How to Achieve Uniformity in Lithium Fluoride Deposition

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiF Deposition Technology Background and Objectives

Lithium Fluoride (LiF) deposition technology has evolved significantly over the past several decades, transitioning from rudimentary vacuum evaporation methods to sophisticated controlled deposition techniques. Initially developed in the 1950s for optical applications, LiF thin films gained prominence due to their exceptional transparency in the ultraviolet spectrum and high refractive index properties. The evolution of this technology has been driven by increasing demands for precision in microelectronics, optoelectronics, and more recently, advanced battery technologies.

The critical challenge in LiF deposition has consistently been achieving uniform layer formation across substrates of varying geometries and dimensions. Historical approaches relied primarily on physical vapor deposition (PVD) techniques, which often resulted in thickness variations exceeding 15% across larger substrates. The technological trajectory has since moved toward more controlled methodologies including atomic layer deposition (ALD) and solution-based processes, each offering distinct advantages for specific applications.

Recent advancements in LiF deposition technology have been catalyzed by its emerging role in lithium-ion battery interfaces, where uniform ultra-thin layers (typically 1-5 nm) are essential for optimizing electrode-electrolyte interactions. The precision requirements have increased exponentially, with modern applications demanding thickness variations below 3% across production-scale substrates. This represents a significant technical challenge that has spurred innovation in both equipment design and process parameters.

The global research focus has shifted toward developing scalable methods that maintain nanometer-level uniformity while increasing throughput capabilities. Particularly noteworthy is the development of modified chemical vapor deposition (CVD) techniques specifically optimized for fluoride compounds, which have demonstrated promising results in laboratory settings but face significant challenges in industrial implementation.

The primary technical objective in contemporary LiF deposition research is to establish methodologies that simultaneously achieve three critical parameters: nanoscale thickness control (±0.5 nm), exceptional uniformity across large areas (>95% consistency), and compatibility with high-volume manufacturing processes. Secondary objectives include reducing process temperatures, minimizing precursor consumption, and ensuring compatibility with sensitive substrate materials.

Looking forward, the technology roadmap for LiF deposition is increasingly focused on developing hybrid approaches that combine the precision of ALD with the throughput advantages of other techniques. The ultimate goal remains establishing reproducible, cost-effective processes for creating perfectly uniform LiF layers that can meet the demanding requirements of next-generation electronic and energy storage devices.

The critical challenge in LiF deposition has consistently been achieving uniform layer formation across substrates of varying geometries and dimensions. Historical approaches relied primarily on physical vapor deposition (PVD) techniques, which often resulted in thickness variations exceeding 15% across larger substrates. The technological trajectory has since moved toward more controlled methodologies including atomic layer deposition (ALD) and solution-based processes, each offering distinct advantages for specific applications.

Recent advancements in LiF deposition technology have been catalyzed by its emerging role in lithium-ion battery interfaces, where uniform ultra-thin layers (typically 1-5 nm) are essential for optimizing electrode-electrolyte interactions. The precision requirements have increased exponentially, with modern applications demanding thickness variations below 3% across production-scale substrates. This represents a significant technical challenge that has spurred innovation in both equipment design and process parameters.

The global research focus has shifted toward developing scalable methods that maintain nanometer-level uniformity while increasing throughput capabilities. Particularly noteworthy is the development of modified chemical vapor deposition (CVD) techniques specifically optimized for fluoride compounds, which have demonstrated promising results in laboratory settings but face significant challenges in industrial implementation.

The primary technical objective in contemporary LiF deposition research is to establish methodologies that simultaneously achieve three critical parameters: nanoscale thickness control (±0.5 nm), exceptional uniformity across large areas (>95% consistency), and compatibility with high-volume manufacturing processes. Secondary objectives include reducing process temperatures, minimizing precursor consumption, and ensuring compatibility with sensitive substrate materials.

Looking forward, the technology roadmap for LiF deposition is increasingly focused on developing hybrid approaches that combine the precision of ALD with the throughput advantages of other techniques. The ultimate goal remains establishing reproducible, cost-effective processes for creating perfectly uniform LiF layers that can meet the demanding requirements of next-generation electronic and energy storage devices.

Market Analysis for Uniform LiF Deposition Applications

The global market for uniform lithium fluoride (LiF) deposition technologies has been experiencing significant growth, driven primarily by advancements in semiconductor manufacturing, optical coatings, and battery technologies. The demand for precise and uniform LiF thin films has intensified as industries require increasingly sophisticated materials with consistent properties at nanoscale dimensions.

In the semiconductor sector, uniform LiF deposition plays a crucial role in the development of next-generation electronic devices. The market is particularly robust in regions with established semiconductor manufacturing bases such as East Asia, North America, and Europe. Industry analysts project that the semiconductor segment alone will drive approximately 40% of the total market demand for uniform LiF deposition technologies over the next five years.

The optical coatings industry represents another substantial market segment, where LiF films are utilized for their excellent transmission properties in the ultraviolet spectrum. This application is particularly valuable in scientific instrumentation, aerospace technologies, and advanced photonics. The optical coatings market segment has been growing steadily at a compound annual growth rate exceeding industry averages.

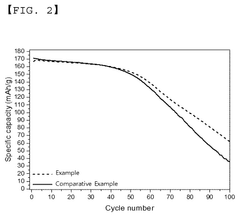

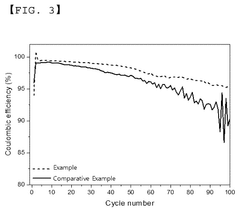

Battery technology applications have emerged as the fastest-growing segment for uniform LiF deposition. As electric vehicle adoption accelerates globally, the demand for high-performance batteries with enhanced safety profiles and longer lifespans has surged. LiF layers, when uniformly deposited, serve as critical components in solid-state batteries and as protective coatings in conventional lithium-ion batteries, significantly improving their performance characteristics.

Market research indicates that the Asia-Pacific region currently dominates the global market for uniform LiF deposition technologies, accounting for over half of the global market share. This dominance is attributed to the region's robust electronics manufacturing ecosystem and aggressive investments in battery production facilities. North America and Europe follow, with particular strength in research-intensive applications and premium electronic products.

The market landscape is characterized by increasing competition among technology providers, with a notable trend toward the development of more cost-effective deposition methods that maintain high uniformity standards. End-users are demonstrating willingness to invest in advanced deposition technologies that can deliver consistent film quality while reducing material waste and processing time.

Future market growth is expected to be driven by emerging applications in quantum computing, where uniform LiF films may serve as key components in qubit isolation and protection. Additionally, the medical device industry has begun exploring applications for uniform LiF coatings in radiation dosimetry and specialized imaging equipment, potentially opening new market segments with distinct requirements and value propositions.

In the semiconductor sector, uniform LiF deposition plays a crucial role in the development of next-generation electronic devices. The market is particularly robust in regions with established semiconductor manufacturing bases such as East Asia, North America, and Europe. Industry analysts project that the semiconductor segment alone will drive approximately 40% of the total market demand for uniform LiF deposition technologies over the next five years.

The optical coatings industry represents another substantial market segment, where LiF films are utilized for their excellent transmission properties in the ultraviolet spectrum. This application is particularly valuable in scientific instrumentation, aerospace technologies, and advanced photonics. The optical coatings market segment has been growing steadily at a compound annual growth rate exceeding industry averages.

Battery technology applications have emerged as the fastest-growing segment for uniform LiF deposition. As electric vehicle adoption accelerates globally, the demand for high-performance batteries with enhanced safety profiles and longer lifespans has surged. LiF layers, when uniformly deposited, serve as critical components in solid-state batteries and as protective coatings in conventional lithium-ion batteries, significantly improving their performance characteristics.

Market research indicates that the Asia-Pacific region currently dominates the global market for uniform LiF deposition technologies, accounting for over half of the global market share. This dominance is attributed to the region's robust electronics manufacturing ecosystem and aggressive investments in battery production facilities. North America and Europe follow, with particular strength in research-intensive applications and premium electronic products.

The market landscape is characterized by increasing competition among technology providers, with a notable trend toward the development of more cost-effective deposition methods that maintain high uniformity standards. End-users are demonstrating willingness to invest in advanced deposition technologies that can deliver consistent film quality while reducing material waste and processing time.

Future market growth is expected to be driven by emerging applications in quantum computing, where uniform LiF films may serve as key components in qubit isolation and protection. Additionally, the medical device industry has begun exploring applications for uniform LiF coatings in radiation dosimetry and specialized imaging equipment, potentially opening new market segments with distinct requirements and value propositions.

Current Challenges in LiF Deposition Uniformity

Achieving uniform deposition of Lithium Fluoride (LiF) remains one of the most significant challenges in advanced battery manufacturing and optoelectronic device fabrication. The non-uniform deposition of LiF layers directly impacts device performance, reliability, and production yields. Current deposition techniques, including thermal evaporation, sputtering, and atomic layer deposition (ALD), each present unique uniformity challenges that have not been fully resolved despite extensive research efforts.

Thermal evaporation, the most widely used method for LiF deposition, suffers from inherent limitations in achieving uniform thickness across large substrate areas. The point-source nature of evaporation creates thickness gradients that become more pronounced as substrate dimensions increase. Industry data indicates thickness variations of 5-15% across 6-inch wafers, exceeding the 3% tolerance typically required for high-performance devices.

Substrate temperature control presents another critical challenge. LiF deposition is highly sensitive to temperature variations across the substrate surface, with even minor fluctuations of 2-3°C resulting in significant morphological differences. Current heating systems struggle to maintain the required temperature uniformity, particularly for large-area substrates or flexible materials with varying thermal conductivity properties.

Chamber pressure stability during deposition cycles represents a persistent technical hurdle. Pressure fluctuations as small as 1×10^-6 Torr can alter the mean free path of LiF molecules, creating non-uniform deposition patterns. Most commercial systems exhibit pressure variations that exceed this threshold, especially during extended deposition runs required for thicker films.

Material purity and source stability issues further complicate uniform deposition. LiF is hygroscopic and can absorb moisture during handling, leading to spattering during evaporation and resultant film defects. Current purification and handling protocols have not eliminated these issues completely, with defect densities remaining above acceptable thresholds for cutting-edge applications.

The interface quality between LiF and underlying substrate materials presents significant challenges for uniform nucleation and growth. Surface energy mismatches and contamination can lead to island formation rather than continuous film growth, particularly at the ultra-thin film thicknesses (1-5 nm) required for advanced battery and optoelectronic applications.

Metrology and in-situ monitoring capabilities remain insufficient for real-time uniformity control. Current thickness monitoring technologies, primarily quartz crystal microbalances, provide only point measurements that fail to capture spatial variations across the substrate. Advanced techniques like spectroscopic ellipsometry offer better spatial resolution but are challenging to implement for in-situ monitoring during the deposition process.

These technical challenges are compounded by scaling issues when transitioning from laboratory to production environments, where maintaining uniformity across larger substrates and higher throughput processes introduces additional complexity that current solutions have not adequately addressed.

Thermal evaporation, the most widely used method for LiF deposition, suffers from inherent limitations in achieving uniform thickness across large substrate areas. The point-source nature of evaporation creates thickness gradients that become more pronounced as substrate dimensions increase. Industry data indicates thickness variations of 5-15% across 6-inch wafers, exceeding the 3% tolerance typically required for high-performance devices.

Substrate temperature control presents another critical challenge. LiF deposition is highly sensitive to temperature variations across the substrate surface, with even minor fluctuations of 2-3°C resulting in significant morphological differences. Current heating systems struggle to maintain the required temperature uniformity, particularly for large-area substrates or flexible materials with varying thermal conductivity properties.

Chamber pressure stability during deposition cycles represents a persistent technical hurdle. Pressure fluctuations as small as 1×10^-6 Torr can alter the mean free path of LiF molecules, creating non-uniform deposition patterns. Most commercial systems exhibit pressure variations that exceed this threshold, especially during extended deposition runs required for thicker films.

Material purity and source stability issues further complicate uniform deposition. LiF is hygroscopic and can absorb moisture during handling, leading to spattering during evaporation and resultant film defects. Current purification and handling protocols have not eliminated these issues completely, with defect densities remaining above acceptable thresholds for cutting-edge applications.

The interface quality between LiF and underlying substrate materials presents significant challenges for uniform nucleation and growth. Surface energy mismatches and contamination can lead to island formation rather than continuous film growth, particularly at the ultra-thin film thicknesses (1-5 nm) required for advanced battery and optoelectronic applications.

Metrology and in-situ monitoring capabilities remain insufficient for real-time uniformity control. Current thickness monitoring technologies, primarily quartz crystal microbalances, provide only point measurements that fail to capture spatial variations across the substrate. Advanced techniques like spectroscopic ellipsometry offer better spatial resolution but are challenging to implement for in-situ monitoring during the deposition process.

These technical challenges are compounded by scaling issues when transitioning from laboratory to production environments, where maintaining uniformity across larger substrates and higher throughput processes introduces additional complexity that current solutions have not adequately addressed.

State-of-the-Art LiF Deposition Methods

01 Deposition methods for uniform lithium fluoride films

Various deposition techniques can be employed to achieve uniform lithium fluoride films. These methods include physical vapor deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), and thermal evaporation. Each method offers specific advantages for controlling film thickness and uniformity across substrates. Process parameters such as temperature, pressure, and deposition rate significantly impact the uniformity of the resulting lithium fluoride layer.- Deposition methods for uniform lithium fluoride films: Various deposition techniques can be employed to achieve uniform lithium fluoride films. These include physical vapor deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), and thermal evaporation. Each method offers specific advantages for controlling film thickness and uniformity across substrates. Process parameters such as temperature, pressure, and deposition rate significantly impact the uniformity of the resulting lithium fluoride layer.

- Substrate preparation and treatment for improved LiF uniformity: Proper substrate preparation is crucial for achieving uniform lithium fluoride deposition. Surface cleaning, planarization, and pre-treatment processes help eliminate contaminants and surface irregularities that could affect deposition uniformity. Techniques such as plasma treatment, chemical cleaning, and thermal annealing of substrates prior to lithium fluoride deposition can significantly enhance film adhesion and uniformity across the substrate surface.

- Process monitoring and control systems for LiF deposition: Advanced monitoring and control systems are essential for maintaining lithium fluoride deposition uniformity. In-situ thickness monitoring, real-time process parameter adjustment, and feedback control mechanisms help ensure consistent deposition across large substrate areas. Optical monitoring techniques, quartz crystal microbalances, and advanced sensor arrays can be integrated into deposition systems to continuously track and adjust the deposition process for optimal uniformity.

- Post-deposition treatments to enhance LiF film uniformity: Various post-deposition treatments can improve the uniformity of lithium fluoride films. Thermal annealing, laser treatment, and plasma processing after deposition help redistribute material and eliminate thickness variations. These treatments can also enhance the optical and electronic properties of lithium fluoride films while improving overall uniformity and reducing defects that may have formed during the initial deposition process.

- Additives and dopants for improved LiF deposition uniformity: Incorporating specific additives or dopants into lithium fluoride films can enhance deposition uniformity. Certain materials can modify surface energy, improve wetting characteristics, and promote more uniform nucleation and growth during deposition. These additives can be introduced during the deposition process or as part of precursor materials to control crystallization behavior and reduce agglomeration, resulting in more uniform lithium fluoride films.

02 Substrate preparation and treatment for improved uniformity

Proper substrate preparation is crucial for achieving uniform lithium fluoride deposition. Surface cleaning, planarization, and pre-treatment processes help eliminate contaminants and surface irregularities that could affect deposition uniformity. Techniques such as plasma treatment, chemical cleaning, and thermal annealing of substrates prior to lithium fluoride deposition can significantly enhance film adhesion and uniformity across the substrate surface.Expand Specific Solutions03 Process parameter optimization for uniform deposition

Optimizing process parameters is essential for achieving uniform lithium fluoride deposition. Key parameters include chamber pressure, substrate temperature, deposition rate, and source-to-substrate distance. Advanced process control systems can monitor and adjust these parameters in real-time to maintain optimal conditions throughout the deposition process. Statistical process control methods help identify the optimal operating window for maximum uniformity across different substrate geometries.Expand Specific Solutions04 Post-deposition treatments to enhance uniformity

Various post-deposition treatments can be applied to improve the uniformity of lithium fluoride films. These include thermal annealing, laser treatment, and plasma processing. Such treatments help redistribute the material, eliminate defects, and improve crystallinity, resulting in more uniform optical and electrical properties. Post-deposition surface planarization techniques can also be employed to reduce thickness variations across the deposited film.Expand Specific Solutions05 Advanced monitoring and characterization techniques

Advanced monitoring and characterization techniques are crucial for assessing and controlling lithium fluoride deposition uniformity. In-situ monitoring tools such as ellipsometry, quartz crystal microbalances, and optical emission spectroscopy provide real-time feedback on deposition rate and uniformity. Post-deposition characterization methods including atomic force microscopy, scanning electron microscopy, and X-ray reflectivity help quantify thickness variations and surface morphology, enabling process refinement for improved uniformity.Expand Specific Solutions

Leading Companies and Research Institutions in LiF Technology

The lithium fluoride deposition uniformity market is in a growth phase, with increasing demand driven by advanced battery technologies and semiconductor applications. The market size is expanding rapidly due to the rising adoption of lithium-based energy storage solutions. Technologically, the field shows varying maturity levels across different application segments. Leading players like Applied Materials and Sion Power are advancing deposition techniques for high-performance batteries, while research institutions such as Harbin Institute of Technology and Central South University are developing fundamental innovations. Companies like Samsung Electronics, Sony, and Panasonic are integrating these technologies into consumer electronics, while specialized materials firms including Resonac, Stella Chemifa, and XTC New Energy Materials are focusing on improving material quality and process reliability for uniform LiF deposition across various substrate types.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced Physical Vapor Deposition (PVD) systems specifically optimized for uniform lithium fluoride deposition. Their Endura® platform incorporates proprietary technology that enables precise control of deposition parameters including temperature, pressure, and target-to-substrate distance. The system utilizes a rotating magnetron sputtering technique with real-time thickness monitoring that achieves uniformity variation of less than ±2% across 300mm substrates. Their process includes pre-deposition surface treatment to ensure optimal adhesion and post-deposition annealing steps to enhance film quality. Applied Materials has also developed specialized LiF co-sputtering techniques that allow for controlled doping with other materials to enhance ionic conductivity while maintaining uniformity. Their systems feature advanced shielding designs that minimize contamination and ensure consistent film properties across large areas.

Strengths: Industry-leading uniformity control across large substrates; integrated metrology for real-time process adjustment; high throughput suitable for industrial production. Weaknesses: Higher capital equipment costs compared to simpler deposition methods; requires specialized technical expertise for operation and maintenance; process optimization can be time-consuming for new material combinations.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a hybrid deposition approach for lithium fluoride that combines elements of thermal evaporation and solution processing to achieve superior uniformity. Their system utilizes a proprietary two-stage process where an initial ultra-thin seed layer is deposited via controlled thermal evaporation under precisely regulated vacuum conditions, followed by a solution-based deposition method using specially formulated LiF precursors. This approach leverages Samsung's expertise in large-area thin film processing from their display manufacturing background. The process incorporates real-time optical monitoring systems that measure thickness variations across the substrate and automatically adjust deposition parameters to maintain uniformity within ±1.5%. Samsung's technology also features specialized substrate rotation mechanisms that ensure even distribution of both vapor-phase and solution-phase materials. For battery applications, they've developed a modified version that can deposit LiF directly onto electrode materials without compromising the electrochemical properties.

Strengths: Scalable to very large substrate areas; combines advantages of both vapor and solution processing; excellent cost-efficiency for mass production. Weaknesses: Complex process integration requiring precise control of multiple deposition stages; sensitive to environmental contaminants; requires specialized equipment not readily available from third-party vendors.

Critical Patents and Research on Uniform LiF Films

Deposition of lithium fluoride on surface of lithium metal and lithium secondary battery using the same

PatentPendingUS20240379940A1

Innovation

- A method of depositing lithium fluoride (LiF) on the surface of lithium metal using physical vapor deposition (PVD) or chemical vapor deposition (CVD) to reform the surface, allowing for improved reversibility and stability, with a deposition thickness of 0.01 to 1 μm, enhancing the performance of lithium metal as a negative electrode.

Fluoride sputtering target and method for preparation thereof

PatentWO2003023084A1

Innovation

- A fluoride sputtering target with a composition ratio deviation of 0.5 or less and a density of 95% or more, made from elements like Al, Ba, Ca, Gd, La, Li, Mg, and Y, is hot-pressed at 50-70% of the melting point in a nitrogen or inert gas atmosphere to enhance density and prevent dissociation, resulting in a robust and uniform film formation.

Material Characterization Techniques for LiF Film Quality

The assessment of lithium fluoride (LiF) film quality requires sophisticated material characterization techniques to ensure uniformity in deposition processes. X-ray Diffraction (XRD) stands as a primary analytical method, providing critical information about crystalline structure, phase composition, and orientation of LiF films. Through XRD analysis, researchers can determine crystallite size and lattice parameters, which directly correlate with film uniformity and quality.

Scanning Electron Microscopy (SEM) and Atomic Force Microscopy (AFM) offer complementary surface morphology analysis at different scales. SEM provides valuable insights into film topography, grain boundaries, and potential defects at the microscale, while AFM achieves nanometer-level resolution for quantitative surface roughness measurements. The root mean square (RMS) roughness values obtained through AFM serve as key indicators of deposition uniformity.

Spectroscopic ellipsometry enables precise measurement of LiF film thickness and optical properties with sub-nanometer accuracy. This non-destructive technique proves particularly valuable for in-situ monitoring during deposition processes, allowing real-time adjustments to achieve optimal uniformity. When combined with mapping capabilities, ellipsometry can generate comprehensive thickness distribution profiles across entire substrates.

Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) and X-ray Photoelectron Spectroscopy (XPS) provide detailed chemical composition analysis of LiF films. ToF-SIMS offers exceptional surface sensitivity with detection limits in the parts-per-billion range, while XPS delivers quantitative elemental composition data and chemical state information. These techniques are crucial for identifying contaminants or compositional variations that may compromise film uniformity.

Electrical characterization methods, including impedance spectroscopy and current-voltage measurements, evaluate the functional properties of LiF films in device contexts. These measurements reveal critical parameters such as ionic conductivity, dielectric properties, and potential barrier characteristics, which directly influence device performance and reliability.

Advanced synchrotron-based techniques like Grazing Incidence X-ray Scattering (GIXS) provide unparalleled insights into thin film structure at atomic scales. These methods can detect subtle structural variations across large sample areas, making them invaluable for uniformity assessment in high-precision applications such as next-generation battery technologies and optoelectronic devices.

Scanning Electron Microscopy (SEM) and Atomic Force Microscopy (AFM) offer complementary surface morphology analysis at different scales. SEM provides valuable insights into film topography, grain boundaries, and potential defects at the microscale, while AFM achieves nanometer-level resolution for quantitative surface roughness measurements. The root mean square (RMS) roughness values obtained through AFM serve as key indicators of deposition uniformity.

Spectroscopic ellipsometry enables precise measurement of LiF film thickness and optical properties with sub-nanometer accuracy. This non-destructive technique proves particularly valuable for in-situ monitoring during deposition processes, allowing real-time adjustments to achieve optimal uniformity. When combined with mapping capabilities, ellipsometry can generate comprehensive thickness distribution profiles across entire substrates.

Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) and X-ray Photoelectron Spectroscopy (XPS) provide detailed chemical composition analysis of LiF films. ToF-SIMS offers exceptional surface sensitivity with detection limits in the parts-per-billion range, while XPS delivers quantitative elemental composition data and chemical state information. These techniques are crucial for identifying contaminants or compositional variations that may compromise film uniformity.

Electrical characterization methods, including impedance spectroscopy and current-voltage measurements, evaluate the functional properties of LiF films in device contexts. These measurements reveal critical parameters such as ionic conductivity, dielectric properties, and potential barrier characteristics, which directly influence device performance and reliability.

Advanced synchrotron-based techniques like Grazing Incidence X-ray Scattering (GIXS) provide unparalleled insights into thin film structure at atomic scales. These methods can detect subtle structural variations across large sample areas, making them invaluable for uniformity assessment in high-precision applications such as next-generation battery technologies and optoelectronic devices.

Environmental and Safety Considerations in LiF Processing

Lithium Fluoride (LiF) processing involves several environmental and safety considerations that must be addressed to ensure sustainable and responsible manufacturing practices. The production and deposition of LiF generates potentially hazardous byproducts, including hydrogen fluoride (HF) gas, which poses significant health risks to workers and surrounding communities if not properly contained and treated.

Exposure to fluoride compounds during LiF processing can cause respiratory irritation, skin burns, and in severe cases, systemic toxicity. Therefore, comprehensive engineering controls such as closed systems, local exhaust ventilation, and proper scrubbing technologies are essential to minimize worker exposure. Personal protective equipment including chemical-resistant gloves, face shields, and respiratory protection must be mandatory in processing areas.

Waste management presents another critical environmental challenge in LiF deposition processes. Spent solutions containing fluoride compounds require specialized treatment before disposal to prevent contamination of water sources. Advanced treatment methods such as precipitation, ion exchange, and membrane filtration have been developed to remove fluoride from wastewater streams, reducing environmental impact while complying with increasingly stringent regulations.

Energy consumption during LiF deposition processes also contributes to environmental concerns. Traditional thermal evaporation methods require significant energy inputs, resulting in substantial carbon footprints. Recent advancements in low-temperature deposition techniques and energy-efficient equipment designs have shown promise in reducing energy requirements while maintaining deposition uniformity.

The storage and handling of raw materials present additional safety challenges. Lithium compounds are highly reactive with water, while fluoride compounds are corrosive. Proper storage facilities with controlled humidity, temperature monitoring, and segregation from incompatible materials are necessary to prevent accidental reactions and releases.

Regulatory compliance frameworks vary globally but generally trend toward more stringent controls on fluoride emissions and waste disposal. Companies engaged in LiF processing must navigate complex regulatory landscapes including REACH in Europe, EPA regulations in the United States, and similar frameworks in Asia. Implementing environmental management systems that exceed minimum compliance requirements can provide competitive advantages while protecting environmental resources.

Sustainable alternatives and green chemistry approaches are emerging as important considerations in LiF processing. Research into less hazardous precursors, solvent-free deposition methods, and closed-loop recycling systems demonstrates the industry's movement toward more environmentally responsible practices while maintaining the high uniformity requirements essential for advanced applications.

Exposure to fluoride compounds during LiF processing can cause respiratory irritation, skin burns, and in severe cases, systemic toxicity. Therefore, comprehensive engineering controls such as closed systems, local exhaust ventilation, and proper scrubbing technologies are essential to minimize worker exposure. Personal protective equipment including chemical-resistant gloves, face shields, and respiratory protection must be mandatory in processing areas.

Waste management presents another critical environmental challenge in LiF deposition processes. Spent solutions containing fluoride compounds require specialized treatment before disposal to prevent contamination of water sources. Advanced treatment methods such as precipitation, ion exchange, and membrane filtration have been developed to remove fluoride from wastewater streams, reducing environmental impact while complying with increasingly stringent regulations.

Energy consumption during LiF deposition processes also contributes to environmental concerns. Traditional thermal evaporation methods require significant energy inputs, resulting in substantial carbon footprints. Recent advancements in low-temperature deposition techniques and energy-efficient equipment designs have shown promise in reducing energy requirements while maintaining deposition uniformity.

The storage and handling of raw materials present additional safety challenges. Lithium compounds are highly reactive with water, while fluoride compounds are corrosive. Proper storage facilities with controlled humidity, temperature monitoring, and segregation from incompatible materials are necessary to prevent accidental reactions and releases.

Regulatory compliance frameworks vary globally but generally trend toward more stringent controls on fluoride emissions and waste disposal. Companies engaged in LiF processing must navigate complex regulatory landscapes including REACH in Europe, EPA regulations in the United States, and similar frameworks in Asia. Implementing environmental management systems that exceed minimum compliance requirements can provide competitive advantages while protecting environmental resources.

Sustainable alternatives and green chemistry approaches are emerging as important considerations in LiF processing. Research into less hazardous precursors, solvent-free deposition methods, and closed-loop recycling systems demonstrates the industry's movement toward more environmentally responsible practices while maintaining the high uniformity requirements essential for advanced applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!