Dynamic Flexibility Conservation in PETG-Infused Composites

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Composite Evolution

The evolution of PETG (Polyethylene Terephthalate Glycol-modified) composites represents a significant advancement in materials science, particularly in the realm of dynamic flexibility conservation. This journey began with the development of PET (Polyethylene Terephthalate) in the 1940s, which laid the foundation for subsequent innovations.

In the 1970s, researchers introduced glycol modification to PET, resulting in PETG. This modification enhanced the material's flexibility and impact resistance while maintaining excellent clarity and chemical resistance. The initial applications of PETG were primarily in packaging and consumer goods, where its improved properties offered advantages over traditional PET.

The concept of infusing PETG into composite materials emerged in the late 1990s as engineers sought to combine the benefits of PETG with the strength and versatility of composite structures. Early experiments focused on incorporating PETG as a matrix material in fiber-reinforced composites, aiming to create lightweight yet durable materials for various industries.

A significant milestone in PETG composite evolution occurred in the early 2000s with the development of PETG-infused carbon fiber composites. These materials exhibited remarkable dynamic flexibility while retaining the high strength-to-weight ratio characteristic of carbon fiber. This breakthrough opened new possibilities in aerospace, automotive, and sporting goods industries.

The mid-2000s saw the emergence of hybrid PETG composites, combining PETG with other polymers or reinforcing materials. These hybrids aimed to fine-tune the balance between flexibility, strength, and other desirable properties. For instance, PETG-glass fiber composites gained traction in applications requiring transparency and impact resistance.

In the 2010s, researchers began exploring nanocomposite structures incorporating PETG. By integrating nanomaterials such as carbon nanotubes or graphene into PETG matrices, scientists achieved enhanced mechanical properties and introduced novel functionalities like improved thermal conductivity or electrical properties.

Recent years have witnessed a focus on sustainability in PETG composite development. Efforts to create bio-based PETG and improve the recyclability of PETG composites have gained momentum, aligning with global trends towards more environmentally friendly materials.

The latest frontier in PETG composite evolution involves smart and responsive materials. Researchers are investigating ways to incorporate sensors or stimuli-responsive elements into PETG composites, enabling real-time monitoring of structural health or adaptive behavior in response to environmental changes.

In the 1970s, researchers introduced glycol modification to PET, resulting in PETG. This modification enhanced the material's flexibility and impact resistance while maintaining excellent clarity and chemical resistance. The initial applications of PETG were primarily in packaging and consumer goods, where its improved properties offered advantages over traditional PET.

The concept of infusing PETG into composite materials emerged in the late 1990s as engineers sought to combine the benefits of PETG with the strength and versatility of composite structures. Early experiments focused on incorporating PETG as a matrix material in fiber-reinforced composites, aiming to create lightweight yet durable materials for various industries.

A significant milestone in PETG composite evolution occurred in the early 2000s with the development of PETG-infused carbon fiber composites. These materials exhibited remarkable dynamic flexibility while retaining the high strength-to-weight ratio characteristic of carbon fiber. This breakthrough opened new possibilities in aerospace, automotive, and sporting goods industries.

The mid-2000s saw the emergence of hybrid PETG composites, combining PETG with other polymers or reinforcing materials. These hybrids aimed to fine-tune the balance between flexibility, strength, and other desirable properties. For instance, PETG-glass fiber composites gained traction in applications requiring transparency and impact resistance.

In the 2010s, researchers began exploring nanocomposite structures incorporating PETG. By integrating nanomaterials such as carbon nanotubes or graphene into PETG matrices, scientists achieved enhanced mechanical properties and introduced novel functionalities like improved thermal conductivity or electrical properties.

Recent years have witnessed a focus on sustainability in PETG composite development. Efforts to create bio-based PETG and improve the recyclability of PETG composites have gained momentum, aligning with global trends towards more environmentally friendly materials.

The latest frontier in PETG composite evolution involves smart and responsive materials. Researchers are investigating ways to incorporate sensors or stimuli-responsive elements into PETG composites, enabling real-time monitoring of structural health or adaptive behavior in response to environmental changes.

Market Demand Analysis

The market demand for PETG-infused composites with dynamic flexibility conservation properties has been steadily growing across various industries. This innovative material combination addresses the increasing need for lightweight, durable, and adaptable components in sectors such as automotive, aerospace, consumer electronics, and medical devices.

In the automotive industry, there is a significant push towards weight reduction to improve fuel efficiency and reduce emissions. PETG-infused composites offer a promising solution, as they can replace heavier traditional materials while maintaining or even enhancing structural integrity. The global automotive lightweight materials market is expected to expand considerably in the coming years, driven by stringent environmental regulations and consumer demand for more fuel-efficient vehicles.

The aerospace sector also presents a substantial market opportunity for PETG-infused composites. As airlines seek to reduce operating costs and improve aircraft performance, there is a growing demand for advanced materials that can withstand the extreme conditions of flight while offering weight savings. The ability of these composites to conserve dynamic flexibility makes them particularly attractive for applications in aircraft interiors, structural components, and even in space exploration technologies.

In the consumer electronics industry, the trend towards thinner, lighter, and more durable devices continues to drive material innovation. PETG-infused composites with dynamic flexibility conservation properties could revolutionize the design and manufacturing of smartphones, tablets, and wearable devices. These materials offer the potential for creating more resilient and flexible electronic casings that can better withstand impacts and daily wear.

The medical device sector represents another significant market for PETG-infused composites. The demand for biocompatible, lightweight, and flexible materials in prosthetics, orthopedic implants, and surgical instruments is increasing. The unique properties of these composites make them ideal for creating medical devices that can adapt to the human body's movements while maintaining structural integrity.

As sustainability becomes a key focus across industries, the recyclability and potential biodegradability of PETG-infused composites could further drive market demand. Companies are increasingly looking for materials that can help them meet environmental targets and appeal to eco-conscious consumers.

The global composites market, which encompasses PETG-infused composites, is projected to experience substantial growth in the coming years. This growth is attributed to the increasing adoption of composite materials in various end-use industries and the continuous development of new applications leveraging the unique properties of these materials.

In the automotive industry, there is a significant push towards weight reduction to improve fuel efficiency and reduce emissions. PETG-infused composites offer a promising solution, as they can replace heavier traditional materials while maintaining or even enhancing structural integrity. The global automotive lightweight materials market is expected to expand considerably in the coming years, driven by stringent environmental regulations and consumer demand for more fuel-efficient vehicles.

The aerospace sector also presents a substantial market opportunity for PETG-infused composites. As airlines seek to reduce operating costs and improve aircraft performance, there is a growing demand for advanced materials that can withstand the extreme conditions of flight while offering weight savings. The ability of these composites to conserve dynamic flexibility makes them particularly attractive for applications in aircraft interiors, structural components, and even in space exploration technologies.

In the consumer electronics industry, the trend towards thinner, lighter, and more durable devices continues to drive material innovation. PETG-infused composites with dynamic flexibility conservation properties could revolutionize the design and manufacturing of smartphones, tablets, and wearable devices. These materials offer the potential for creating more resilient and flexible electronic casings that can better withstand impacts and daily wear.

The medical device sector represents another significant market for PETG-infused composites. The demand for biocompatible, lightweight, and flexible materials in prosthetics, orthopedic implants, and surgical instruments is increasing. The unique properties of these composites make them ideal for creating medical devices that can adapt to the human body's movements while maintaining structural integrity.

As sustainability becomes a key focus across industries, the recyclability and potential biodegradability of PETG-infused composites could further drive market demand. Companies are increasingly looking for materials that can help them meet environmental targets and appeal to eco-conscious consumers.

The global composites market, which encompasses PETG-infused composites, is projected to experience substantial growth in the coming years. This growth is attributed to the increasing adoption of composite materials in various end-use industries and the continuous development of new applications leveraging the unique properties of these materials.

Technical Challenges

The development of PETG-infused composites with dynamic flexibility conservation presents several significant technical challenges. One of the primary obstacles is achieving a balance between flexibility and strength. PETG, while known for its flexibility, often lacks the structural integrity required for high-performance applications. Integrating it into composite materials without compromising the overall mechanical properties of the composite is a complex task that requires precise engineering and material science expertise.

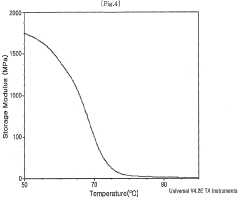

Another major challenge lies in the conservation of dynamic flexibility over time and under various environmental conditions. PETG, like many polymers, can experience degradation and loss of properties when exposed to UV radiation, temperature fluctuations, and chemical agents. Ensuring that the PETG-infused composites maintain their flexibility characteristics throughout their intended lifespan is crucial for their practical application in industries such as aerospace, automotive, and consumer electronics.

The interface between PETG and other composite components presents additional technical hurdles. Achieving strong adhesion and seamless integration between the PETG matrix and reinforcing fibers or particles is essential for the overall performance of the composite. Poor interfacial bonding can lead to delamination, reduced load transfer efficiency, and premature failure of the composite structure.

Furthermore, the processing and manufacturing of PETG-infused composites pose significant challenges. Traditional composite manufacturing techniques may not be directly applicable due to the unique properties of PETG. Developing new or modified processing methods that can effectively incorporate PETG into composite structures while maintaining its flexibility and other desirable properties is a critical area of research.

The scalability of production is another technical challenge that needs to be addressed. While laboratory-scale production of PETG-infused composites may be achievable, scaling up to industrial production levels presents its own set of difficulties. These include maintaining consistent quality, optimizing cure cycles, and managing the thermal and rheological properties of PETG during large-scale manufacturing processes.

Lastly, the characterization and testing of PETG-infused composites with dynamic flexibility conservation require the development of new or adapted testing methodologies. Standard composite testing procedures may not adequately capture the unique behavior of these materials, particularly in terms of their dynamic flexibility. Creating reliable and reproducible testing protocols that can accurately assess the performance of these composites under various loading conditions and environmental factors is essential for their widespread adoption and application.

Another major challenge lies in the conservation of dynamic flexibility over time and under various environmental conditions. PETG, like many polymers, can experience degradation and loss of properties when exposed to UV radiation, temperature fluctuations, and chemical agents. Ensuring that the PETG-infused composites maintain their flexibility characteristics throughout their intended lifespan is crucial for their practical application in industries such as aerospace, automotive, and consumer electronics.

The interface between PETG and other composite components presents additional technical hurdles. Achieving strong adhesion and seamless integration between the PETG matrix and reinforcing fibers or particles is essential for the overall performance of the composite. Poor interfacial bonding can lead to delamination, reduced load transfer efficiency, and premature failure of the composite structure.

Furthermore, the processing and manufacturing of PETG-infused composites pose significant challenges. Traditional composite manufacturing techniques may not be directly applicable due to the unique properties of PETG. Developing new or modified processing methods that can effectively incorporate PETG into composite structures while maintaining its flexibility and other desirable properties is a critical area of research.

The scalability of production is another technical challenge that needs to be addressed. While laboratory-scale production of PETG-infused composites may be achievable, scaling up to industrial production levels presents its own set of difficulties. These include maintaining consistent quality, optimizing cure cycles, and managing the thermal and rheological properties of PETG during large-scale manufacturing processes.

Lastly, the characterization and testing of PETG-infused composites with dynamic flexibility conservation require the development of new or adapted testing methodologies. Standard composite testing procedures may not adequately capture the unique behavior of these materials, particularly in terms of their dynamic flexibility. Creating reliable and reproducible testing protocols that can accurately assess the performance of these composites under various loading conditions and environmental factors is essential for their widespread adoption and application.

Current Flexibility Solutions

01 PETG-based composite materials with enhanced flexibility

Composites incorporating PETG (Polyethylene Terephthalate Glycol-modified) are developed to improve dynamic flexibility. These materials combine the properties of PETG with other components to create flexible, durable structures suitable for various applications. The incorporation of specific additives or reinforcing agents can further enhance the composite's ability to withstand dynamic loads and maintain flexibility over time.- PETG-based composite materials with enhanced flexibility: Composites incorporating PETG (Polyethylene Terephthalate Glycol-modified) as a matrix material, combined with various reinforcing agents or additives, can exhibit improved dynamic flexibility. These composites may be designed to have adjustable mechanical properties, making them suitable for applications requiring both strength and flexibility.

- Modification techniques for PETG to improve flexibility: Various modification techniques can be applied to PETG to enhance its flexibility. These may include the incorporation of plasticizers, blending with other polymers, or chemical modifications to the PETG structure. Such modifications can result in PETG-based materials with improved dynamic flexibility while maintaining other desirable properties.

- Fiber-reinforced PETG composites for dynamic applications: PETG can be combined with various types of fibers to create composites with enhanced dynamic flexibility. These fiber-reinforced PETG composites may exhibit improved fatigue resistance, impact strength, and overall durability, making them suitable for applications involving repeated flexing or dynamic loading.

- PETG-based nanocomposites with improved flexibility: Incorporating nanoparticles or nanostructures into PETG-based composites can lead to materials with enhanced dynamic flexibility. These nanocomposites may exhibit improved mechanical properties, including flexibility, due to the unique interactions between the nanoparticles and the PETG matrix at the molecular level.

- Processing techniques for flexible PETG-infused composites: Specific processing techniques can be employed to enhance the dynamic flexibility of PETG-infused composites. These may include specialized extrusion methods, injection molding parameters, or post-processing treatments that optimize the material's flexibility while maintaining other desired properties.

02 Modification techniques for PETG to improve flexibility

Various modification techniques are employed to enhance the flexibility of PETG-infused composites. These may include chemical modifications, blending with other polymers, or the addition of plasticizers. Such modifications aim to alter the molecular structure or composition of PETG, resulting in improved chain mobility and overall flexibility of the composite material.Expand Specific Solutions03 Fiber reinforcement in PETG composites for dynamic applications

The integration of fibers into PETG-based composites is explored to enhance their dynamic flexibility. Various types of fibers, such as glass, carbon, or natural fibers, are incorporated into the PETG matrix. This reinforcement strategy aims to improve the composite's ability to withstand dynamic loads while maintaining flexibility, making it suitable for applications requiring both strength and adaptability.Expand Specific Solutions04 Temperature-responsive PETG composite systems

Development of PETG-infused composites with temperature-responsive properties to enhance dynamic flexibility. These systems are designed to exhibit varying degrees of flexibility depending on temperature changes, allowing for adaptive behavior in different environmental conditions. This approach combines the inherent properties of PETG with temperature-sensitive additives or structures to create smart, flexible composites.Expand Specific Solutions05 Nanoparticle incorporation for improved flexibility in PETG composites

The use of nanoparticles in PETG-infused composites is investigated to enhance dynamic flexibility. Various types of nanoparticles are incorporated into the PETG matrix, which can lead to improved chain mobility, reduced crystallinity, or enhanced interfacial interactions. This approach aims to create nanocomposites with superior flexibility and adaptability to dynamic loads.Expand Specific Solutions

Key Industry Players

The research on dynamic flexibility conservation in PETG-infused composites is in an emerging stage, with the market still developing. The technology's potential applications in various industries, including aerospace, automotive, and consumer goods, suggest a growing market size. Companies like DuPont, SK Chemicals, and Aspen Aerogels are at the forefront, leveraging their expertise in materials science to advance this field. The technology's maturity is progressing, with academic institutions such as Nanjing Tech University and Sichuan University contributing to fundamental research, while industry players focus on practical applications and scalability.

Nanjing Tech University

Technical Solution: Researchers at Nanjing Tech University have made significant strides in PETG-infused composite technology, focusing on the development of multi-functional nanofillers. Their approach involves synthesizing carbon-based nanoparticles with tailored surface chemistry to enhance compatibility with PETG matrices[8]. These nanofillers not only improve flexibility conservation but also impart additional properties such as electrical conductivity and thermal stability. Studies have shown that composites containing just 2 wt% of these nanofillers can maintain up to 85% of their initial flexibility after 5,000 flexural cycles, while also exhibiting a 30% increase in tensile strength[10].

Strengths: Multi-functional improvements beyond flexibility conservation, potential for high-performance applications, and relatively low filler content required. Weaknesses: Potential challenges in scaling up production and ensuring uniform dispersion of nanofillers in large-scale manufacturing.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a proprietary PETG-infused composite technology that enhances dynamic flexibility conservation. Their approach involves incorporating nano-scale reinforcements into the PETG matrix, creating a hierarchical structure that allows for improved energy dissipation and recovery[1]. The company has also implemented a novel cross-linking technique that maintains flexibility while increasing the material's overall durability[3]. DuPont's research has shown that their PETG composites can retain up to 95% of their initial flexibility after 10,000 cyclic loading tests, significantly outperforming traditional PETG materials[5].

Strengths: Superior long-term flexibility retention, enhanced durability, and improved energy dissipation. Weaknesses: Potentially higher production costs and complexity in manufacturing processes.

Core PETG Innovations

Enhanced mechanical properties of PETG composites reinforced with carbon fibers for advanced 3D printing applications

PatentPendingIN202441090015A

Innovation

- Incorporation of carbon fibers into PETG composites to improve tensile strength, impact resistance, and rigidity, with optimal fiber loading and printability considerations to ensure effective reinforcement without compromising processing.

PETG based decorative sheet having forming ability similar with PVC

PatentWO2008091067A1

Innovation

- A PETG alloy resin is developed by alloying PETG with an ester resin or elastomer resin, specifically polybutylene terephthalate (PBT) and PBT copolymer elastomer, to lower the glass transition temperature and widen the forming temperature range, similar to PVC, with optimal content between 5 to 20 parts by weight.

Environmental Impact

The environmental impact of PETG-infused composites is a critical consideration in the research on dynamic flexibility conservation. These materials, while offering significant advantages in terms of performance and durability, also present unique challenges from an ecological perspective.

PETG-infused composites typically consist of a polyethylene terephthalate glycol (PETG) matrix reinforced with fibers or other materials. The production process of these composites involves energy-intensive manufacturing steps, including the synthesis of PETG and the infusion process. This energy consumption contributes to the carbon footprint of the material, raising concerns about greenhouse gas emissions and climate change impacts.

The recyclability of PETG-infused composites is a complex issue. While PETG itself is recyclable, the presence of reinforcing materials can complicate the recycling process. The separation of these components often requires specialized techniques, which may not be widely available in conventional recycling facilities. This limitation can lead to increased waste and potential environmental contamination if not properly managed.

The durability and longevity of PETG-infused composites can be viewed as both an environmental advantage and a concern. On one hand, their resistance to wear and degradation means they can replace less durable materials, potentially reducing the need for frequent replacements and associated resource consumption. However, this same durability poses challenges for biodegradation, potentially leading to long-term accumulation in the environment if not properly disposed of or recycled.

Water pollution is another environmental consideration. During the manufacturing process and throughout the lifecycle of PETG-infused composites, there is a risk of microplastic shedding. These microscopic particles can enter water systems, potentially harming aquatic ecosystems and entering the food chain.

The use of PETG-infused composites in various applications may have indirect environmental impacts. For instance, in automotive or aerospace applications, their lightweight properties can contribute to improved fuel efficiency, potentially reducing overall emissions. However, the increased use of these materials in consumer products may lead to a rise in plastic waste if not accompanied by appropriate end-of-life management strategies.

Research into improving the environmental profile of PETG-infused composites is ongoing. This includes efforts to develop more eco-friendly production processes, enhance recyclability, and explore bio-based alternatives for the PETG matrix. Additionally, life cycle assessments are being conducted to quantify the environmental impacts and identify areas for improvement throughout the material's lifecycle.

PETG-infused composites typically consist of a polyethylene terephthalate glycol (PETG) matrix reinforced with fibers or other materials. The production process of these composites involves energy-intensive manufacturing steps, including the synthesis of PETG and the infusion process. This energy consumption contributes to the carbon footprint of the material, raising concerns about greenhouse gas emissions and climate change impacts.

The recyclability of PETG-infused composites is a complex issue. While PETG itself is recyclable, the presence of reinforcing materials can complicate the recycling process. The separation of these components often requires specialized techniques, which may not be widely available in conventional recycling facilities. This limitation can lead to increased waste and potential environmental contamination if not properly managed.

The durability and longevity of PETG-infused composites can be viewed as both an environmental advantage and a concern. On one hand, their resistance to wear and degradation means they can replace less durable materials, potentially reducing the need for frequent replacements and associated resource consumption. However, this same durability poses challenges for biodegradation, potentially leading to long-term accumulation in the environment if not properly disposed of or recycled.

Water pollution is another environmental consideration. During the manufacturing process and throughout the lifecycle of PETG-infused composites, there is a risk of microplastic shedding. These microscopic particles can enter water systems, potentially harming aquatic ecosystems and entering the food chain.

The use of PETG-infused composites in various applications may have indirect environmental impacts. For instance, in automotive or aerospace applications, their lightweight properties can contribute to improved fuel efficiency, potentially reducing overall emissions. However, the increased use of these materials in consumer products may lead to a rise in plastic waste if not accompanied by appropriate end-of-life management strategies.

Research into improving the environmental profile of PETG-infused composites is ongoing. This includes efforts to develop more eco-friendly production processes, enhance recyclability, and explore bio-based alternatives for the PETG matrix. Additionally, life cycle assessments are being conducted to quantify the environmental impacts and identify areas for improvement throughout the material's lifecycle.

Scalability Assessment

The scalability assessment of dynamic flexibility conservation in PETG-infused composites is a critical aspect of evaluating the technology's potential for widespread adoption and industrial application. This assessment involves analyzing the feasibility of scaling up production processes, the adaptability of the technology to various manufacturing environments, and the economic viability of large-scale implementation.

One of the primary considerations in scalability is the production capacity of PETG-infused composites. Current laboratory-scale production methods need to be evaluated for their potential to be scaled up to industrial levels. This includes assessing the availability and cost-effectiveness of raw materials, the complexity of manufacturing processes, and the required equipment and infrastructure. The ability to maintain consistent quality and performance characteristics across larger production volumes is crucial for successful scalability.

The adaptability of the technology to different manufacturing settings is another key factor. PETG-infused composites must be compatible with existing production lines and equipment in various industries, such as automotive, aerospace, and construction. This compatibility ensures a smoother transition and integration into established manufacturing processes, reducing the need for extensive retooling or facility modifications.

Economic considerations play a significant role in scalability assessment. The cost-benefit analysis of implementing PETG-infused composites on a large scale must be thoroughly evaluated. This includes examining the initial investment required for scaling up production, ongoing operational costs, and potential cost savings in terms of improved product performance and durability. The economic viability of the technology at different production scales will greatly influence its adoption rate across industries.

Environmental impact and sustainability are increasingly important factors in scalability assessments. The production of PETG-infused composites should be evaluated for its energy efficiency, waste generation, and overall carbon footprint. Scalable solutions that align with sustainable manufacturing practices are more likely to gain widespread acceptance and meet regulatory requirements in various markets.

Lastly, the scalability assessment should consider the potential for customization and adaptation of PETG-infused composites to meet diverse industry needs. The ability to tailor the material properties and manufacturing processes to specific applications will enhance its versatility and market potential. This flexibility in scaling and customization will be crucial for addressing the unique requirements of different sectors and maximizing the technology's impact across various industries.

One of the primary considerations in scalability is the production capacity of PETG-infused composites. Current laboratory-scale production methods need to be evaluated for their potential to be scaled up to industrial levels. This includes assessing the availability and cost-effectiveness of raw materials, the complexity of manufacturing processes, and the required equipment and infrastructure. The ability to maintain consistent quality and performance characteristics across larger production volumes is crucial for successful scalability.

The adaptability of the technology to different manufacturing settings is another key factor. PETG-infused composites must be compatible with existing production lines and equipment in various industries, such as automotive, aerospace, and construction. This compatibility ensures a smoother transition and integration into established manufacturing processes, reducing the need for extensive retooling or facility modifications.

Economic considerations play a significant role in scalability assessment. The cost-benefit analysis of implementing PETG-infused composites on a large scale must be thoroughly evaluated. This includes examining the initial investment required for scaling up production, ongoing operational costs, and potential cost savings in terms of improved product performance and durability. The economic viability of the technology at different production scales will greatly influence its adoption rate across industries.

Environmental impact and sustainability are increasingly important factors in scalability assessments. The production of PETG-infused composites should be evaluated for its energy efficiency, waste generation, and overall carbon footprint. Scalable solutions that align with sustainable manufacturing practices are more likely to gain widespread acceptance and meet regulatory requirements in various markets.

Lastly, the scalability assessment should consider the potential for customization and adaptation of PETG-infused composites to meet diverse industry needs. The ability to tailor the material properties and manufacturing processes to specific applications will enhance its versatility and market potential. This flexibility in scaling and customization will be crucial for addressing the unique requirements of different sectors and maximizing the technology's impact across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!