processes of PETG-based products.

In the context of consumer products, regulatory bodies may impose standards for mechanical properties, durability, and fire resistance of 3D printed PETG structures. This could involve rigorous testing protocols to ensure that these structures meet or exceed the performance criteria of traditionally manufactured counterparts. Additionally, labeling requirements may be implemented to inform consumers about the nature of the 3D printed product and any specific care instructions.

For medical applications, regulatory hurdles are particularly stringent. 3D printed PETG-based medical devices or implants would likely require extensive clinical trials and safety evaluations before gaining approval from agencies like the FDA or EMA. Manufacturers would need to demonstrate biocompatibility, sterility, and long-term stability of these structures in physiological environments.

Intellectual property considerations also intersect with regulatory frameworks. As 3D printing enables easier replication of designs, regulators may need to address issues of copyright infringement and establish guidelines for the protection of patented designs in the context of 3D printed PETG structures.

Standardization efforts are likely to emerge as the technology matures. Organizations such as ISO and ASTM may develop specific standards for 3D printed PETG structures, covering aspects like material specifications, printing processes, and quality control measures. Compliance with these standards could become a regulatory requirement in various jurisdictions.

As the field of 3D printed PETG-based structures continues to advance, it is crucial for researchers and manufacturers to stay abreast of evolving regulations and actively engage with regulatory bodies to shape appropriate guidelines. This proactive approach will be essential in navigating the complex regulatory landscape and ensuring the successful development and commercialization of innovative PETG-based 3D printed products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!