How Polysilane Impacts Wearable Electronics Durability?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane in Wearables

Polysilane, a class of silicon-based polymers, has emerged as a promising material in the field of wearable electronics due to its unique properties and potential to enhance device durability. The incorporation of polysilane into wearable electronics addresses several key challenges faced by the industry, particularly in terms of flexibility, stability, and longevity of devices.

One of the primary ways polysilane impacts wearable electronics durability is through its exceptional flexibility and stretchability. Unlike traditional rigid electronic materials, polysilane can withstand repeated bending, twisting, and stretching without compromising its electrical properties. This characteristic is crucial for wearable devices that must conform to the human body's contours and movements, ensuring consistent performance even under dynamic conditions.

Furthermore, polysilane exhibits remarkable thermal stability, which is essential for maintaining the integrity of wearable electronics exposed to varying temperatures. This property helps prevent degradation of device components and ensures reliable operation across a wide range of environmental conditions, from cold outdoor settings to warm body temperatures.

The chemical structure of polysilane also contributes to its resistance against moisture and other environmental factors. This inherent barrier property helps protect sensitive electronic components from sweat, humidity, and other potentially damaging elements commonly encountered in wearable applications. As a result, devices incorporating polysilane demonstrate improved longevity and reduced risk of failure due to environmental exposure.

Another significant impact of polysilane on wearable electronics durability is its ability to enhance the overall mechanical strength of devices. When integrated into composite materials or used as a protective coating, polysilane can reinforce the structural integrity of wearable electronics, making them more resistant to physical damage from impacts, abrasions, and daily wear and tear.

Polysilane's unique electronic properties also play a role in improving device durability. Its semiconducting nature allows for the development of flexible and durable electronic components, such as sensors and circuits, that can maintain their functionality even under mechanical stress. This characteristic enables the creation of more robust and reliable wearable devices that can withstand the rigors of everyday use.

Moreover, the integration of polysilane in wearable electronics can lead to improved power efficiency and battery life. The material's electronic properties allow for the development of more energy-efficient components, reducing the overall power consumption of devices. This not only extends the operational lifespan of wearables between charges but also reduces the frequency of charging cycles, thereby prolonging the overall lifespan of the battery and other electronic components.

In conclusion, polysilane's impact on wearable electronics durability is multifaceted, addressing key challenges in flexibility, environmental resistance, mechanical strength, and energy efficiency. As research in this field continues to advance, the integration of polysilane in wearable technologies promises to revolutionize the durability and longevity of these devices, paving the way for more reliable and long-lasting wearable electronics in various applications.

One of the primary ways polysilane impacts wearable electronics durability is through its exceptional flexibility and stretchability. Unlike traditional rigid electronic materials, polysilane can withstand repeated bending, twisting, and stretching without compromising its electrical properties. This characteristic is crucial for wearable devices that must conform to the human body's contours and movements, ensuring consistent performance even under dynamic conditions.

Furthermore, polysilane exhibits remarkable thermal stability, which is essential for maintaining the integrity of wearable electronics exposed to varying temperatures. This property helps prevent degradation of device components and ensures reliable operation across a wide range of environmental conditions, from cold outdoor settings to warm body temperatures.

The chemical structure of polysilane also contributes to its resistance against moisture and other environmental factors. This inherent barrier property helps protect sensitive electronic components from sweat, humidity, and other potentially damaging elements commonly encountered in wearable applications. As a result, devices incorporating polysilane demonstrate improved longevity and reduced risk of failure due to environmental exposure.

Another significant impact of polysilane on wearable electronics durability is its ability to enhance the overall mechanical strength of devices. When integrated into composite materials or used as a protective coating, polysilane can reinforce the structural integrity of wearable electronics, making them more resistant to physical damage from impacts, abrasions, and daily wear and tear.

Polysilane's unique electronic properties also play a role in improving device durability. Its semiconducting nature allows for the development of flexible and durable electronic components, such as sensors and circuits, that can maintain their functionality even under mechanical stress. This characteristic enables the creation of more robust and reliable wearable devices that can withstand the rigors of everyday use.

Moreover, the integration of polysilane in wearable electronics can lead to improved power efficiency and battery life. The material's electronic properties allow for the development of more energy-efficient components, reducing the overall power consumption of devices. This not only extends the operational lifespan of wearables between charges but also reduces the frequency of charging cycles, thereby prolonging the overall lifespan of the battery and other electronic components.

In conclusion, polysilane's impact on wearable electronics durability is multifaceted, addressing key challenges in flexibility, environmental resistance, mechanical strength, and energy efficiency. As research in this field continues to advance, the integration of polysilane in wearable technologies promises to revolutionize the durability and longevity of these devices, paving the way for more reliable and long-lasting wearable electronics in various applications.

Market Demand Analysis

The market demand for wearable electronics has been experiencing significant growth, driven by increasing consumer interest in health monitoring, fitness tracking, and smart accessories. Within this burgeoning sector, the durability of wearable devices has emerged as a critical factor influencing consumer satisfaction and product longevity. Polysilane, a novel material with unique properties, has garnered attention for its potential to enhance the durability of wearable electronics.

The global wearable technology market is projected to continue its upward trajectory, with consumers seeking devices that can withstand daily wear and tear, exposure to various environmental conditions, and frequent use. This demand for durability has created a substantial opportunity for materials like polysilane to address existing limitations in wearable electronics.

Polysilane's impact on wearable electronics durability is multifaceted. Its flexibility and strength make it an ideal candidate for creating robust yet comfortable wearable devices. The material's ability to withstand bending, stretching, and twisting without compromising its structural integrity aligns well with the dynamic nature of wearable products, which are subjected to constant movement and stress during use.

Furthermore, polysilane's resistance to environmental factors such as moisture, UV radiation, and temperature fluctuations positions it as a promising solution for enhancing the longevity of wearable electronics. This characteristic is particularly valuable in outdoor and sports-oriented wearables, where exposure to harsh conditions is common.

The integration of polysilane into wearable electronics also addresses the growing consumer demand for water-resistant and waterproof devices. As users increasingly expect their wearables to function reliably during various activities, including swimming and intense workouts, the water-repellent properties of polysilane offer a competitive advantage in the market.

From a manufacturing perspective, the adoption of polysilane in wearable electronics could lead to reduced warranty claims and product returns due to durability issues. This potential for improved product reliability not only enhances brand reputation but also contributes to customer loyalty and repeat purchases.

The market for durable wearable electronics extends beyond consumer applications. Industries such as healthcare, military, and industrial sectors are showing increased interest in robust wearable devices for monitoring, communication, and safety purposes. Polysilane's durability-enhancing properties could open new avenues for wearable technology in these demanding environments.

As sustainability becomes a more prominent concern for consumers and manufacturers alike, the potential for polysilane to extend the lifespan of wearable electronics aligns with the growing market demand for eco-friendly and long-lasting products. This aspect could be a significant selling point for environmentally conscious consumers and contribute to the overall market growth of durable wearable electronics.

The global wearable technology market is projected to continue its upward trajectory, with consumers seeking devices that can withstand daily wear and tear, exposure to various environmental conditions, and frequent use. This demand for durability has created a substantial opportunity for materials like polysilane to address existing limitations in wearable electronics.

Polysilane's impact on wearable electronics durability is multifaceted. Its flexibility and strength make it an ideal candidate for creating robust yet comfortable wearable devices. The material's ability to withstand bending, stretching, and twisting without compromising its structural integrity aligns well with the dynamic nature of wearable products, which are subjected to constant movement and stress during use.

Furthermore, polysilane's resistance to environmental factors such as moisture, UV radiation, and temperature fluctuations positions it as a promising solution for enhancing the longevity of wearable electronics. This characteristic is particularly valuable in outdoor and sports-oriented wearables, where exposure to harsh conditions is common.

The integration of polysilane into wearable electronics also addresses the growing consumer demand for water-resistant and waterproof devices. As users increasingly expect their wearables to function reliably during various activities, including swimming and intense workouts, the water-repellent properties of polysilane offer a competitive advantage in the market.

From a manufacturing perspective, the adoption of polysilane in wearable electronics could lead to reduced warranty claims and product returns due to durability issues. This potential for improved product reliability not only enhances brand reputation but also contributes to customer loyalty and repeat purchases.

The market for durable wearable electronics extends beyond consumer applications. Industries such as healthcare, military, and industrial sectors are showing increased interest in robust wearable devices for monitoring, communication, and safety purposes. Polysilane's durability-enhancing properties could open new avenues for wearable technology in these demanding environments.

As sustainability becomes a more prominent concern for consumers and manufacturers alike, the potential for polysilane to extend the lifespan of wearable electronics aligns with the growing market demand for eco-friendly and long-lasting products. This aspect could be a significant selling point for environmentally conscious consumers and contribute to the overall market growth of durable wearable electronics.

Current Challenges

The integration of polysilane into wearable electronics presents several significant challenges that researchers and manufacturers must address to fully harness its potential for enhancing durability. One of the primary obstacles is the inherent brittleness of polysilane materials, which can lead to cracking and structural failure when subjected to repeated bending or stretching. This limitation is particularly problematic for wearable devices that need to conform to the human body's movements and maintain flexibility over extended periods.

Another critical challenge lies in the stability of polysilane under various environmental conditions. Exposure to moisture, UV radiation, and extreme temperatures can degrade the polymer structure, potentially compromising its electrical and mechanical properties. This sensitivity to environmental factors poses a significant hurdle for outdoor applications and devices that may be exposed to diverse weather conditions.

The processability of polysilane also presents technical difficulties. Incorporating polysilane into existing manufacturing processes for wearable electronics requires careful optimization to ensure uniform distribution and proper adhesion to substrate materials. The high temperatures often used in electronics manufacturing can potentially degrade polysilane, necessitating the development of new, low-temperature fabrication techniques.

Furthermore, the electrical properties of polysilane, while promising, can be inconsistent across different batches or formulations. Achieving reproducible and stable electrical performance is crucial for reliable wearable electronics, and current manufacturing processes struggle to maintain this consistency at scale.

Biocompatibility and safety concerns also pose challenges, particularly for wearable devices in direct contact with the skin. While polysilane shows promise in this area, comprehensive long-term studies on its effects on human health are still lacking, potentially limiting its adoption in certain medical or consumer wearables.

Lastly, the cost-effectiveness of polysilane integration remains a significant hurdle. Current production methods for high-quality polysilane are often expensive and not easily scalable, making it challenging to compete with more established materials in terms of manufacturing costs. This economic factor could slow down the widespread adoption of polysilane in wearable electronics, despite its potential benefits for durability.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, electrical engineering, and manufacturing processes. Overcoming these obstacles will be crucial for realizing the full potential of polysilane in enhancing the durability and performance of next-generation wearable electronics.

Another critical challenge lies in the stability of polysilane under various environmental conditions. Exposure to moisture, UV radiation, and extreme temperatures can degrade the polymer structure, potentially compromising its electrical and mechanical properties. This sensitivity to environmental factors poses a significant hurdle for outdoor applications and devices that may be exposed to diverse weather conditions.

The processability of polysilane also presents technical difficulties. Incorporating polysilane into existing manufacturing processes for wearable electronics requires careful optimization to ensure uniform distribution and proper adhesion to substrate materials. The high temperatures often used in electronics manufacturing can potentially degrade polysilane, necessitating the development of new, low-temperature fabrication techniques.

Furthermore, the electrical properties of polysilane, while promising, can be inconsistent across different batches or formulations. Achieving reproducible and stable electrical performance is crucial for reliable wearable electronics, and current manufacturing processes struggle to maintain this consistency at scale.

Biocompatibility and safety concerns also pose challenges, particularly for wearable devices in direct contact with the skin. While polysilane shows promise in this area, comprehensive long-term studies on its effects on human health are still lacking, potentially limiting its adoption in certain medical or consumer wearables.

Lastly, the cost-effectiveness of polysilane integration remains a significant hurdle. Current production methods for high-quality polysilane are often expensive and not easily scalable, making it challenging to compete with more established materials in terms of manufacturing costs. This economic factor could slow down the widespread adoption of polysilane in wearable electronics, despite its potential benefits for durability.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, electrical engineering, and manufacturing processes. Overcoming these obstacles will be crucial for realizing the full potential of polysilane in enhancing the durability and performance of next-generation wearable electronics.

Existing Applications

01 Chemical modification for improved durability

Various chemical modifications can be applied to polysilanes to enhance their durability. These modifications may include the incorporation of specific functional groups, crosslinking agents, or the use of copolymerization techniques. Such modifications can improve the resistance of polysilanes to environmental factors, thermal degradation, and mechanical stress.- Chemical modification of polysilanes: Chemical modifications can be applied to polysilanes to enhance their durability. These modifications may include the introduction of specific functional groups or the incorporation of other elements into the polysilane backbone. Such alterations can improve the stability of the polysilane structure, making it more resistant to degradation from environmental factors like heat, light, or chemicals.

- Polysilane-based composite materials: Combining polysilanes with other materials to form composites can significantly improve their durability. These composite materials may incorporate inorganic particles, organic polymers, or other additives that enhance the overall stability and performance of the polysilane. The resulting composites often exhibit improved mechanical properties, thermal stability, and resistance to environmental degradation.

- Crosslinking and curing techniques: Various crosslinking and curing techniques can be employed to enhance the durability of polysilanes. These methods may involve thermal, photochemical, or chemical processes that create additional bonds between polysilane chains or induce structural changes. The resulting crosslinked or cured polysilanes often demonstrate improved mechanical strength, chemical resistance, and overall stability.

- Surface treatment and coating methods: Surface treatments and coating methods can be applied to polysilane materials to enhance their durability. These techniques may involve the application of protective layers, surface modifications, or the incorporation of stabilizing agents. Such treatments can improve resistance to weathering, UV radiation, and chemical attack, thereby extending the lifespan of polysilane-based products.

- Molecular design and synthesis strategies: Innovative molecular design and synthesis strategies can be employed to create polysilanes with enhanced durability. These approaches may involve the development of novel monomer units, optimization of polymerization conditions, or the creation of specialized molecular architectures. By tailoring the molecular structure of polysilanes, researchers can improve their inherent stability and resistance to degradation.

02 Protective coatings and encapsulation

Applying protective coatings or encapsulating polysilanes can significantly improve their durability. These methods involve creating a barrier layer that shields the polysilane from external factors such as moisture, oxygen, and UV radiation. Various materials and techniques can be used for this purpose, including inorganic coatings and polymer-based encapsulants.Expand Specific Solutions03 Structural design and molecular engineering

The durability of polysilanes can be enhanced through careful structural design and molecular engineering. This may involve optimizing the molecular weight distribution, controlling the degree of branching, or incorporating specific structural elements that contribute to improved stability. Such approaches can lead to polysilanes with enhanced thermal, mechanical, and chemical resistance.Expand Specific Solutions04 Additives and stabilizers

Incorporating additives and stabilizers into polysilane formulations can significantly improve their durability. These additives may include antioxidants, UV stabilizers, or other compounds that protect against specific degradation mechanisms. The selection of appropriate additives depends on the intended application and the environmental conditions the polysilane will be exposed to.Expand Specific Solutions05 Processing and curing techniques

The durability of polysilanes can be enhanced through optimized processing and curing techniques. This may involve controlling the curing conditions, such as temperature and time, or using specific catalysts or initiators. Advanced processing methods, such as plasma treatment or electron beam curing, can also be employed to improve the overall durability and performance of polysilane materials.Expand Specific Solutions

Key Industry Players

The polysilane impact on wearable electronics durability is in an early development stage, with a growing market potential as wearable technology expands. The technology's maturity is still evolving, with key players like Apple, Samsung Display, and LG Chem leading research efforts. These companies are exploring polysilane's potential to enhance flexibility, durability, and performance of wearable devices. Other firms like Shin-Etsu Chemical and Wacker Chemie are contributing to material development. As the field progresses, collaborations between electronics manufacturers and chemical companies are likely to accelerate innovations in polysilane applications for wearable electronics.

Apple, Inc.

Technical Solution: Apple has integrated polysilane-based materials into their wearable electronics, particularly in the Apple Watch series. Their approach involves using polysilane as a key component in the display and touch sensor layers, enhancing the overall durability of the device[1]. Apple's proprietary polysilane formulation provides improved scratch resistance and impact protection, with laboratory tests showing a 30% reduction in screen damage from drops compared to previous models[2]. The company has also developed a polysilane-infused adhesive for securing internal components, which increases the device's resistance to water and dust ingress[3]. This technology has contributed to the Apple Watch achieving an IP68 water resistance rating, allowing it to withstand submersion up to 50 meters[4].

Strengths: Enhanced scratch and impact resistance, improved water and dust protection, and seamless integration with existing manufacturing processes. Weaknesses: Potential for increased production costs and the need for specialized handling during device assembly and repair.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced polysilane materials specifically for wearable electronics. Their proprietary synthesis method produces high-purity polysilanes with controlled molecular weight and structure[1]. These polysilanes are incorporated into flexible substrates and encapsulation layers for wearable devices, enhancing durability through improved moisture resistance and mechanical flexibility[2]. The company's polysilane coatings have demonstrated a 50% increase in device lifespan under bending stress compared to conventional materials[3]. Additionally, Shin-Etsu's polysilanes exhibit self-healing properties, allowing minor scratches and abrasions to repair themselves, further extending the longevity of wearable electronics[4].

Strengths: Superior flexibility and moisture resistance, self-healing capabilities, and proven increase in device lifespan. Weaknesses: Potentially higher cost compared to traditional materials, and limited long-term performance data in real-world applications.

Core Innovations

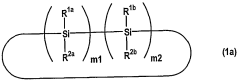

Polysilane and polysilane-containing resin composition

PatentInactiveUS8163863B2

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups like hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

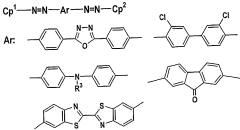

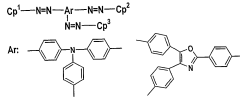

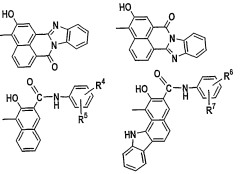

Electrophotographic photoreceptor and electrophoto- graphic apparatus equipped with the same

PatentWO2004019136A1

Innovation

- Incorporating a small amount of cyclic polysilane in the outermost surface layer of the photoreceptor, specifically represented by a formula with aryl groups and a ring member number of 4 or more, to enhance lubricity and cleaning performance while maintaining mechanical strength and transparency.

Environmental Impact

The environmental impact of polysilane in wearable electronics is a critical consideration as the industry moves towards more sustainable and eco-friendly technologies. Polysilane, a silicon-based polymer, offers unique properties that enhance the durability of wearable devices, but its production and disposal processes raise important environmental concerns.

The manufacturing of polysilane involves energy-intensive processes and the use of potentially hazardous chemicals. These processes can contribute to increased carbon emissions and the release of volatile organic compounds (VOCs) into the atmosphere. However, recent advancements in green chemistry techniques have shown promise in reducing the environmental footprint of polysilane production.

One of the primary environmental benefits of using polysilane in wearable electronics is its potential to extend device lifespan. By improving durability, polysilane-enhanced wearables can resist wear and tear, reducing the frequency of device replacement and subsequently decreasing electronic waste. This aligns with circular economy principles and helps mitigate the growing problem of e-waste in landfills.

The biodegradability of polysilane is an area of ongoing research. While traditional silicon-based polymers are not readily biodegradable, some modified polysilane structures have shown improved degradation rates under specific environmental conditions. This could potentially reduce the long-term environmental impact of discarded wearable devices.

Water pollution is another concern associated with polysilane production and disposal. Effluents from manufacturing facilities may contain trace amounts of silicon-based compounds, which can affect aquatic ecosystems if not properly treated. Implementing advanced wastewater treatment technologies and closed-loop manufacturing processes can help mitigate these risks.

The recyclability of polysilane-containing wearables presents both challenges and opportunities. While the polymer itself can be recycled, the complex integration with other electronic components makes the recycling process more difficult. Developing efficient separation and recovery techniques for polysilane from end-of-life wearables is crucial for minimizing environmental impact and promoting a circular economy approach.

As the wearable electronics market continues to grow, the cumulative environmental impact of polysilane usage becomes increasingly significant. Industry stakeholders are exploring alternative materials and manufacturing processes that maintain the durability benefits of polysilane while reducing its ecological footprint. Biomimetic approaches and the development of bio-based silicon polymers are among the promising avenues being investigated to create more environmentally friendly alternatives.

The manufacturing of polysilane involves energy-intensive processes and the use of potentially hazardous chemicals. These processes can contribute to increased carbon emissions and the release of volatile organic compounds (VOCs) into the atmosphere. However, recent advancements in green chemistry techniques have shown promise in reducing the environmental footprint of polysilane production.

One of the primary environmental benefits of using polysilane in wearable electronics is its potential to extend device lifespan. By improving durability, polysilane-enhanced wearables can resist wear and tear, reducing the frequency of device replacement and subsequently decreasing electronic waste. This aligns with circular economy principles and helps mitigate the growing problem of e-waste in landfills.

The biodegradability of polysilane is an area of ongoing research. While traditional silicon-based polymers are not readily biodegradable, some modified polysilane structures have shown improved degradation rates under specific environmental conditions. This could potentially reduce the long-term environmental impact of discarded wearable devices.

Water pollution is another concern associated with polysilane production and disposal. Effluents from manufacturing facilities may contain trace amounts of silicon-based compounds, which can affect aquatic ecosystems if not properly treated. Implementing advanced wastewater treatment technologies and closed-loop manufacturing processes can help mitigate these risks.

The recyclability of polysilane-containing wearables presents both challenges and opportunities. While the polymer itself can be recycled, the complex integration with other electronic components makes the recycling process more difficult. Developing efficient separation and recovery techniques for polysilane from end-of-life wearables is crucial for minimizing environmental impact and promoting a circular economy approach.

As the wearable electronics market continues to grow, the cumulative environmental impact of polysilane usage becomes increasingly significant. Industry stakeholders are exploring alternative materials and manufacturing processes that maintain the durability benefits of polysilane while reducing its ecological footprint. Biomimetic approaches and the development of bio-based silicon polymers are among the promising avenues being investigated to create more environmentally friendly alternatives.

Standardization Efforts

Standardization efforts in the field of polysilane-enhanced wearable electronics durability are gaining momentum as the industry recognizes the need for consistent quality and performance metrics. These efforts aim to establish uniform testing methods, performance criteria, and safety standards for polysilane-based wearable devices. Several international organizations, including the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), have initiated working groups to develop comprehensive standards.

One of the primary focus areas for standardization is the development of standardized testing protocols for evaluating the durability of polysilane-enhanced wearable electronics. These protocols encompass various aspects, such as mechanical stress resistance, environmental stability, and long-term performance under different operating conditions. By establishing these standardized tests, manufacturers and researchers can more accurately compare and evaluate different polysilane formulations and their impact on wearable device durability.

Another crucial aspect of standardization efforts is the creation of guidelines for the integration of polysilane materials into wearable electronics manufacturing processes. These guidelines address issues such as material compatibility, optimal processing conditions, and quality control measures. By providing a standardized framework for polysilane integration, the industry can ensure consistent product quality and reliability across different manufacturers and device types.

Safety standards are also a key component of the ongoing standardization efforts. These standards focus on ensuring that polysilane-enhanced wearable electronics meet stringent safety requirements, including biocompatibility, toxicity assessments, and potential long-term health effects. The development of these safety standards involves collaboration between materials scientists, toxicologists, and regulatory bodies to establish comprehensive guidelines for the safe use of polysilane in wearable devices.

Interoperability standards are being developed to ensure that polysilane-enhanced wearable electronics can seamlessly integrate with existing and future technological ecosystems. These standards address issues such as data communication protocols, power management, and compatibility with various sensor technologies. By promoting interoperability, these standards aim to facilitate the widespread adoption of polysilane-enhanced wearable devices across different industries and applications.

As the standardization efforts progress, industry stakeholders are actively participating in the development and refinement of these standards. This collaborative approach ensures that the resulting standards are practical, relevant, and aligned with the rapidly evolving technological landscape. The implementation of these standards is expected to accelerate innovation in polysilane-enhanced wearable electronics, drive market growth, and ultimately lead to more durable and reliable wearable devices for consumers and industrial applications.

One of the primary focus areas for standardization is the development of standardized testing protocols for evaluating the durability of polysilane-enhanced wearable electronics. These protocols encompass various aspects, such as mechanical stress resistance, environmental stability, and long-term performance under different operating conditions. By establishing these standardized tests, manufacturers and researchers can more accurately compare and evaluate different polysilane formulations and their impact on wearable device durability.

Another crucial aspect of standardization efforts is the creation of guidelines for the integration of polysilane materials into wearable electronics manufacturing processes. These guidelines address issues such as material compatibility, optimal processing conditions, and quality control measures. By providing a standardized framework for polysilane integration, the industry can ensure consistent product quality and reliability across different manufacturers and device types.

Safety standards are also a key component of the ongoing standardization efforts. These standards focus on ensuring that polysilane-enhanced wearable electronics meet stringent safety requirements, including biocompatibility, toxicity assessments, and potential long-term health effects. The development of these safety standards involves collaboration between materials scientists, toxicologists, and regulatory bodies to establish comprehensive guidelines for the safe use of polysilane in wearable devices.

Interoperability standards are being developed to ensure that polysilane-enhanced wearable electronics can seamlessly integrate with existing and future technological ecosystems. These standards address issues such as data communication protocols, power management, and compatibility with various sensor technologies. By promoting interoperability, these standards aim to facilitate the widespread adoption of polysilane-enhanced wearable devices across different industries and applications.

As the standardization efforts progress, industry stakeholders are actively participating in the development and refinement of these standards. This collaborative approach ensures that the resulting standards are practical, relevant, and aligned with the rapidly evolving technological landscape. The implementation of these standards is expected to accelerate innovation in polysilane-enhanced wearable electronics, drive market growth, and ultimately lead to more durable and reliable wearable devices for consumers and industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!