How to Adjust GC-MS Split Ratio for Concentrated Samples

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GC-MS Split Ratio Background and Objectives

Gas Chromatography-Mass Spectrometry (GC-MS) has evolved significantly since its inception in the 1950s, becoming an indispensable analytical technique in various industries including pharmaceuticals, environmental monitoring, food safety, and forensic science. The split ratio, a critical parameter in GC-MS analysis, determines the proportion of sample that enters the column versus the amount discarded through the split vent. This parameter has become increasingly important as analytical demands have shifted toward more concentrated samples.

Historically, GC-MS systems operated with fixed split ratios, limiting analytical flexibility. The technological evolution has progressed from manual adjustment systems to sophisticated electronic flow controllers that allow precise, real-time modifications of split ratios. This advancement has enabled analysts to handle a wider concentration range of analytes, improving both the sensitivity and dynamic range of analyses.

The primary objective of split ratio optimization for concentrated samples is to prevent column overloading while maintaining analytical integrity. Overloading can lead to peak distortion, reduced resolution, and potential contamination of the ion source, ultimately compromising data quality and instrument longevity. Conversely, excessive splitting may result in sensitivity loss for trace components.

Current technological trends indicate a move toward intelligent, automated split ratio adjustment systems that can respond to sample concentration in real-time. These systems utilize machine learning algorithms to predict optimal split ratios based on preliminary sample screening, significantly reducing method development time and enhancing analytical precision.

Another emerging goal is the development of universal split ratio protocols that can accommodate multi-component samples with vastly different concentration levels in a single run. This would represent a significant advancement over current methods that often require multiple analyses with different split ratios to capture both high and low concentration analytes effectively.

The integration of split ratio optimization with other GC-MS parameters such as temperature programming and carrier gas flow rate is becoming increasingly important. This holistic approach aims to create comprehensive analytical methods that maximize separation efficiency while minimizing analysis time and resource consumption.

From a practical perspective, the objective is to establish standardized guidelines for split ratio adjustment that can be readily implemented across different laboratory settings and GC-MS platforms. This standardization would facilitate method transfer between laboratories and improve the reproducibility of analytical results, addressing a significant challenge in the current analytical landscape.

Historically, GC-MS systems operated with fixed split ratios, limiting analytical flexibility. The technological evolution has progressed from manual adjustment systems to sophisticated electronic flow controllers that allow precise, real-time modifications of split ratios. This advancement has enabled analysts to handle a wider concentration range of analytes, improving both the sensitivity and dynamic range of analyses.

The primary objective of split ratio optimization for concentrated samples is to prevent column overloading while maintaining analytical integrity. Overloading can lead to peak distortion, reduced resolution, and potential contamination of the ion source, ultimately compromising data quality and instrument longevity. Conversely, excessive splitting may result in sensitivity loss for trace components.

Current technological trends indicate a move toward intelligent, automated split ratio adjustment systems that can respond to sample concentration in real-time. These systems utilize machine learning algorithms to predict optimal split ratios based on preliminary sample screening, significantly reducing method development time and enhancing analytical precision.

Another emerging goal is the development of universal split ratio protocols that can accommodate multi-component samples with vastly different concentration levels in a single run. This would represent a significant advancement over current methods that often require multiple analyses with different split ratios to capture both high and low concentration analytes effectively.

The integration of split ratio optimization with other GC-MS parameters such as temperature programming and carrier gas flow rate is becoming increasingly important. This holistic approach aims to create comprehensive analytical methods that maximize separation efficiency while minimizing analysis time and resource consumption.

From a practical perspective, the objective is to establish standardized guidelines for split ratio adjustment that can be readily implemented across different laboratory settings and GC-MS platforms. This standardization would facilitate method transfer between laboratories and improve the reproducibility of analytical results, addressing a significant challenge in the current analytical landscape.

Market Demand for Concentrated Sample Analysis

The global market for concentrated sample analysis using GC-MS technology has experienced substantial growth over the past decade, primarily driven by increasing demands in pharmaceutical research, environmental monitoring, food safety testing, and forensic applications. Current market valuations indicate that the analytical instrumentation sector focusing on concentrated sample analysis exceeds $5 billion annually, with a compound annual growth rate of approximately 6.8% projected through 2028.

Pharmaceutical and biotechnology sectors represent the largest market segment, accounting for nearly 35% of the total demand for advanced GC-MS technologies capable of handling concentrated samples. This is largely attributed to the stringent regulatory requirements for drug development and quality control processes, where precise analysis of complex concentrated matrices is essential for ensuring product safety and efficacy.

Environmental testing laboratories constitute the second-largest market segment, representing approximately 28% of the demand. The growing concerns regarding environmental pollutants and the implementation of stricter environmental regulations worldwide have significantly increased the need for sensitive and accurate analysis of concentrated environmental samples, particularly in water and soil testing applications.

Food and beverage industry demands have shown the most rapid growth rate at 8.2% annually, driven by increasing consumer awareness regarding food safety and quality. The ability to accurately analyze concentrated food extracts for contaminants, additives, and natural compounds has become a critical requirement for regulatory compliance and quality assurance programs globally.

Regional market analysis reveals that North America currently holds the largest market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate due to expanding industrial activities, increasing environmental concerns, and strengthening regulatory frameworks in countries like China, India, and South Korea.

End-user surveys indicate that laboratories are increasingly seeking GC-MS systems with advanced split ratio adjustment capabilities specifically designed for concentrated samples. This demand is driven by the need to reduce sample preparation time, minimize dilution errors, and enhance analytical throughput while maintaining instrument longevity. Approximately 72% of laboratory managers cited improved handling of concentrated samples as a key factor influencing their purchasing decisions for new GC-MS systems.

The market is also witnessing a growing demand for automated split ratio adjustment technologies, with an estimated 65% of potential buyers expressing interest in systems offering intelligent, sample-adaptive split ratio optimization features that can automatically adjust parameters based on sample concentration levels.

Pharmaceutical and biotechnology sectors represent the largest market segment, accounting for nearly 35% of the total demand for advanced GC-MS technologies capable of handling concentrated samples. This is largely attributed to the stringent regulatory requirements for drug development and quality control processes, where precise analysis of complex concentrated matrices is essential for ensuring product safety and efficacy.

Environmental testing laboratories constitute the second-largest market segment, representing approximately 28% of the demand. The growing concerns regarding environmental pollutants and the implementation of stricter environmental regulations worldwide have significantly increased the need for sensitive and accurate analysis of concentrated environmental samples, particularly in water and soil testing applications.

Food and beverage industry demands have shown the most rapid growth rate at 8.2% annually, driven by increasing consumer awareness regarding food safety and quality. The ability to accurately analyze concentrated food extracts for contaminants, additives, and natural compounds has become a critical requirement for regulatory compliance and quality assurance programs globally.

Regional market analysis reveals that North America currently holds the largest market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate due to expanding industrial activities, increasing environmental concerns, and strengthening regulatory frameworks in countries like China, India, and South Korea.

End-user surveys indicate that laboratories are increasingly seeking GC-MS systems with advanced split ratio adjustment capabilities specifically designed for concentrated samples. This demand is driven by the need to reduce sample preparation time, minimize dilution errors, and enhance analytical throughput while maintaining instrument longevity. Approximately 72% of laboratory managers cited improved handling of concentrated samples as a key factor influencing their purchasing decisions for new GC-MS systems.

The market is also witnessing a growing demand for automated split ratio adjustment technologies, with an estimated 65% of potential buyers expressing interest in systems offering intelligent, sample-adaptive split ratio optimization features that can automatically adjust parameters based on sample concentration levels.

Current Challenges in GC-MS Split Ratio Optimization

Gas chromatography-mass spectrometry (GC-MS) split ratio optimization presents several significant challenges when analyzing concentrated samples. The fundamental issue stems from the delicate balance required between achieving adequate sensitivity and preventing system overload. When highly concentrated samples are introduced into the GC-MS system, traditional split ratios often prove inadequate, leading to column overloading, detector saturation, and compromised data quality.

One primary challenge is the non-linear response that occurs when concentrated analytes exceed the linear dynamic range of the detector. This results in peak distortion, inaccurate quantification, and potential misidentification of compounds. Analysts frequently struggle to determine the optimal split ratio that maintains chromatographic integrity while ensuring sufficient sensitivity for trace components that may coexist with highly abundant analytes.

Sample matrix complexity compounds these difficulties, as high-concentration samples often contain multiple components with varying volatilities and concentrations. This heterogeneity makes establishing a universal split ratio problematic, as what works for one analyte may be suboptimal for others within the same sample. The challenge becomes particularly acute in environmental, pharmaceutical, and petrochemical analyses where concentration ranges can span several orders of magnitude.

Instrument contamination represents another significant concern. Insufficient splitting of concentrated samples leads to excessive deposition of sample residues on critical components including the inlet liner, column, and ion source. This contamination accelerates system degradation, increases maintenance frequency, and introduces carryover effects that compromise subsequent analyses.

The dynamic nature of split ratio optimization also presents methodological challenges. Current approaches often rely heavily on trial-and-error processes that are time-consuming and sample-intensive. While theoretical models exist, they frequently fail to account for real-world variables such as matrix effects, analyte-specific behaviors, and instrument-to-instrument variations.

Automation limitations further complicate the situation. Most GC-MS systems lack intelligent, adaptive split ratio control capabilities that could dynamically adjust parameters based on real-time assessment of sample concentration. This forces analysts to make educated guesses about appropriate split ratios before analysis, often resulting in repeated runs and sample waste.

Finally, there exists a significant knowledge gap in standardized protocols for split ratio optimization across different sample types and concentration ranges. The absence of comprehensive guidelines leaves analysts without clear direction when confronting new or challenging sample matrices, leading to inconsistent methodologies and compromised data comparability across laboratories.

One primary challenge is the non-linear response that occurs when concentrated analytes exceed the linear dynamic range of the detector. This results in peak distortion, inaccurate quantification, and potential misidentification of compounds. Analysts frequently struggle to determine the optimal split ratio that maintains chromatographic integrity while ensuring sufficient sensitivity for trace components that may coexist with highly abundant analytes.

Sample matrix complexity compounds these difficulties, as high-concentration samples often contain multiple components with varying volatilities and concentrations. This heterogeneity makes establishing a universal split ratio problematic, as what works for one analyte may be suboptimal for others within the same sample. The challenge becomes particularly acute in environmental, pharmaceutical, and petrochemical analyses where concentration ranges can span several orders of magnitude.

Instrument contamination represents another significant concern. Insufficient splitting of concentrated samples leads to excessive deposition of sample residues on critical components including the inlet liner, column, and ion source. This contamination accelerates system degradation, increases maintenance frequency, and introduces carryover effects that compromise subsequent analyses.

The dynamic nature of split ratio optimization also presents methodological challenges. Current approaches often rely heavily on trial-and-error processes that are time-consuming and sample-intensive. While theoretical models exist, they frequently fail to account for real-world variables such as matrix effects, analyte-specific behaviors, and instrument-to-instrument variations.

Automation limitations further complicate the situation. Most GC-MS systems lack intelligent, adaptive split ratio control capabilities that could dynamically adjust parameters based on real-time assessment of sample concentration. This forces analysts to make educated guesses about appropriate split ratios before analysis, often resulting in repeated runs and sample waste.

Finally, there exists a significant knowledge gap in standardized protocols for split ratio optimization across different sample types and concentration ranges. The absence of comprehensive guidelines leaves analysts without clear direction when confronting new or challenging sample matrices, leading to inconsistent methodologies and compromised data comparability across laboratories.

Established Methodologies for Split Ratio Adjustment

01 Optimization of split ratio for improved sensitivity and resolution

The split ratio in GC-MS analysis significantly impacts the sensitivity and resolution of the analytical method. Optimizing the split ratio allows for better detection of trace compounds while maintaining chromatographic separation. Lower split ratios (e.g., 10:1 or 5:1) increase sensitivity for trace analysis, while higher split ratios (e.g., 50:1 or 100:1) are suitable for samples with higher analyte concentrations. The optimal split ratio depends on the specific application, sample concentration, and target analytes.- Optimization of split ratio for improved sensitivity and resolution: The split ratio in GC-MS analysis significantly impacts the sensitivity and resolution of the analytical method. Optimizing this parameter involves finding the right balance between sample load and column efficiency. Lower split ratios allow more sample to enter the column, increasing sensitivity for trace analysis, while higher split ratios prevent column overloading and improve peak resolution. The optimal split ratio depends on sample concentration, column specifications, and the specific compounds being analyzed.

- Split ratio control systems and mechanisms: Advanced GC-MS systems incorporate precise split ratio control mechanisms to ensure reproducible analytical results. These systems may include electronic flow controllers, precision valves, and automated split ratio adjustment capabilities. Some designs feature dynamic split ratio control that can be programmed to change during analysis, allowing for optimization at different stages of compound separation. These control systems help maintain consistent sample introduction and improve quantitative analysis reliability.

- Split ratio applications for specific sample types: Different sample types require tailored split ratio strategies in GC-MS analysis. For environmental samples with complex matrices, higher split ratios may be used to prevent contamination of the column. In contrast, biological samples containing trace compounds of interest might require splitless or low split ratio injection. Volatile organic compounds often benefit from moderate split ratios that balance sensitivity with chromatographic performance. The selection of appropriate split ratios based on sample characteristics is crucial for accurate analytical results.

- Split ratio influence on quantitative analysis: The split ratio directly affects quantitative analysis in GC-MS by determining the amount of sample reaching the detector. Consistent split ratios are essential for reliable quantification, as variations can lead to inconsistent response factors. Calibration methods must account for the selected split ratio, and internal standards are often used to compensate for any variations. Some advanced methods incorporate split ratio correction factors in quantitative calculations to improve accuracy across different analytical runs.

- Innovative split ratio techniques for enhanced performance: Novel approaches to split ratio management have been developed to enhance GC-MS performance. These include pulsed split injection, where a high initial split ratio is briefly followed by a lower ratio to improve peak shape while maintaining sensitivity. Programmable temperature vaporization injectors allow for split ratio optimization based on temperature profiles. Some systems incorporate dual-split technology that enables simultaneous analysis at different split ratios. These innovative techniques expand the analytical capabilities of GC-MS for challenging applications.

02 Splitless and split injection techniques for different sample types

GC-MS analysis employs both split and splitless injection modes depending on sample characteristics. Splitless injection is preferred for trace analysis and dilute samples, allowing the entire sample to enter the column. Split injection divides the sample at a predetermined ratio, with only a portion entering the column, making it suitable for concentrated samples. The choice between these techniques and the specific split ratio used depends on sample concentration, volatility of analytes, and the analytical requirements of the method.Expand Specific Solutions03 Automated split ratio control systems

Advanced GC-MS systems incorporate automated split ratio control mechanisms that allow for precise and reproducible sample introduction. These systems can dynamically adjust the split ratio during analysis, optimizing separation and detection parameters based on the chromatographic profile. Automated split ratio control improves method reproducibility, reduces operator error, and enables complex analytical sequences with varying split ratios for different sample types or analytical phases.Expand Specific Solutions04 Split ratio influence on quantitative analysis

The split ratio directly affects quantitative analysis in GC-MS by influencing the amount of sample reaching the detector. Consistent split ratios are crucial for accurate quantification, as variations can lead to significant errors in concentration calculations. Calibration methods must account for the selected split ratio, and internal standards are often used to compensate for variations. For accurate quantitative analysis, the split ratio must be optimized based on the concentration range of target analytes and validated for linearity, precision, and accuracy.Expand Specific Solutions05 Split ratio optimization for specific applications

Different analytical applications require specific split ratio optimization strategies. Environmental samples often require lower split ratios to detect trace contaminants, while petroleum analysis may use higher split ratios due to sample complexity and higher analyte concentrations. Biological sample analysis frequently employs moderate split ratios with careful optimization to balance sensitivity and separation. Food and flavor analysis may use variable split ratios depending on the concentration of volatile compounds. The optimization process considers factors such as matrix effects, target compound concentration, and required detection limits.Expand Specific Solutions

Leading Manufacturers and Research Groups in GC-MS Technology

The GC-MS split ratio adjustment for concentrated samples market is in a mature growth phase, with an estimated global market size of $1.5-2 billion. The technology has reached high maturity levels, with established players dominating the competitive landscape. Shimadzu Corp. and Thermo Fisher Scientific (through Thermo Finnigan Corp. and Thermo Fisher Scientific Bremen GmbH) lead the market with comprehensive GC-MS solutions featuring advanced split ratio control technologies. Specialized players like Entech Instruments and LECO Corp. offer niche innovations for specific applications. Waters Corp. (through Micromass UK) provides complementary technologies, while research institutions like Emory University and National University of Singapore contribute to technological advancements through academic research and industry collaborations.

Shimadzu Corp.

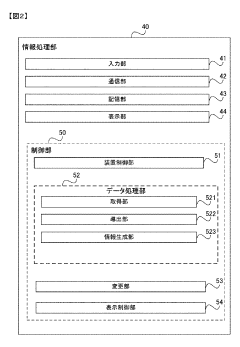

Technical Solution: Shimadzu has developed advanced split ratio control systems for their GC-MS instruments that automatically optimize split ratios based on sample concentration. Their technology incorporates intelligent flow controllers that can dynamically adjust split ratios from 1:1 to 1:1000 with high precision. For concentrated samples, Shimadzu's AOC-6000 autosampler works in conjunction with their LabSolutions software to implement a concentration-dependent split ratio adjustment protocol. This system uses preliminary detector response to estimate sample concentration and automatically modifies the split ratio to prevent column overloading and detector saturation. Their Smart Split technology enables programmable split ratio changes during a single run, allowing for optimal chromatographic separation of both high and low concentration analytes in complex matrices.

Strengths: Precise electronic flow control allows for reproducible split ratios even at high split values; automated concentration-dependent adjustment reduces manual method development time. Weaknesses: Higher initial investment cost; requires regular maintenance of split/splitless inlet components to maintain performance at extreme split ratios.

Thermo Finnigan Corp.

Technical Solution: Thermo Finnigan has pioneered the Split Flow Technology (SFT) for handling concentrated samples in GC-MS analysis. Their approach incorporates a dual-path split system that divides the sample flow post-column but pre-detector, allowing a portion of the eluent to bypass the mass spectrometer when concentrations exceed optimal detection ranges. For highly concentrated samples, their PTV (Programmable Temperature Vaporization) injector technology enables split ratio adjustments from 1:1 to 1:7000, with electronic pneumatic control providing 0.01 psi precision. The company's QuanLab Forms software includes algorithms that automatically calculate optimal split ratios based on estimated sample concentration and desired detector response. Their iConnect Split/Splitless (SSL) injector technology features rapid pneumatic switching between split and splitless modes, allowing for method flexibility when dealing with varying sample concentrations.

Strengths: Extremely wide range of available split ratios; high-precision electronic pneumatic control; software integration for automated method development. Weaknesses: Complex system requires thorough operator training; higher maintenance requirements for the advanced pneumatic components.

Key Technical Innovations in Sample Introduction Systems

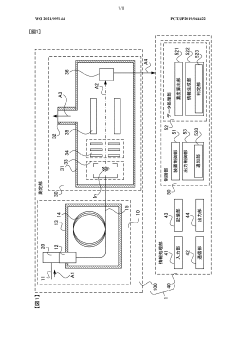

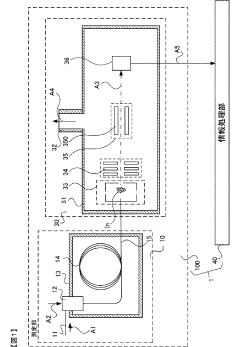

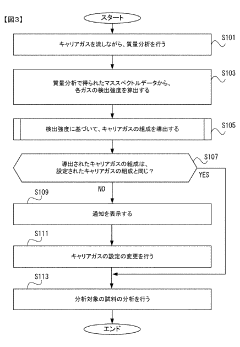

Analysis method, analysis device, and program

PatentWO2021095144A1

Innovation

- An analysis method and device that accounts for influencing substances by generating adjustment information from reference samples, allowing for accurate derivation of analyte concentrations through adjusted calibration curves, which correct for the impact of these substances on signal intensities.

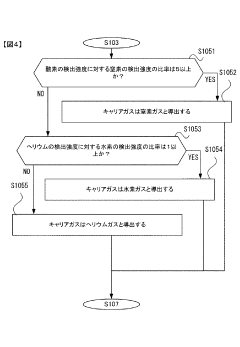

Gas chromatograph mass spectrometer, mass spectrometry method and program

PatentActiveJP2021165653A

Innovation

- A gas chromatograph mass spectrometer system that derives the composition of gases used in separation and mass analysis sections based on the intensity of signals detected in mass spectrometry, allowing for accurate identification of the actual gases employed, and includes a program to automate this process.

Method Validation and Quality Control Considerations

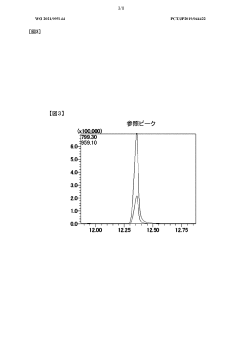

Method validation is essential when adjusting GC-MS split ratios for concentrated samples to ensure reliable and reproducible results. The validation process should include linearity assessment across the anticipated concentration range, with particular attention to the upper limits where detector saturation may occur. Establishing calibration curves with varying split ratios (typically 10:1, 20:1, 50:1, and 100:1) helps determine the optimal ratio for different analyte concentrations while maintaining acceptable peak shapes and resolution.

Precision metrics must be rigorously evaluated through replicate injections at each split ratio setting. Acceptable criteria typically include relative standard deviation (RSD) values below 2% for retention times and below 5% for peak areas. For concentrated samples, higher split ratios often yield better precision due to reduced column overloading and detector saturation effects.

Accuracy validation requires analyzing certified reference materials at different dilution levels with corresponding split ratio adjustments. Recovery rates between 95-105% generally indicate appropriate split ratio selection. When analyzing concentrated samples, matrix effects must be carefully evaluated as they can significantly impact ionization efficiency and quantitative accuracy.

Detection and quantification limits should be established for each split ratio setting, recognizing that higher split ratios will inherently increase these limits. This trade-off must be balanced against the need to analyze concentrated samples without preprocessing steps that could introduce additional variables.

System suitability tests should be incorporated into routine analysis workflows, including regular verification of split ratio accuracy using flow measurements. Drift in split ratios can occur due to septum wear, carrier gas pressure fluctuations, or injector contamination, necessitating periodic verification using standard compounds.

Quality control charts tracking critical parameters (peak areas, retention times, resolution factors) across different split ratio settings provide valuable long-term performance data. These charts help identify systematic errors or instrumental drift that may require maintenance intervention or method adjustment.

Cross-validation between different split ratio approaches and alternative dilution techniques is recommended to confirm method robustness. This comparison helps establish equivalence between analyzing diluted samples at lower split ratios versus concentrated samples at higher split ratios, ensuring consistent quantitative results regardless of the approach selected.

Precision metrics must be rigorously evaluated through replicate injections at each split ratio setting. Acceptable criteria typically include relative standard deviation (RSD) values below 2% for retention times and below 5% for peak areas. For concentrated samples, higher split ratios often yield better precision due to reduced column overloading and detector saturation effects.

Accuracy validation requires analyzing certified reference materials at different dilution levels with corresponding split ratio adjustments. Recovery rates between 95-105% generally indicate appropriate split ratio selection. When analyzing concentrated samples, matrix effects must be carefully evaluated as they can significantly impact ionization efficiency and quantitative accuracy.

Detection and quantification limits should be established for each split ratio setting, recognizing that higher split ratios will inherently increase these limits. This trade-off must be balanced against the need to analyze concentrated samples without preprocessing steps that could introduce additional variables.

System suitability tests should be incorporated into routine analysis workflows, including regular verification of split ratio accuracy using flow measurements. Drift in split ratios can occur due to septum wear, carrier gas pressure fluctuations, or injector contamination, necessitating periodic verification using standard compounds.

Quality control charts tracking critical parameters (peak areas, retention times, resolution factors) across different split ratio settings provide valuable long-term performance data. These charts help identify systematic errors or instrumental drift that may require maintenance intervention or method adjustment.

Cross-validation between different split ratio approaches and alternative dilution techniques is recommended to confirm method robustness. This comparison helps establish equivalence between analyzing diluted samples at lower split ratios versus concentrated samples at higher split ratios, ensuring consistent quantitative results regardless of the approach selected.

Environmental and Safety Implications of Split Ratio Optimization

The optimization of split ratio in GC-MS analysis carries significant environmental and safety implications that extend beyond mere analytical performance. Laboratory waste management represents a primary environmental concern, as higher split ratios generate substantial volumes of sample waste that require proper disposal. These wastes often contain volatile organic compounds (VOCs) and other potentially hazardous chemicals that can contribute to air pollution and pose risks to environmental ecosystems if improperly managed.

Solvent consumption patterns are directly influenced by split ratio settings. Lower split ratios generally reduce solvent usage throughout the analytical process, aligning with green chemistry principles and sustainable laboratory practices. This reduction in solvent consumption not only decreases operational costs but also minimizes the environmental footprint associated with solvent production, transportation, and disposal.

Laboratory air quality emerges as a critical safety consideration when working with concentrated samples. Improper split ratio settings may lead to excessive release of volatile compounds into the laboratory environment, potentially exposing personnel to harmful substances. This risk is particularly pronounced when analyzing toxic, carcinogenic, or otherwise hazardous compounds, necessitating careful optimization of split parameters to minimize fugitive emissions.

Energy efficiency considerations also factor into split ratio decisions. Higher split flows require greater carrier gas consumption and potentially increased instrument power usage. In high-throughput laboratories conducting numerous analyses daily, these energy implications can become substantial over time, affecting both operational costs and environmental impact through increased carbon footprint.

Risk assessment protocols should be integrated into split ratio optimization strategies, especially when dealing with highly concentrated samples of unknown or hazardous materials. This includes evaluating potential consequences of system overloading, column damage, and detector contamination, which could lead to safety incidents or release of harmful substances.

Regulatory compliance represents another dimension of split ratio optimization, with many jurisdictions implementing increasingly stringent requirements regarding laboratory emissions and waste management. Organizations must ensure their analytical methods, including split ratio parameters, align with applicable environmental regulations and safety standards to avoid potential legal and financial penalties.

Solvent consumption patterns are directly influenced by split ratio settings. Lower split ratios generally reduce solvent usage throughout the analytical process, aligning with green chemistry principles and sustainable laboratory practices. This reduction in solvent consumption not only decreases operational costs but also minimizes the environmental footprint associated with solvent production, transportation, and disposal.

Laboratory air quality emerges as a critical safety consideration when working with concentrated samples. Improper split ratio settings may lead to excessive release of volatile compounds into the laboratory environment, potentially exposing personnel to harmful substances. This risk is particularly pronounced when analyzing toxic, carcinogenic, or otherwise hazardous compounds, necessitating careful optimization of split parameters to minimize fugitive emissions.

Energy efficiency considerations also factor into split ratio decisions. Higher split flows require greater carrier gas consumption and potentially increased instrument power usage. In high-throughput laboratories conducting numerous analyses daily, these energy implications can become substantial over time, affecting both operational costs and environmental impact through increased carbon footprint.

Risk assessment protocols should be integrated into split ratio optimization strategies, especially when dealing with highly concentrated samples of unknown or hazardous materials. This includes evaluating potential consequences of system overloading, column damage, and detector contamination, which could lead to safety incidents or release of harmful substances.

Regulatory compliance represents another dimension of split ratio optimization, with many jurisdictions implementing increasingly stringent requirements regarding laboratory emissions and waste management. Organizations must ensure their analytical methods, including split ratio parameters, align with applicable environmental regulations and safety standards to avoid potential legal and financial penalties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!