How to Address Measurement Bias in Dynamic Light Scattering

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dynamic Light Scattering Technology Background and Objectives

Dynamic Light Scattering (DLS) emerged in the 1960s as a powerful technique for measuring particle size distributions in colloidal suspensions. The technology leverages the Brownian motion of particles in suspension, analyzing the intensity fluctuations in scattered light to determine particle size characteristics. Over decades, DLS has evolved from basic laboratory setups to sophisticated commercial instruments capable of analyzing complex biological samples, nanoparticles, and polymers.

The evolution of DLS technology has been marked by significant improvements in laser sources, detection systems, and data processing algorithms. Early systems utilized simple photon correlation techniques, while modern instruments employ advanced multi-angle detection and machine learning approaches to extract more accurate and comprehensive information from scattered light patterns.

Current technological trends in DLS focus on addressing measurement biases that have historically limited the technique's accuracy and reliability. These biases arise from multiple sources including dust contamination, multiple scattering effects, sample polydispersity, and concentration-dependent interactions. The field is moving toward more robust measurement protocols and advanced algorithms that can identify and correct for these biases.

The primary objective of current DLS research is to develop methodologies that systematically identify, quantify, and mitigate measurement biases. This includes creating standardized calibration procedures, implementing advanced statistical approaches for data analysis, and developing multi-parameter measurement techniques that can cross-validate results through complementary measurements.

Another significant goal is enhancing the resolution of DLS for polydisperse samples, where traditional analysis methods often fail to accurately represent complex particle size distributions. This is particularly important for biological applications, where protein aggregates or vesicles may exhibit heterogeneous size profiles that are clinically relevant.

The integration of DLS with other analytical techniques represents another important technological direction. Hybrid systems combining DLS with techniques such as Raman spectroscopy, static light scattering, or microscopy methods provide multi-dimensional characterization capabilities that can help validate measurements and reduce systematic biases.

From an industrial perspective, there is growing demand for automated, high-throughput DLS systems that maintain measurement accuracy while increasing sample processing capacity. This is driving development of microfluidic DLS platforms and parallel measurement systems that can analyze multiple samples simultaneously while implementing sophisticated bias correction algorithms.

The ultimate technological objective is to transform DLS from a relative measurement technique to an absolute one, where results are independent of instrument configuration, sample preparation methods, and analysis parameters. This would establish DLS as a truly standardized method for particle characterization across research and industrial applications.

The evolution of DLS technology has been marked by significant improvements in laser sources, detection systems, and data processing algorithms. Early systems utilized simple photon correlation techniques, while modern instruments employ advanced multi-angle detection and machine learning approaches to extract more accurate and comprehensive information from scattered light patterns.

Current technological trends in DLS focus on addressing measurement biases that have historically limited the technique's accuracy and reliability. These biases arise from multiple sources including dust contamination, multiple scattering effects, sample polydispersity, and concentration-dependent interactions. The field is moving toward more robust measurement protocols and advanced algorithms that can identify and correct for these biases.

The primary objective of current DLS research is to develop methodologies that systematically identify, quantify, and mitigate measurement biases. This includes creating standardized calibration procedures, implementing advanced statistical approaches for data analysis, and developing multi-parameter measurement techniques that can cross-validate results through complementary measurements.

Another significant goal is enhancing the resolution of DLS for polydisperse samples, where traditional analysis methods often fail to accurately represent complex particle size distributions. This is particularly important for biological applications, where protein aggregates or vesicles may exhibit heterogeneous size profiles that are clinically relevant.

The integration of DLS with other analytical techniques represents another important technological direction. Hybrid systems combining DLS with techniques such as Raman spectroscopy, static light scattering, or microscopy methods provide multi-dimensional characterization capabilities that can help validate measurements and reduce systematic biases.

From an industrial perspective, there is growing demand for automated, high-throughput DLS systems that maintain measurement accuracy while increasing sample processing capacity. This is driving development of microfluidic DLS platforms and parallel measurement systems that can analyze multiple samples simultaneously while implementing sophisticated bias correction algorithms.

The ultimate technological objective is to transform DLS from a relative measurement technique to an absolute one, where results are independent of instrument configuration, sample preparation methods, and analysis parameters. This would establish DLS as a truly standardized method for particle characterization across research and industrial applications.

Market Analysis for Bias-Free DLS Applications

The Dynamic Light Scattering (DLS) technology market has experienced significant growth over the past decade, driven primarily by increasing applications in pharmaceutical research, biotechnology, and materials science. The global market for DLS instruments was valued at approximately $300 million in 2022 and is projected to reach $450 million by 2027, representing a compound annual growth rate of 8.5%.

The demand for bias-free DLS applications stems from critical requirements across multiple industries. In pharmaceuticals, accurate particle size analysis directly impacts drug formulation stability, bioavailability, and regulatory approval processes. Even small measurement biases can lead to batch rejections or compromised product quality, translating to substantial financial losses.

Biotechnology represents another key market segment, where researchers require precise characterization of proteins, antibodies, and other biomolecules. The growing focus on biologics and nanomedicine has intensified the need for highly accurate DLS measurements, as these applications involve particles in the 1-100 nm range where measurement bias is most problematic.

Academic research institutions constitute approximately 30% of the DLS market, with industrial applications accounting for the remaining 70%. Geographically, North America leads with 40% market share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (5%). The Asia-Pacific region, particularly China and India, is experiencing the fastest growth due to expanding pharmaceutical manufacturing and research capabilities.

Market analysis reveals a significant price premium for advanced DLS systems with bias correction capabilities. Instruments featuring sophisticated algorithms and hardware improvements command 15-25% higher prices compared to standard models, indicating strong market willingness to pay for enhanced measurement accuracy.

Customer surveys indicate that measurement reliability and reproducibility rank among the top three purchasing criteria for DLS instruments, alongside ease of use and technical support quality. This underscores the market's recognition of bias issues as a critical factor in technology adoption.

The competitive landscape shows increasing differentiation based on bias mitigation capabilities. Leading manufacturers have begun highlighting their bias correction technologies in marketing materials, suggesting recognition of this feature as a key competitive advantage. Smaller, specialized companies have also emerged, focusing exclusively on software solutions that address measurement bias in existing DLS systems.

Future market growth for bias-free DLS applications is expected to be driven by emerging applications in nanomedicine, food science, and environmental monitoring, where precise particle characterization is essential for regulatory compliance and product development.

The demand for bias-free DLS applications stems from critical requirements across multiple industries. In pharmaceuticals, accurate particle size analysis directly impacts drug formulation stability, bioavailability, and regulatory approval processes. Even small measurement biases can lead to batch rejections or compromised product quality, translating to substantial financial losses.

Biotechnology represents another key market segment, where researchers require precise characterization of proteins, antibodies, and other biomolecules. The growing focus on biologics and nanomedicine has intensified the need for highly accurate DLS measurements, as these applications involve particles in the 1-100 nm range where measurement bias is most problematic.

Academic research institutions constitute approximately 30% of the DLS market, with industrial applications accounting for the remaining 70%. Geographically, North America leads with 40% market share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (5%). The Asia-Pacific region, particularly China and India, is experiencing the fastest growth due to expanding pharmaceutical manufacturing and research capabilities.

Market analysis reveals a significant price premium for advanced DLS systems with bias correction capabilities. Instruments featuring sophisticated algorithms and hardware improvements command 15-25% higher prices compared to standard models, indicating strong market willingness to pay for enhanced measurement accuracy.

Customer surveys indicate that measurement reliability and reproducibility rank among the top three purchasing criteria for DLS instruments, alongside ease of use and technical support quality. This underscores the market's recognition of bias issues as a critical factor in technology adoption.

The competitive landscape shows increasing differentiation based on bias mitigation capabilities. Leading manufacturers have begun highlighting their bias correction technologies in marketing materials, suggesting recognition of this feature as a key competitive advantage. Smaller, specialized companies have also emerged, focusing exclusively on software solutions that address measurement bias in existing DLS systems.

Future market growth for bias-free DLS applications is expected to be driven by emerging applications in nanomedicine, food science, and environmental monitoring, where precise particle characterization is essential for regulatory compliance and product development.

Current Challenges in DLS Measurement Accuracy

Dynamic Light Scattering (DLS) technology faces several significant measurement accuracy challenges that impede its broader application and reliability. The fundamental issue stems from the inherent sensitivity of DLS to various environmental and sample-related factors. Temperature fluctuations, even minor ones of 0.1°C, can significantly alter viscosity and diffusion coefficients, leading to substantial measurement errors. This sensitivity necessitates precise temperature control systems that many commercial instruments struggle to maintain consistently.

Sample polydispersity presents another major challenge, as DLS inherently favors larger particles due to their stronger scattering intensity (proportional to the sixth power of particle diameter). This bias often results in overestimation of larger particle populations and underrepresentation of smaller ones in heterogeneous samples. The mathematical algorithms used to convert correlation functions to size distributions further compound this issue, as they typically assume spherical particles and may introduce artifacts when dealing with non-spherical morphologies.

Concentration effects significantly impact measurement accuracy, with both extremely dilute and concentrated samples presenting unique challenges. In highly dilute solutions, insufficient scattering intensity leads to poor signal-to-noise ratios, while concentrated samples suffer from multiple scattering events that violate the fundamental assumptions of DLS theory. The optimal concentration window varies substantially depending on particle properties, making standardization difficult across different sample types.

Dust contamination remains a persistent practical challenge, as even microscopic dust particles can dominate scattering signals due to their relatively large size compared to nanoscale analytes. Despite careful filtration and sample preparation protocols, complete elimination of dust interference remains elusive in many laboratory settings.

The interpretation of DLS data presents additional complexities. Current analysis algorithms struggle with multimodal distributions, particularly when size populations overlap or when one population significantly outnumbers another. The mathematical inversion of correlation functions represents an ill-posed problem, meaning multiple size distributions can produce nearly identical correlation functions, leading to ambiguity in results.

Instrument-specific biases further complicate cross-laboratory comparisons, as different commercial systems employ varying optical configurations, detection angles, and proprietary algorithms. This lack of standardization makes it difficult to establish universal protocols or compare results between different instrument platforms, limiting the reproducibility essential for scientific and industrial applications.

Recent studies have also highlighted the challenge of measuring non-spherical or flexible particles, as standard DLS theory assumes rigid spherical scatterers. Biological samples like proteins and polymers often deviate significantly from this idealized model, leading to systematic errors in size determination that current correction factors inadequately address.

Sample polydispersity presents another major challenge, as DLS inherently favors larger particles due to their stronger scattering intensity (proportional to the sixth power of particle diameter). This bias often results in overestimation of larger particle populations and underrepresentation of smaller ones in heterogeneous samples. The mathematical algorithms used to convert correlation functions to size distributions further compound this issue, as they typically assume spherical particles and may introduce artifacts when dealing with non-spherical morphologies.

Concentration effects significantly impact measurement accuracy, with both extremely dilute and concentrated samples presenting unique challenges. In highly dilute solutions, insufficient scattering intensity leads to poor signal-to-noise ratios, while concentrated samples suffer from multiple scattering events that violate the fundamental assumptions of DLS theory. The optimal concentration window varies substantially depending on particle properties, making standardization difficult across different sample types.

Dust contamination remains a persistent practical challenge, as even microscopic dust particles can dominate scattering signals due to their relatively large size compared to nanoscale analytes. Despite careful filtration and sample preparation protocols, complete elimination of dust interference remains elusive in many laboratory settings.

The interpretation of DLS data presents additional complexities. Current analysis algorithms struggle with multimodal distributions, particularly when size populations overlap or when one population significantly outnumbers another. The mathematical inversion of correlation functions represents an ill-posed problem, meaning multiple size distributions can produce nearly identical correlation functions, leading to ambiguity in results.

Instrument-specific biases further complicate cross-laboratory comparisons, as different commercial systems employ varying optical configurations, detection angles, and proprietary algorithms. This lack of standardization makes it difficult to establish universal protocols or compare results between different instrument platforms, limiting the reproducibility essential for scientific and industrial applications.

Recent studies have also highlighted the challenge of measuring non-spherical or flexible particles, as standard DLS theory assumes rigid spherical scatterers. Biological samples like proteins and polymers often deviate significantly from this idealized model, leading to systematic errors in size determination that current correction factors inadequately address.

Current Approaches to Mitigate Measurement Bias in DLS

01 Bias correction methods in DLS measurements

Various methods have been developed to correct bias in dynamic light scattering measurements. These techniques include algorithmic corrections, calibration procedures, and statistical approaches that compensate for systematic errors. By implementing these correction methods, researchers can obtain more accurate particle size distributions and reduce measurement artifacts that commonly occur in DLS analysis.- Bias correction methods in DLS measurements: Various methods have been developed to correct bias in dynamic light scattering measurements. These include algorithmic approaches that compensate for systematic errors, statistical methods to reduce measurement variability, and calibration techniques using reference standards. These correction methods help improve the accuracy of particle size determination by minimizing the effects of instrument-related biases and environmental factors.

- Temperature and viscosity effects on DLS measurement bias: Temperature fluctuations and sample viscosity significantly impact dynamic light scattering measurements, introducing bias in particle size determination. Temperature affects Brownian motion of particles and changes sample viscosity, while viscosity variations directly influence diffusion coefficients. Controlling these parameters through temperature stabilization systems and viscosity compensation algorithms is essential for reducing measurement bias and improving data reliability.

- Multiple scattering correction techniques: Multiple scattering effects in concentrated samples can introduce significant bias in dynamic light scattering measurements. Advanced correction techniques have been developed to address this issue, including cross-correlation methods, mathematical modeling of multiple scattering events, and specialized optical configurations. These approaches help extract accurate particle size information even from samples where light undergoes multiple scattering events before detection.

- Signal processing algorithms for bias reduction: Specialized signal processing algorithms have been developed to reduce bias in dynamic light scattering data analysis. These include advanced correlation function analysis, noise filtering techniques, and mathematical transformations that improve data quality. Machine learning approaches are also being implemented to identify and correct systematic errors in the measurement process, resulting in more accurate particle size distributions.

- Optical design improvements to minimize bias: Innovations in optical design have significantly reduced measurement bias in dynamic light scattering instruments. These include advanced detector configurations, improved laser sources with enhanced stability, and optimized scattering geometry. Fiber optic implementations and specialized optical components help minimize stray light and improve signal quality, resulting in more accurate and reproducible particle size measurements across different sample types.

02 Sample preparation techniques to minimize bias

Proper sample preparation is crucial for reducing measurement bias in dynamic light scattering. This includes methods for controlling sample concentration, eliminating dust particles, preventing aggregation, and ensuring sample homogeneity. Advanced filtration techniques and specialized sample handling protocols can significantly improve measurement accuracy by reducing artifacts that lead to bias in particle size determination.Expand Specific Solutions03 Instrument design improvements for bias reduction

Innovations in DLS instrument design have focused on reducing measurement bias through improved optical configurations, detection systems, and signal processing. These advancements include multi-angle detection, enhanced laser stability, and specialized scattering geometries that minimize unwanted reflections and interference. Such design improvements help to obtain more reliable and reproducible particle size measurements across different sample types.Expand Specific Solutions04 Data analysis algorithms for bias compensation

Sophisticated data analysis algorithms have been developed to address bias in dynamic light scattering measurements. These include advanced correlation function analysis, machine learning approaches, and statistical methods that can identify and correct systematic errors. By applying these algorithms, researchers can extract more accurate information about particle size distributions, particularly in complex or polydisperse samples where traditional analysis methods often introduce bias.Expand Specific Solutions05 Environmental factor control to reduce measurement bias

Controlling environmental factors is essential for minimizing bias in dynamic light scattering measurements. This includes temperature stabilization, vibration isolation, and electromagnetic interference shielding. Methods for maintaining consistent measurement conditions and accounting for environmental variations help ensure reproducible results and reduce systematic errors that can bias particle size determinations.Expand Specific Solutions

Leading Companies and Research Institutions in DLS Technology

Dynamic Light Scattering (DLS) measurement bias represents a significant challenge in the evolving field of nanoparticle characterization. The market is currently in a growth phase, with an estimated global value exceeding $400 million and projected CAGR of 8-10%. Leading companies like Malvern Panalytical, Horiba Ltd., and Shimadzu Corp. have developed advanced algorithms and hardware solutions to address polydispersity effects and multiple scattering issues. Wyatt Technology LLC has pioneered multi-angle DLS systems, while Anton Paar GmbH offers temperature-controlled solutions to minimize thermal gradient bias. Academic institutions including Xi'an Jiaotong University and Fraunhofer-Gesellschaft are advancing theoretical frameworks for bias correction. The technology is approaching maturity with standardization efforts underway, though challenges remain in complex biological sample analysis.

Horiba Ltd.

Technical Solution: Horiba has developed advanced multi-angle dynamic light scattering (MADLS) systems that address measurement bias through simultaneous detection at multiple scattering angles. Their technology incorporates proprietary algorithms that combine data from different angles to compensate for concentration-dependent effects and multiple scattering phenomena. The system employs adaptive correlation techniques that automatically adjust measurement parameters based on sample characteristics, reducing bias from dust particles and aggregates. Horiba's SZ-100 series specifically implements temperature gradient correction mechanisms that minimize convection effects which can significantly skew DLS measurements. Additionally, their instruments feature automatic optimization of attenuator settings to ensure measurements remain within the optimal detection range, preventing signal saturation bias that commonly affects conventional DLS systems.

Strengths: Superior multi-angle detection capabilities allow for more accurate characterization of polydisperse samples and non-spherical particles. Their temperature control systems (±0.1°C precision) minimize thermal-induced measurement errors. Weaknesses: Higher complexity and cost compared to single-angle systems, and requires more sophisticated data interpretation skills from operators.

Shimadzu Corp.

Technical Solution: Shimadzu has pioneered a comprehensive approach to addressing DLS measurement bias through their SALD series instruments, which combine traditional DLS with proprietary optical design innovations. Their technology implements a dual-detector system that simultaneously measures scattered light at both forward and backward angles, enabling more accurate characterization across diverse particle size distributions. Shimadzu's instruments incorporate advanced signal processing algorithms that apply mathematical corrections for non-linear detector responses and laser fluctuations, significantly reducing systematic measurement errors. The company has developed specialized sample handling protocols that minimize dust contamination through automated filtration systems integrated directly into the measurement chamber. Their latest systems feature machine learning algorithms that can identify and compensate for common measurement artifacts by comparing results against a database of known particle standards, effectively reducing operator-dependent biases in data interpretation.

Strengths: Exceptional stability in measurements across different sample concentrations due to proprietary optical configurations and automated dilution systems. Their software provides comprehensive uncertainty analysis with each measurement. Weaknesses: System calibration is relatively complex and time-consuming compared to competitors, potentially introducing new sources of error if not performed correctly.

Critical Patents and Algorithms for DLS Bias Correction

Dynamic light scattering measurement device, dynamic light scattering measurement and analysis method, and measurement and analysis program

PatentActiveJP2022077588A

Innovation

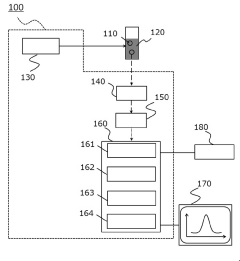

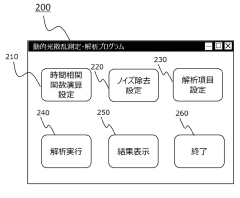

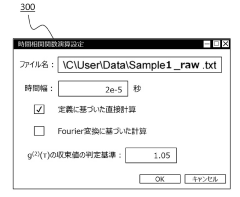

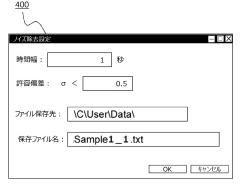

- A dynamic light scattering measurement device and method that includes a photon detection system, data collection, and information processing to calculate a time correlation function, with noise determination and removal units to eliminate contaminants, allowing for accurate particle size and distribution measurement without preprocessing.

Dynamic light scattering for particle size distribution measurement

PatentWO2019108731A1

Innovation

- The implementation of multispectral DLS techniques, which involve directing light of different wavelengths into the mixture and detecting corresponding signals to determine particle size distribution by processing differences in scattered light intensities, allowing for more accurate separation of particle species and reduction of interference from air bubbles.

Standardization Efforts in DLS Methodology

The standardization of Dynamic Light Scattering (DLS) methodology has gained significant momentum in recent years as researchers and industry professionals recognize the critical need for consistent measurement protocols. International organizations such as ISO (International Organization for Standardization) and ASTM International have developed specific guidelines addressing various aspects of DLS measurements, including sample preparation, instrument calibration, and data analysis procedures.

ISO 22412, established in 2017 and updated in 2022, represents a cornerstone document that outlines standardized procedures for particle size analysis using DLS. This standard provides detailed protocols for instrument validation, measurement conditions, and reporting requirements, significantly reducing inter-laboratory variations in results.

The National Institute of Standards and Technology (NIST) has contributed substantially to standardization efforts by developing reference materials specifically designed for DLS calibration. These materials, with certified size distributions and stability characteristics, allow laboratories worldwide to validate their measurement systems against a common reference point, thereby enhancing result comparability across different instruments and facilities.

Industry consortia have also emerged to address standardization challenges specific to particular applications of DLS. For example, the Nanotechnology Characterization Laboratory (NCL) has established protocols specifically tailored for nanomedicine applications, where precise particle characterization is crucial for regulatory approval and clinical translation.

Collaborative measurement comparison studies, often organized by metrology institutes, have proven invaluable in identifying sources of measurement bias. These round-robin tests involve multiple laboratories measuring identical samples using their standard procedures, with subsequent statistical analysis revealing systematic biases and variability sources. The findings from these studies directly inform refinements to standardization documents.

Software standardization represents another critical frontier in DLS methodology. Efforts are underway to establish standard algorithms for data processing, particularly for polydisperse samples where interpretation complexities often lead to measurement biases. The development of open-source analysis tools with transparent algorithms has facilitated more consistent data interpretation across the scientific community.

Educational initiatives complement these technical standardization efforts, with professional organizations offering specialized training programs and certification in DLS methodology. These programs ensure that operators understand not only the theoretical principles but also the practical considerations necessary for bias-minimized measurements, thereby addressing the human factor in measurement variability.

ISO 22412, established in 2017 and updated in 2022, represents a cornerstone document that outlines standardized procedures for particle size analysis using DLS. This standard provides detailed protocols for instrument validation, measurement conditions, and reporting requirements, significantly reducing inter-laboratory variations in results.

The National Institute of Standards and Technology (NIST) has contributed substantially to standardization efforts by developing reference materials specifically designed for DLS calibration. These materials, with certified size distributions and stability characteristics, allow laboratories worldwide to validate their measurement systems against a common reference point, thereby enhancing result comparability across different instruments and facilities.

Industry consortia have also emerged to address standardization challenges specific to particular applications of DLS. For example, the Nanotechnology Characterization Laboratory (NCL) has established protocols specifically tailored for nanomedicine applications, where precise particle characterization is crucial for regulatory approval and clinical translation.

Collaborative measurement comparison studies, often organized by metrology institutes, have proven invaluable in identifying sources of measurement bias. These round-robin tests involve multiple laboratories measuring identical samples using their standard procedures, with subsequent statistical analysis revealing systematic biases and variability sources. The findings from these studies directly inform refinements to standardization documents.

Software standardization represents another critical frontier in DLS methodology. Efforts are underway to establish standard algorithms for data processing, particularly for polydisperse samples where interpretation complexities often lead to measurement biases. The development of open-source analysis tools with transparent algorithms has facilitated more consistent data interpretation across the scientific community.

Educational initiatives complement these technical standardization efforts, with professional organizations offering specialized training programs and certification in DLS methodology. These programs ensure that operators understand not only the theoretical principles but also the practical considerations necessary for bias-minimized measurements, thereby addressing the human factor in measurement variability.

Cross-Validation Techniques with Complementary Technologies

Cross-validation with complementary technologies represents a critical approach to mitigating measurement bias in Dynamic Light Scattering (DLS). This methodology involves systematically comparing DLS results with data obtained from alternative particle characterization techniques to identify discrepancies and establish measurement reliability.

Electron microscopy techniques, particularly Transmission Electron Microscopy (TEM) and Scanning Electron Microscopy (SEM), offer direct visualization of particle morphology and size distribution, providing valuable reference points against which DLS data can be validated. While DLS excels at ensemble measurements in solution, microscopy techniques reveal individual particle characteristics that may be obscured in DLS analysis.

Small-Angle X-ray Scattering (SAXS) serves as another powerful complementary technique, offering size and shape information based on different physical principles than DLS. SAXS measurements are less affected by dust contamination and can provide more reliable data for polydisperse samples, making it particularly valuable for cross-validation purposes when sample heterogeneity is suspected.

Analytical ultracentrifugation (AUC) provides orthogonal measurements of particle size based on sedimentation behavior, which can help identify cases where DLS results are skewed by the presence of large aggregates or contaminants. The combination of DLS and AUC data enables more comprehensive characterization of complex colloidal systems.

Field-Flow Fractionation (FFF) coupled with multiple detectors offers separation capabilities that complement DLS measurements. This technique can fractionate samples prior to DLS analysis, reducing the confounding effects of polydispersity and enabling more accurate size distribution assessments of complex mixtures.

Statistical approaches for cross-validation include Bland-Altman analysis, which quantifies the agreement between measurement methods, and orthogonal regression techniques that account for measurement errors in both methods. These statistical frameworks provide objective criteria for evaluating the consistency between DLS and complementary techniques.

Machine learning algorithms are increasingly being applied to integrate multi-technique data, automatically identifying patterns of measurement bias across different sample types. These computational approaches can develop correction factors specific to particular sample characteristics, improving the accuracy of DLS measurements for challenging samples.

Standardized protocols for cross-validation should include measurement of reference materials across all techniques, systematic variation of sample conditions, and statistical analysis of inter-technique variability. This structured approach ensures that cross-validation becomes a routine component of DLS measurement workflows rather than an occasional troubleshooting tool.

Electron microscopy techniques, particularly Transmission Electron Microscopy (TEM) and Scanning Electron Microscopy (SEM), offer direct visualization of particle morphology and size distribution, providing valuable reference points against which DLS data can be validated. While DLS excels at ensemble measurements in solution, microscopy techniques reveal individual particle characteristics that may be obscured in DLS analysis.

Small-Angle X-ray Scattering (SAXS) serves as another powerful complementary technique, offering size and shape information based on different physical principles than DLS. SAXS measurements are less affected by dust contamination and can provide more reliable data for polydisperse samples, making it particularly valuable for cross-validation purposes when sample heterogeneity is suspected.

Analytical ultracentrifugation (AUC) provides orthogonal measurements of particle size based on sedimentation behavior, which can help identify cases where DLS results are skewed by the presence of large aggregates or contaminants. The combination of DLS and AUC data enables more comprehensive characterization of complex colloidal systems.

Field-Flow Fractionation (FFF) coupled with multiple detectors offers separation capabilities that complement DLS measurements. This technique can fractionate samples prior to DLS analysis, reducing the confounding effects of polydispersity and enabling more accurate size distribution assessments of complex mixtures.

Statistical approaches for cross-validation include Bland-Altman analysis, which quantifies the agreement between measurement methods, and orthogonal regression techniques that account for measurement errors in both methods. These statistical frameworks provide objective criteria for evaluating the consistency between DLS and complementary techniques.

Machine learning algorithms are increasingly being applied to integrate multi-technique data, automatically identifying patterns of measurement bias across different sample types. These computational approaches can develop correction factors specific to particular sample characteristics, improving the accuracy of DLS measurements for challenging samples.

Standardized protocols for cross-validation should include measurement of reference materials across all techniques, systematic variation of sample conditions, and statistical analysis of inter-technique variability. This structured approach ensures that cross-validation becomes a routine component of DLS measurement workflows rather than an occasional troubleshooting tool.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!