How Polysilane Facilitates High-Precision Research Tools?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Background

Polysilanes, a class of silicon-based polymers with a backbone consisting of silicon atoms, have emerged as a significant material in the development of high-precision research tools. The history of polysilanes dates back to the early 20th century when they were first synthesized, but their potential in advanced applications was not fully realized until the late 1970s and early 1980s.

The unique electronic and optical properties of polysilanes stem from their σ-conjugated backbone, which allows for efficient electron delocalization along the silicon chain. This characteristic sets polysilanes apart from their carbon-based counterparts and opens up a wide range of applications in various fields, including optoelectronics, photolithography, and sensing technologies.

The synthesis of polysilanes has evolved significantly over the years. Early methods involved the Wurtz coupling reaction of dichlorosilanes, which often resulted in low molecular weight polymers with limited applications. However, advancements in synthetic techniques, such as anionic polymerization and catalytic dehydrogenative coupling, have enabled the production of high molecular weight polysilanes with controlled structures and properties.

One of the key features that make polysilanes valuable in high-precision research tools is their photosensitivity. When exposed to ultraviolet light, polysilanes undergo photodegradation, leading to chain scission and changes in their physical and chemical properties. This photosensitivity has been harnessed in the development of photoresists for microlithography, allowing for the creation of intricate patterns on semiconductor surfaces with high resolution.

The optical properties of polysilanes, particularly their high refractive indices and nonlinear optical responses, have also contributed to their use in advanced optical devices. These properties can be fine-tuned by modifying the substituents on the silicon atoms or by incorporating other elements into the polymer backbone, providing a versatile platform for customizing materials for specific research applications.

In recent years, the integration of polysilanes with other materials, such as nanoparticles and biological molecules, has opened up new avenues for their use in high-precision research tools. For instance, polysilane-based hybrid materials have shown promise in biosensing applications, where their unique electronic properties can be exploited for signal transduction and amplification.

The ongoing research into polysilanes continues to uncover new properties and potential applications. As our understanding of these materials deepens, their role in facilitating high-precision research tools is expected to expand, potentially revolutionizing fields such as nanoscale fabrication, quantum computing, and advanced spectroscopy.

The unique electronic and optical properties of polysilanes stem from their σ-conjugated backbone, which allows for efficient electron delocalization along the silicon chain. This characteristic sets polysilanes apart from their carbon-based counterparts and opens up a wide range of applications in various fields, including optoelectronics, photolithography, and sensing technologies.

The synthesis of polysilanes has evolved significantly over the years. Early methods involved the Wurtz coupling reaction of dichlorosilanes, which often resulted in low molecular weight polymers with limited applications. However, advancements in synthetic techniques, such as anionic polymerization and catalytic dehydrogenative coupling, have enabled the production of high molecular weight polysilanes with controlled structures and properties.

One of the key features that make polysilanes valuable in high-precision research tools is their photosensitivity. When exposed to ultraviolet light, polysilanes undergo photodegradation, leading to chain scission and changes in their physical and chemical properties. This photosensitivity has been harnessed in the development of photoresists for microlithography, allowing for the creation of intricate patterns on semiconductor surfaces with high resolution.

The optical properties of polysilanes, particularly their high refractive indices and nonlinear optical responses, have also contributed to their use in advanced optical devices. These properties can be fine-tuned by modifying the substituents on the silicon atoms or by incorporating other elements into the polymer backbone, providing a versatile platform for customizing materials for specific research applications.

In recent years, the integration of polysilanes with other materials, such as nanoparticles and biological molecules, has opened up new avenues for their use in high-precision research tools. For instance, polysilane-based hybrid materials have shown promise in biosensing applications, where their unique electronic properties can be exploited for signal transduction and amplification.

The ongoing research into polysilanes continues to uncover new properties and potential applications. As our understanding of these materials deepens, their role in facilitating high-precision research tools is expected to expand, potentially revolutionizing fields such as nanoscale fabrication, quantum computing, and advanced spectroscopy.

Market Analysis

The market for high-precision research tools facilitated by polysilane technology is experiencing significant growth, driven by increasing demand for advanced analytical and measurement capabilities across various scientific and industrial sectors. Polysilane-based tools offer superior performance in areas such as nanoscale imaging, spectroscopy, and materials characterization, making them essential for cutting-edge research and development activities.

In the semiconductor industry, polysilane-enabled tools are crucial for the development and production of next-generation microchips and electronic devices. As the industry continues to push the boundaries of miniaturization and performance, the need for ultra-high-precision measurement and analysis tools grows exponentially. This sector alone represents a substantial portion of the market for polysilane-facilitated research instruments.

The life sciences and biotechnology sectors are also major contributors to the market demand for polysilane-based high-precision tools. These industries require advanced imaging and analytical capabilities for studying cellular structures, biomolecules, and drug interactions at the molecular level. The ability of polysilane-enabled instruments to provide unprecedented resolution and sensitivity makes them invaluable for groundbreaking research in fields such as genomics, proteomics, and drug discovery.

Materials science and nanotechnology research represent another significant market segment for polysilane-facilitated tools. As researchers explore novel materials and nanostructures for applications in energy storage, electronics, and advanced manufacturing, the need for high-precision characterization tools becomes paramount. Polysilane-based instruments offer the capability to analyze material properties and structures at the atomic and molecular scales, driving innovation in this rapidly evolving field.

The environmental and climate research sectors are emerging as growing markets for polysilane-enabled high-precision tools. These instruments play a crucial role in analyzing air and water quality, studying climate change indicators, and developing new environmental remediation technologies. The ability to detect and measure trace contaminants and pollutants with extreme accuracy is driving the adoption of polysilane-based tools in environmental monitoring and research applications.

As the global research and development landscape continues to evolve, the market for polysilane-facilitated high-precision tools is expected to expand further. The increasing focus on interdisciplinary research and the convergence of different scientific fields create new opportunities for advanced analytical instruments. Additionally, the growing emphasis on reproducibility and precision in scientific research is likely to drive further demand for these cutting-edge tools across academic, government, and industrial research institutions worldwide.

In the semiconductor industry, polysilane-enabled tools are crucial for the development and production of next-generation microchips and electronic devices. As the industry continues to push the boundaries of miniaturization and performance, the need for ultra-high-precision measurement and analysis tools grows exponentially. This sector alone represents a substantial portion of the market for polysilane-facilitated research instruments.

The life sciences and biotechnology sectors are also major contributors to the market demand for polysilane-based high-precision tools. These industries require advanced imaging and analytical capabilities for studying cellular structures, biomolecules, and drug interactions at the molecular level. The ability of polysilane-enabled instruments to provide unprecedented resolution and sensitivity makes them invaluable for groundbreaking research in fields such as genomics, proteomics, and drug discovery.

Materials science and nanotechnology research represent another significant market segment for polysilane-facilitated tools. As researchers explore novel materials and nanostructures for applications in energy storage, electronics, and advanced manufacturing, the need for high-precision characterization tools becomes paramount. Polysilane-based instruments offer the capability to analyze material properties and structures at the atomic and molecular scales, driving innovation in this rapidly evolving field.

The environmental and climate research sectors are emerging as growing markets for polysilane-enabled high-precision tools. These instruments play a crucial role in analyzing air and water quality, studying climate change indicators, and developing new environmental remediation technologies. The ability to detect and measure trace contaminants and pollutants with extreme accuracy is driving the adoption of polysilane-based tools in environmental monitoring and research applications.

As the global research and development landscape continues to evolve, the market for polysilane-facilitated high-precision tools is expected to expand further. The increasing focus on interdisciplinary research and the convergence of different scientific fields create new opportunities for advanced analytical instruments. Additionally, the growing emphasis on reproducibility and precision in scientific research is likely to drive further demand for these cutting-edge tools across academic, government, and industrial research institutions worldwide.

Technical Challenges

Polysilane-based high-precision research tools face several significant technical challenges that hinder their widespread adoption and optimal performance. One of the primary obstacles is the inherent instability of polysilane materials. These compounds are highly sensitive to environmental factors such as light, heat, and oxygen, which can lead to rapid degradation and loss of functionality. This instability poses difficulties in maintaining consistent performance over extended periods, limiting the reliability of research tools incorporating polysilane technology.

Another critical challenge lies in the synthesis and processing of polysilane materials. Achieving precise control over the molecular weight, polydispersity, and structural uniformity of polysilanes remains a complex task. The variability in these parameters can significantly impact the optical and electronic properties of the resulting materials, affecting the accuracy and reproducibility of research results. Furthermore, the scalability of polysilane synthesis processes presents obstacles to large-scale production and commercialization of polysilane-based research tools.

The integration of polysilanes into existing research tool platforms also presents technical hurdles. Compatibility issues may arise when incorporating polysilane materials into conventional device architectures, requiring careful engineering and design considerations. Additionally, the interface between polysilanes and other materials used in research tools can introduce complexities in terms of charge transfer, energy coupling, and overall system performance.

Characterization and quality control of polysilane-based research tools pose another set of challenges. The unique properties of polysilanes necessitate the development of specialized analytical techniques and standards to accurately assess their performance and reliability. Establishing robust quality control measures is crucial for ensuring consistent results across different batches of polysilane materials and research tools.

The long-term stability and durability of polysilane-based research tools remain areas of concern. Addressing issues related to material degradation, device lifetime, and performance consistency over extended periods is essential for their practical implementation in research settings. This challenge is particularly critical for applications requiring prolonged operation or exposure to harsh environmental conditions.

Lastly, the optimization of polysilane properties for specific research applications presents ongoing challenges. Tailoring the electronic, optical, and structural characteristics of polysilanes to meet the diverse requirements of various research fields demands continuous innovation in material design and synthesis strategies. Balancing performance enhancements with cost-effectiveness and ease of manufacturing adds another layer of complexity to the development of polysilane-based high-precision research tools.

Another critical challenge lies in the synthesis and processing of polysilane materials. Achieving precise control over the molecular weight, polydispersity, and structural uniformity of polysilanes remains a complex task. The variability in these parameters can significantly impact the optical and electronic properties of the resulting materials, affecting the accuracy and reproducibility of research results. Furthermore, the scalability of polysilane synthesis processes presents obstacles to large-scale production and commercialization of polysilane-based research tools.

The integration of polysilanes into existing research tool platforms also presents technical hurdles. Compatibility issues may arise when incorporating polysilane materials into conventional device architectures, requiring careful engineering and design considerations. Additionally, the interface between polysilanes and other materials used in research tools can introduce complexities in terms of charge transfer, energy coupling, and overall system performance.

Characterization and quality control of polysilane-based research tools pose another set of challenges. The unique properties of polysilanes necessitate the development of specialized analytical techniques and standards to accurately assess their performance and reliability. Establishing robust quality control measures is crucial for ensuring consistent results across different batches of polysilane materials and research tools.

The long-term stability and durability of polysilane-based research tools remain areas of concern. Addressing issues related to material degradation, device lifetime, and performance consistency over extended periods is essential for their practical implementation in research settings. This challenge is particularly critical for applications requiring prolonged operation or exposure to harsh environmental conditions.

Lastly, the optimization of polysilane properties for specific research applications presents ongoing challenges. Tailoring the electronic, optical, and structural characteristics of polysilanes to meet the diverse requirements of various research fields demands continuous innovation in material design and synthesis strategies. Balancing performance enhancements with cost-effectiveness and ease of manufacturing adds another layer of complexity to the development of polysilane-based high-precision research tools.

Current Applications

01 Synthesis and properties of polysilanes

Polysilanes are silicon-based polymers with a backbone consisting of silicon atoms. They can be synthesized through various methods and exhibit unique optical and electronic properties. These materials have applications in photoresists, semiconductors, and optoelectronic devices due to their high thermal stability and conductivity.- Synthesis and properties of polysilanes: Polysilanes are synthesized through various methods and exhibit unique properties. These silicon-based polymers have a backbone consisting of silicon atoms and can be modified with different substituents. They possess interesting optical and electronic properties, making them suitable for various applications in materials science and electronics.

- Applications of polysilanes in coatings and films: Polysilanes are utilized in the production of coatings and films with enhanced properties. These materials can be applied to various substrates to improve characteristics such as durability, heat resistance, and optical properties. The unique structure of polysilanes contributes to their effectiveness in forming protective and functional layers.

- Polysilanes in photoresist and lithography applications: Polysilanes play a significant role in photoresist formulations and lithography processes. Their photosensitive nature and ability to undergo photochemical reactions make them valuable in the production of microelectronic devices and semiconductor manufacturing. These materials can be used to create precise patterns and structures at the microscale.

- Functionalization and modification of polysilanes: Polysilanes can be functionalized and modified to enhance their properties or introduce new functionalities. This includes the incorporation of various organic groups, crosslinking agents, or other reactive moieties. Such modifications allow for the tailoring of polysilanes for specific applications and the development of novel hybrid materials.

- Polysilanes in electronic and optoelectronic devices: Polysilanes find applications in electronic and optoelectronic devices due to their unique electronic structure and optical properties. They can be used as charge transport materials, light-emitting components, or as precursors for silicon-based materials in solar cells and other electronic devices. The ability to tune their properties makes them versatile materials for various electronic applications.

02 Polysilane-based coatings and films

Polysilanes can be used to create thin films and coatings with specific properties. These films can be applied to various substrates and may exhibit characteristics such as improved adhesion, chemical resistance, or optical properties. The process of forming these coatings often involves deposition techniques or curing methods to achieve the desired film structure.Expand Specific Solutions03 Polysilane derivatives and modifications

Various modifications can be made to the basic polysilane structure to enhance or alter its properties. This includes the incorporation of functional groups, copolymerization with other monomers, or the creation of hybrid materials. These modifications can lead to improved solubility, processability, or specific functionalities for targeted applications.Expand Specific Solutions04 Applications in lithography and semiconductor processing

Polysilanes have found significant use in lithography and semiconductor processing. They can serve as photoresists or pattern-forming materials in the fabrication of microelectronic devices. The silicon-based structure of polysilanes allows for high etch resistance and compatibility with existing semiconductor manufacturing processes.Expand Specific Solutions05 Polysilane-based composites and hybrid materials

Polysilanes can be combined with other materials to create composites or hybrid structures with enhanced properties. These may include inorganic-organic hybrid materials, nanocomposites, or blends with other polymers. Such combinations can lead to materials with improved mechanical, thermal, or electrical properties for various applications.Expand Specific Solutions

Key Industry Players

The development of polysilane-based high-precision research tools is in an emerging phase, with a growing market driven by increasing demand for advanced materials in various industries. The technology's maturity is still evolving, as evidenced by ongoing research and development efforts from key players. Companies like Osaka Gas Co., Ltd., Air Liquide SA, and Eastman Chemical Co. are at the forefront, leveraging their expertise in chemical engineering and materials science to advance polysilane applications. Japanese firms, including Nippon Paint Co., Ltd. and Japan Science & Technology Agency, are also making significant contributions, highlighting the global nature of this technological race. As the field progresses, collaborations between industry leaders and research institutions are likely to accelerate innovation and commercialization of polysilane-based tools.

Evonik Operations GmbH

Technical Solution: Evonik has developed a range of specialized polysilane materials tailored for high-precision research applications. Their innovative approach includes the synthesis of hyperbranched polysilanes with enhanced thermal and mechanical properties, suitable for use in advanced optical and electronic devices[9]. Evonik's polysilanes feature unique surface functionalization, allowing for improved integration with other materials and increased sensitivity in sensor applications[10]. The company has also explored the use of polysilane-based nanocomposites in the development of high-performance coatings for precision optics and analytical instruments[11]. Additionally, Evonik has made significant progress in the field of polysilane-based 3D printing materials, enabling the fabrication of complex, high-precision components for research equipment[12].

Strengths: Diverse portfolio of polysilane products, strong focus on customization for specific applications. Weaknesses: May face challenges in competing with established suppliers in some niche markets.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has made significant contributions to the development of polysilane-based technologies for high-precision research tools. Their approach focuses on the synthesis of novel polysilane structures with enhanced photophysical properties, suitable for use in advanced spectroscopy and imaging systems[17]. Fraunhofer researchers have developed polysilane-based photoresists with improved resolution and sensitivity for nanolithography applications, enabling the fabrication of complex nanostructures for cutting-edge research[18]. The institute has also explored the use of polysilanes in the development of high-performance gas sensors and chemical detectors, leveraging the materials' unique electronic properties[19]. Additionally, Fraunhofer has made advancements in polysilane-based organic electronics, paving the way for new generations of flexible and printable research instruments[20].

Strengths: Strong interdisciplinary research approach, close collaboration with industry partners. Weaknesses: May face challenges in commercialization and technology transfer of some research outcomes.

Core Innovations

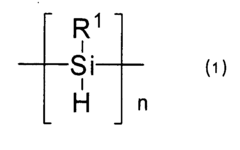

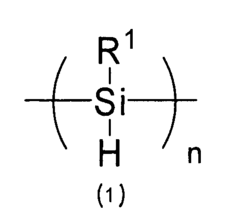

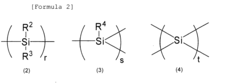

Polysilane and polysilane-containing resin composition

PatentInactiveUS8163863B2

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups like hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Polysilane and resin composition containing polysilane

PatentInactiveEP1958979A1

Innovation

- Introducing a Si-H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups such as hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Regulatory Framework

The regulatory framework surrounding polysilane and its applications in high-precision research tools is complex and multifaceted, involving various governmental agencies and international bodies. At the national level, organizations such as the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) play crucial roles in regulating the use, handling, and disposal of polysilane-based materials. These agencies establish guidelines for workplace safety, environmental protection, and proper waste management practices.

In the context of research and development, institutions working with polysilane must adhere to strict laboratory safety protocols and obtain necessary permits for its use. The National Institutes of Health (NIH) and similar bodies in other countries provide guidelines for the safe handling of chemical compounds in research settings. Additionally, the Food and Drug Administration (FDA) may be involved in regulating polysilane-based tools used in biomedical research or diagnostic applications.

Internationally, the European Chemicals Agency (ECHA) and its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impact the use of polysilane in research tools within the European Union. Similar regulatory bodies exist in other regions, such as Japan's Ministry of Economy, Trade and Industry (METI) and China's State Administration for Market Regulation (SAMR).

The transportation of polysilane and related materials is subject to regulations set by the International Air Transport Association (IATA) and the International Maritime Organization (IMO). These organizations establish guidelines for the safe packaging, labeling, and shipping of potentially hazardous materials used in research.

As polysilane-facilitated high-precision research tools often involve nanotechnology, specific regulations addressing nanomaterials come into play. Various countries have developed or are in the process of developing regulatory frameworks for nanomaterials, which may impact the development and use of polysilane-based tools. The Organization for Economic Co-operation and Development (OECD) has been instrumental in harmonizing international approaches to nanotechnology regulation.

Intellectual property considerations are also a significant aspect of the regulatory landscape. Patent offices worldwide, such as the United States Patent and Trademark Office (USPTO) and the European Patent Office (EPO), play crucial roles in protecting innovations related to polysilane-based research tools. Researchers and companies must navigate complex patent laws to secure their intellectual property rights while ensuring compliance with existing patents.

In the context of research and development, institutions working with polysilane must adhere to strict laboratory safety protocols and obtain necessary permits for its use. The National Institutes of Health (NIH) and similar bodies in other countries provide guidelines for the safe handling of chemical compounds in research settings. Additionally, the Food and Drug Administration (FDA) may be involved in regulating polysilane-based tools used in biomedical research or diagnostic applications.

Internationally, the European Chemicals Agency (ECHA) and its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impact the use of polysilane in research tools within the European Union. Similar regulatory bodies exist in other regions, such as Japan's Ministry of Economy, Trade and Industry (METI) and China's State Administration for Market Regulation (SAMR).

The transportation of polysilane and related materials is subject to regulations set by the International Air Transport Association (IATA) and the International Maritime Organization (IMO). These organizations establish guidelines for the safe packaging, labeling, and shipping of potentially hazardous materials used in research.

As polysilane-facilitated high-precision research tools often involve nanotechnology, specific regulations addressing nanomaterials come into play. Various countries have developed or are in the process of developing regulatory frameworks for nanomaterials, which may impact the development and use of polysilane-based tools. The Organization for Economic Co-operation and Development (OECD) has been instrumental in harmonizing international approaches to nanotechnology regulation.

Intellectual property considerations are also a significant aspect of the regulatory landscape. Patent offices worldwide, such as the United States Patent and Trademark Office (USPTO) and the European Patent Office (EPO), play crucial roles in protecting innovations related to polysilane-based research tools. Researchers and companies must navigate complex patent laws to secure their intellectual property rights while ensuring compliance with existing patents.

Environmental Impact

The environmental impact of polysilane in high-precision research tools is a critical aspect to consider as these materials become increasingly prevalent in advanced scientific and technological applications. Polysilanes, being silicon-based polymers, offer unique properties that contribute to the development of highly sensitive and accurate research instruments. However, their production, use, and disposal present both challenges and opportunities from an environmental perspective.

The synthesis of polysilanes typically involves energy-intensive processes and the use of potentially hazardous chemicals. This raises concerns about the carbon footprint associated with their production and the potential for chemical pollution if not properly managed. However, advancements in green chemistry techniques are gradually improving the environmental profile of polysilane manufacturing, with efforts focused on developing more sustainable synthesis methods and reducing the use of toxic precursors.

In terms of their application in research tools, polysilanes contribute to enhanced efficiency and precision, which can indirectly lead to positive environmental outcomes. By enabling more accurate measurements and analyses, these materials facilitate research that can drive innovations in clean energy, environmental monitoring, and sustainable technologies. This indirect benefit should be weighed against the direct environmental costs of their production and use.

The durability and stability of polysilanes in research instruments also play a role in their environmental impact. While these properties ensure long-lasting performance, they may pose challenges for end-of-life management. The disposal or recycling of polysilane-containing devices requires careful consideration to prevent potential environmental contamination. Research into biodegradable variants of polysilanes is ongoing, aiming to address this concern and improve the overall lifecycle sustainability of these materials.

Furthermore, the use of polysilanes in high-precision tools may contribute to the miniaturization of research equipment. This trend towards smaller, more efficient devices can lead to reduced material consumption and energy usage in laboratory settings, aligning with broader sustainability goals in scientific research.

As the demand for high-precision research tools grows, it is crucial to continue assessing and mitigating the environmental impacts of polysilanes throughout their lifecycle. This includes exploring alternative materials, optimizing production processes, and developing effective recycling and disposal methods. By addressing these challenges, the scientific community can harness the benefits of polysilanes while minimizing their environmental footprint, ensuring a more sustainable approach to advanced research and development.

The synthesis of polysilanes typically involves energy-intensive processes and the use of potentially hazardous chemicals. This raises concerns about the carbon footprint associated with their production and the potential for chemical pollution if not properly managed. However, advancements in green chemistry techniques are gradually improving the environmental profile of polysilane manufacturing, with efforts focused on developing more sustainable synthesis methods and reducing the use of toxic precursors.

In terms of their application in research tools, polysilanes contribute to enhanced efficiency and precision, which can indirectly lead to positive environmental outcomes. By enabling more accurate measurements and analyses, these materials facilitate research that can drive innovations in clean energy, environmental monitoring, and sustainable technologies. This indirect benefit should be weighed against the direct environmental costs of their production and use.

The durability and stability of polysilanes in research instruments also play a role in their environmental impact. While these properties ensure long-lasting performance, they may pose challenges for end-of-life management. The disposal or recycling of polysilane-containing devices requires careful consideration to prevent potential environmental contamination. Research into biodegradable variants of polysilanes is ongoing, aiming to address this concern and improve the overall lifecycle sustainability of these materials.

Furthermore, the use of polysilanes in high-precision tools may contribute to the miniaturization of research equipment. This trend towards smaller, more efficient devices can lead to reduced material consumption and energy usage in laboratory settings, aligning with broader sustainability goals in scientific research.

As the demand for high-precision research tools grows, it is crucial to continue assessing and mitigating the environmental impacts of polysilanes throughout their lifecycle. This includes exploring alternative materials, optimizing production processes, and developing effective recycling and disposal methods. By addressing these challenges, the scientific community can harness the benefits of polysilanes while minimizing their environmental footprint, ensuring a more sustainable approach to advanced research and development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!