How to Achieve Cost-Efficient Graphene Battery Manufacturing?

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries have emerged as a promising technology in the energy storage landscape, offering potential advantages over traditional lithium-ion batteries. The evolution of graphene batteries can be traced back to the discovery of graphene in 2004, which sparked intense research into its applications across various fields, including energy storage.

Initially, graphene was primarily used as an additive to enhance the performance of existing battery technologies. Researchers found that incorporating graphene into electrode materials could improve conductivity, stability, and overall battery performance. This phase of development focused on optimizing the integration of graphene into conventional battery designs.

As research progressed, scientists began exploring the possibility of using graphene as a primary component in battery electrodes. This shift marked a significant milestone in graphene battery evolution, as it opened up new avenues for battery design and performance enhancement. The unique properties of graphene, such as its high surface area, excellent electrical conductivity, and mechanical strength, made it an ideal candidate for next-generation energy storage solutions.

The objectives of graphene battery development have evolved alongside technological advancements. The primary goals now include achieving higher energy density, faster charging rates, improved cycle life, and enhanced safety compared to traditional lithium-ion batteries. Additionally, there is a growing emphasis on developing cost-effective manufacturing processes to make graphene batteries commercially viable.

One of the key objectives in graphene battery evolution is to overcome the challenges associated with large-scale production. While graphene shows immense promise in laboratory settings, translating these results into industrial-scale manufacturing has proven to be a significant hurdle. Researchers and engineers are working on developing scalable production methods that can maintain the quality and performance of graphene while reducing costs.

Another important objective is to optimize the integration of graphene into battery components. This includes developing new electrode designs, electrolyte formulations, and cell architectures that can fully leverage the unique properties of graphene. The aim is to create batteries that not only outperform current technologies but also offer new functionalities and applications.

As the technology matures, the focus is shifting towards achieving cost-efficient manufacturing processes. This involves exploring innovative production techniques, such as roll-to-roll manufacturing, that can significantly reduce the cost of graphene battery production. The ultimate goal is to develop graphene batteries that are not only superior in performance but also economically competitive with existing battery technologies.

Initially, graphene was primarily used as an additive to enhance the performance of existing battery technologies. Researchers found that incorporating graphene into electrode materials could improve conductivity, stability, and overall battery performance. This phase of development focused on optimizing the integration of graphene into conventional battery designs.

As research progressed, scientists began exploring the possibility of using graphene as a primary component in battery electrodes. This shift marked a significant milestone in graphene battery evolution, as it opened up new avenues for battery design and performance enhancement. The unique properties of graphene, such as its high surface area, excellent electrical conductivity, and mechanical strength, made it an ideal candidate for next-generation energy storage solutions.

The objectives of graphene battery development have evolved alongside technological advancements. The primary goals now include achieving higher energy density, faster charging rates, improved cycle life, and enhanced safety compared to traditional lithium-ion batteries. Additionally, there is a growing emphasis on developing cost-effective manufacturing processes to make graphene batteries commercially viable.

One of the key objectives in graphene battery evolution is to overcome the challenges associated with large-scale production. While graphene shows immense promise in laboratory settings, translating these results into industrial-scale manufacturing has proven to be a significant hurdle. Researchers and engineers are working on developing scalable production methods that can maintain the quality and performance of graphene while reducing costs.

Another important objective is to optimize the integration of graphene into battery components. This includes developing new electrode designs, electrolyte formulations, and cell architectures that can fully leverage the unique properties of graphene. The aim is to create batteries that not only outperform current technologies but also offer new functionalities and applications.

As the technology matures, the focus is shifting towards achieving cost-efficient manufacturing processes. This involves exploring innovative production techniques, such as roll-to-roll manufacturing, that can significantly reduce the cost of graphene battery production. The ultimate goal is to develop graphene batteries that are not only superior in performance but also economically competitive with existing battery technologies.

Market Demand Analysis for Graphene Batteries

The market demand for graphene batteries is experiencing significant growth, driven by the increasing need for high-performance energy storage solutions across various industries. The automotive sector, particularly electric vehicles (EVs), represents a major market for graphene batteries. As global EV adoption accelerates, the demand for batteries with higher energy density, faster charging capabilities, and longer lifespans continues to rise. Graphene batteries, with their potential to offer these advantages, are well-positioned to capture a substantial share of this expanding market.

Consumer electronics is another key sector driving the demand for graphene batteries. Smartphones, laptops, and wearable devices require batteries that can deliver longer usage times while maintaining compact form factors. Graphene batteries' ability to provide higher energy density and faster charging times aligns well with these requirements, making them attractive to manufacturers and consumers alike.

The renewable energy sector also presents a significant market opportunity for graphene batteries. As the world transitions towards cleaner energy sources, the need for efficient and reliable energy storage systems grows. Graphene batteries could play a crucial role in grid-scale energy storage, helping to balance supply and demand in renewable energy systems and improve overall grid stability.

Industrial applications form another substantial market segment for graphene batteries. Industries such as aerospace, marine, and telecommunications require robust, high-performance energy storage solutions. Graphene batteries' potential for improved durability and performance in extreme conditions makes them well-suited for these demanding applications.

The healthcare sector is emerging as a promising market for graphene batteries, particularly in medical devices and implantable technologies. The batteries' potential for miniaturization and biocompatibility could revolutionize power sources for pacemakers, hearing aids, and other medical devices.

While the market potential for graphene batteries is substantial, it is important to note that the technology is still in its early stages of commercialization. The current market size is relatively small compared to traditional lithium-ion batteries. However, as manufacturing processes improve and costs decrease, the market is expected to grow rapidly. Industry analysts project that the graphene battery market could reach several billion dollars within the next decade, with a compound annual growth rate (CAGR) in the double digits.

To fully capitalize on this market potential, addressing the challenges of cost-efficient manufacturing is crucial. As production scales up and becomes more efficient, the cost of graphene batteries is expected to decrease, making them more competitive with existing battery technologies. This cost reduction will be a key factor in driving widespread adoption across various industries and accelerating market growth.

Consumer electronics is another key sector driving the demand for graphene batteries. Smartphones, laptops, and wearable devices require batteries that can deliver longer usage times while maintaining compact form factors. Graphene batteries' ability to provide higher energy density and faster charging times aligns well with these requirements, making them attractive to manufacturers and consumers alike.

The renewable energy sector also presents a significant market opportunity for graphene batteries. As the world transitions towards cleaner energy sources, the need for efficient and reliable energy storage systems grows. Graphene batteries could play a crucial role in grid-scale energy storage, helping to balance supply and demand in renewable energy systems and improve overall grid stability.

Industrial applications form another substantial market segment for graphene batteries. Industries such as aerospace, marine, and telecommunications require robust, high-performance energy storage solutions. Graphene batteries' potential for improved durability and performance in extreme conditions makes them well-suited for these demanding applications.

The healthcare sector is emerging as a promising market for graphene batteries, particularly in medical devices and implantable technologies. The batteries' potential for miniaturization and biocompatibility could revolutionize power sources for pacemakers, hearing aids, and other medical devices.

While the market potential for graphene batteries is substantial, it is important to note that the technology is still in its early stages of commercialization. The current market size is relatively small compared to traditional lithium-ion batteries. However, as manufacturing processes improve and costs decrease, the market is expected to grow rapidly. Industry analysts project that the graphene battery market could reach several billion dollars within the next decade, with a compound annual growth rate (CAGR) in the double digits.

To fully capitalize on this market potential, addressing the challenges of cost-efficient manufacturing is crucial. As production scales up and becomes more efficient, the cost of graphene batteries is expected to decrease, making them more competitive with existing battery technologies. This cost reduction will be a key factor in driving widespread adoption across various industries and accelerating market growth.

Current Challenges in Graphene Battery Production

Despite the promising potential of graphene batteries, their widespread adoption and cost-efficient manufacturing face several significant challenges. One of the primary obstacles is the high production cost of graphene itself. The current methods for synthesizing high-quality graphene, such as chemical vapor deposition (CVD) or epitaxial growth, are expensive and not easily scalable for mass production. This results in a substantial increase in the overall cost of graphene batteries, making them less competitive compared to traditional lithium-ion batteries.

Another major challenge lies in the complexity of integrating graphene into battery components. The process of incorporating graphene into electrodes, electrolytes, or other battery structures requires precise control and advanced manufacturing techniques. This complexity not only adds to the production costs but also introduces potential quality control issues, which can affect the performance and reliability of the final product.

The lack of standardization in graphene production and battery manufacturing processes further complicates cost-efficient production. Without established industry standards, manufacturers face difficulties in optimizing their production lines and achieving economies of scale. This absence of standardization also hinders the development of automated manufacturing processes, which are crucial for reducing labor costs and increasing production efficiency.

Material wastage during the manufacturing process presents another significant challenge. The current methods of graphene synthesis and battery assembly often result in considerable material loss, which directly impacts the cost-effectiveness of production. Developing more efficient production techniques that minimize waste and maximize the utilization of graphene is essential for reducing overall manufacturing costs.

The need for specialized equipment and facilities for graphene battery production also contributes to the high costs. Many of the processes involved in graphene synthesis and battery assembly require controlled environments and sophisticated machinery, which demand substantial capital investment. This requirement creates a high barrier to entry for new manufacturers and limits the expansion of production capacity in the industry.

Furthermore, the relatively low production volumes of graphene batteries compared to conventional batteries result in higher per-unit costs. The limited demand and production scale prevent manufacturers from benefiting from economies of scale, which is crucial for driving down costs in battery production. Overcoming this challenge requires not only technological advancements but also market development to increase demand and justify larger-scale production.

Another major challenge lies in the complexity of integrating graphene into battery components. The process of incorporating graphene into electrodes, electrolytes, or other battery structures requires precise control and advanced manufacturing techniques. This complexity not only adds to the production costs but also introduces potential quality control issues, which can affect the performance and reliability of the final product.

The lack of standardization in graphene production and battery manufacturing processes further complicates cost-efficient production. Without established industry standards, manufacturers face difficulties in optimizing their production lines and achieving economies of scale. This absence of standardization also hinders the development of automated manufacturing processes, which are crucial for reducing labor costs and increasing production efficiency.

Material wastage during the manufacturing process presents another significant challenge. The current methods of graphene synthesis and battery assembly often result in considerable material loss, which directly impacts the cost-effectiveness of production. Developing more efficient production techniques that minimize waste and maximize the utilization of graphene is essential for reducing overall manufacturing costs.

The need for specialized equipment and facilities for graphene battery production also contributes to the high costs. Many of the processes involved in graphene synthesis and battery assembly require controlled environments and sophisticated machinery, which demand substantial capital investment. This requirement creates a high barrier to entry for new manufacturers and limits the expansion of production capacity in the industry.

Furthermore, the relatively low production volumes of graphene batteries compared to conventional batteries result in higher per-unit costs. The limited demand and production scale prevent manufacturers from benefiting from economies of scale, which is crucial for driving down costs in battery production. Overcoming this challenge requires not only technological advancements but also market development to increase demand and justify larger-scale production.

Cost-Efficient Manufacturing Techniques

01 Cost-effective graphene production methods

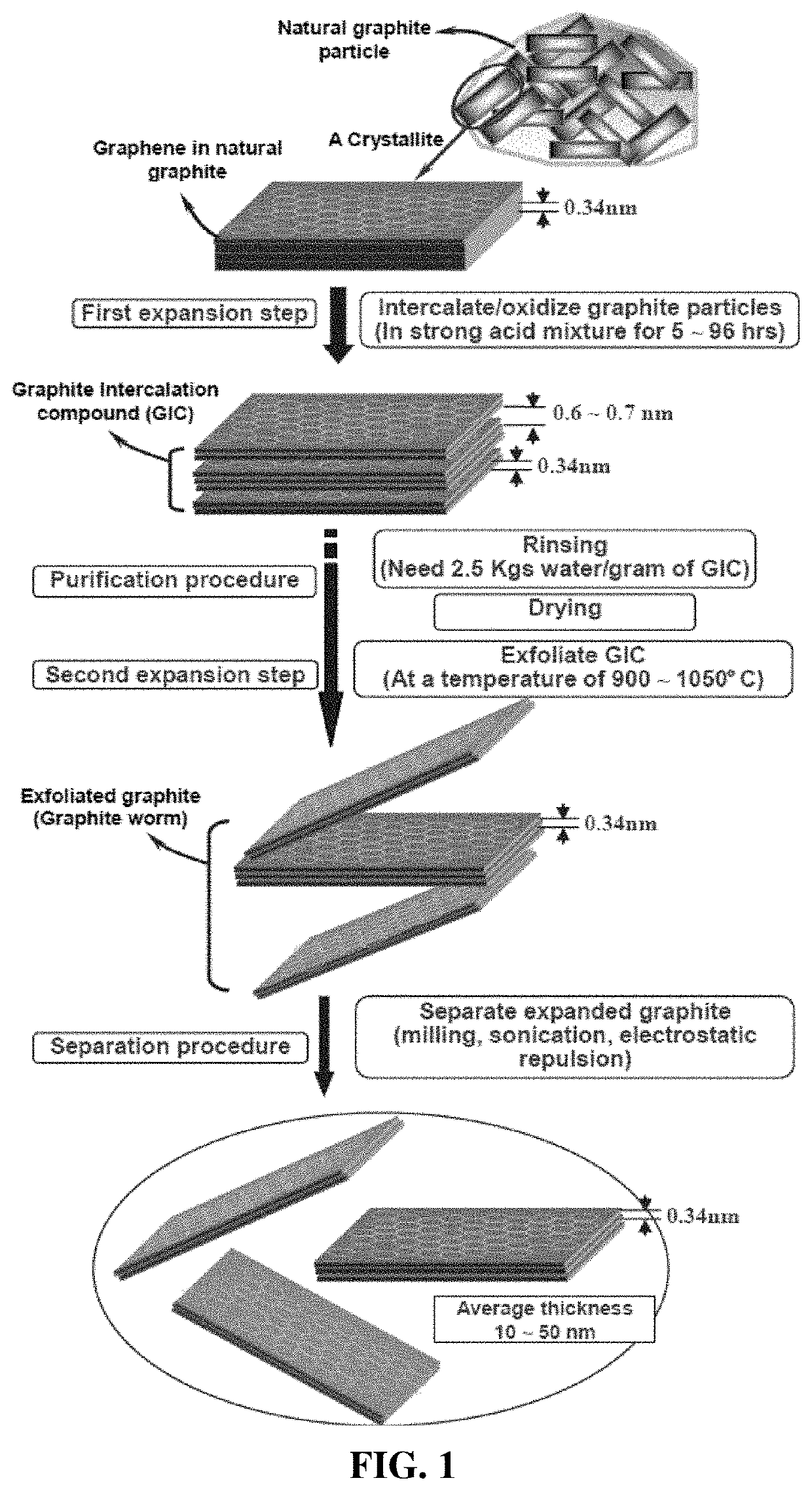

Various methods have been developed to produce graphene more cost-effectively for battery applications. These include improved chemical vapor deposition techniques, exfoliation processes, and scalable synthesis methods. By reducing the production costs of graphene, the overall cost-efficiency of graphene batteries can be significantly improved.- Cost-effective graphene production methods: Developing efficient and scalable methods for producing high-quality graphene at lower costs is crucial for improving the cost-efficiency of graphene batteries. These methods may include chemical vapor deposition, liquid-phase exfoliation, or electrochemical exfoliation techniques that can be optimized for large-scale production while maintaining the desired properties of graphene.

- Graphene-based composite materials for electrodes: Incorporating graphene into composite materials for battery electrodes can enhance performance while potentially reducing costs. These composites may combine graphene with other conductive materials or active materials to optimize the electrode's properties, such as conductivity, capacity, and stability, while minimizing the amount of expensive materials used.

- Optimized battery design and architecture: Innovative battery designs that leverage graphene's unique properties can improve overall performance and cost-efficiency. This may include novel electrode structures, electrolyte formulations, or cell configurations that maximize the benefits of graphene while minimizing material usage and manufacturing complexity.

- Recycling and reuse of graphene materials: Developing efficient methods for recycling and reusing graphene materials from spent batteries can significantly reduce costs and improve sustainability. This may involve processes for extracting and purifying graphene from used electrodes or developing battery designs that facilitate easier disassembly and material recovery.

- Integration with renewable energy systems: Combining graphene batteries with renewable energy systems can enhance overall cost-efficiency by improving energy storage and utilization. This integration may involve optimizing battery performance for specific renewable energy applications, such as solar or wind power, and developing smart energy management systems that maximize the benefits of graphene batteries in renewable energy contexts.

02 Enhanced energy density and storage capacity

Graphene-based batteries demonstrate higher energy density and storage capacity compared to traditional lithium-ion batteries. This improvement allows for longer-lasting and more powerful batteries, potentially reducing the overall cost per unit of energy stored and increasing the cost-efficiency of graphene batteries in various applications.Expand Specific Solutions03 Improved charging speed and cycle life

Graphene batteries exhibit faster charging speeds and longer cycle life compared to conventional batteries. This increased durability and reduced charging time can lead to lower operational costs and extended battery lifespan, contributing to the overall cost-efficiency of graphene battery technology.Expand Specific Solutions04 Integration with renewable energy systems

Graphene batteries can be effectively integrated with renewable energy systems, such as solar and wind power. This integration allows for more efficient energy storage and distribution, potentially reducing the overall costs associated with renewable energy implementation and improving the cost-efficiency of the entire energy system.Expand Specific Solutions05 Lightweight and flexible design

The lightweight and flexible nature of graphene allows for the development of batteries with reduced material costs and increased versatility. This characteristic enables the creation of more compact and adaptable energy storage solutions, potentially leading to cost savings in various applications, from portable electronics to electric vehicles.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery manufacturing landscape is in a dynamic phase, with the market poised for significant growth as the technology matures. Key players like Global Graphene Group, Honeycomb Battery Co., and Nanotek Instruments are driving innovation in cost-efficient production methods. The industry is transitioning from research to commercialization, with companies like Dongguan Amperex Technology Ltd. and VARTA Microbattery GmbH exploring large-scale manufacturing possibilities. While the market size is expanding, it remains relatively niche compared to traditional battery technologies. The competition is intensifying as both established battery manufacturers and specialized graphene companies vie for market share, focusing on overcoming production scalability and cost challenges to achieve widespread adoption.

Dongguan Amperex Technology Ltd.

Technical Solution: Dongguan Amperex Technology Ltd. (ATL) has developed a cost-efficient graphene battery manufacturing process that focuses on integrating graphene into existing lithium-ion battery production lines. Their approach involves the use of graphene-enhanced electrodes, which improve the overall performance and lifespan of the batteries[7]. ATL's manufacturing process utilizes a proprietary graphene dispersion technique that ensures uniform distribution of graphene throughout the electrode material, leading to enhanced conductivity and energy density. The company has also implemented advanced automation and quality control systems in their production lines, significantly reducing manufacturing costs and improving consistency[8]. ATL's process includes a unique heat treatment step that optimizes the graphene-electrode interface, further enhancing battery performance while maintaining cost-effectiveness[9].

Strengths: Integration with existing production lines, advanced automation, improved battery performance. Weaknesses: May require ongoing research to maintain competitive edge in rapidly evolving graphene technology.

Global Graphene Group, Inc.

Technical Solution: Global Graphene Group (G3) has developed a cost-efficient graphene battery manufacturing process using their proprietary graphene technology. Their approach involves a scalable production method for high-quality graphene materials, which are then integrated into battery electrodes. G3's process utilizes a roll-to-roll manufacturing technique that allows for continuous production of graphene-enhanced battery components[1]. This method significantly reduces production costs while maintaining high performance. The company has also developed a unique graphene oxide reduction process that enhances the electrical conductivity of the material, leading to improved battery efficiency[2]. G3's manufacturing process incorporates environmentally friendly water-based graphene dispersions, reducing the use of harmful solvents and further lowering production costs[3].

Strengths: Scalable production, cost-effective manufacturing, improved battery performance. Weaknesses: May require significant initial investment for equipment and process optimization.

Innovative Graphene Synthesis Methods

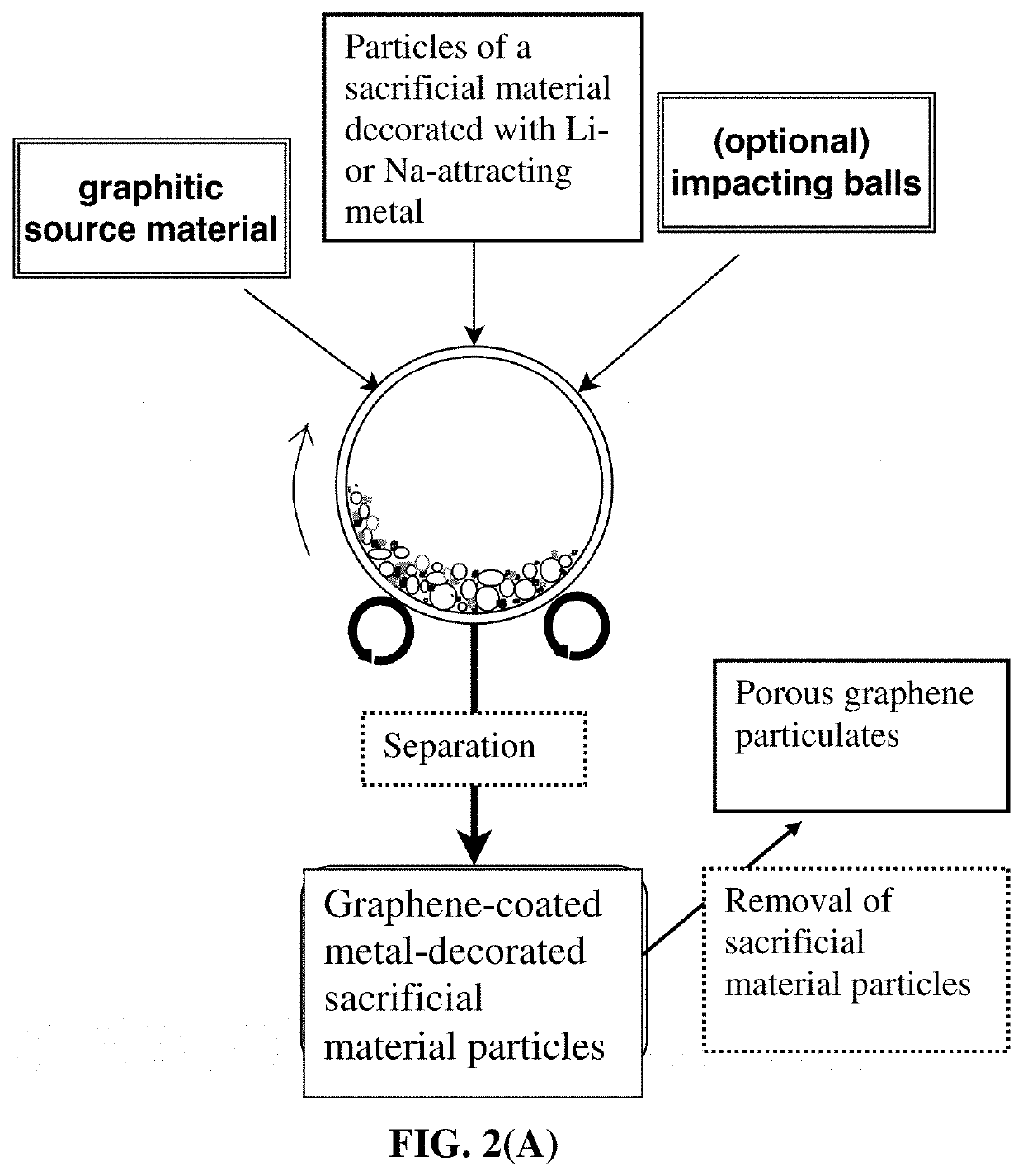

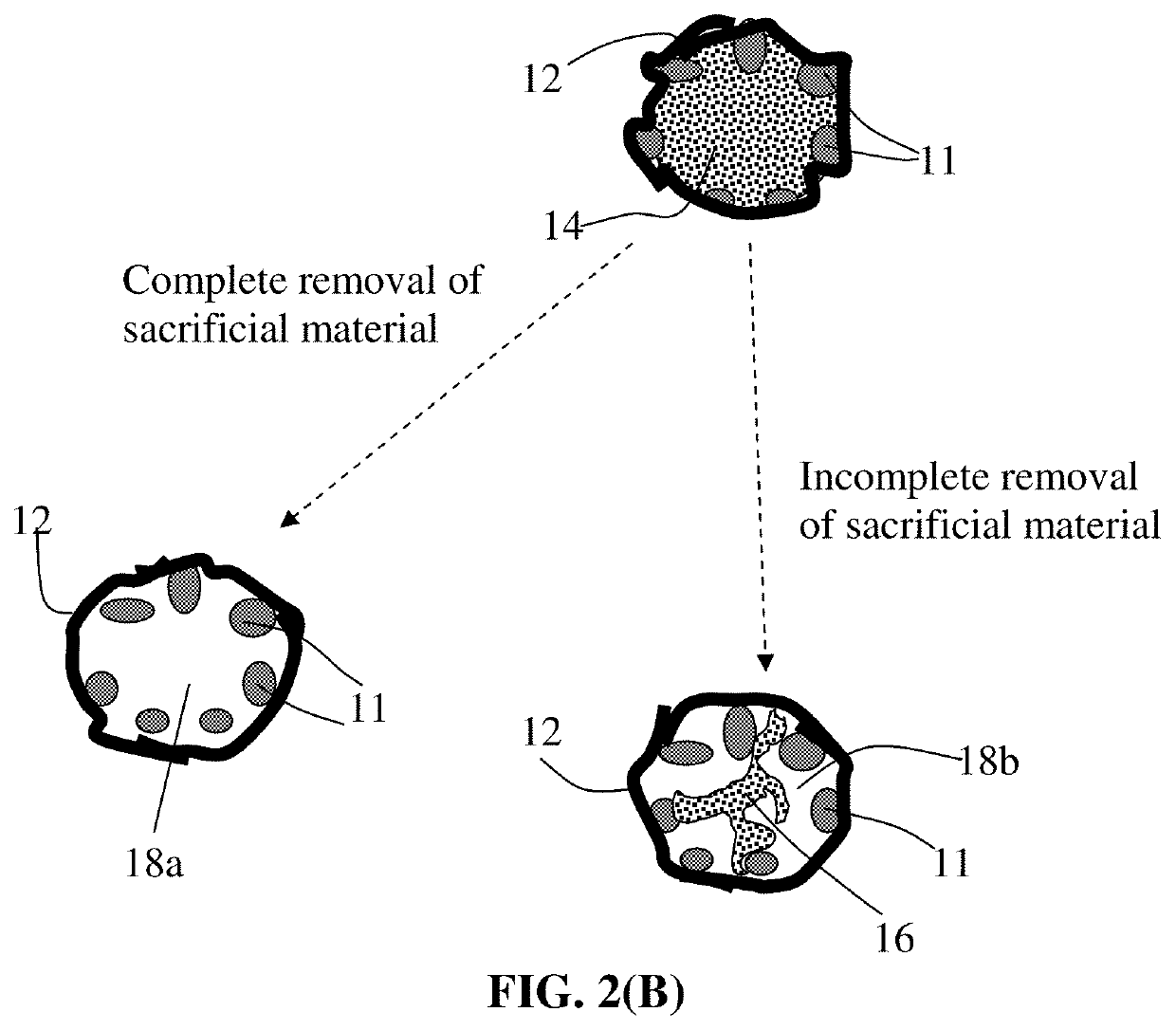

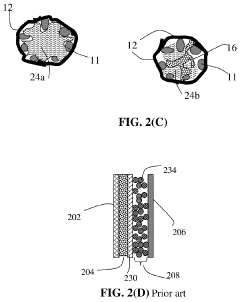

Process for producing porous particulates of graphene shell-protected alkali metal, electrodes, and alkali metal battery

PatentPendingUS20200287207A1

Innovation

- The development of porous graphene particulates pre-loaded with lithium or sodium metal, where a graphene shell encapsulates a porous core with a lithium- or sodium-attracting metal, preventing dendrite formation and enhancing ion conductivity, is used as an anode active material in lithium or sodium metal batteries.

Preparation method of high purity graphene

PatentActiveKR1020210073045A

Innovation

- A method involving heat treatments, separation of graphite from waste cathode materials, and synthesis of graphene from treated graphite, utilizing waste cathode materials and batteries, including steps such as heat treatment, acid immersion, and further purification processes.

Supply Chain Optimization Strategies

Optimizing the supply chain is crucial for achieving cost-efficient graphene battery manufacturing. A well-structured supply chain can significantly reduce production costs, improve efficiency, and enhance overall competitiveness in the market. To achieve this, manufacturers must focus on several key strategies.

Firstly, strategic sourcing of raw materials is essential. Graphene and other battery components should be procured from reliable suppliers who can provide consistent quality at competitive prices. Establishing long-term partnerships with these suppliers can lead to better pricing, priority access to materials, and collaborative innovation efforts. Additionally, diversifying the supplier base can mitigate risks associated with supply disruptions and price fluctuations.

Inventory management plays a critical role in supply chain optimization. Implementing just-in-time (JIT) inventory systems can help reduce carrying costs and minimize waste. Advanced forecasting techniques, coupled with real-time demand data, can ensure that production aligns closely with market needs, preventing overproduction and reducing storage expenses.

Streamlining the production process is another vital aspect of supply chain optimization. Adopting lean manufacturing principles can eliminate inefficiencies, reduce waste, and improve overall productivity. Automation and robotics can be integrated into the production line to increase precision and speed while reducing labor costs. Continuous improvement methodologies, such as Six Sigma, can be employed to identify and address bottlenecks in the manufacturing process.

Logistics optimization is crucial for reducing transportation costs and improving delivery times. Utilizing advanced route planning software and consolidating shipments can lead to significant savings. Exploring alternative transportation modes, such as rail or sea freight for long-distance shipments, can offer cost advantages over traditional road transport.

Implementing a robust supply chain management system is essential for coordinating all these elements effectively. Advanced software solutions can provide real-time visibility across the entire supply chain, enabling better decision-making and rapid response to changes in demand or supply conditions. These systems can also facilitate better collaboration between different stakeholders in the supply chain, from suppliers to distributors.

Sustainability considerations should also be integrated into supply chain strategies. Adopting circular economy principles, such as recycling and reusing materials, can not only reduce costs but also improve the environmental footprint of graphene battery production. This approach can lead to long-term cost savings and enhance the company's reputation in an increasingly eco-conscious market.

By implementing these supply chain optimization strategies, graphene battery manufacturers can significantly reduce production costs, improve operational efficiency, and gain a competitive edge in the market. The key lies in viewing the supply chain as an integrated system and continuously seeking opportunities for improvement and innovation.

Firstly, strategic sourcing of raw materials is essential. Graphene and other battery components should be procured from reliable suppliers who can provide consistent quality at competitive prices. Establishing long-term partnerships with these suppliers can lead to better pricing, priority access to materials, and collaborative innovation efforts. Additionally, diversifying the supplier base can mitigate risks associated with supply disruptions and price fluctuations.

Inventory management plays a critical role in supply chain optimization. Implementing just-in-time (JIT) inventory systems can help reduce carrying costs and minimize waste. Advanced forecasting techniques, coupled with real-time demand data, can ensure that production aligns closely with market needs, preventing overproduction and reducing storage expenses.

Streamlining the production process is another vital aspect of supply chain optimization. Adopting lean manufacturing principles can eliminate inefficiencies, reduce waste, and improve overall productivity. Automation and robotics can be integrated into the production line to increase precision and speed while reducing labor costs. Continuous improvement methodologies, such as Six Sigma, can be employed to identify and address bottlenecks in the manufacturing process.

Logistics optimization is crucial for reducing transportation costs and improving delivery times. Utilizing advanced route planning software and consolidating shipments can lead to significant savings. Exploring alternative transportation modes, such as rail or sea freight for long-distance shipments, can offer cost advantages over traditional road transport.

Implementing a robust supply chain management system is essential for coordinating all these elements effectively. Advanced software solutions can provide real-time visibility across the entire supply chain, enabling better decision-making and rapid response to changes in demand or supply conditions. These systems can also facilitate better collaboration between different stakeholders in the supply chain, from suppliers to distributors.

Sustainability considerations should also be integrated into supply chain strategies. Adopting circular economy principles, such as recycling and reusing materials, can not only reduce costs but also improve the environmental footprint of graphene battery production. This approach can lead to long-term cost savings and enhance the company's reputation in an increasingly eco-conscious market.

By implementing these supply chain optimization strategies, graphene battery manufacturers can significantly reduce production costs, improve operational efficiency, and gain a competitive edge in the market. The key lies in viewing the supply chain as an integrated system and continuously seeking opportunities for improvement and innovation.

Environmental Impact Assessment

The environmental impact of graphene battery manufacturing is a critical consideration in the pursuit of cost-efficient production methods. The production process of graphene-based batteries involves several stages that can potentially affect the environment, including raw material extraction, synthesis of graphene, battery assembly, and disposal.

One of the primary environmental concerns is the energy-intensive nature of graphene production. Traditional methods of graphene synthesis, such as chemical vapor deposition (CVD) and exfoliation, require significant energy inputs, contributing to greenhouse gas emissions. However, recent advancements in production techniques, such as electrochemical exfoliation and plasma-enhanced CVD, have shown promise in reducing energy consumption and associated carbon footprints.

Water usage and potential contamination are also important factors to consider. The production of graphene often involves the use of various chemicals and solvents, which, if not properly managed, can lead to water pollution. Implementing closed-loop water recycling systems and developing eco-friendly synthesis methods can help mitigate these risks and reduce the overall water footprint of graphene battery manufacturing.

The sourcing of raw materials for graphene production, particularly graphite, raises concerns about land use and ecosystem disruption. Sustainable mining practices and the exploration of alternative carbon sources, such as biomass or recycled materials, could help address these issues and promote a more circular economy approach to graphene battery production.

End-of-life considerations for graphene batteries are crucial for assessing their long-term environmental impact. While graphene batteries have the potential for longer lifespans compared to traditional lithium-ion batteries, proper recycling and disposal methods must be developed to prevent environmental contamination and recover valuable materials. Research into efficient recycling processes for graphene-based batteries is ongoing, with promising results in material recovery and reuse.

The potential benefits of graphene batteries in terms of improved energy storage capacity and longer lifespans could lead to reduced overall environmental impact in the long term. By enabling more efficient energy storage and potentially reducing the frequency of battery replacements, graphene batteries may contribute to a decrease in electronic waste and resource consumption.

To achieve cost-efficient graphene battery manufacturing while minimizing environmental impact, a holistic approach is necessary. This includes optimizing production processes, investing in cleaner energy sources for manufacturing, developing sustainable sourcing strategies, and establishing robust recycling infrastructure. Continuous research and innovation in green chemistry and sustainable engineering practices will be key to balancing economic viability with environmental stewardship in the graphene battery industry.

One of the primary environmental concerns is the energy-intensive nature of graphene production. Traditional methods of graphene synthesis, such as chemical vapor deposition (CVD) and exfoliation, require significant energy inputs, contributing to greenhouse gas emissions. However, recent advancements in production techniques, such as electrochemical exfoliation and plasma-enhanced CVD, have shown promise in reducing energy consumption and associated carbon footprints.

Water usage and potential contamination are also important factors to consider. The production of graphene often involves the use of various chemicals and solvents, which, if not properly managed, can lead to water pollution. Implementing closed-loop water recycling systems and developing eco-friendly synthesis methods can help mitigate these risks and reduce the overall water footprint of graphene battery manufacturing.

The sourcing of raw materials for graphene production, particularly graphite, raises concerns about land use and ecosystem disruption. Sustainable mining practices and the exploration of alternative carbon sources, such as biomass or recycled materials, could help address these issues and promote a more circular economy approach to graphene battery production.

End-of-life considerations for graphene batteries are crucial for assessing their long-term environmental impact. While graphene batteries have the potential for longer lifespans compared to traditional lithium-ion batteries, proper recycling and disposal methods must be developed to prevent environmental contamination and recover valuable materials. Research into efficient recycling processes for graphene-based batteries is ongoing, with promising results in material recovery and reuse.

The potential benefits of graphene batteries in terms of improved energy storage capacity and longer lifespans could lead to reduced overall environmental impact in the long term. By enabling more efficient energy storage and potentially reducing the frequency of battery replacements, graphene batteries may contribute to a decrease in electronic waste and resource consumption.

To achieve cost-efficient graphene battery manufacturing while minimizing environmental impact, a holistic approach is necessary. This includes optimizing production processes, investing in cleaner energy sources for manufacturing, developing sustainable sourcing strategies, and establishing robust recycling infrastructure. Continuous research and innovation in green chemistry and sustainable engineering practices will be key to balancing economic viability with environmental stewardship in the graphene battery industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!