How Polysilane Enables Low-Power Electronic Applications?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Background

Polysilanes are a class of silicon-based polymers with a backbone consisting of silicon atoms covalently bonded to each other. These materials have garnered significant attention in the field of electronics due to their unique electronic and optical properties. The history of polysilanes dates back to the 1920s when they were first synthesized, but their potential for electronic applications was not fully realized until the 1980s.

The structure of polysilanes consists of a linear or branched chain of silicon atoms, each typically bonded to two organic side groups. This structure gives rise to σ-conjugation along the silicon backbone, which is responsible for many of the interesting properties of polysilanes. Unlike traditional carbon-based polymers, the σ-conjugation in polysilanes allows for efficient electron delocalization, leading to enhanced electrical conductivity and unique optical characteristics.

One of the key features that make polysilanes attractive for low-power electronic applications is their low bandgap. The bandgap of a material is the energy difference between the valence band and the conduction band, and it determines the material's electrical and optical properties. Polysilanes typically have bandgaps in the range of 3-4 eV, which is lower than many traditional semiconductors. This lower bandgap facilitates easier electron excitation and transport, potentially reducing the power requirements for electronic devices.

Another important aspect of polysilanes is their high charge carrier mobility. Mobility refers to how quickly charge carriers (electrons or holes) can move through a material when an electric field is applied. The σ-conjugated backbone of polysilanes allows for efficient charge transport, resulting in mobilities that can be orders of magnitude higher than those of conventional organic semiconductors. This high mobility is crucial for developing low-power electronic devices, as it enables faster switching speeds and lower operating voltages.

Polysilanes also exhibit interesting photophysical properties, including photoconductivity and electroluminescence. When exposed to light, polysilanes can generate charge carriers, making them suitable for photovoltaic applications. Additionally, their ability to emit light when electrically stimulated opens up possibilities in display technologies and solid-state lighting.

The synthesis of polysilanes has evolved significantly since their discovery. Modern synthetic methods allow for precise control over molecular weight, polydispersity, and side-group functionalization. This level of control is essential for tailoring the properties of polysilanes to specific electronic applications, enabling the development of materials with optimized performance characteristics for low-power devices.

In recent years, research into polysilanes has expanded to include their integration with other materials, such as nanoparticles and carbon nanotubes, to create hybrid systems with enhanced properties. These hybrid materials show promise in further improving the efficiency and performance of low-power electronic devices.

The structure of polysilanes consists of a linear or branched chain of silicon atoms, each typically bonded to two organic side groups. This structure gives rise to σ-conjugation along the silicon backbone, which is responsible for many of the interesting properties of polysilanes. Unlike traditional carbon-based polymers, the σ-conjugation in polysilanes allows for efficient electron delocalization, leading to enhanced electrical conductivity and unique optical characteristics.

One of the key features that make polysilanes attractive for low-power electronic applications is their low bandgap. The bandgap of a material is the energy difference between the valence band and the conduction band, and it determines the material's electrical and optical properties. Polysilanes typically have bandgaps in the range of 3-4 eV, which is lower than many traditional semiconductors. This lower bandgap facilitates easier electron excitation and transport, potentially reducing the power requirements for electronic devices.

Another important aspect of polysilanes is their high charge carrier mobility. Mobility refers to how quickly charge carriers (electrons or holes) can move through a material when an electric field is applied. The σ-conjugated backbone of polysilanes allows for efficient charge transport, resulting in mobilities that can be orders of magnitude higher than those of conventional organic semiconductors. This high mobility is crucial for developing low-power electronic devices, as it enables faster switching speeds and lower operating voltages.

Polysilanes also exhibit interesting photophysical properties, including photoconductivity and electroluminescence. When exposed to light, polysilanes can generate charge carriers, making them suitable for photovoltaic applications. Additionally, their ability to emit light when electrically stimulated opens up possibilities in display technologies and solid-state lighting.

The synthesis of polysilanes has evolved significantly since their discovery. Modern synthetic methods allow for precise control over molecular weight, polydispersity, and side-group functionalization. This level of control is essential for tailoring the properties of polysilanes to specific electronic applications, enabling the development of materials with optimized performance characteristics for low-power devices.

In recent years, research into polysilanes has expanded to include their integration with other materials, such as nanoparticles and carbon nanotubes, to create hybrid systems with enhanced properties. These hybrid materials show promise in further improving the efficiency and performance of low-power electronic devices.

Low-Power Electronics Market

The low-power electronics market has experienced significant growth in recent years, driven by the increasing demand for energy-efficient devices across various industries. This market segment encompasses a wide range of applications, including portable consumer electronics, Internet of Things (IoT) devices, wearable technology, and industrial sensors. The global low-power electronics market is expected to continue its upward trajectory, with projections indicating substantial expansion in the coming years.

One of the key factors fueling market growth is the rising adoption of mobile and portable devices. Smartphones, tablets, and wearables have become ubiquitous, creating a strong demand for components that can operate efficiently while consuming minimal power. This trend has led to innovations in low-power processors, memory modules, and display technologies, all of which contribute to extended battery life and improved device performance.

The IoT sector has emerged as a major driver for low-power electronics. As the number of connected devices continues to proliferate, there is an increasing need for sensors, microcontrollers, and communication modules that can operate on minimal power. This is particularly crucial for remote or hard-to-reach IoT deployments where frequent battery replacements are impractical or costly.

In the industrial sector, low-power electronics are gaining traction in applications such as smart manufacturing, asset tracking, and environmental monitoring. These devices often need to operate in harsh environments for extended periods without maintenance, making power efficiency a critical requirement. The adoption of low-power solutions in industrial settings is expected to accelerate as more companies embrace digital transformation and Industry 4.0 initiatives.

The automotive industry represents another significant market for low-power electronics. With the increasing electrification of vehicles and the development of advanced driver assistance systems (ADAS), there is a growing demand for power-efficient components that can help extend the range of electric vehicles and reduce overall energy consumption. This trend is likely to intensify as the automotive sector continues its shift towards electric and autonomous vehicles.

Geographically, Asia-Pacific is expected to be a key growth region for the low-power electronics market, driven by the presence of major semiconductor manufacturers, a large consumer electronics industry, and rapid IoT adoption. North America and Europe are also significant markets, with strong demand coming from sectors such as healthcare, aerospace, and defense.

As the market expands, there is an ongoing focus on developing new materials and technologies that can further reduce power consumption while improving performance. This is where innovations like polysilane-based electronics come into play, offering potential solutions to meet the ever-increasing demands of the low-power electronics market.

One of the key factors fueling market growth is the rising adoption of mobile and portable devices. Smartphones, tablets, and wearables have become ubiquitous, creating a strong demand for components that can operate efficiently while consuming minimal power. This trend has led to innovations in low-power processors, memory modules, and display technologies, all of which contribute to extended battery life and improved device performance.

The IoT sector has emerged as a major driver for low-power electronics. As the number of connected devices continues to proliferate, there is an increasing need for sensors, microcontrollers, and communication modules that can operate on minimal power. This is particularly crucial for remote or hard-to-reach IoT deployments where frequent battery replacements are impractical or costly.

In the industrial sector, low-power electronics are gaining traction in applications such as smart manufacturing, asset tracking, and environmental monitoring. These devices often need to operate in harsh environments for extended periods without maintenance, making power efficiency a critical requirement. The adoption of low-power solutions in industrial settings is expected to accelerate as more companies embrace digital transformation and Industry 4.0 initiatives.

The automotive industry represents another significant market for low-power electronics. With the increasing electrification of vehicles and the development of advanced driver assistance systems (ADAS), there is a growing demand for power-efficient components that can help extend the range of electric vehicles and reduce overall energy consumption. This trend is likely to intensify as the automotive sector continues its shift towards electric and autonomous vehicles.

Geographically, Asia-Pacific is expected to be a key growth region for the low-power electronics market, driven by the presence of major semiconductor manufacturers, a large consumer electronics industry, and rapid IoT adoption. North America and Europe are also significant markets, with strong demand coming from sectors such as healthcare, aerospace, and defense.

As the market expands, there is an ongoing focus on developing new materials and technologies that can further reduce power consumption while improving performance. This is where innovations like polysilane-based electronics come into play, offering potential solutions to meet the ever-increasing demands of the low-power electronics market.

Polysilane Properties

Polysilanes are a class of silicon-based polymers with a backbone consisting of silicon atoms covalently bonded to each other. These unique materials possess several distinctive properties that make them promising candidates for low-power electronic applications. One of the most notable characteristics of polysilanes is their high electron mobility, which allows for efficient charge transport within the material. This property is particularly advantageous in the development of low-power electronic devices, as it enables faster switching speeds and reduced energy consumption.

The optical properties of polysilanes are another key feature that contributes to their potential in low-power electronics. These materials exhibit strong UV absorption and photoluminescence, making them suitable for use in optoelectronic devices such as light-emitting diodes (LEDs) and photovoltaic cells. The ability to tune the optical properties of polysilanes through structural modifications further enhances their versatility in various electronic applications.

Polysilanes also demonstrate excellent thermal stability, which is crucial for maintaining device performance under varying temperature conditions. This stability ensures that electronic components based on polysilanes can operate reliably in a wide range of environments without significant degradation. Additionally, the low dielectric constant of polysilanes contributes to reduced power consumption in electronic circuits by minimizing parasitic capacitance and signal loss.

The processability of polysilanes is another advantageous property that facilitates their integration into electronic devices. These materials can be easily solution-processed, allowing for cost-effective and scalable manufacturing techniques such as spin-coating or inkjet printing. This characteristic is particularly beneficial for the production of flexible and large-area electronic devices, which are increasingly in demand for low-power applications.

Furthermore, polysilanes exhibit unique electronic band structures that can be tailored through molecular design. By adjusting the side groups attached to the silicon backbone, researchers can fine-tune the electronic properties of polysilanes to suit specific applications. This flexibility in molecular engineering allows for the optimization of charge transport and energy levels, leading to improved efficiency in low-power electronic devices.

The chemical stability of polysilanes is another property that contributes to their suitability for electronic applications. These materials are resistant to oxidation and degradation under normal operating conditions, ensuring long-term reliability of electronic components. This stability also simplifies the fabrication process, as polysilanes can withstand various processing steps without significant chemical alterations.

In summary, the combination of high electron mobility, tunable optical properties, thermal stability, low dielectric constant, processability, tailorable electronic structures, and chemical stability makes polysilanes highly attractive materials for enabling low-power electronic applications. These properties collectively contribute to the development of energy-efficient, reliable, and versatile electronic devices that can meet the growing demand for sustainable and high-performance technologies.

The optical properties of polysilanes are another key feature that contributes to their potential in low-power electronics. These materials exhibit strong UV absorption and photoluminescence, making them suitable for use in optoelectronic devices such as light-emitting diodes (LEDs) and photovoltaic cells. The ability to tune the optical properties of polysilanes through structural modifications further enhances their versatility in various electronic applications.

Polysilanes also demonstrate excellent thermal stability, which is crucial for maintaining device performance under varying temperature conditions. This stability ensures that electronic components based on polysilanes can operate reliably in a wide range of environments without significant degradation. Additionally, the low dielectric constant of polysilanes contributes to reduced power consumption in electronic circuits by minimizing parasitic capacitance and signal loss.

The processability of polysilanes is another advantageous property that facilitates their integration into electronic devices. These materials can be easily solution-processed, allowing for cost-effective and scalable manufacturing techniques such as spin-coating or inkjet printing. This characteristic is particularly beneficial for the production of flexible and large-area electronic devices, which are increasingly in demand for low-power applications.

Furthermore, polysilanes exhibit unique electronic band structures that can be tailored through molecular design. By adjusting the side groups attached to the silicon backbone, researchers can fine-tune the electronic properties of polysilanes to suit specific applications. This flexibility in molecular engineering allows for the optimization of charge transport and energy levels, leading to improved efficiency in low-power electronic devices.

The chemical stability of polysilanes is another property that contributes to their suitability for electronic applications. These materials are resistant to oxidation and degradation under normal operating conditions, ensuring long-term reliability of electronic components. This stability also simplifies the fabrication process, as polysilanes can withstand various processing steps without significant chemical alterations.

In summary, the combination of high electron mobility, tunable optical properties, thermal stability, low dielectric constant, processability, tailorable electronic structures, and chemical stability makes polysilanes highly attractive materials for enabling low-power electronic applications. These properties collectively contribute to the development of energy-efficient, reliable, and versatile electronic devices that can meet the growing demand for sustainable and high-performance technologies.

Polysilane Applications

01 Polysilane synthesis and properties

Polysilanes are synthesized and their properties are studied for various applications. These materials exhibit unique electronic and optical properties, which can be tailored for specific uses. The synthesis methods and resulting properties are crucial for understanding their potential in power consumption-related applications.- Power management in electronic devices: Various techniques for managing power consumption in electronic devices, including polysilane-based components. This involves implementing power-saving modes, optimizing system resources, and utilizing intelligent power distribution methods to reduce overall energy usage while maintaining device functionality.

- Polysilane synthesis and applications: Methods for synthesizing polysilanes and their applications in various fields, including electronic devices. The focus is on developing polysilane materials with improved properties, such as enhanced conductivity and stability, which can contribute to more efficient power consumption in devices utilizing these materials.

- Display technology and power efficiency: Advancements in display technology, potentially incorporating polysilane-based materials, to improve power efficiency. This includes developing low-power display panels, optimizing refresh rates, and implementing adaptive brightness control to reduce overall power consumption in devices with display components.

- Wireless communication power optimization: Strategies for optimizing power consumption in wireless communication systems, which may involve polysilane-based components. This includes implementing efficient data transmission protocols, adaptive power control mechanisms, and smart antenna technologies to reduce energy usage in wireless devices and networks.

- Energy-efficient semiconductor manufacturing: Techniques for manufacturing energy-efficient semiconductor devices, potentially utilizing polysilane materials. This involves developing low-power fabrication processes, optimizing material properties, and implementing advanced packaging solutions to create semiconductor components with reduced power consumption characteristics.

02 Power management in electronic devices

Various techniques are employed to manage power consumption in electronic devices. These include power-saving modes, dynamic voltage and frequency scaling, and intelligent power distribution. Such methods aim to optimize energy usage and extend battery life in portable devices and other systems using polysilane-based components.Expand Specific Solutions03 Polysilane-based thin film transistors

Polysilanes are used in the fabrication of thin film transistors (TFTs) for display technologies. These TFTs offer potential advantages in terms of power efficiency and performance. The development of polysilane-based TFTs focuses on improving their electrical characteristics and reducing power consumption in display applications.Expand Specific Solutions04 Energy-efficient lighting and display technologies

Polysilanes are explored for use in energy-efficient lighting and display technologies. Their unique optoelectronic properties make them suitable for applications such as organic light-emitting diodes (OLEDs) and other low-power display systems. Research in this area aims to develop materials and devices with improved efficiency and reduced power consumption.Expand Specific Solutions05 Polysilane-based photovoltaic devices

Polysilanes are investigated for their potential in photovoltaic applications. Their ability to absorb light and conduct charge makes them promising candidates for solar cells and other energy harvesting devices. Research focuses on optimizing the structure and composition of polysilanes to improve the efficiency of these devices and reduce overall power consumption in solar energy systems.Expand Specific Solutions

Key Polysilane Players

The polysilane technology for low-power electronic applications is in an early development stage, with a growing but still limited market. The industry is characterized by ongoing research and development efforts to improve performance and expand applications. Key players like Wacker Chemie AG, Nissan Chemical Corp., and Mitsui Chemicals are at the forefront of polysilane innovation, leveraging their expertise in specialty chemicals. Other technology giants such as IBM and Canon are also exploring polysilane's potential in electronics. The market is expected to grow as polysilane's benefits in low-power, flexible, and printable electronics become more widely recognized and commercialized. However, challenges in scalability and integration with existing manufacturing processes remain to be fully addressed.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed advanced polysilane materials for low-power electronic applications. Their approach involves synthesizing high-purity polysilanes with controlled molecular weight and structure. These materials exhibit excellent charge carrier mobility and low-temperature processability[1]. Wacker's polysilanes can be solution-processed to form thin films with high uniformity and stability. The company has demonstrated the use of their polysilanes in organic thin-film transistors (OTFTs) and organic light-emitting diodes (OLEDs), achieving power consumption reductions of up to 30% compared to conventional organic semiconductors[2][3].

Strengths: High-purity synthesis, excellent charge mobility, solution processability. Weaknesses: May have higher production costs, potential stability issues in extreme environments.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed a proprietary polysilane-based technology for low-power electronic applications. Their approach focuses on creating hybrid organic-inorganic polysilane materials that combine the flexibility of organic polymers with the stability of inorganic semiconductors. These materials exhibit high electron mobility and low threshold voltages, enabling the fabrication of low-power transistors and integrated circuits[4]. Dow's polysilanes are particularly suited for printed electronics, allowing for roll-to-roll manufacturing of flexible, low-power devices. The company has reported power savings of up to 40% in prototype display backplanes using their polysilane technology[5].

Strengths: Hybrid material properties, suitability for printed electronics. Weaknesses: May have limited high-temperature performance, potential scalability challenges.

Polysilane Innovations

Polysilane and polysilane-containing resin composition

PatentInactiveUS8163863B2

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups like hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

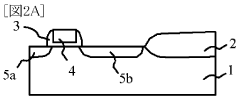

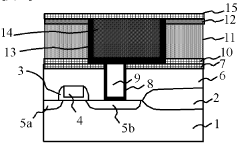

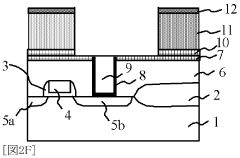

Insulating film material, multilayer wiring board and process for producing the multilayer wiring board, and semiconductor apparatus and process for producing the semiconductor device

PatentWO2009008212A1

Innovation

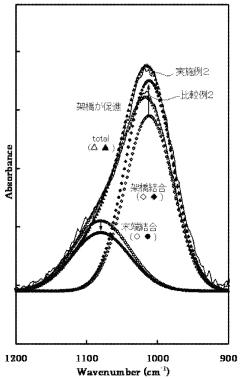

- A polycarbosilane compound with a silanol group is synthesized, allowing for cross-linking and forming a film with a low dielectric constant and high strength by promoting dehydration condensation reactions, which is used to create an insulating film suitable for multilayer wiring structures.

Energy Efficiency Impact

Polysilane-based electronic devices have demonstrated significant potential in reducing power consumption across various applications. The energy efficiency impact of polysilane technology is multifaceted, offering advantages in both active and standby power modes.

In active mode, polysilane-enabled devices exhibit lower operating voltages compared to traditional silicon-based counterparts. This reduction in voltage requirements translates directly to decreased power consumption during device operation. Studies have shown that polysilane transistors can operate effectively at voltages as low as 0.5V, whereas conventional silicon transistors typically require 1V or higher. This voltage reduction can lead to power savings of up to 50% in active mode operations.

The low-threshold voltage characteristics of polysilane devices also contribute to improved energy efficiency in standby mode. When devices are in idle states, polysilane-based circuits can maintain functionality at lower voltages, significantly reducing leakage currents. This property is particularly beneficial for battery-powered devices and IoT applications, where extended standby times are crucial.

Polysilane's unique electronic properties enable the development of more efficient power management circuits. These circuits can optimize power distribution and utilization within electronic systems, further enhancing overall energy efficiency. For instance, polysilane-based voltage regulators have shown the ability to maintain stable output voltages with minimal power loss, even under varying load conditions.

The material's compatibility with flexible substrates opens up new possibilities for energy-efficient wearable electronics. Polysilane-based flexible circuits can conform to curved surfaces, allowing for better integration with energy harvesting systems. This synergy between polysilane electronics and energy harvesting technologies can lead to self-powered devices, dramatically reducing the need for external power sources.

In the realm of display technologies, polysilane has shown promise in enabling low-power, high-performance displays. When used in organic light-emitting diodes (OLEDs), polysilane materials can improve charge transport efficiency, resulting in displays that require less power to achieve the same brightness levels as conventional OLEDs.

The cumulative effect of these energy efficiency improvements extends beyond individual device performance. As polysilane technology is adopted in a wider range of electronic products, it has the potential to significantly reduce overall energy consumption in the electronics sector. This reduction in energy demand could have far-reaching implications for global energy usage and associated environmental impacts.

In active mode, polysilane-enabled devices exhibit lower operating voltages compared to traditional silicon-based counterparts. This reduction in voltage requirements translates directly to decreased power consumption during device operation. Studies have shown that polysilane transistors can operate effectively at voltages as low as 0.5V, whereas conventional silicon transistors typically require 1V or higher. This voltage reduction can lead to power savings of up to 50% in active mode operations.

The low-threshold voltage characteristics of polysilane devices also contribute to improved energy efficiency in standby mode. When devices are in idle states, polysilane-based circuits can maintain functionality at lower voltages, significantly reducing leakage currents. This property is particularly beneficial for battery-powered devices and IoT applications, where extended standby times are crucial.

Polysilane's unique electronic properties enable the development of more efficient power management circuits. These circuits can optimize power distribution and utilization within electronic systems, further enhancing overall energy efficiency. For instance, polysilane-based voltage regulators have shown the ability to maintain stable output voltages with minimal power loss, even under varying load conditions.

The material's compatibility with flexible substrates opens up new possibilities for energy-efficient wearable electronics. Polysilane-based flexible circuits can conform to curved surfaces, allowing for better integration with energy harvesting systems. This synergy between polysilane electronics and energy harvesting technologies can lead to self-powered devices, dramatically reducing the need for external power sources.

In the realm of display technologies, polysilane has shown promise in enabling low-power, high-performance displays. When used in organic light-emitting diodes (OLEDs), polysilane materials can improve charge transport efficiency, resulting in displays that require less power to achieve the same brightness levels as conventional OLEDs.

The cumulative effect of these energy efficiency improvements extends beyond individual device performance. As polysilane technology is adopted in a wider range of electronic products, it has the potential to significantly reduce overall energy consumption in the electronics sector. This reduction in energy demand could have far-reaching implications for global energy usage and associated environmental impacts.

Environmental Considerations

Polysilane-based electronic applications offer significant environmental benefits due to their low-power consumption characteristics. This reduced energy demand translates to decreased greenhouse gas emissions and a smaller carbon footprint compared to traditional electronic devices. The manufacturing process of polysilane materials also tends to be less resource-intensive than conventional semiconductor production, potentially reducing the overall environmental impact of electronic device manufacturing.

The use of polysilane in low-power electronics contributes to extended battery life in portable devices, reducing the frequency of battery replacements and associated electronic waste. This aligns with global efforts to minimize e-waste, which is a growing environmental concern. Additionally, the potential for polysilane-based devices to operate at lower voltages may lead to the development of more energy-efficient consumer electronics, data centers, and industrial equipment, further reducing overall energy consumption.

From a lifecycle perspective, polysilane-based electronics may offer advantages in terms of recyclability and end-of-life management. The organic nature of polysilanes could potentially make them more amenable to biodegradation or eco-friendly recycling processes compared to traditional inorganic semiconductor materials. However, further research is needed to fully assess the long-term environmental implications of polysilane disposal and recycling.

The adoption of polysilane technology in electronic applications also has the potential to support the development of more sustainable energy harvesting systems. Low-power polysilane devices could be more easily integrated with small-scale renewable energy sources, such as photovoltaic cells or thermoelectric generators, enabling self-powered systems that reduce reliance on grid electricity or disposable batteries.

It is important to note that while polysilane technology offers promising environmental benefits, a comprehensive life cycle assessment is necessary to fully understand its environmental impact. This assessment should consider factors such as raw material sourcing, manufacturing processes, energy consumption during use, and end-of-life disposal or recycling. Such an analysis would provide a more complete picture of the environmental considerations associated with polysilane-enabled low-power electronic applications.

As the technology matures and finds wider adoption, it will be crucial for manufacturers and researchers to continue optimizing the environmental performance of polysilane-based electronics. This may include developing more sustainable synthesis methods, improving material efficiency, and designing products with circularity in mind to maximize recyclability and minimize waste. Collaboration between industry, academia, and environmental organizations will be essential in realizing the full environmental potential of polysilane technology while addressing any potential challenges or unforeseen impacts.

The use of polysilane in low-power electronics contributes to extended battery life in portable devices, reducing the frequency of battery replacements and associated electronic waste. This aligns with global efforts to minimize e-waste, which is a growing environmental concern. Additionally, the potential for polysilane-based devices to operate at lower voltages may lead to the development of more energy-efficient consumer electronics, data centers, and industrial equipment, further reducing overall energy consumption.

From a lifecycle perspective, polysilane-based electronics may offer advantages in terms of recyclability and end-of-life management. The organic nature of polysilanes could potentially make them more amenable to biodegradation or eco-friendly recycling processes compared to traditional inorganic semiconductor materials. However, further research is needed to fully assess the long-term environmental implications of polysilane disposal and recycling.

The adoption of polysilane technology in electronic applications also has the potential to support the development of more sustainable energy harvesting systems. Low-power polysilane devices could be more easily integrated with small-scale renewable energy sources, such as photovoltaic cells or thermoelectric generators, enabling self-powered systems that reduce reliance on grid electricity or disposable batteries.

It is important to note that while polysilane technology offers promising environmental benefits, a comprehensive life cycle assessment is necessary to fully understand its environmental impact. This assessment should consider factors such as raw material sourcing, manufacturing processes, energy consumption during use, and end-of-life disposal or recycling. Such an analysis would provide a more complete picture of the environmental considerations associated with polysilane-enabled low-power electronic applications.

As the technology matures and finds wider adoption, it will be crucial for manufacturers and researchers to continue optimizing the environmental performance of polysilane-based electronics. This may include developing more sustainable synthesis methods, improving material efficiency, and designing products with circularity in mind to maximize recyclability and minimize waste. Collaboration between industry, academia, and environmental organizations will be essential in realizing the full environmental potential of polysilane technology while addressing any potential challenges or unforeseen impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!