How to Develop Anti-Reflective Coatings Using Polysilane?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane ARC Background and Objectives

Anti-reflective coatings (ARCs) have been a crucial component in various optical and electronic applications for decades. The development of ARCs using polysilane represents a significant advancement in this field, offering potential improvements in performance and versatility. Polysilanes, a class of silicon-based polymers, have garnered attention due to their unique optical and electronic properties, making them promising candidates for ARC applications.

The evolution of ARC technology has been driven by the increasing demand for high-performance optical systems in industries such as solar energy, display technologies, and photonics. Traditional ARCs, often based on inorganic materials like silicon dioxide or titanium dioxide, have limitations in terms of flexibility, cost-effectiveness, and ease of application. The exploration of polysilane-based ARCs aims to address these challenges while potentially enhancing the overall performance of anti-reflective systems.

The primary objective of developing polysilane ARCs is to create coatings that can effectively reduce surface reflections across a broad spectrum of wavelengths. This goal is particularly important in applications such as solar cells, where maximizing light absorption is critical for improving energy conversion efficiency. Additionally, researchers aim to develop polysilane ARCs that offer improved durability, environmental stability, and compatibility with various substrate materials.

Another key objective is to leverage the unique properties of polysilanes, such as their tunable refractive index and optical transparency, to create ARCs with enhanced functionality. This includes the potential for developing smart coatings that can adapt to changing environmental conditions or respond to specific stimuli, opening up new possibilities in adaptive optics and sensor technologies.

The development of polysilane ARCs also aligns with broader trends in materials science and nanotechnology. Researchers are exploring ways to incorporate nanostructures and advanced fabrication techniques to further enhance the performance of these coatings. This includes investigating methods to control the molecular structure and orientation of polysilanes at the nanoscale, potentially leading to ARCs with unprecedented anti-reflective properties.

As the field progresses, there is a growing focus on sustainable and environmentally friendly manufacturing processes. The development of polysilane ARCs offers opportunities to explore greener synthesis methods and reduce the environmental impact associated with traditional coating technologies. This aligns with global efforts to promote sustainable innovation and reduce the carbon footprint of advanced materials production.

The evolution of ARC technology has been driven by the increasing demand for high-performance optical systems in industries such as solar energy, display technologies, and photonics. Traditional ARCs, often based on inorganic materials like silicon dioxide or titanium dioxide, have limitations in terms of flexibility, cost-effectiveness, and ease of application. The exploration of polysilane-based ARCs aims to address these challenges while potentially enhancing the overall performance of anti-reflective systems.

The primary objective of developing polysilane ARCs is to create coatings that can effectively reduce surface reflections across a broad spectrum of wavelengths. This goal is particularly important in applications such as solar cells, where maximizing light absorption is critical for improving energy conversion efficiency. Additionally, researchers aim to develop polysilane ARCs that offer improved durability, environmental stability, and compatibility with various substrate materials.

Another key objective is to leverage the unique properties of polysilanes, such as their tunable refractive index and optical transparency, to create ARCs with enhanced functionality. This includes the potential for developing smart coatings that can adapt to changing environmental conditions or respond to specific stimuli, opening up new possibilities in adaptive optics and sensor technologies.

The development of polysilane ARCs also aligns with broader trends in materials science and nanotechnology. Researchers are exploring ways to incorporate nanostructures and advanced fabrication techniques to further enhance the performance of these coatings. This includes investigating methods to control the molecular structure and orientation of polysilanes at the nanoscale, potentially leading to ARCs with unprecedented anti-reflective properties.

As the field progresses, there is a growing focus on sustainable and environmentally friendly manufacturing processes. The development of polysilane ARCs offers opportunities to explore greener synthesis methods and reduce the environmental impact associated with traditional coating technologies. This aligns with global efforts to promote sustainable innovation and reduce the carbon footprint of advanced materials production.

Market Analysis for Polysilane-based ARCs

The market for polysilane-based anti-reflective coatings (ARCs) is experiencing significant growth, driven by increasing demand in various industries such as optics, electronics, and solar energy. The global ARC market is projected to reach substantial value in the coming years, with polysilane-based solutions playing a crucial role in this expansion.

In the optics and electronics sectors, the demand for high-performance ARCs is rising due to the growing need for improved display technologies, advanced optical systems, and precision instruments. Polysilane-based ARCs offer superior optical properties, including high transparency and low refractive index, making them ideal for these applications. The consumer electronics market, in particular, is driving significant demand for ARCs in smartphone displays, tablets, and other devices that require enhanced visual clarity and reduced glare.

The solar energy industry represents another major market for polysilane-based ARCs. As the global push for renewable energy sources intensifies, the efficiency of solar panels becomes increasingly critical. Polysilane-based ARCs can significantly improve the light absorption capabilities of solar cells, leading to higher energy conversion rates. This application is expected to see substantial growth as countries worldwide invest in solar energy infrastructure.

Emerging technologies such as augmented reality (AR) and virtual reality (VR) are also contributing to the market expansion for polysilane-based ARCs. These applications require high-quality optical components with minimal reflection and maximum light transmission, creating new opportunities for advanced coating solutions.

The automotive industry is another sector showing increased interest in polysilane-based ARCs. With the growing integration of displays and sensors in modern vehicles, there is a rising demand for anti-reflective solutions that can enhance visibility and improve the performance of various automotive components.

Geographically, Asia-Pacific is expected to dominate the market for polysilane-based ARCs, driven by the region's strong presence in electronics manufacturing and rapid adoption of solar energy technologies. North America and Europe are also significant markets, particularly in high-tech industries and research sectors.

Despite the positive outlook, the market faces challenges such as the high cost of production for advanced ARCs and the need for continuous innovation to meet evolving industry requirements. However, ongoing research and development efforts are focused on improving the cost-effectiveness and performance of polysilane-based ARCs, which is likely to address these challenges and further drive market growth.

In conclusion, the market for polysilane-based ARCs shows promising growth potential across multiple industries. The unique properties of these coatings, combined with increasing demand for high-performance optical solutions, position them as a key technology in the evolving landscape of anti-reflective materials.

In the optics and electronics sectors, the demand for high-performance ARCs is rising due to the growing need for improved display technologies, advanced optical systems, and precision instruments. Polysilane-based ARCs offer superior optical properties, including high transparency and low refractive index, making them ideal for these applications. The consumer electronics market, in particular, is driving significant demand for ARCs in smartphone displays, tablets, and other devices that require enhanced visual clarity and reduced glare.

The solar energy industry represents another major market for polysilane-based ARCs. As the global push for renewable energy sources intensifies, the efficiency of solar panels becomes increasingly critical. Polysilane-based ARCs can significantly improve the light absorption capabilities of solar cells, leading to higher energy conversion rates. This application is expected to see substantial growth as countries worldwide invest in solar energy infrastructure.

Emerging technologies such as augmented reality (AR) and virtual reality (VR) are also contributing to the market expansion for polysilane-based ARCs. These applications require high-quality optical components with minimal reflection and maximum light transmission, creating new opportunities for advanced coating solutions.

The automotive industry is another sector showing increased interest in polysilane-based ARCs. With the growing integration of displays and sensors in modern vehicles, there is a rising demand for anti-reflective solutions that can enhance visibility and improve the performance of various automotive components.

Geographically, Asia-Pacific is expected to dominate the market for polysilane-based ARCs, driven by the region's strong presence in electronics manufacturing and rapid adoption of solar energy technologies. North America and Europe are also significant markets, particularly in high-tech industries and research sectors.

Despite the positive outlook, the market faces challenges such as the high cost of production for advanced ARCs and the need for continuous innovation to meet evolving industry requirements. However, ongoing research and development efforts are focused on improving the cost-effectiveness and performance of polysilane-based ARCs, which is likely to address these challenges and further drive market growth.

In conclusion, the market for polysilane-based ARCs shows promising growth potential across multiple industries. The unique properties of these coatings, combined with increasing demand for high-performance optical solutions, position them as a key technology in the evolving landscape of anti-reflective materials.

Current Challenges in Polysilane ARC Development

The development of anti-reflective coatings (ARCs) using polysilane faces several significant challenges that hinder widespread adoption and optimal performance. One of the primary obstacles is the inherent instability of polysilane materials when exposed to ultraviolet (UV) light. This photosensitivity can lead to degradation of the coating over time, reducing its effectiveness and longevity, particularly in outdoor applications or environments with high UV exposure.

Another major challenge lies in achieving precise control over the refractive index of polysilane-based ARCs. The refractive index is crucial for maximizing anti-reflective properties, and even slight variations can significantly impact performance. Current manufacturing processes struggle to consistently produce polysilane coatings with the desired refractive index across large surface areas, limiting their applicability in industries requiring uniform, high-performance ARCs.

The adhesion of polysilane coatings to various substrates presents another hurdle. While polysilanes show promise on certain materials, their adhesion properties are not universally strong across all substrate types. This limitation restricts the range of applications and necessitates the development of specialized surface treatments or adhesion promoters, adding complexity and cost to the manufacturing process.

Scalability and cost-effectiveness remain significant challenges in polysilane ARC production. Current synthesis methods for high-quality polysilanes are often complex and expensive, involving multiple steps and requiring stringent environmental controls. This complexity translates to higher production costs, making polysilane ARCs less competitive compared to traditional coating technologies in many market segments.

Environmental and health concerns associated with the synthesis and application of polysilane coatings also pose challenges. Some precursor materials and solvents used in polysilane production can be toxic or environmentally harmful, necessitating careful handling and disposal procedures. This aspect not only increases production costs but also raises regulatory hurdles in certain regions.

The long-term durability of polysilane ARCs under various environmental conditions remains a concern. While these coatings show promising initial performance, their resistance to factors such as temperature fluctuations, humidity, and mechanical abrasion needs further improvement to meet the demanding requirements of many industrial applications.

Lastly, the integration of polysilane ARCs into existing manufacturing processes presents technical challenges. Many industries have established coating application methods, and the adoption of polysilane-based solutions may require significant modifications to production lines and equipment, creating barriers to implementation.

Another major challenge lies in achieving precise control over the refractive index of polysilane-based ARCs. The refractive index is crucial for maximizing anti-reflective properties, and even slight variations can significantly impact performance. Current manufacturing processes struggle to consistently produce polysilane coatings with the desired refractive index across large surface areas, limiting their applicability in industries requiring uniform, high-performance ARCs.

The adhesion of polysilane coatings to various substrates presents another hurdle. While polysilanes show promise on certain materials, their adhesion properties are not universally strong across all substrate types. This limitation restricts the range of applications and necessitates the development of specialized surface treatments or adhesion promoters, adding complexity and cost to the manufacturing process.

Scalability and cost-effectiveness remain significant challenges in polysilane ARC production. Current synthesis methods for high-quality polysilanes are often complex and expensive, involving multiple steps and requiring stringent environmental controls. This complexity translates to higher production costs, making polysilane ARCs less competitive compared to traditional coating technologies in many market segments.

Environmental and health concerns associated with the synthesis and application of polysilane coatings also pose challenges. Some precursor materials and solvents used in polysilane production can be toxic or environmentally harmful, necessitating careful handling and disposal procedures. This aspect not only increases production costs but also raises regulatory hurdles in certain regions.

The long-term durability of polysilane ARCs under various environmental conditions remains a concern. While these coatings show promising initial performance, their resistance to factors such as temperature fluctuations, humidity, and mechanical abrasion needs further improvement to meet the demanding requirements of many industrial applications.

Lastly, the integration of polysilane ARCs into existing manufacturing processes presents technical challenges. Many industries have established coating application methods, and the adoption of polysilane-based solutions may require significant modifications to production lines and equipment, creating barriers to implementation.

Existing Polysilane ARC Fabrication Methods

01 Multilayer anti-reflective coatings

Multilayer anti-reflective coatings are designed to reduce reflectivity by using alternating layers of high and low refractive index materials. These coatings can be optimized for specific wavelengths and incident angles, providing enhanced performance across a broad spectrum of light.- Multi-layer anti-reflective coatings: Multi-layer anti-reflective coatings are designed to reduce reflectivity by using alternating layers of high and low refractive index materials. These coatings can be optimized for specific wavelengths and incident angles, providing enhanced performance across a broad spectrum of light.

- Nanostructured anti-reflective surfaces: Nanostructured surfaces can be created to reduce reflectivity by mimicking natural anti-reflective structures found in nature, such as moth eyes. These surfaces typically consist of sub-wavelength features that gradually change the refractive index, minimizing reflection across a wide range of wavelengths and angles.

- Graded-index anti-reflective coatings: Graded-index anti-reflective coatings feature a gradual change in refractive index from the substrate to the air interface. This smooth transition reduces reflections by eliminating abrupt changes in refractive index, resulting in improved optical performance and durability.

- Porous anti-reflective coatings: Porous anti-reflective coatings utilize nanoscale pores or voids within the coating material to lower the effective refractive index. These coatings can achieve very low reflectivity while maintaining good mechanical and environmental stability, making them suitable for various applications.

- Photoresist-based anti-reflective coatings: Photoresist-based anti-reflective coatings are specifically designed for use in photolithography processes. These coatings help reduce reflections from the substrate during exposure, improving pattern resolution and reducing unwanted artifacts in semiconductor manufacturing.

02 Nanostructured anti-reflective surfaces

Nanostructured surfaces can be created to reduce reflectivity by mimicking natural anti-reflective structures found in nature, such as moth eyes. These surfaces typically consist of arrays of nanoscale features that gradually change the refractive index, minimizing reflection across a wide range of wavelengths and angles.Expand Specific Solutions03 Graded-index anti-reflective coatings

Graded-index anti-reflective coatings feature a gradual change in refractive index from the substrate to the air interface. This smooth transition reduces reflections by eliminating abrupt changes in refractive index, resulting in improved optical performance and durability.Expand Specific Solutions04 Sol-gel derived anti-reflective coatings

Sol-gel processes can be used to create porous anti-reflective coatings with low refractive indices. These coatings can be easily applied to various substrates and offer excellent optical properties, including high transmittance and low reflectivity across a wide range of wavelengths.Expand Specific Solutions05 Photoresist-based anti-reflective coatings

Anti-reflective coatings can be created using photoresist materials, which are particularly useful in lithography processes. These coatings help to minimize reflections and standing waves during exposure, improving pattern resolution and overall lithographic performance.Expand Specific Solutions

Key Players in Polysilane and ARC Industries

The development of anti-reflective coatings using polysilane is in a growth phase, with increasing market demand driven by applications in optics, electronics, and solar energy. The global market for anti-reflective coatings is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Nissan Chemical Corp., Dow Silicones Corp., and FUJIFILM Corp. leading innovation. These firms, along with others such as First Solar, Inc. and Guardian Glass LLC, are investing in R&D to improve coating performance, durability, and cost-effectiveness. The technology's maturity varies across different applications, with some sectors seeing commercial deployment while others remain in the research phase.

Nissan Chemical Corp.

Technical Solution: Nissan Chemical Corp. has developed a novel approach to anti-reflective coatings using polysilane materials. Their method involves synthesizing polysilane compounds with specific molecular structures that enhance light transmission and reduce surface reflections. The company utilizes a sol-gel process to create thin, uniform coatings of polysilane-based materials on various substrates[1]. These coatings are engineered to have a refractive index gradient, which effectively minimizes light reflection across a broad spectrum of wavelengths[3]. Nissan Chemical's polysilane coatings also incorporate nanoparticles to further improve durability and scratch resistance[5].

Strengths: High optical performance, broad spectrum effectiveness, and improved durability. Weaknesses: Potentially higher production costs and limited compatibility with certain substrates.

Dow Silicones Corp.

Technical Solution: Dow Silicones Corp. has pioneered a polysilane-based anti-reflective coating technology that leverages their expertise in silicone chemistry. Their approach involves creating branched polysilane structures with carefully controlled molecular weights to achieve optimal optical properties[2]. The company employs a plasma-enhanced chemical vapor deposition (PECVD) process to apply ultra-thin layers of their polysilane coatings, resulting in excellent uniformity and adhesion[4]. Dow's coatings are designed to be hydrophobic, which enhances their self-cleaning properties and longevity in outdoor applications[6].

Strengths: Excellent uniformity, strong adhesion, and self-cleaning properties. Weaknesses: May require specialized equipment for application and potentially higher initial costs.

Core Innovations in Polysilane ARC Research

Polysilanesiloxane resins for use in an antireflective coating

PatentWO2012122342A1

Innovation

- Polysilane-polysiloxane copolymer resins are developed, comprising specific units and molar ratios, synthesized through hydrolytic condensation of trimethoxysilanes and permethoxyneopentasilane, which form a hybrid structure with enhanced light absorption at 193 nm and improved etch selectivity.

A coating composition for anti-reflection

PatentActiveKR1020190088838A

Innovation

- A coating composition comprising polysilazane, titanium dioxide precursor, surfactant, and solvent is used to form a porous silica film with reduced refractive index and reflectance, enhanced transmittance, and improved low-temperature curing properties, achieved through heat treatment to create pores and promote hydrophilicity.

Environmental Impact of Polysilane ARCs

The environmental impact of polysilane-based anti-reflective coatings (ARCs) is a crucial consideration in their development and application. These coatings, while offering significant benefits in optical performance, also present potential environmental challenges that must be carefully evaluated and addressed.

Polysilane ARCs are typically synthesized using organosilicon compounds, which can have varying degrees of environmental impact depending on their specific composition and manufacturing processes. The production of these materials often involves the use of organic solvents and energy-intensive processes, which can contribute to air and water pollution if not properly managed.

One of the primary environmental concerns associated with polysilane ARCs is their potential for releasing volatile organic compounds (VOCs) during application and curing. These emissions can contribute to air pollution and may have adverse effects on both human health and the environment. However, recent advancements in polysilane chemistry have led to the development of low-VOC and VOC-free formulations, significantly reducing this environmental risk.

The durability and longevity of polysilane ARCs also play a role in their environmental impact. Coatings with higher durability require less frequent replacement, reducing waste generation and the need for additional resources over time. Researchers are continuously working on improving the weatherability and scratch resistance of these coatings to extend their service life and minimize environmental footprint.

End-of-life considerations for polysilane ARCs are another important aspect of their environmental impact. The disposal or recycling of coated materials can be challenging due to the presence of these specialized coatings. Efforts are being made to develop more easily recyclable polysilane formulations and to establish effective recycling processes for coated materials.

On the positive side, the use of polysilane ARCs can contribute to energy efficiency in various applications. By reducing light reflection and improving light transmission, these coatings can enhance the performance of solar panels, LED displays, and other optical devices. This increased efficiency can lead to reduced energy consumption and, consequently, lower greenhouse gas emissions over the lifetime of the coated products.

The environmental impact of polysilane ARCs also extends to their potential for reducing material usage in certain applications. For instance, in optical lenses and displays, the anti-reflective properties of these coatings can allow for the use of thinner substrates, potentially reducing the overall material consumption and associated environmental footprint of the final products.

As environmental regulations become more stringent, the development of polysilane ARCs is increasingly focused on green chemistry principles. This includes the use of less hazardous precursors, water-based formulations, and more energy-efficient manufacturing processes. These advancements aim to minimize the environmental impact of polysilane ARCs throughout their lifecycle, from production to disposal.

Polysilane ARCs are typically synthesized using organosilicon compounds, which can have varying degrees of environmental impact depending on their specific composition and manufacturing processes. The production of these materials often involves the use of organic solvents and energy-intensive processes, which can contribute to air and water pollution if not properly managed.

One of the primary environmental concerns associated with polysilane ARCs is their potential for releasing volatile organic compounds (VOCs) during application and curing. These emissions can contribute to air pollution and may have adverse effects on both human health and the environment. However, recent advancements in polysilane chemistry have led to the development of low-VOC and VOC-free formulations, significantly reducing this environmental risk.

The durability and longevity of polysilane ARCs also play a role in their environmental impact. Coatings with higher durability require less frequent replacement, reducing waste generation and the need for additional resources over time. Researchers are continuously working on improving the weatherability and scratch resistance of these coatings to extend their service life and minimize environmental footprint.

End-of-life considerations for polysilane ARCs are another important aspect of their environmental impact. The disposal or recycling of coated materials can be challenging due to the presence of these specialized coatings. Efforts are being made to develop more easily recyclable polysilane formulations and to establish effective recycling processes for coated materials.

On the positive side, the use of polysilane ARCs can contribute to energy efficiency in various applications. By reducing light reflection and improving light transmission, these coatings can enhance the performance of solar panels, LED displays, and other optical devices. This increased efficiency can lead to reduced energy consumption and, consequently, lower greenhouse gas emissions over the lifetime of the coated products.

The environmental impact of polysilane ARCs also extends to their potential for reducing material usage in certain applications. For instance, in optical lenses and displays, the anti-reflective properties of these coatings can allow for the use of thinner substrates, potentially reducing the overall material consumption and associated environmental footprint of the final products.

As environmental regulations become more stringent, the development of polysilane ARCs is increasingly focused on green chemistry principles. This includes the use of less hazardous precursors, water-based formulations, and more energy-efficient manufacturing processes. These advancements aim to minimize the environmental impact of polysilane ARCs throughout their lifecycle, from production to disposal.

Optical Performance Metrics for Polysilane ARCs

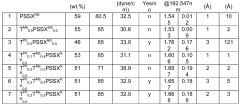

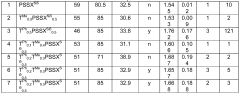

The optical performance of polysilane-based anti-reflective coatings (ARCs) is crucial for their effectiveness in various applications. Key metrics used to evaluate these coatings include refractive index, transmittance, reflectance, and absorption. The refractive index of polysilane ARCs typically ranges from 1.4 to 1.6, which is lower than that of many substrate materials, allowing for effective light transmission.

Transmittance is a critical parameter, measuring the percentage of incident light that passes through the coating. High-quality polysilane ARCs can achieve transmittance values exceeding 99% across specific wavelength ranges, particularly in the visible and near-infrared spectrum. This high transmittance is essential for applications in solar cells, optical displays, and precision optics.

Reflectance, conversely, quantifies the amount of light reflected from the coated surface. Effective polysilane ARCs can reduce reflectance to less than 0.5% at targeted wavelengths, significantly improving the optical efficiency of the underlying device or material. The wavelength-dependent nature of reflectance is often characterized using spectrophotometry, allowing for optimization across specific spectral ranges.

Absorption is another crucial metric, particularly for applications where minimal energy loss is critical. Polysilane ARCs typically exhibit low absorption coefficients, often less than 0.1% across the visible spectrum. This low absorption contributes to the overall high transmittance and efficiency of the coating.

The durability and environmental stability of polysilane ARCs are also important considerations in their optical performance. Metrics such as adhesion strength, scratch resistance, and stability under various environmental conditions (temperature, humidity, UV exposure) are evaluated to ensure long-term performance. Advanced polysilane formulations have demonstrated excellent stability, maintaining their optical properties over extended periods and under harsh conditions.

Thickness uniformity and surface roughness are additional factors that influence the optical performance of polysilane ARCs. Uniform coating thickness, typically in the range of 50-200 nm, is crucial for consistent optical properties across the coated surface. Surface roughness, ideally maintained below 1 nm RMS, ensures minimal scattering and optimal light transmission.

The angular dependence of transmittance and reflectance is another important consideration, particularly for applications involving non-normal light incidence. High-performance polysilane ARCs maintain their anti-reflective properties over a wide range of incident angles, often up to 60 degrees from normal.

Transmittance is a critical parameter, measuring the percentage of incident light that passes through the coating. High-quality polysilane ARCs can achieve transmittance values exceeding 99% across specific wavelength ranges, particularly in the visible and near-infrared spectrum. This high transmittance is essential for applications in solar cells, optical displays, and precision optics.

Reflectance, conversely, quantifies the amount of light reflected from the coated surface. Effective polysilane ARCs can reduce reflectance to less than 0.5% at targeted wavelengths, significantly improving the optical efficiency of the underlying device or material. The wavelength-dependent nature of reflectance is often characterized using spectrophotometry, allowing for optimization across specific spectral ranges.

Absorption is another crucial metric, particularly for applications where minimal energy loss is critical. Polysilane ARCs typically exhibit low absorption coefficients, often less than 0.1% across the visible spectrum. This low absorption contributes to the overall high transmittance and efficiency of the coating.

The durability and environmental stability of polysilane ARCs are also important considerations in their optical performance. Metrics such as adhesion strength, scratch resistance, and stability under various environmental conditions (temperature, humidity, UV exposure) are evaluated to ensure long-term performance. Advanced polysilane formulations have demonstrated excellent stability, maintaining their optical properties over extended periods and under harsh conditions.

Thickness uniformity and surface roughness are additional factors that influence the optical performance of polysilane ARCs. Uniform coating thickness, typically in the range of 50-200 nm, is crucial for consistent optical properties across the coated surface. Surface roughness, ideally maintained below 1 nm RMS, ensures minimal scattering and optimal light transmission.

The angular dependence of transmittance and reflectance is another important consideration, particularly for applications involving non-normal light incidence. High-performance polysilane ARCs maintain their anti-reflective properties over a wide range of incident angles, often up to 60 degrees from normal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!